Patents

Literature

82 results about "Reservoir modelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

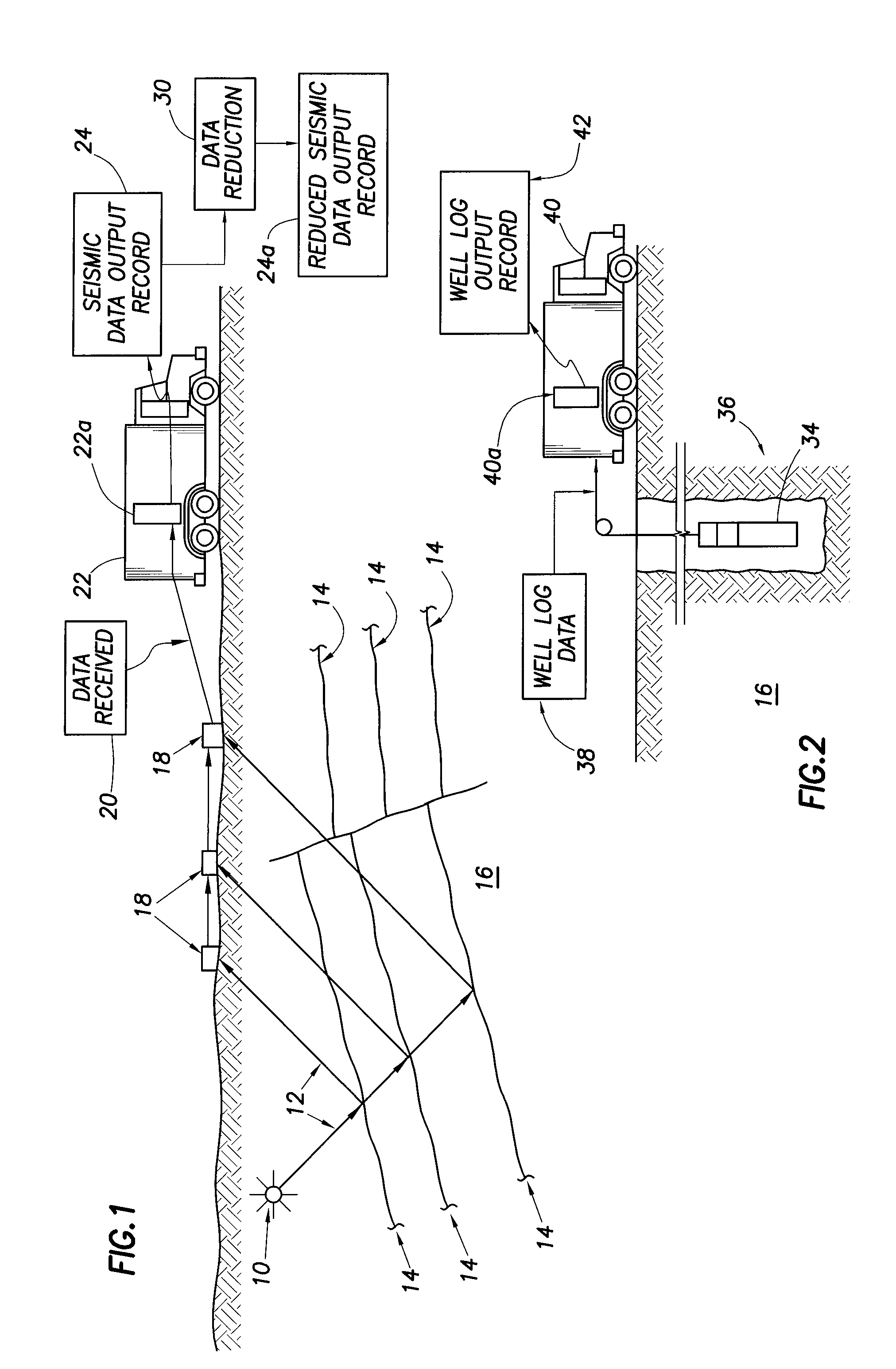

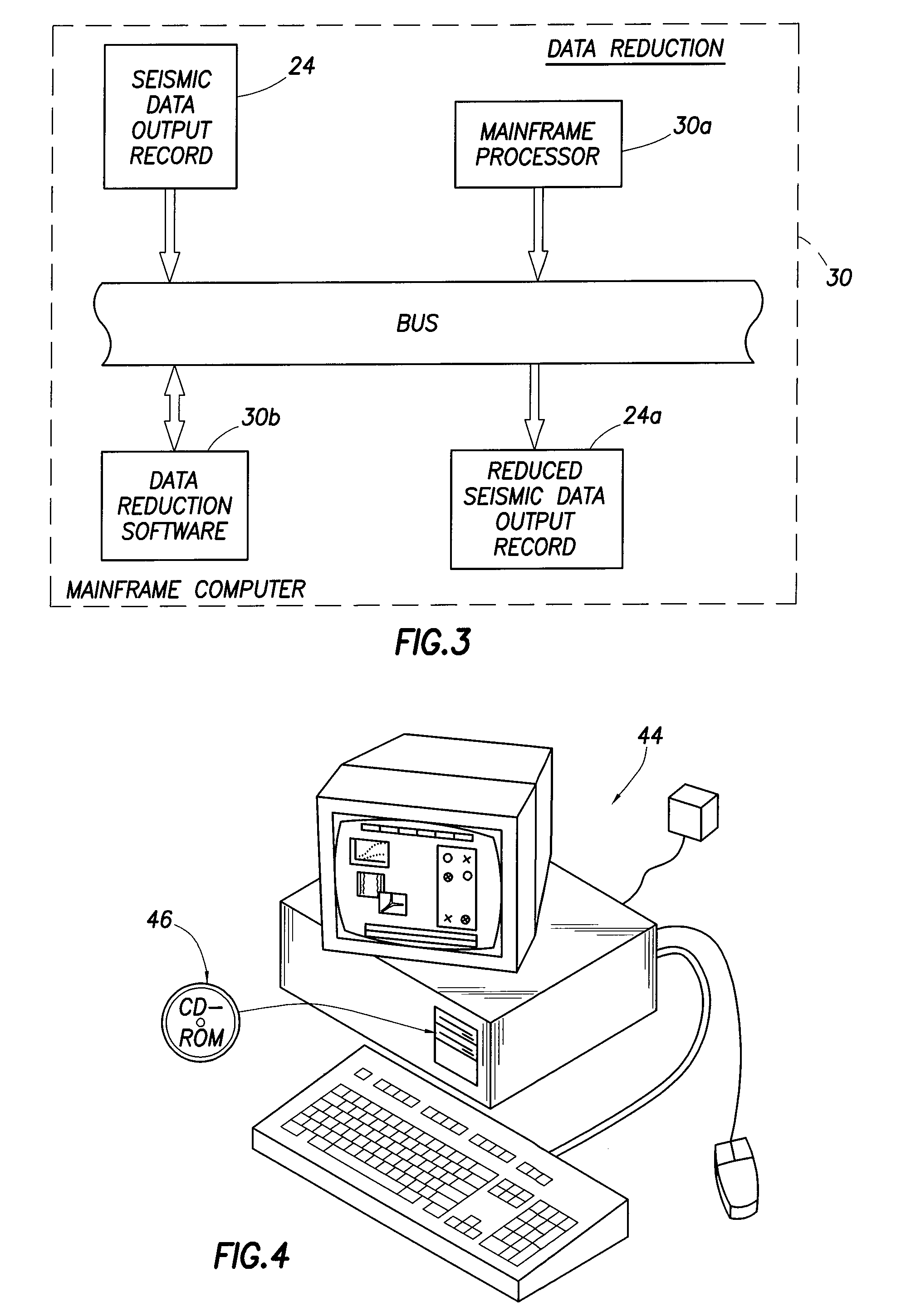

Method for estimating and/or reducing uncertainty in reservoir models of potential petroleum reservoirs

ActiveUS7254091B1Reduce uncertaintyGreat constraintSeismic signal processingSpecial data processing applicationsSoil scienceInter layer

