Method for improving resin performance in suspension polymerization production resin through interpenetrating method

A technology of suspension polymerization and resin performance, applied in chemical instruments and methods, anion exchange, ion exchange, etc., can solve problems such as long cycle, high production cost, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

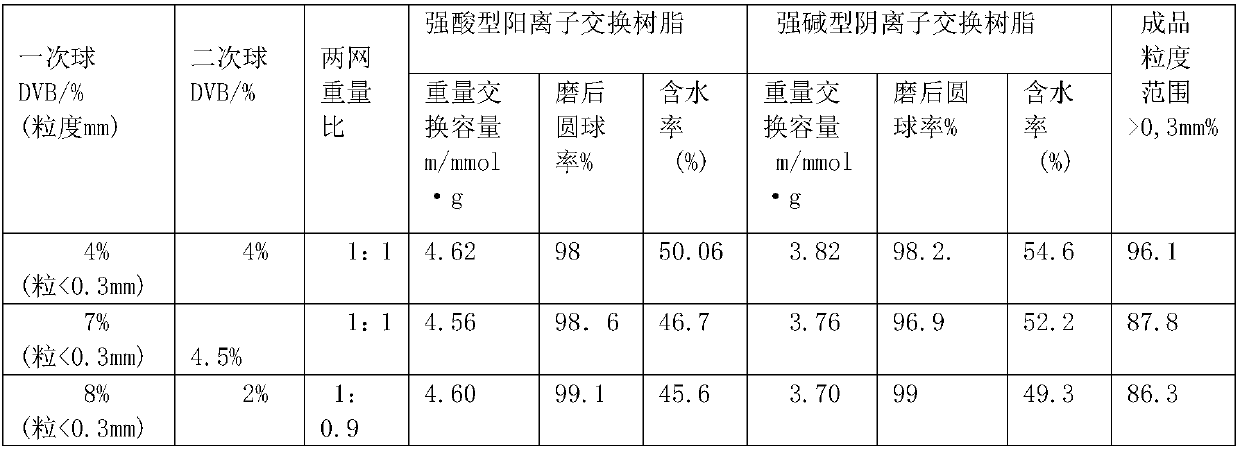

[0029] In the process of producing styrene-divinylbenzene suspension polymerization gel ion exchange resin (white ball), select the primary polymerization beads with cross-linking degrees of 4%, 7%, 8%, and particle diameter 0.315mm.

[0030] The obtained white balls were reacted according to the conventional sulfonation process; the concentration of sulfuric acid was 93%, the amount of swelling agent dichloroethane was 25% (wt / v), the sulfonation temperature was 80-105°C, and the sulfonation time was 10h. After the material is cooled, the gradient dilution method is used for post-treatment according to the conventional process to obtain a strong-acid cation exchange resin. Table 1 shows the properties of white balls with qualified particle size and their strong acid resins made of conventional primary waste white balls.

[0031] The obtained white balls are processed according to the conventional chloromethylation process (the volume ratio of the balls to chloromethyl ether i...