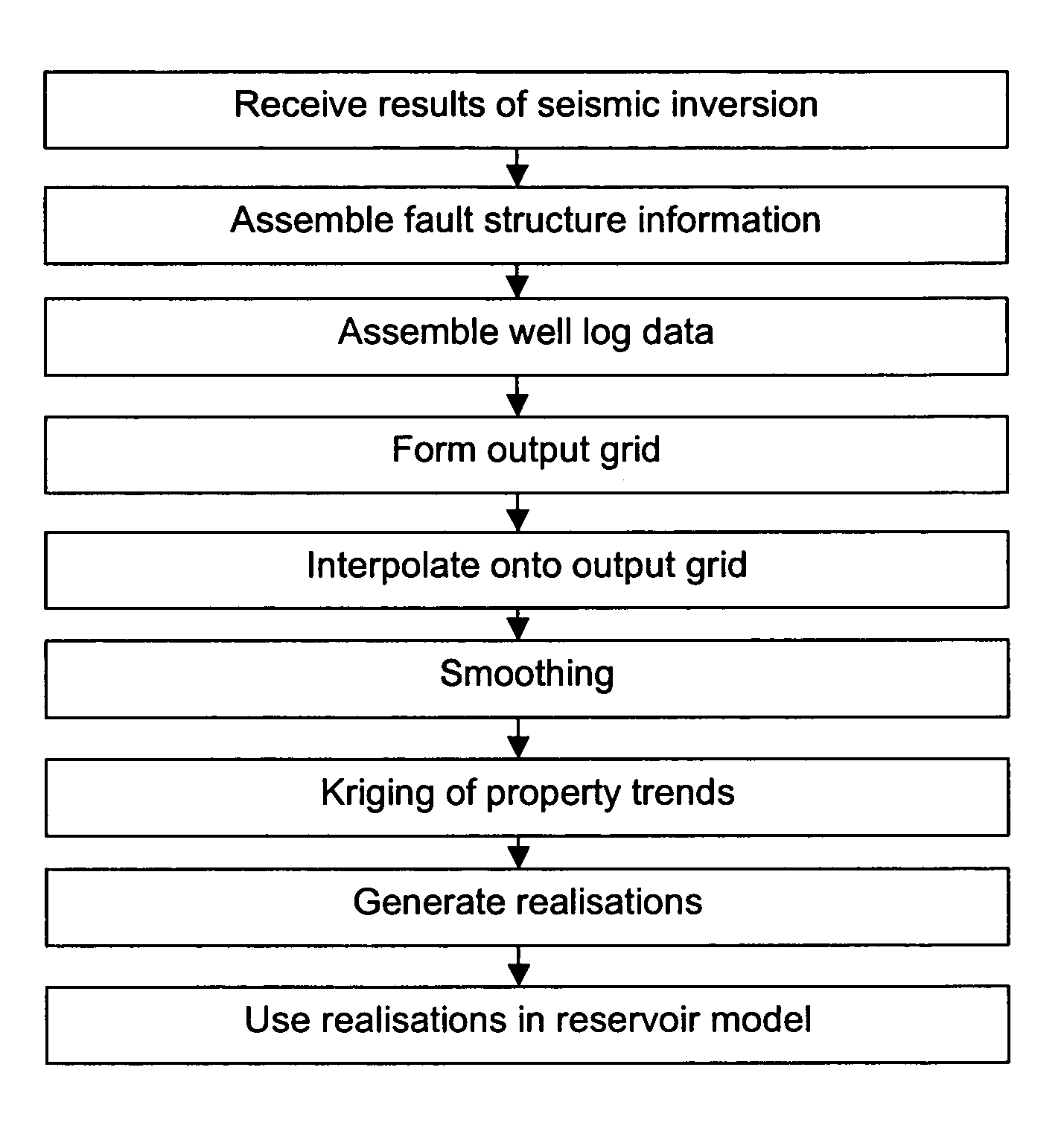

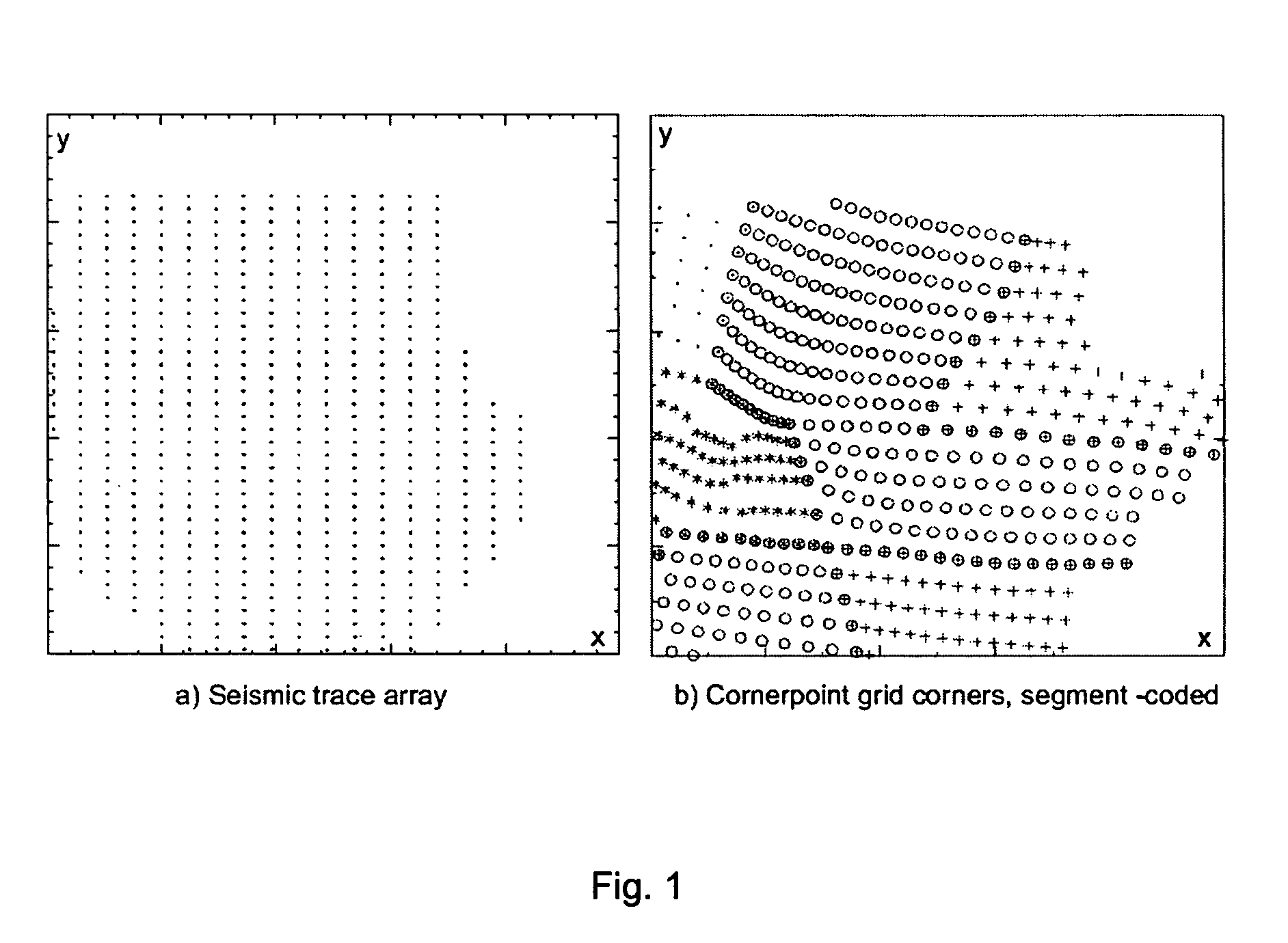

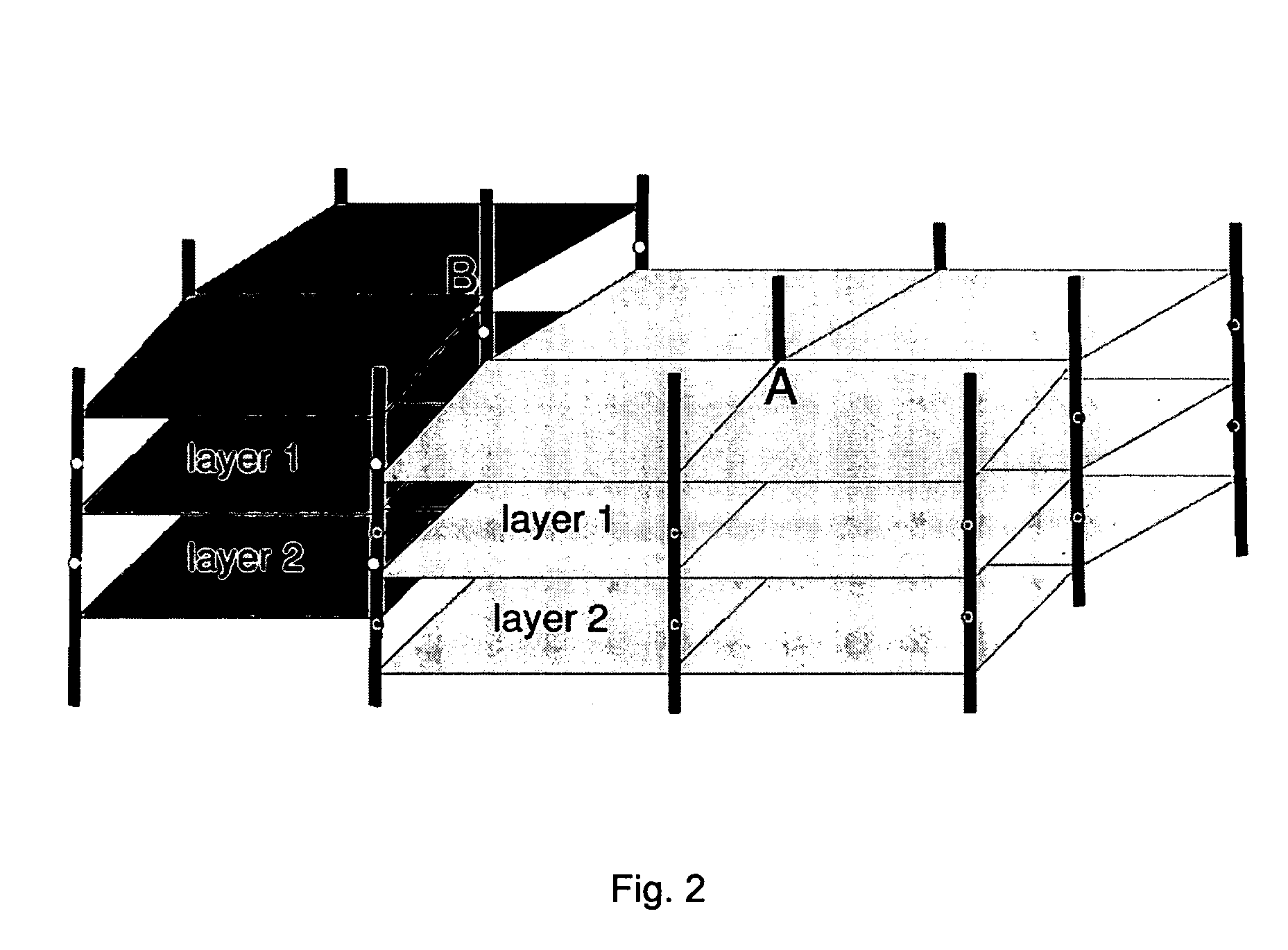

A method for estimating and / or reducing uncertainty in reservoir models of potential petroleum reservoirs comprises receiving the results of a stochastic seismic inversion, and transforming the inversion data into a form suitable for reservoir modelling and flow simulations, while honoring inter-property and inter-layer correlations in the inversion data as well as measured well data and other geological constraints.

Owner:BHP BILLITON INNOVATION PTY LTD

Method of modelling the production of an oil reservoir

InactiveUS20060047489A1Risk minimizationSimple and inexpensiveElectric/magnetic detection for well-loggingFluid removalGeomorphologyReservoir modelling

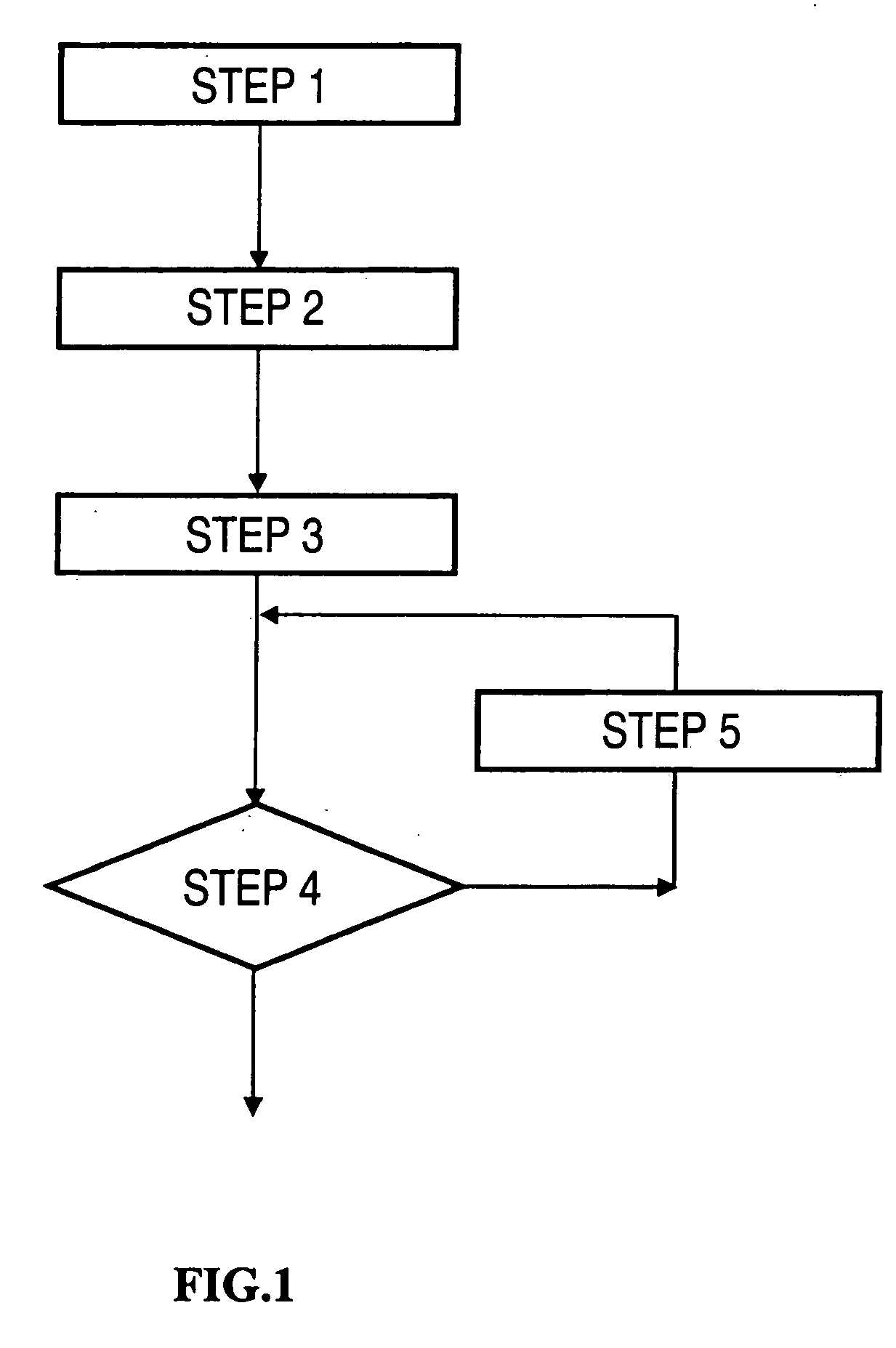

The invention stimulates the production of an oil reservoir by carrying out a sequence of steps of constructing a flow simulator from physical data measured in the oil reservoir; determining a first analytical model relating the production of the reservoir as a function of time by taking account of parameters having an influence on the production of the reservoir, the first model best adjusting to a finite number of production values obtained by the reservoir simulator; selecting at least one new production value, this new value being obtained by the reservoir simulator; and determining a second model by adjusting the first model so that the second model interpolates the new production value.

Owner:INST FR DU PETROLE

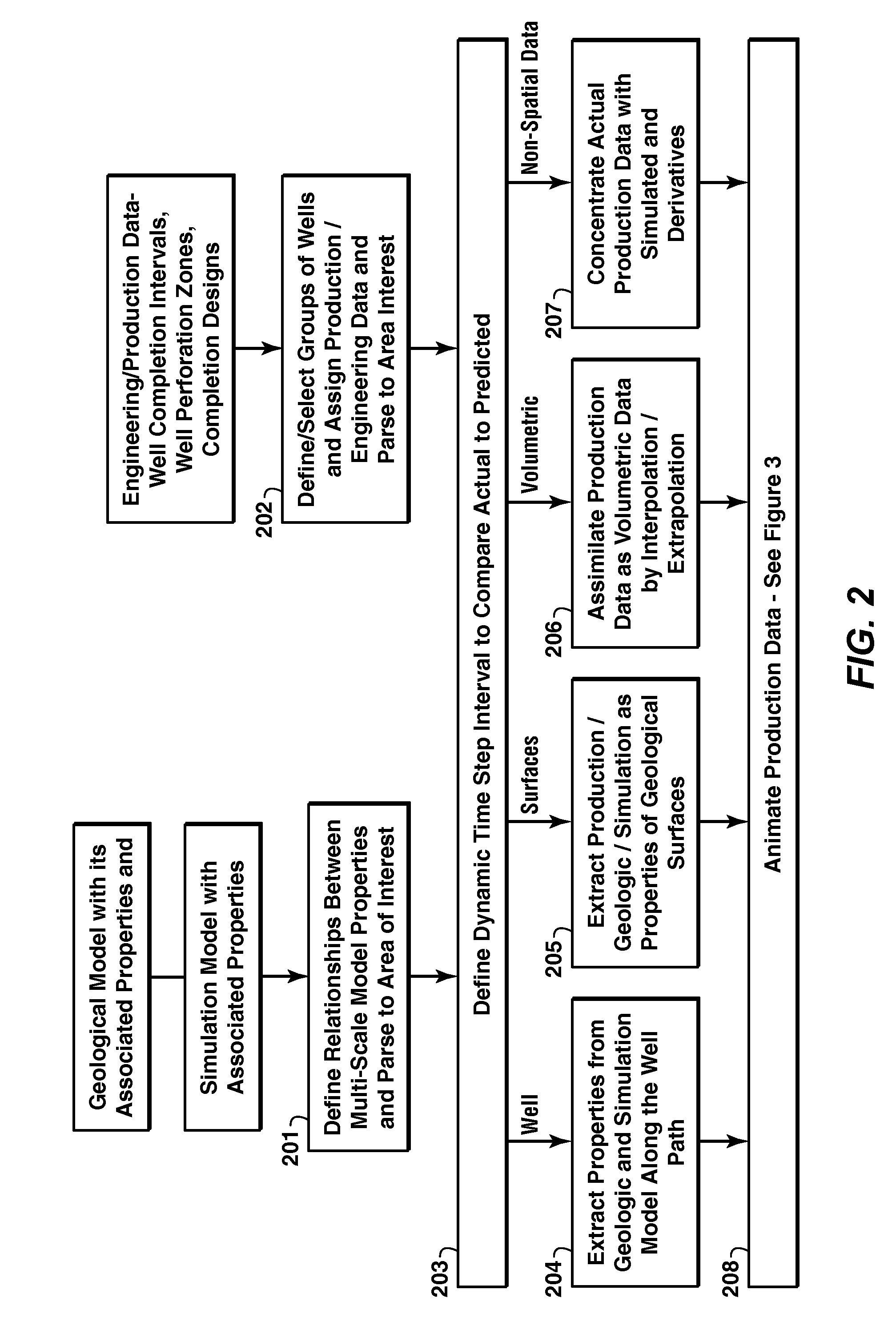

Iterative Reservoir Surveillance

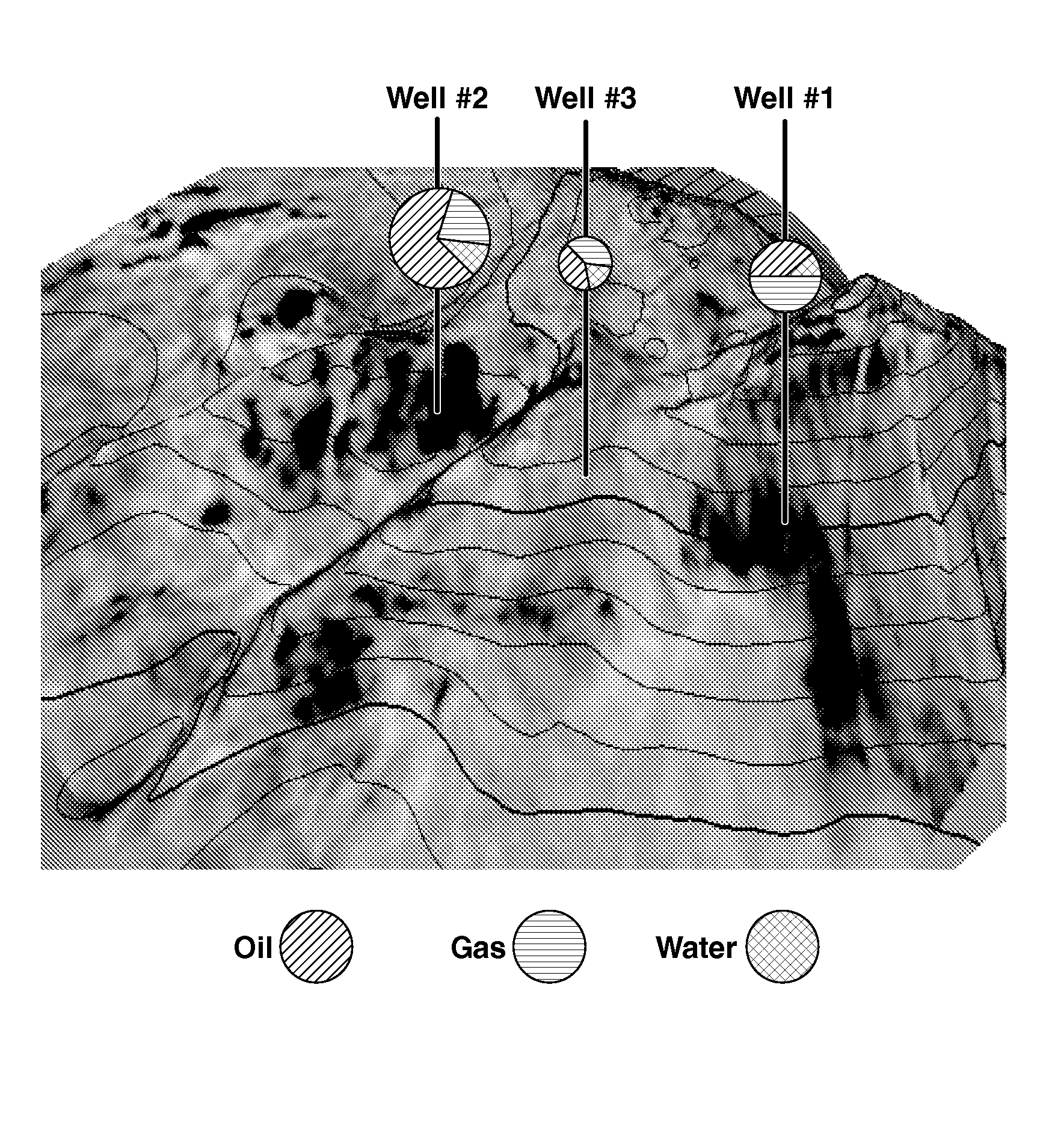

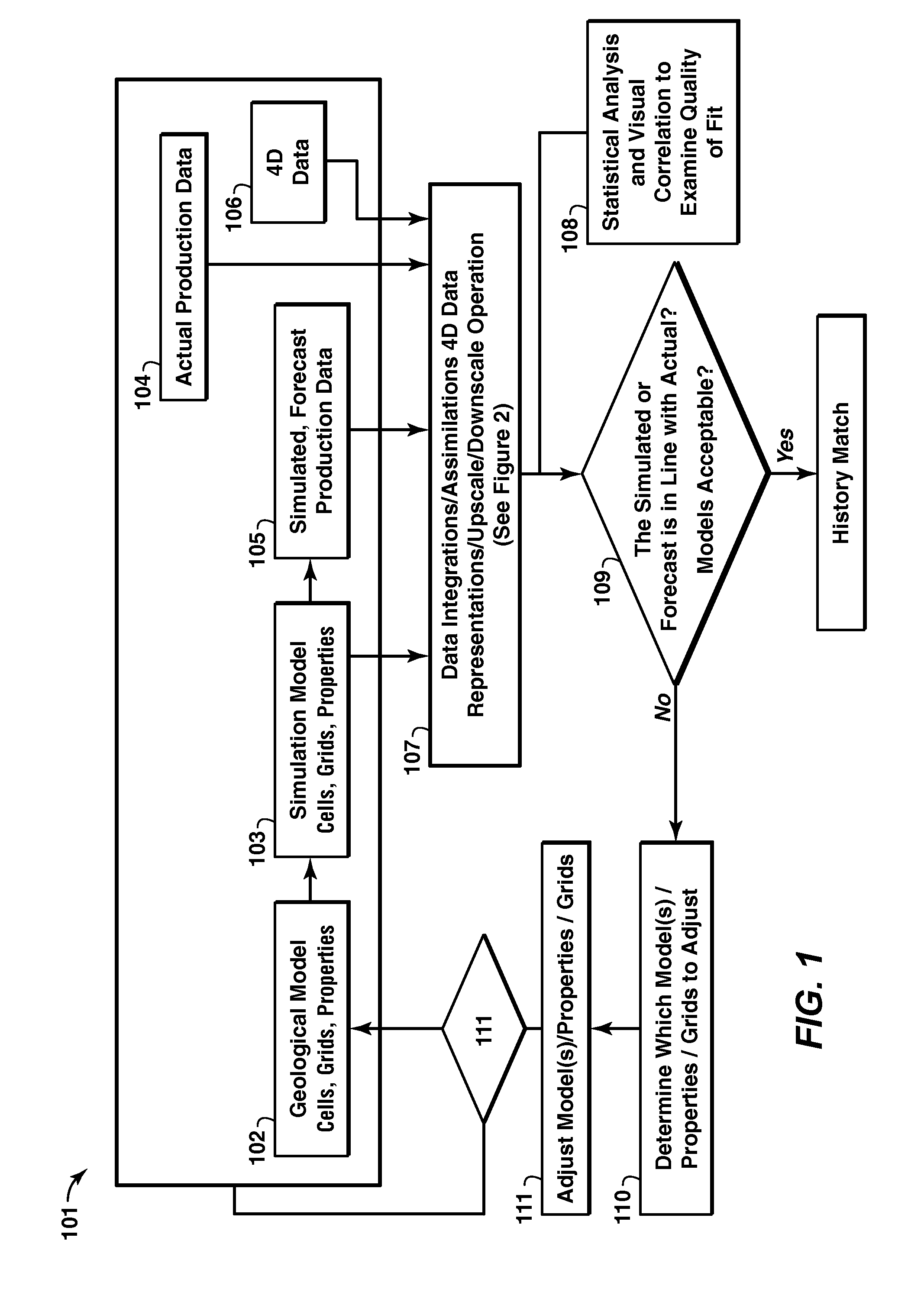

Method for reservoir surveillance using a three-dimensional Earth Model (101) to improve and expedite the surveillance at all scales of investigation (field, reservoir, fault compartment, and individual well) and at all time steps (minutes, hours, days, months, years). The new method allows users to rapidly identify anomalous field and well performance (109) and provides capability to investigate root causes of the performance deviation from predicted (110). Animated co-rendered displays (107) of the earth model and actual (104) and simulated (105) production data enable the user to interactively determine model adjustments back at the basic level of the Earth Model, which are then propagated to a geologic model (102) and then to the reservoir simulator (103) to update it (111) in a physically constrained way.