Embodiment 2

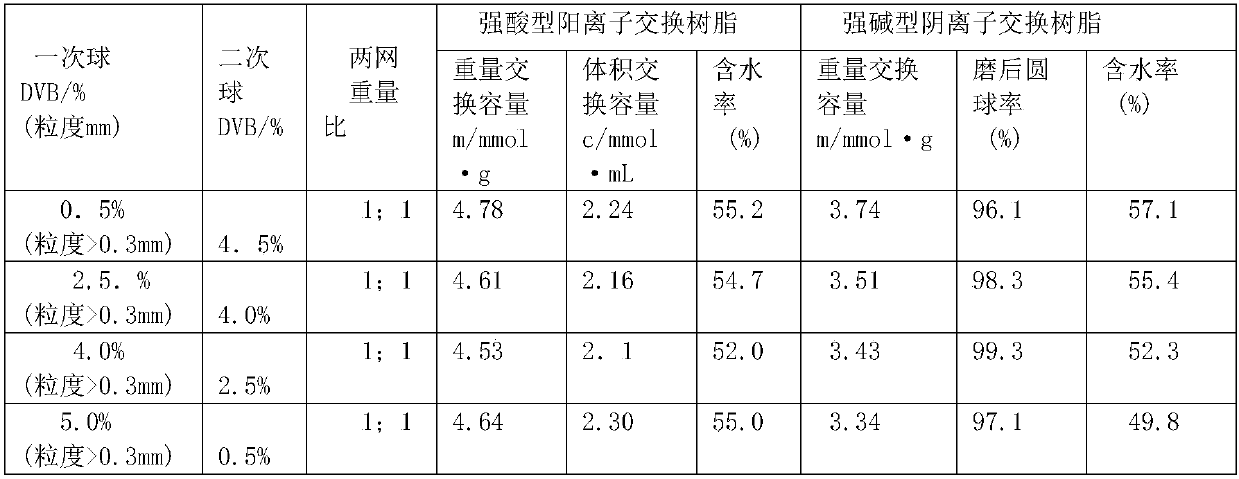

[0035] The styrene monomer is prepared with divinylbenzene DVB accounting for 0.5, 2.5%, 4.0%, 4.5% by weight, adding 0.5%-0.4% benzoyl peroxide BPO by weight, and adding a dispersant in advance; Animal gelatin or polyvinyl alcohol (accounting for 0.6-6,8% by weight of the water phase), the ratio of water phase to monomer is 1:1-1.25. Raise the temperature to 60°C under stirring, adjust the particle size at 60°C, react at 80°C for 3 hours (beads have sunk in the cold water test tube). , washed with boiling water, drained, dried at 10-105°C, and sieved. Wait for the second polymerization. Sieve the aggregated beads of primary polymerization to remove beads less than 0.06mm, boil and wash them in boiling water for 2-3 times, each time for 30 minutes, and then wash them with warm water for 3 times, remove the gelatin or Dispersants such as polyvinyl alcohol and impurities are thoroughly washed, dried at a temperature not higher than 105°C, and prepared St, DVB 0.5%-4.5% (the sa...

Embodiment 3

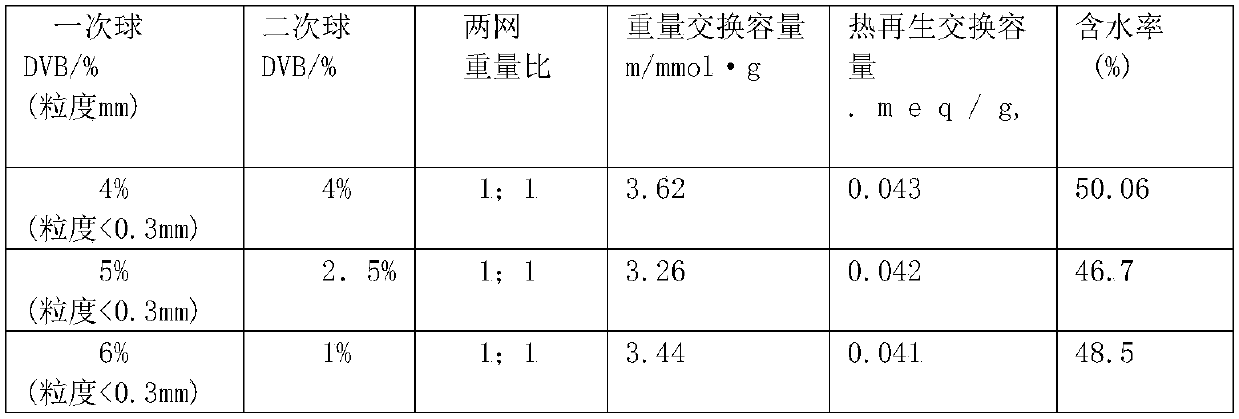

[0041] By the mixed monomer of methyl acrylate (MA) and divinylbenzene (DVB) with acidic functional group, MA, DVB (wherein DVB mass fraction is 1.0%, 2.5%, 4.0% and initiator benzoyl peroxide (BPO mass fraction is 0.4%-0.8%) solution, fully stirs and makes BPO dissolve completely.In the cross-linking that is formed by styrene divinylbenzene is DVB: in 4%, 5%, 6% white ball (respectively adopt embodiment 2 in the process condition of one-time polymerization to obtain), the amount of mixed monomer is the same as the amount in the primary polymerization beads, carry out the polymerization reaction respectively in the reactor by the technology and the conditions of the secondary polymerization in Example 1, dehydration, drying Dry and sieve, obtain the white ball of particle diameter > 0.315mm.Its white ball is reacted by conventional chloromethylation in embodiment 1, amination reaction can technology and condition again, while amination reaction, make acrylic acid Ester hydroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com