Owner:EXXONMOBIL UPSTREAM RES CO

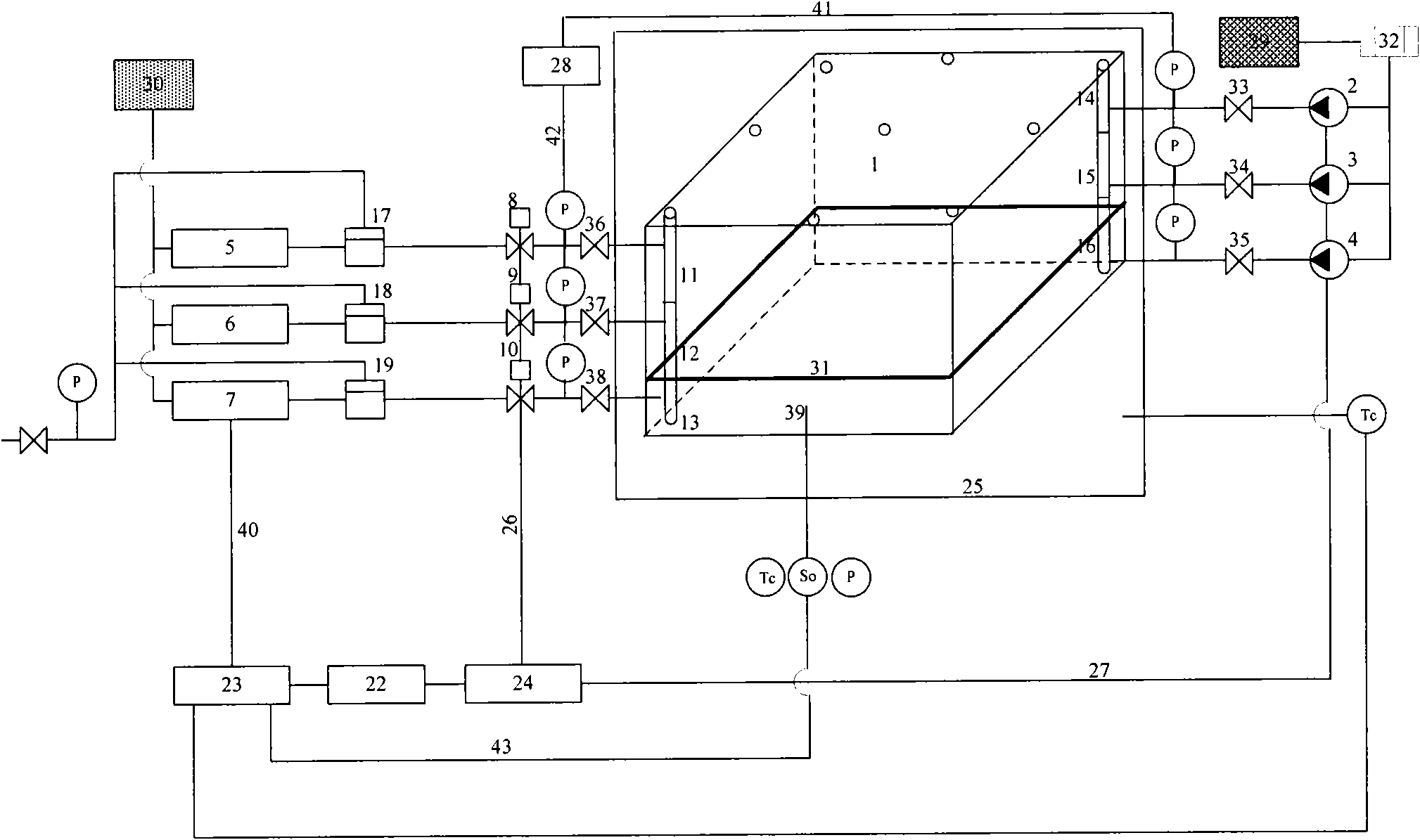

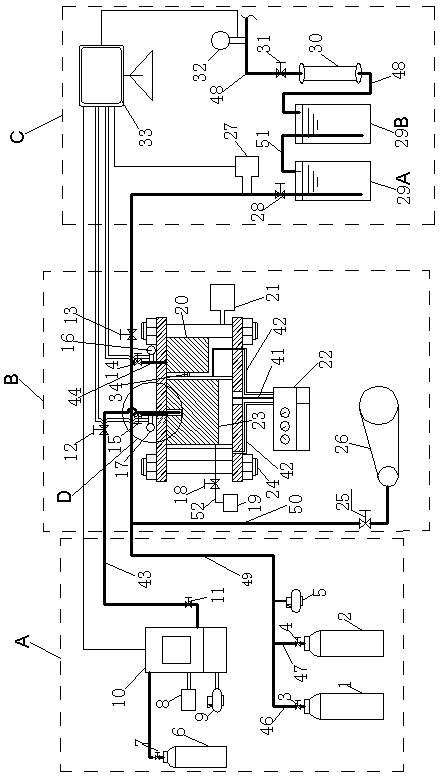

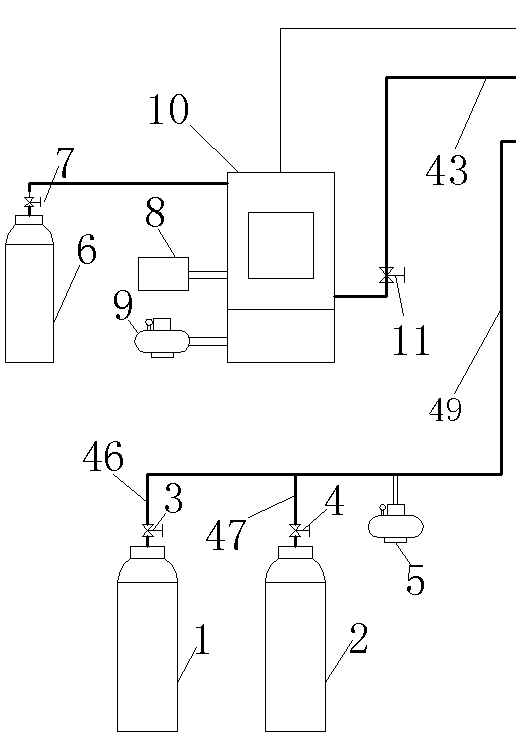

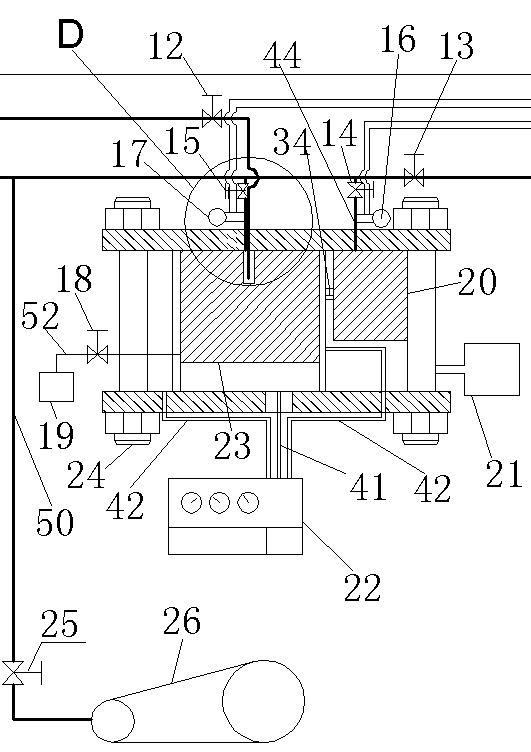

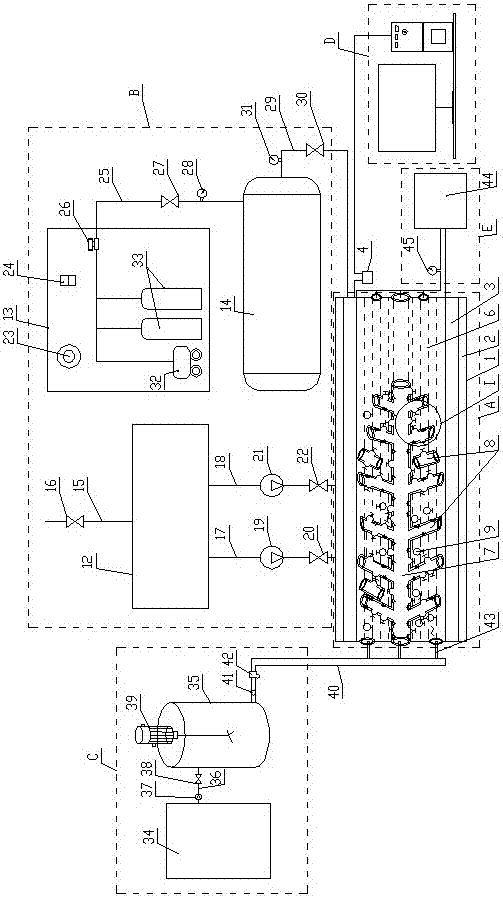

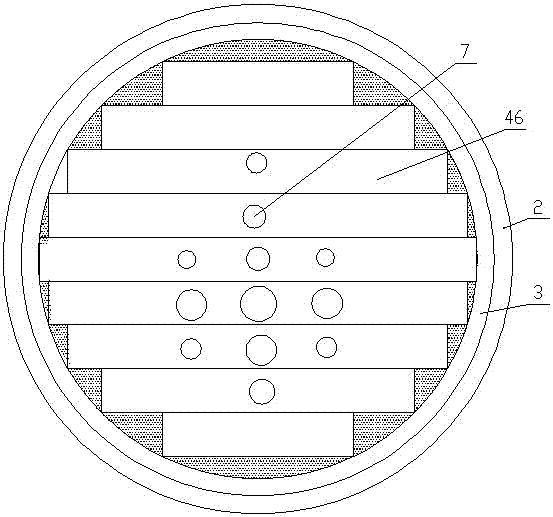

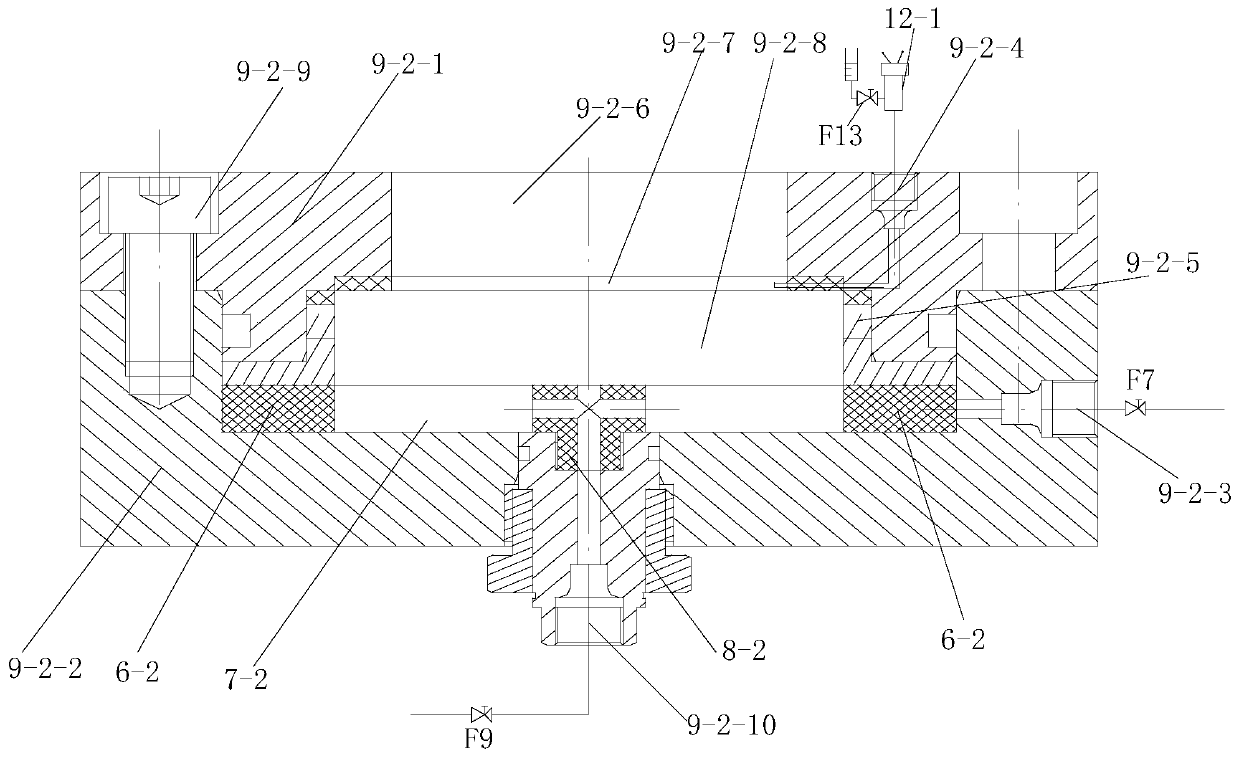

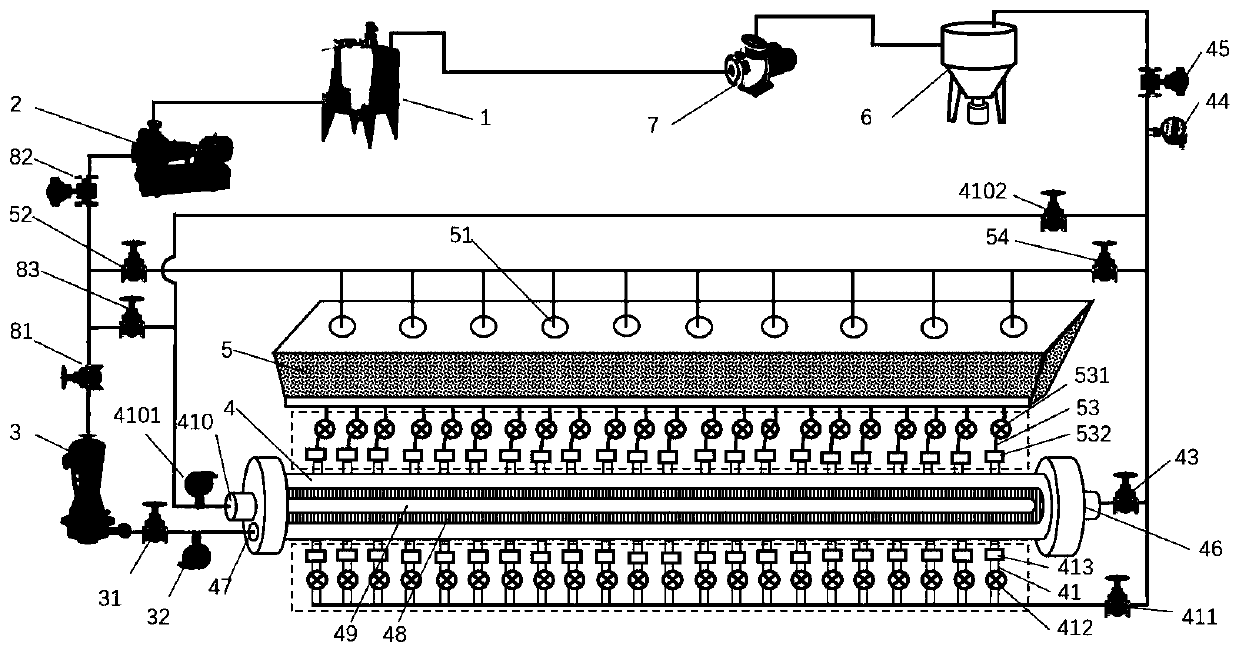

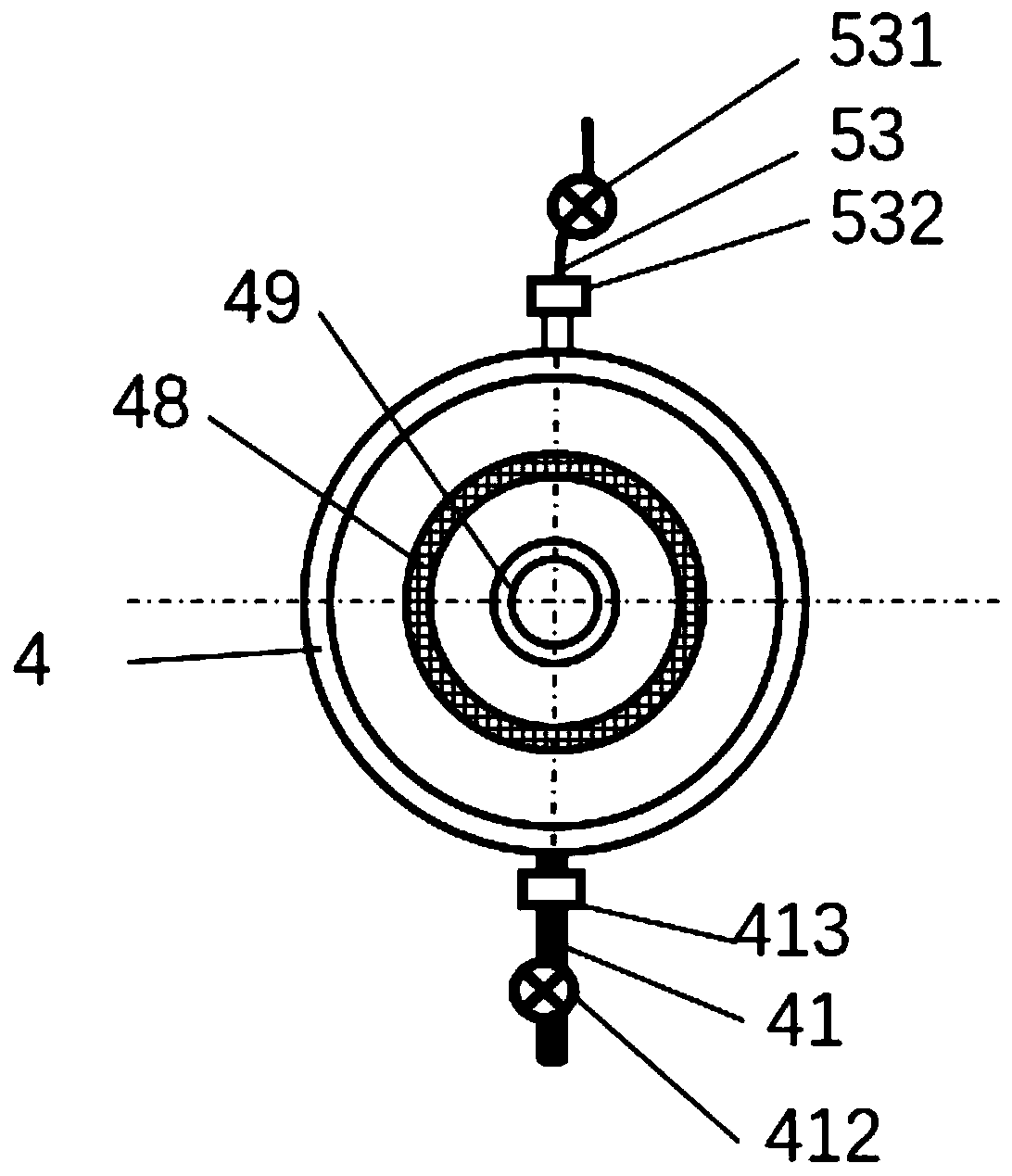

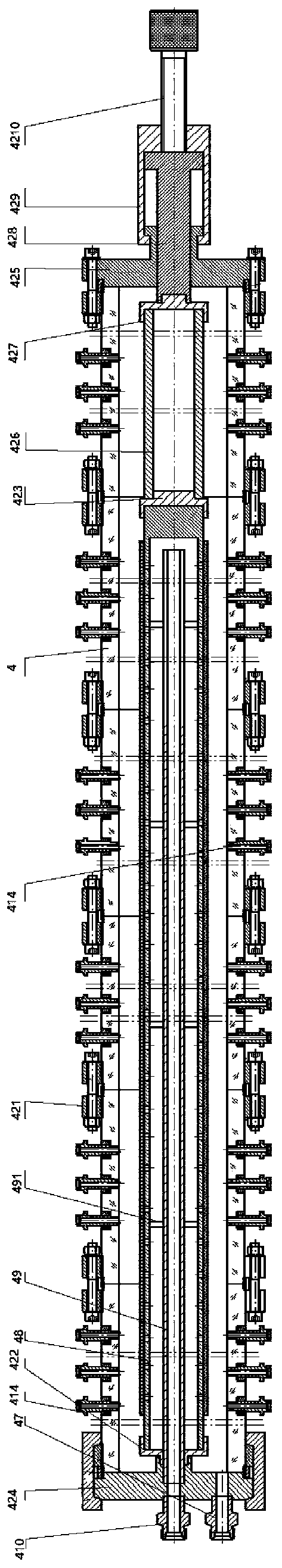

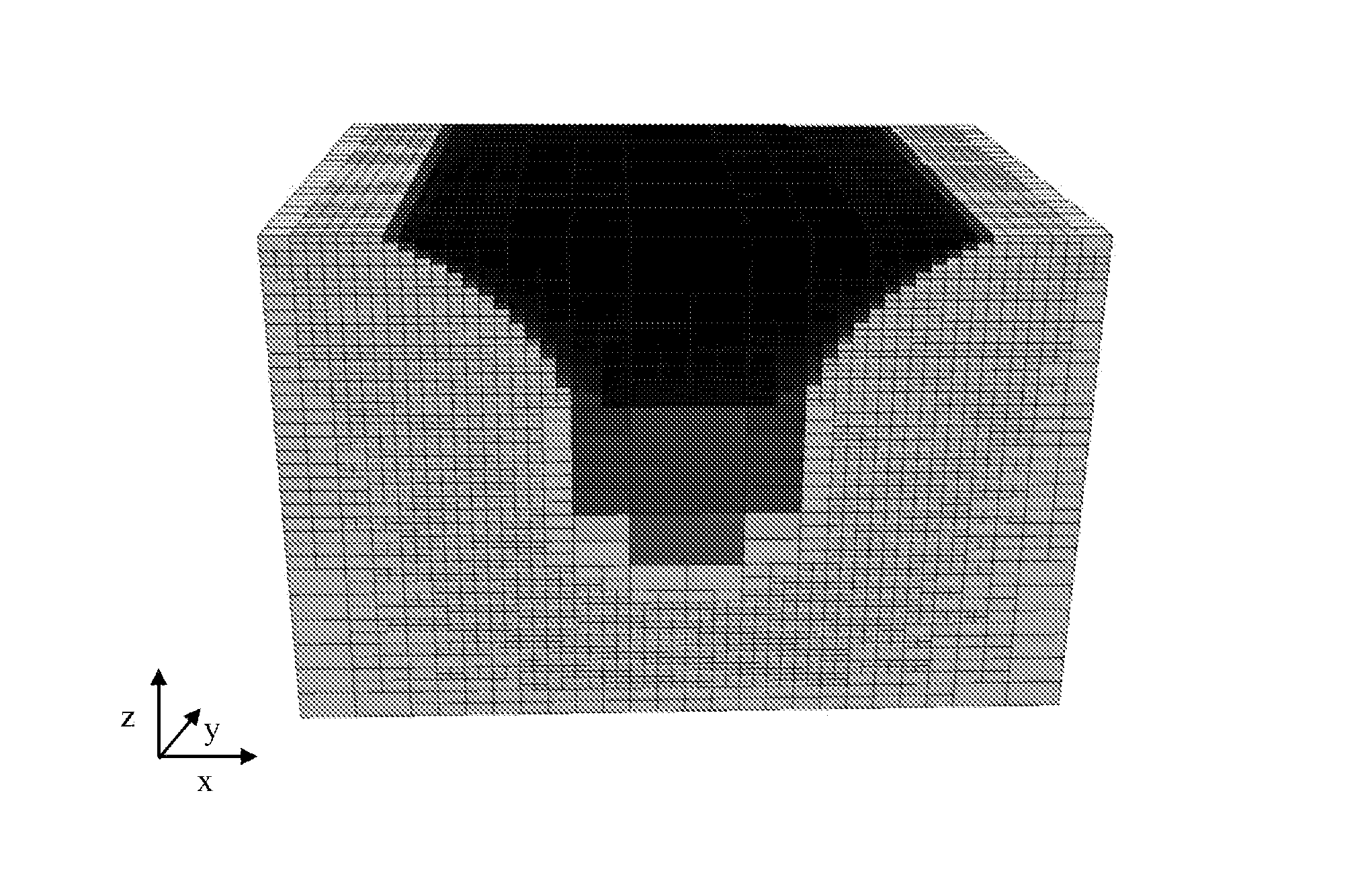

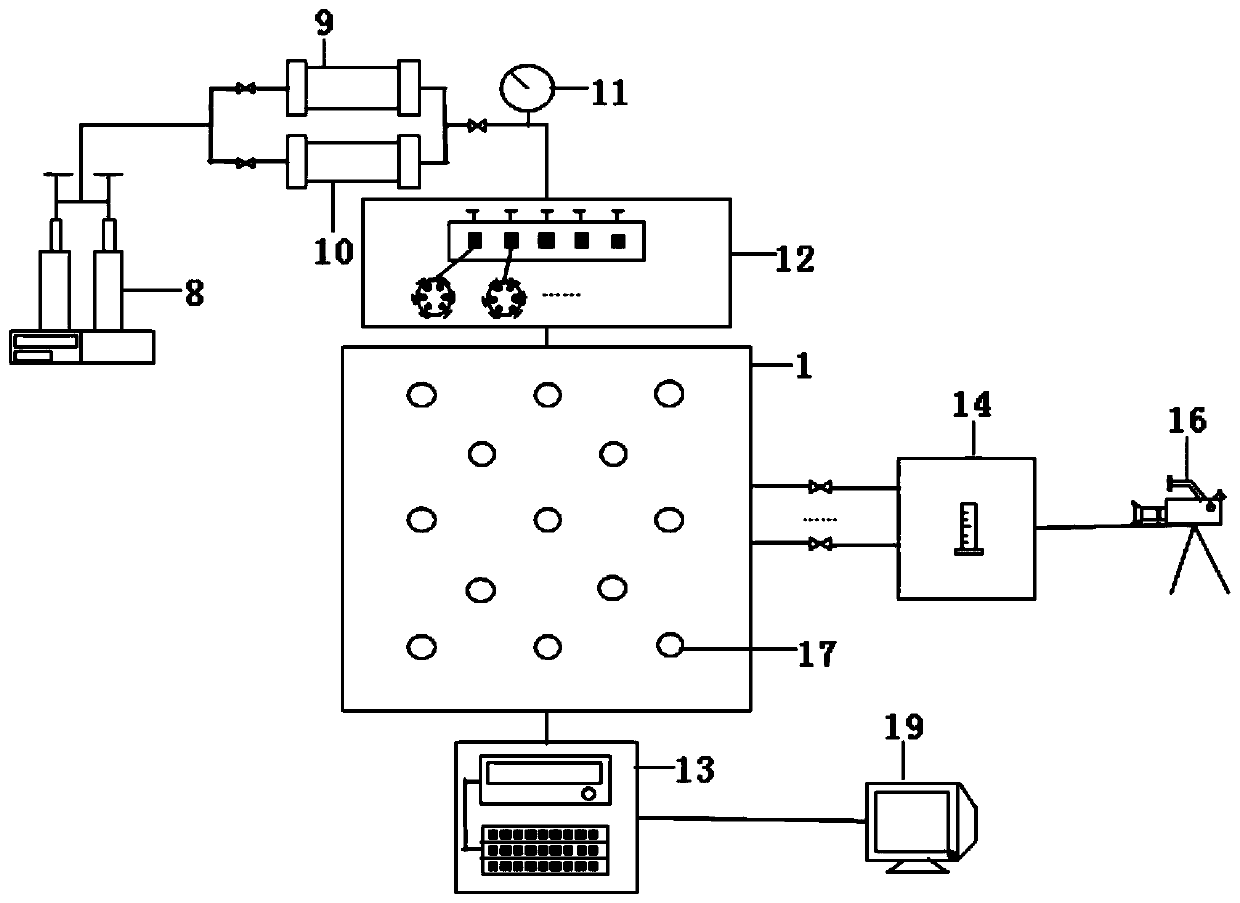

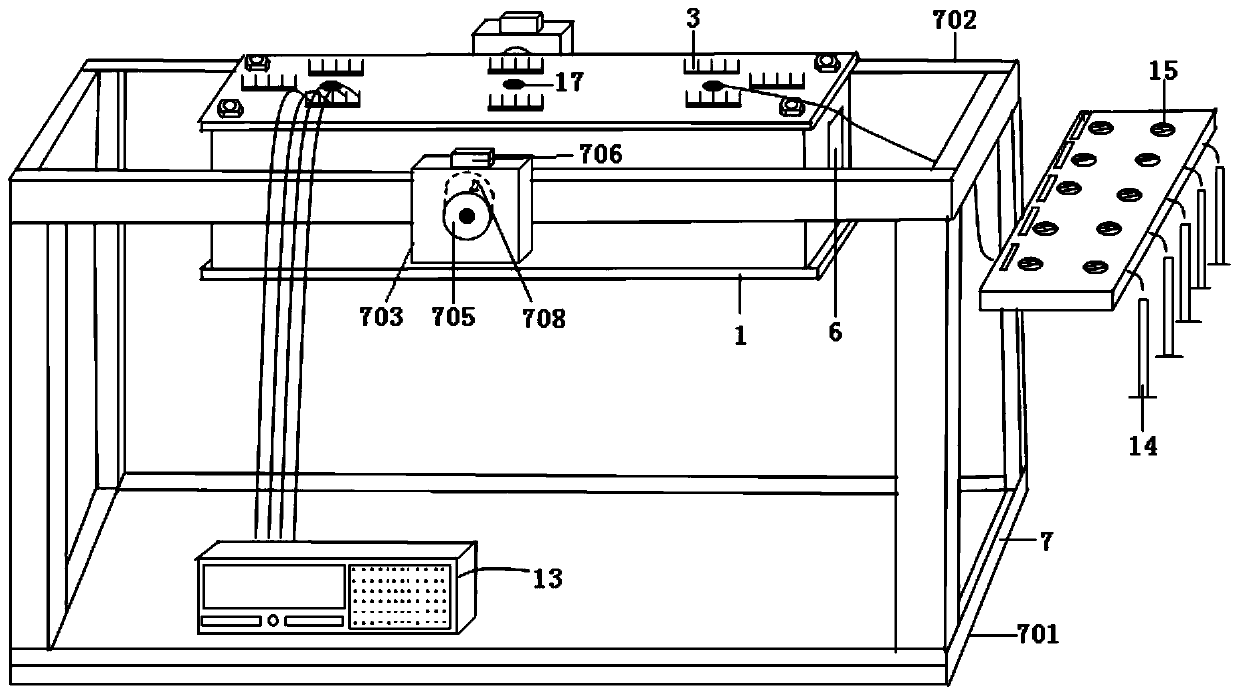

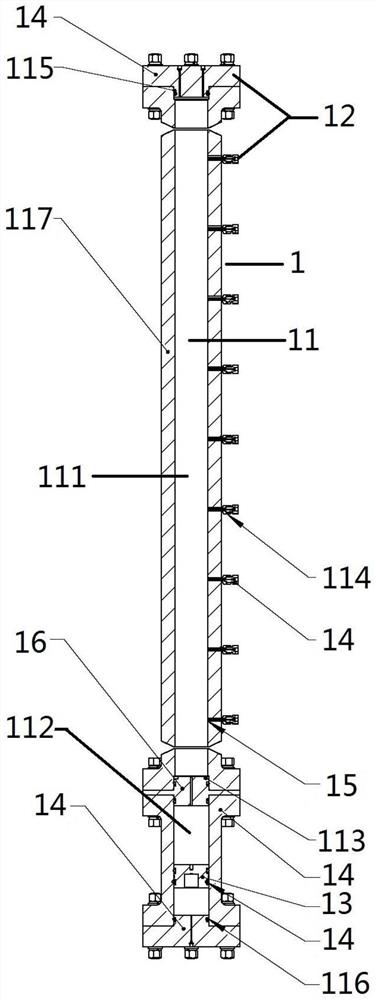

Intelligent oil well simulation experiment system and working method

InactiveCN102022112AEasy to operateFast and easy data collection and processingBorehole/well accessoriesTraffic volumeAutomatic control

The invention discloses an intelligent oil well simulation experiment system and a experiment method. The intelligent oil well simulation experiment system comprises a three-dimensional heterogenous reservoir simulating box, a wellbore hole simulator, a fluid injecting module, a fluid generating module, a data acquiring module, an automatic control module, a constant temperature module, a saturation probe, a pressure sensor and a temperature sensor. The wellbore hole simulator is arranged in the three-dimensional heterogenous reservoir simulating box, the automatic control modules realizes the real-time extraction and injection on the wellbore hole simulator through controlling the fluid injecting module and the fluid generating module; and the data acquiring module is used for monitoringinjected and extracted fluid, and monitoring the saturation, the temperature and the pressure in the simulating box in real time, and a computer is used for optimizing and analyzing the monitoring data, controlling the injection and extraction flow in real time through the automatic control module, simulating and realizing multilayer comingling production, sectional extraction of a horizontal well, extraction of a multi-branch well and control strategy of an injection and extracting well, and perfecting the researches of real-time optimization, real-time regulation and the like of the production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

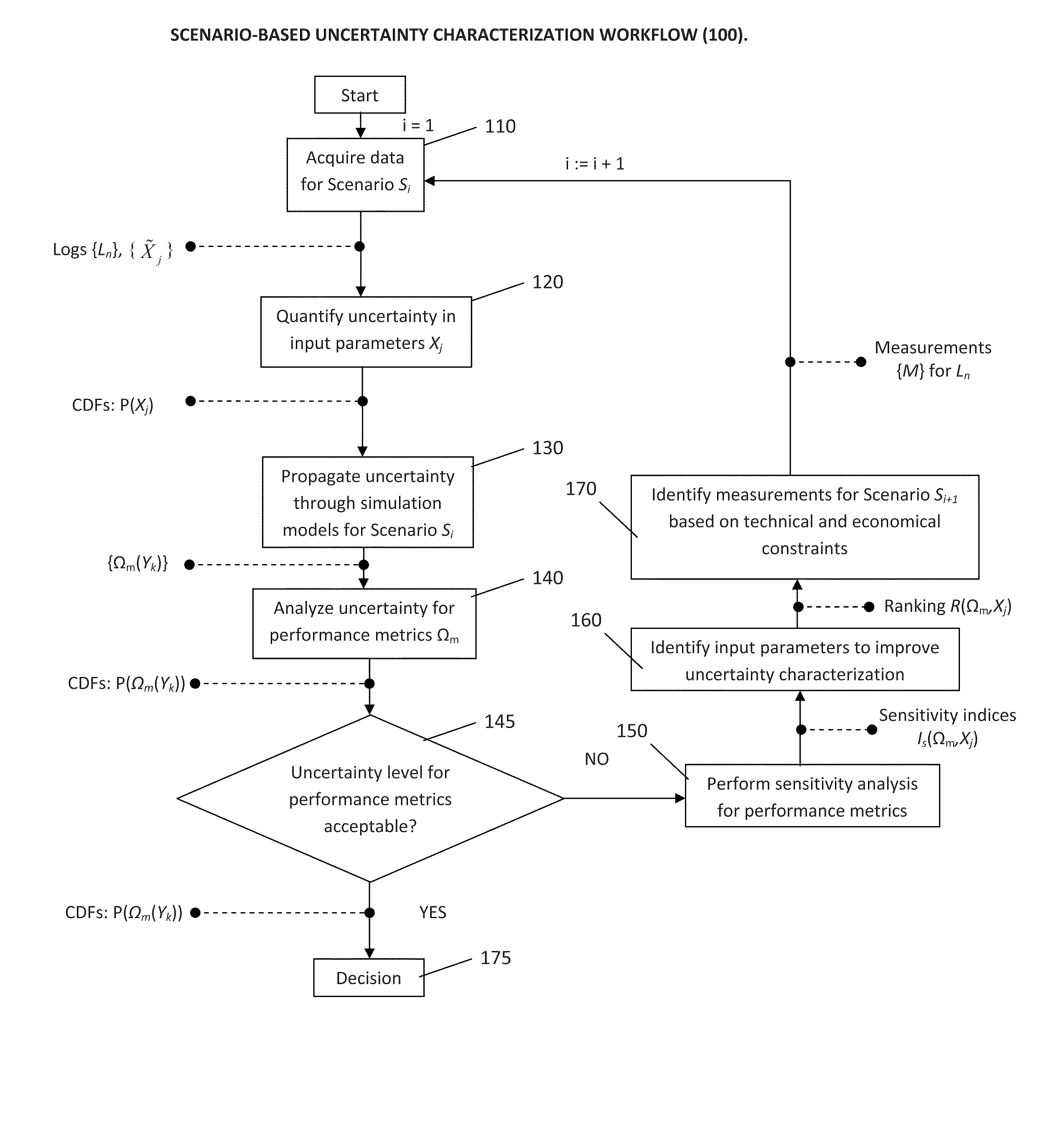

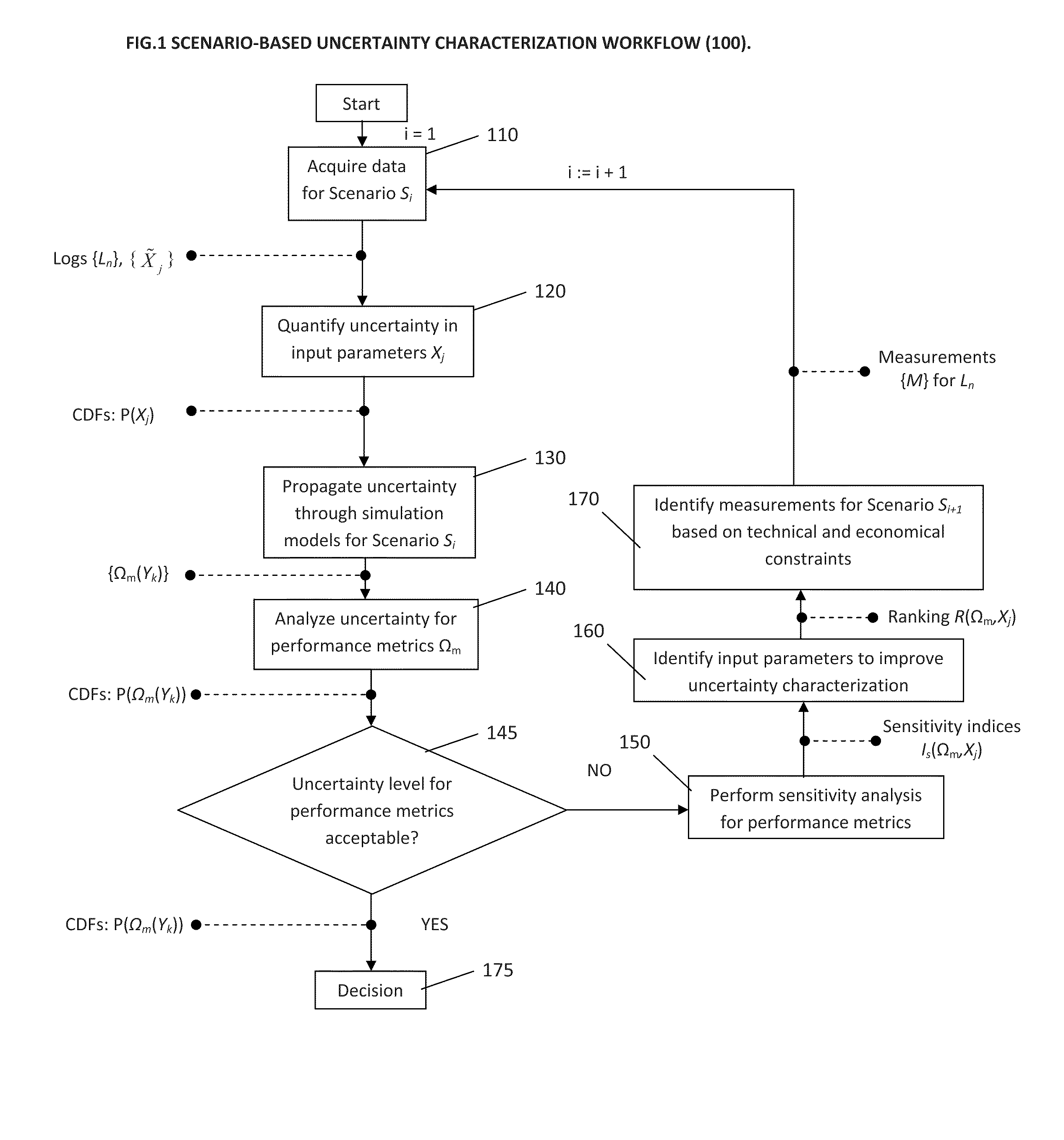

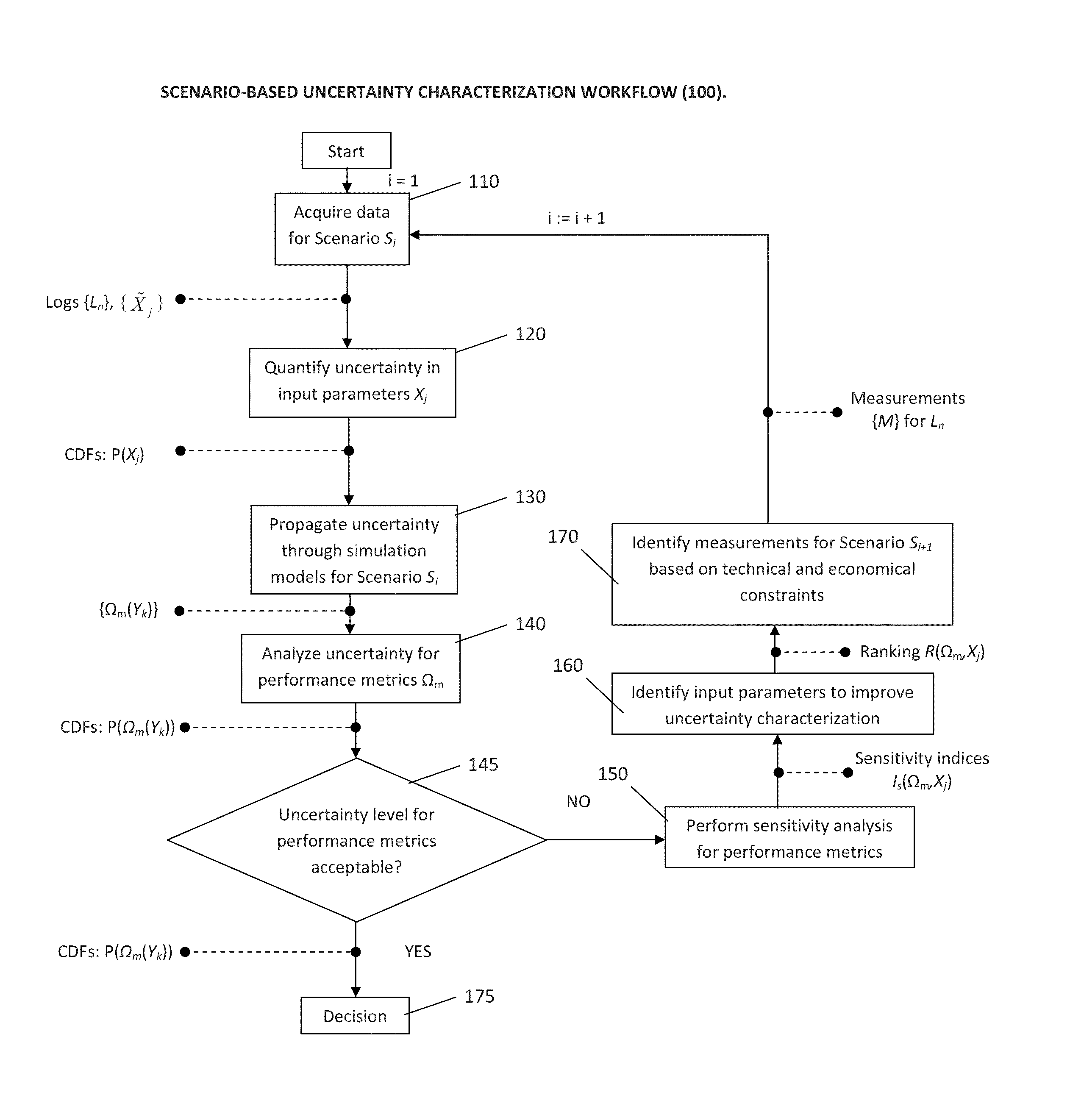

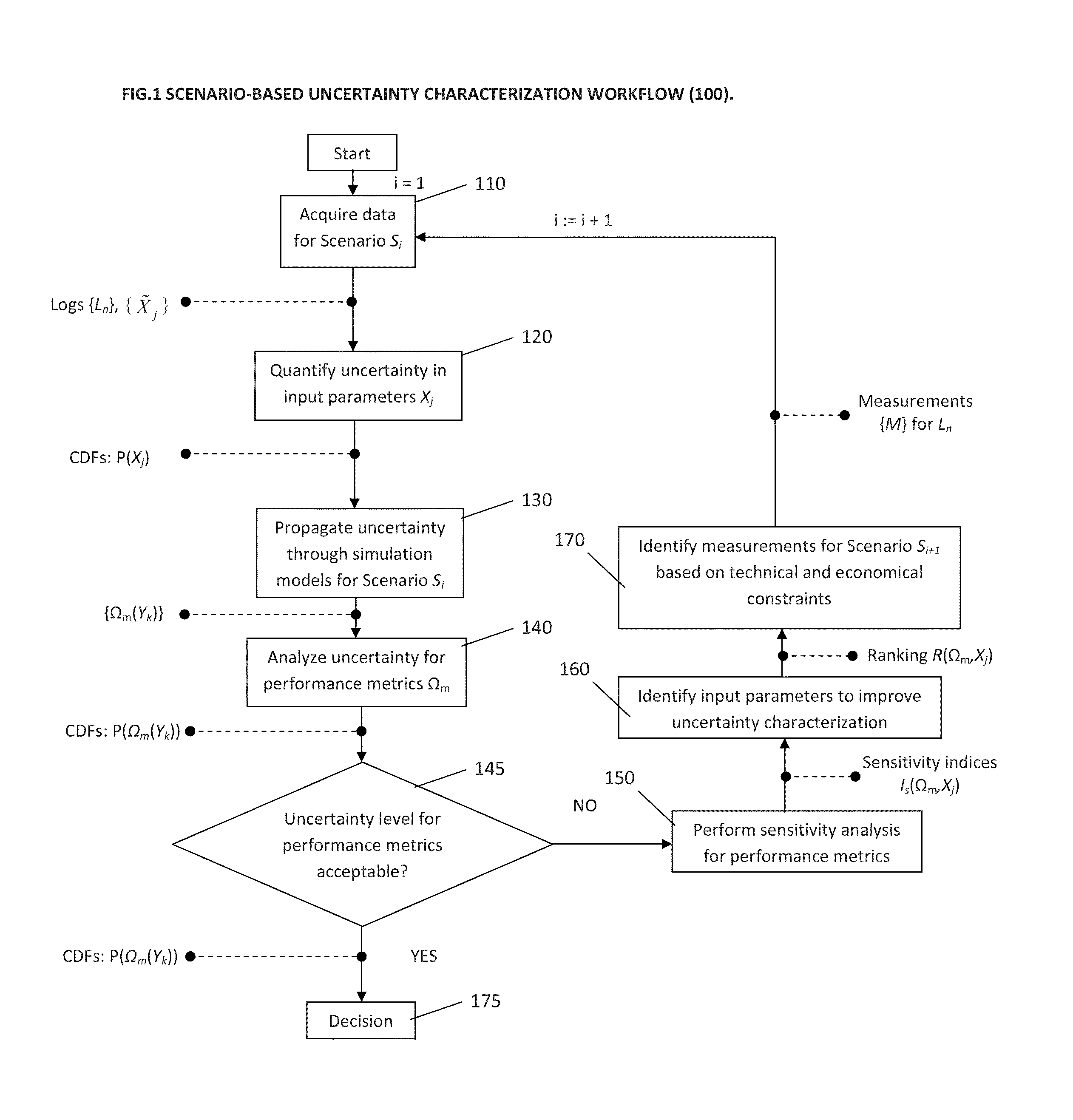

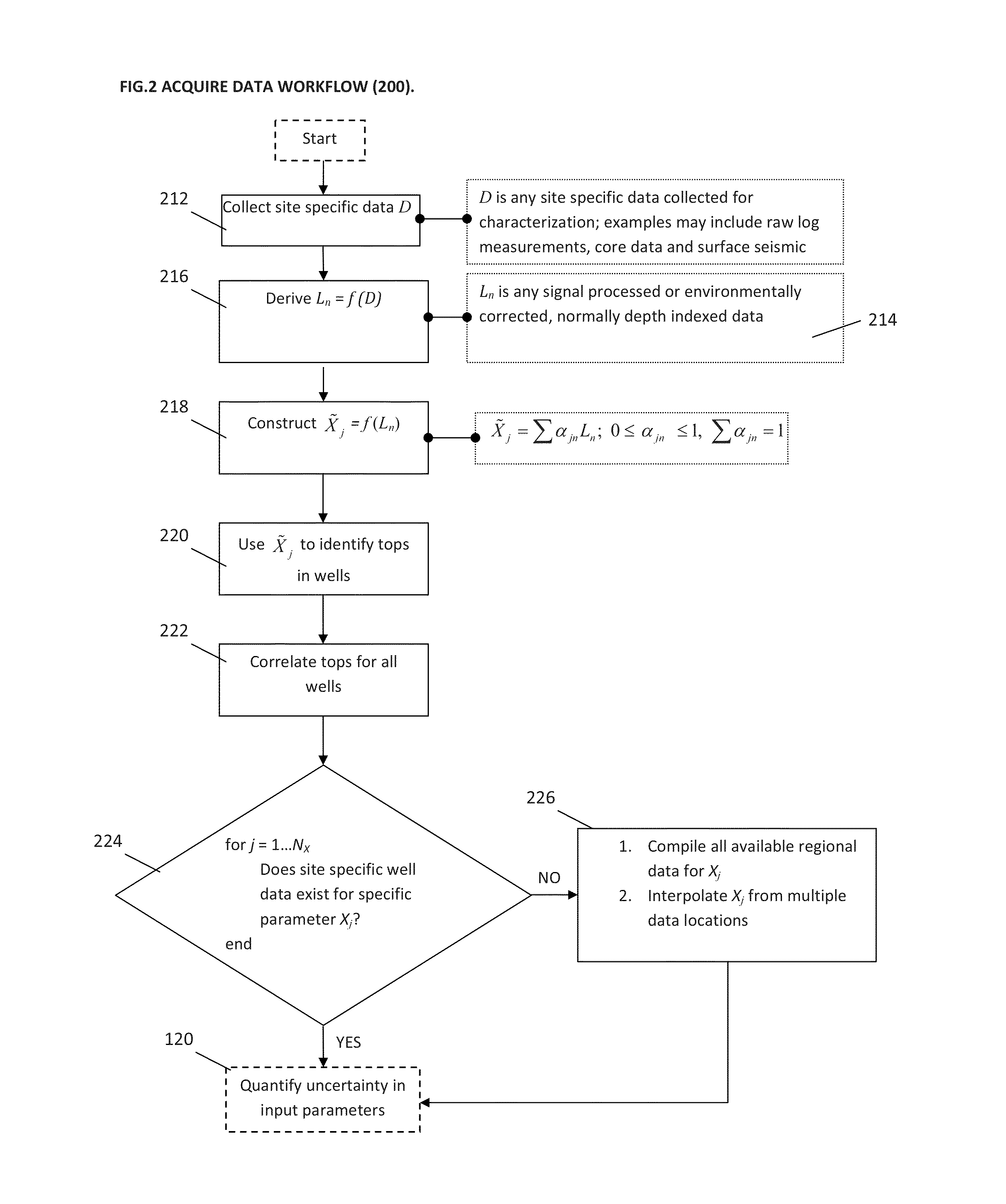

Method for uncertainty quantifiation in the performance and risk assessment of a carbon dioxide storage site

ActiveUS20100299126A1SeismologyComputation using non-denominational number representationCarbon dioxideRisk assessment

A CO2 sequestration site is evaluated by incorporating a consistent petrophysical framework having uncertainties expressed in the form of probability density functions of wellbore measurements, by systematically propagating the uncertainties in generating probability density functions or cumulative distribution functions of the parameters used in a reservoir simulation, by using the reservoir simulation to transform the first set of parameters into output variables with uncertainties, and by using the output variables and uncertainties to generate an answer product from which uncertainty levels of performance metrics can be ascertained.

Owner:SCHLUMBERGER TECH CORP

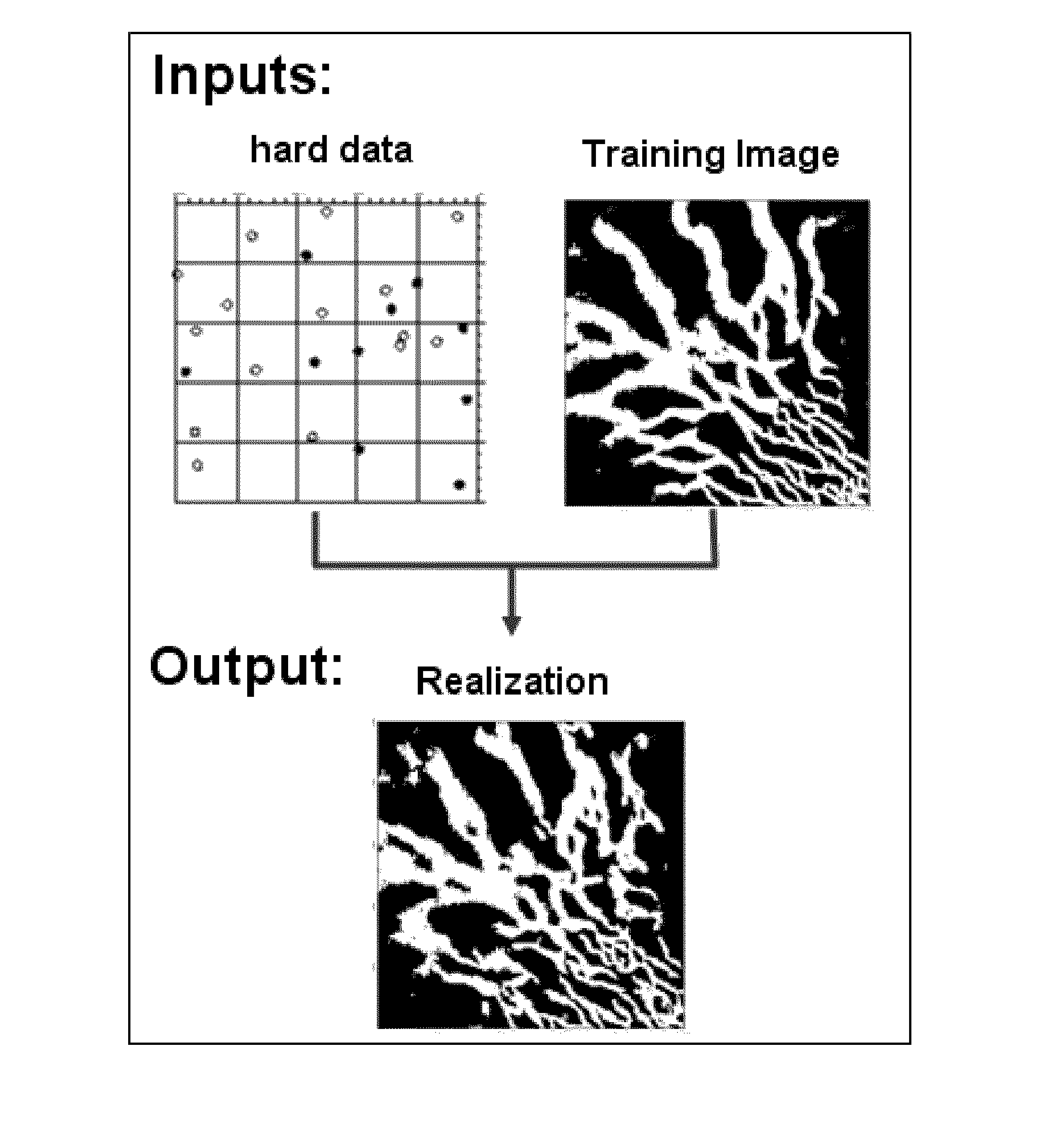

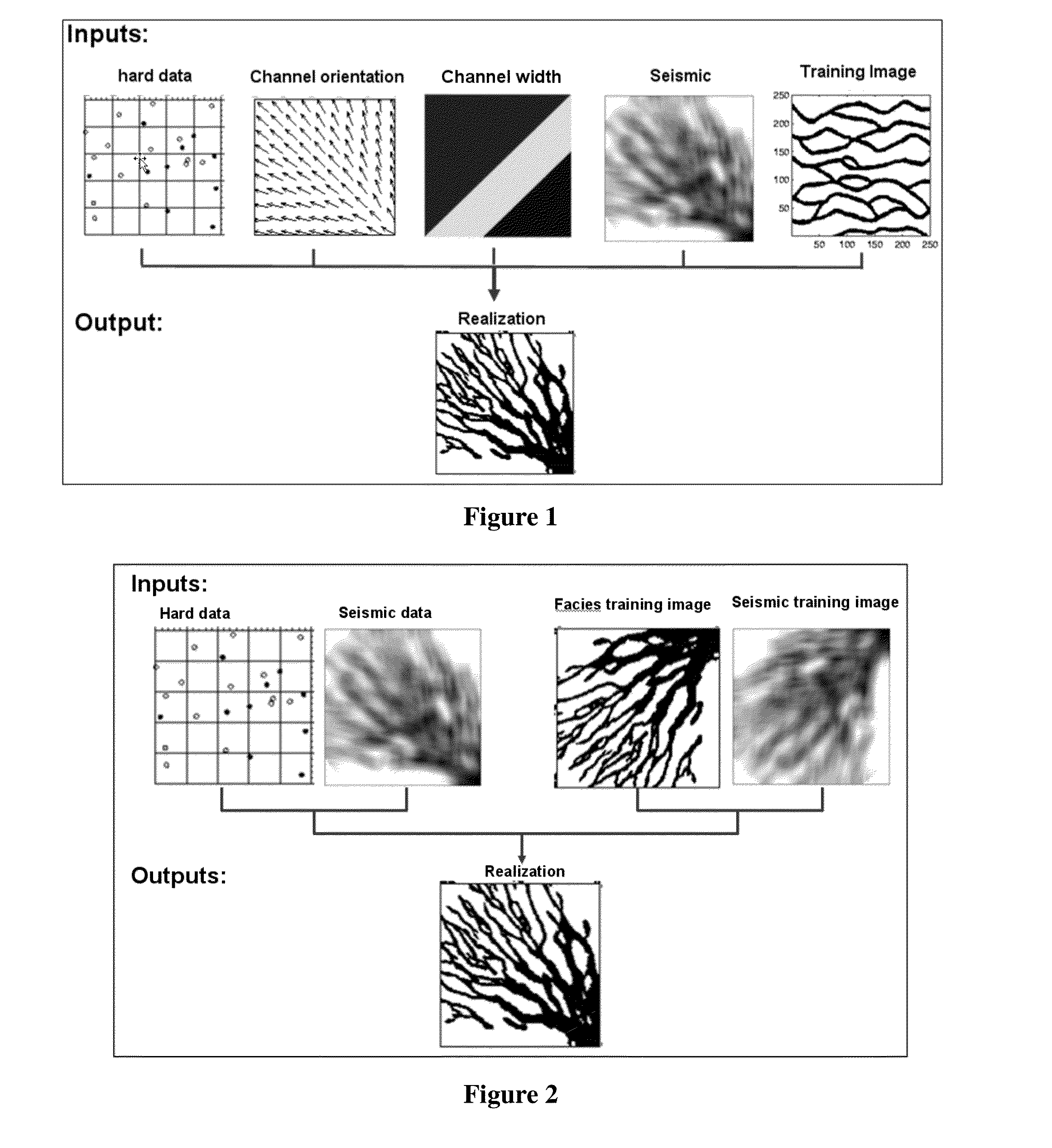

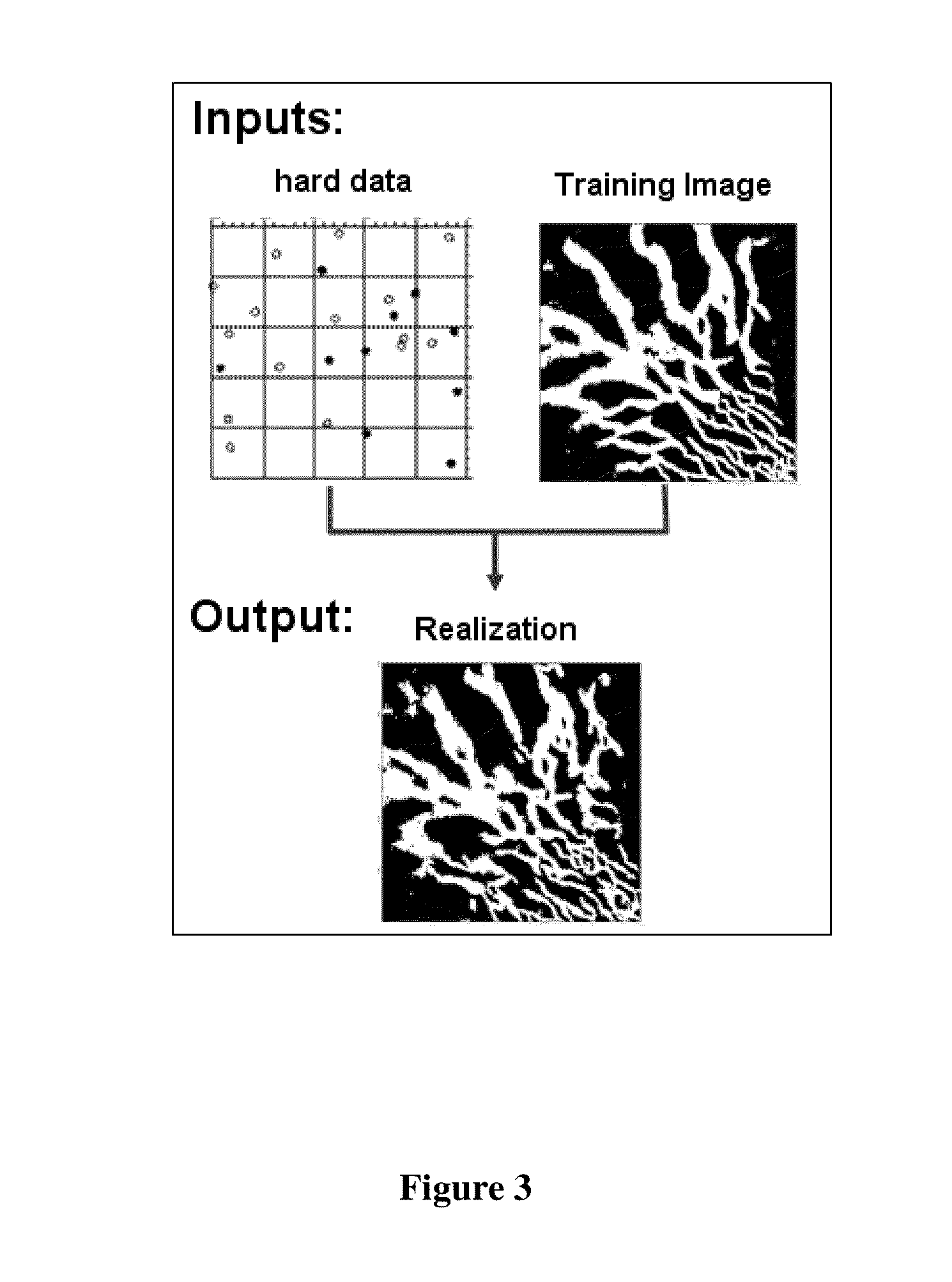

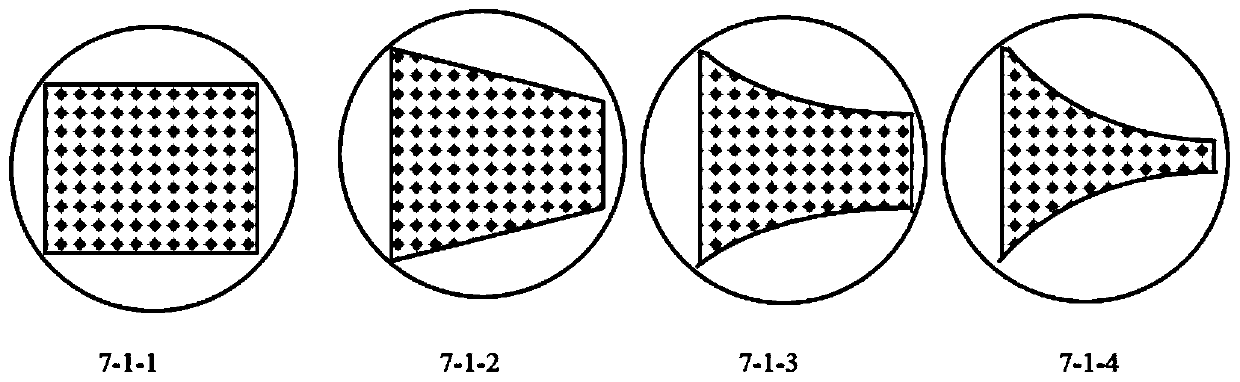

Reservoir modelling with multiple point statistics from a non-stationary training image

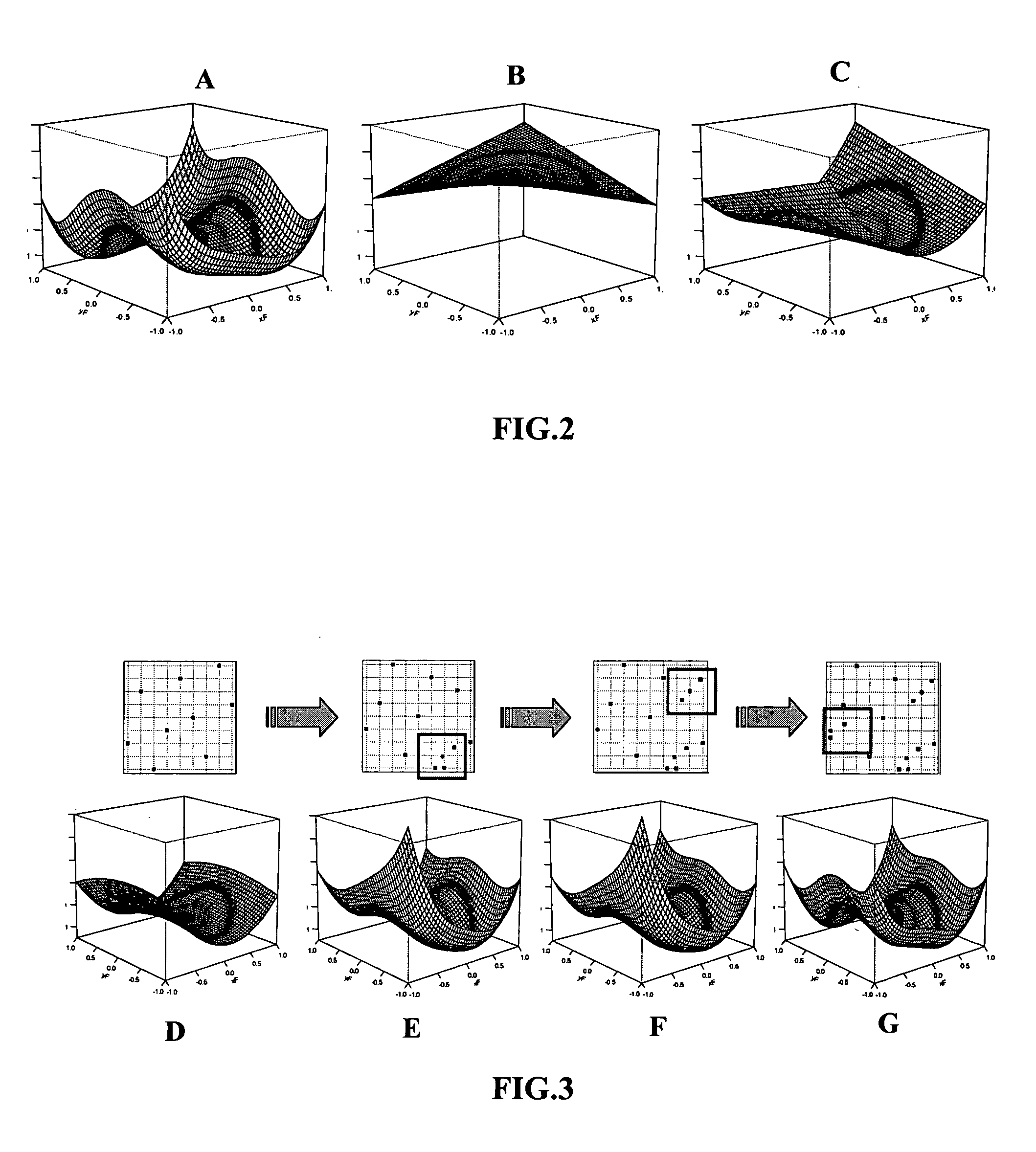

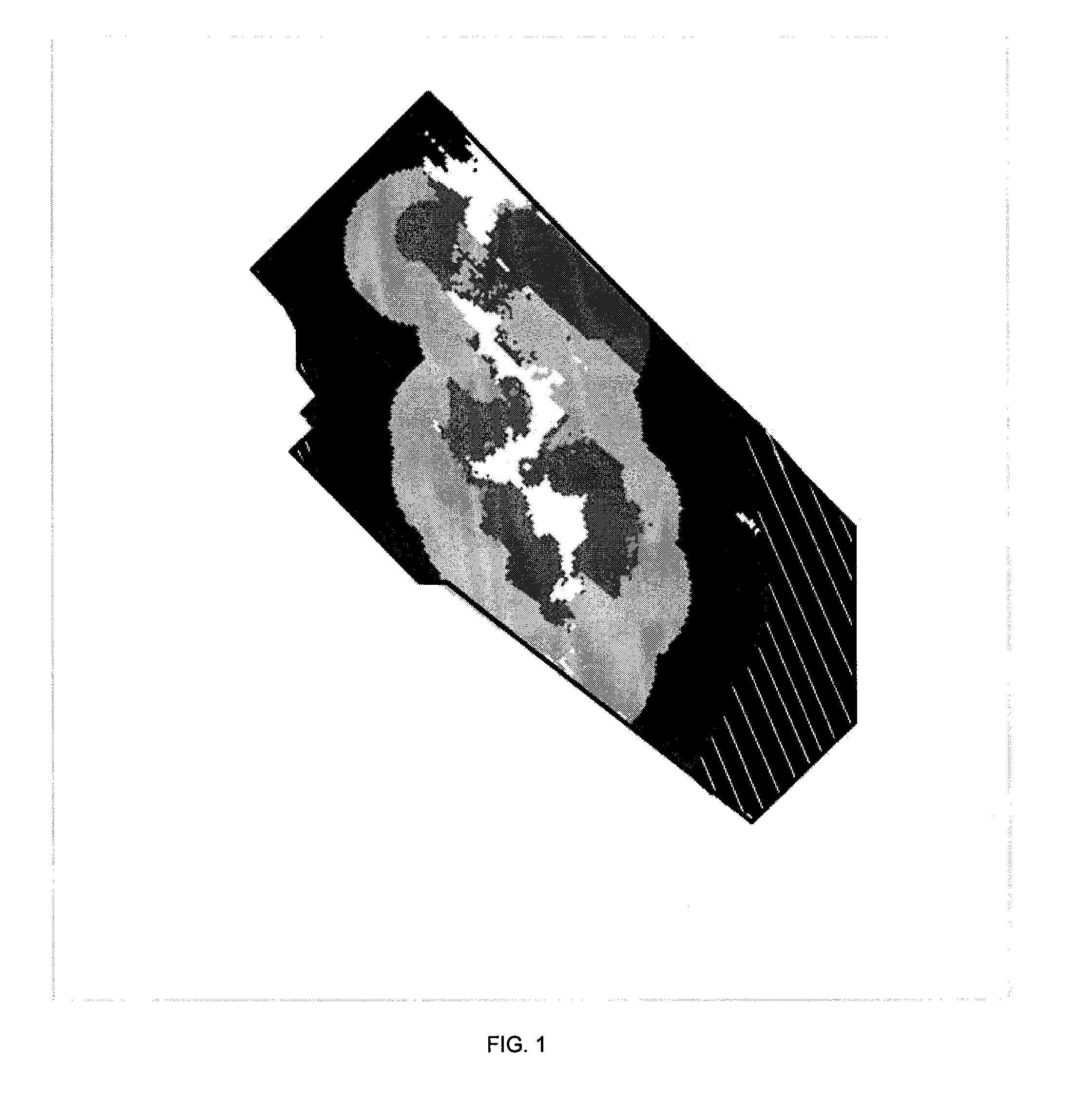

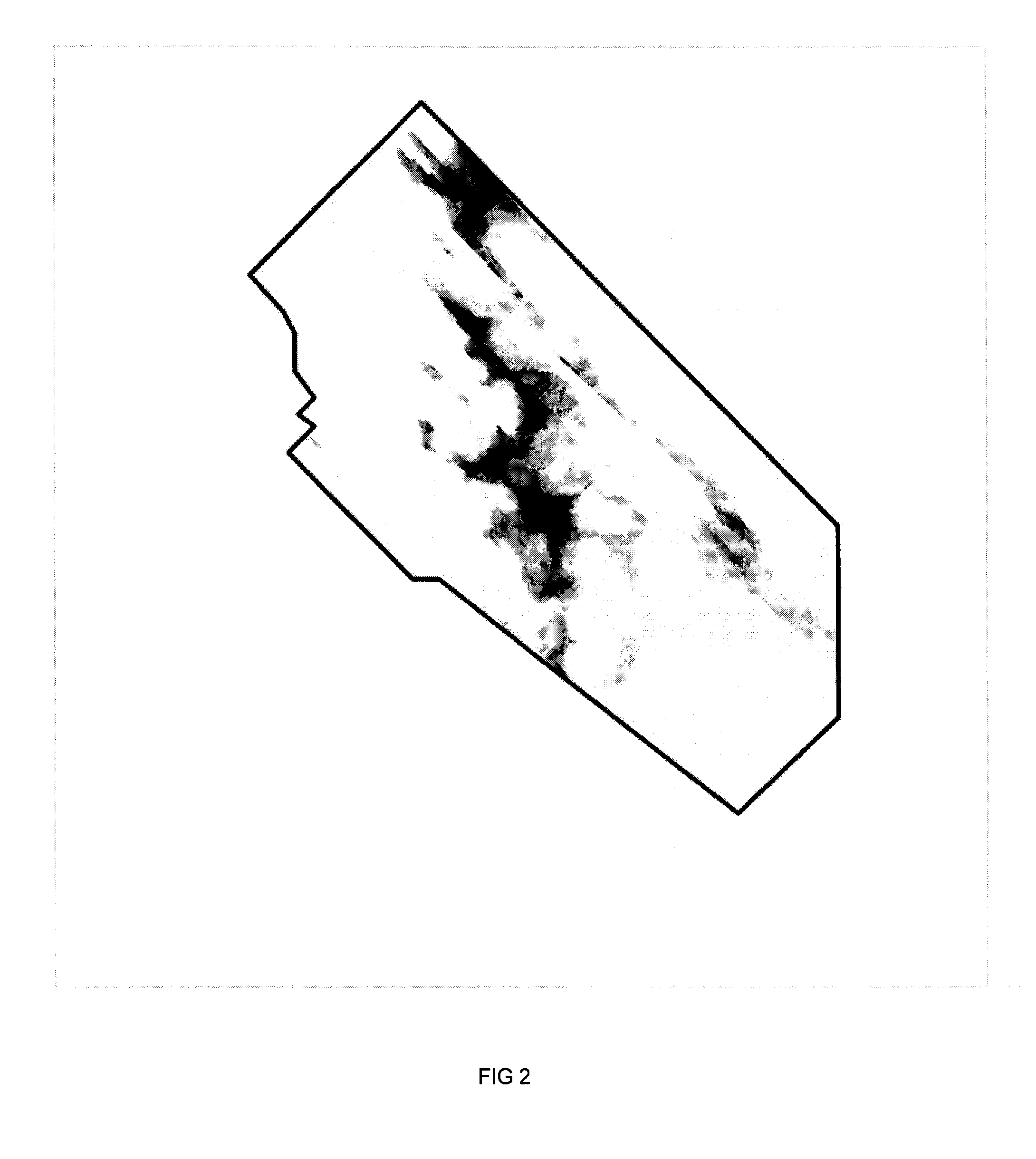

A multiple point simulation technique for generating a model realization of a subterranean formation having different facies is described which uses a non-stationary training image which reflects facies spatial trends across the formation. The realization is formed by sequentially populating each cell; a facies pattern of neighboring cells is identified for each cell in the model grid, and then corresponding facies patterns identified in the training image. The probability of a target cell in the model grid having a given facies is calculated based on the proportion of occurrences of the corresponding facies pattern where the central cell has that facies. The contribution of each corresponding facies pattern occurrence in the training image to this proportion or probability is weighted according to the distance between its central cell and the training image cell corresponding in location to the target cell in the model grid.

Owner:CONOCOPHILLIPS CO

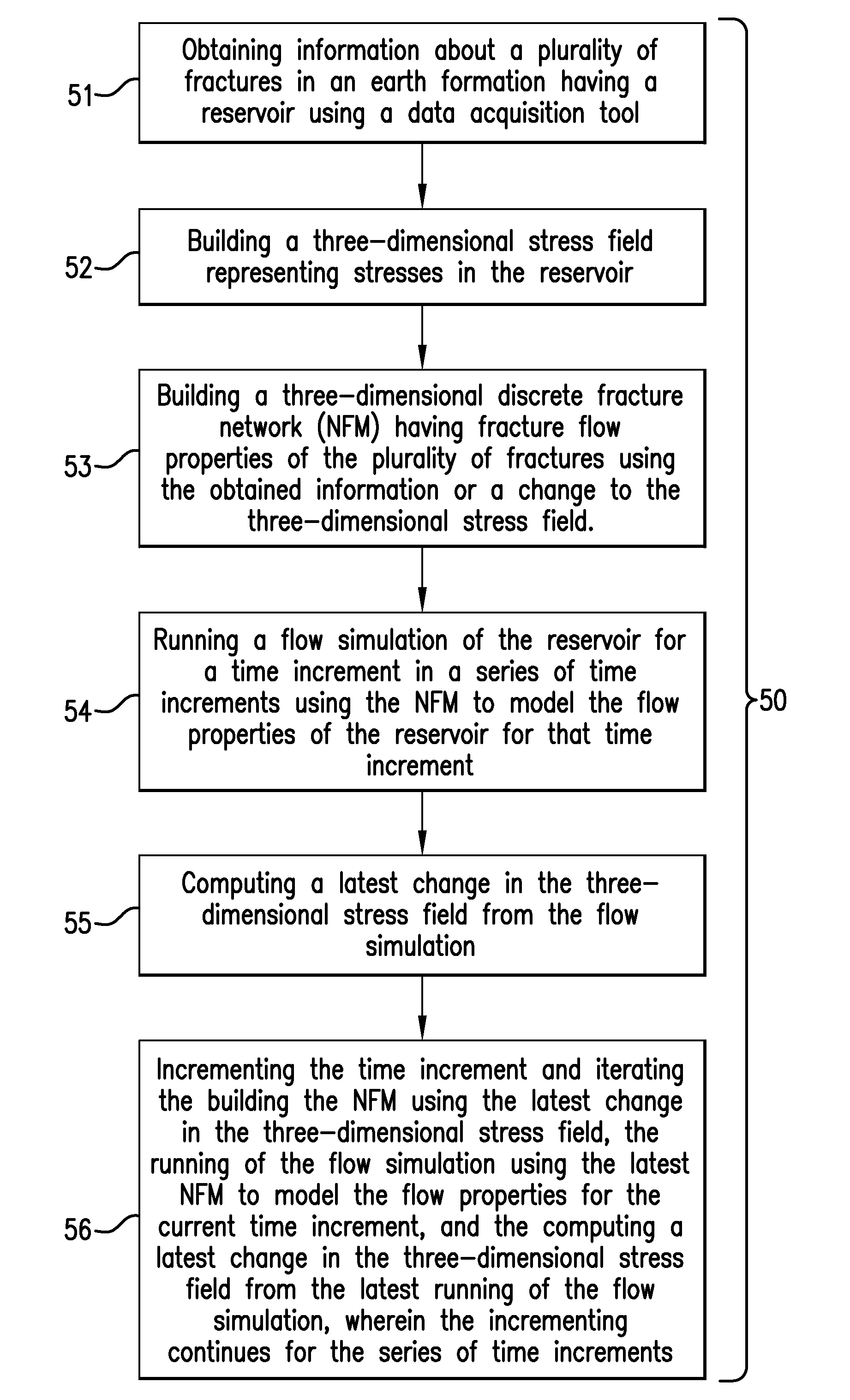

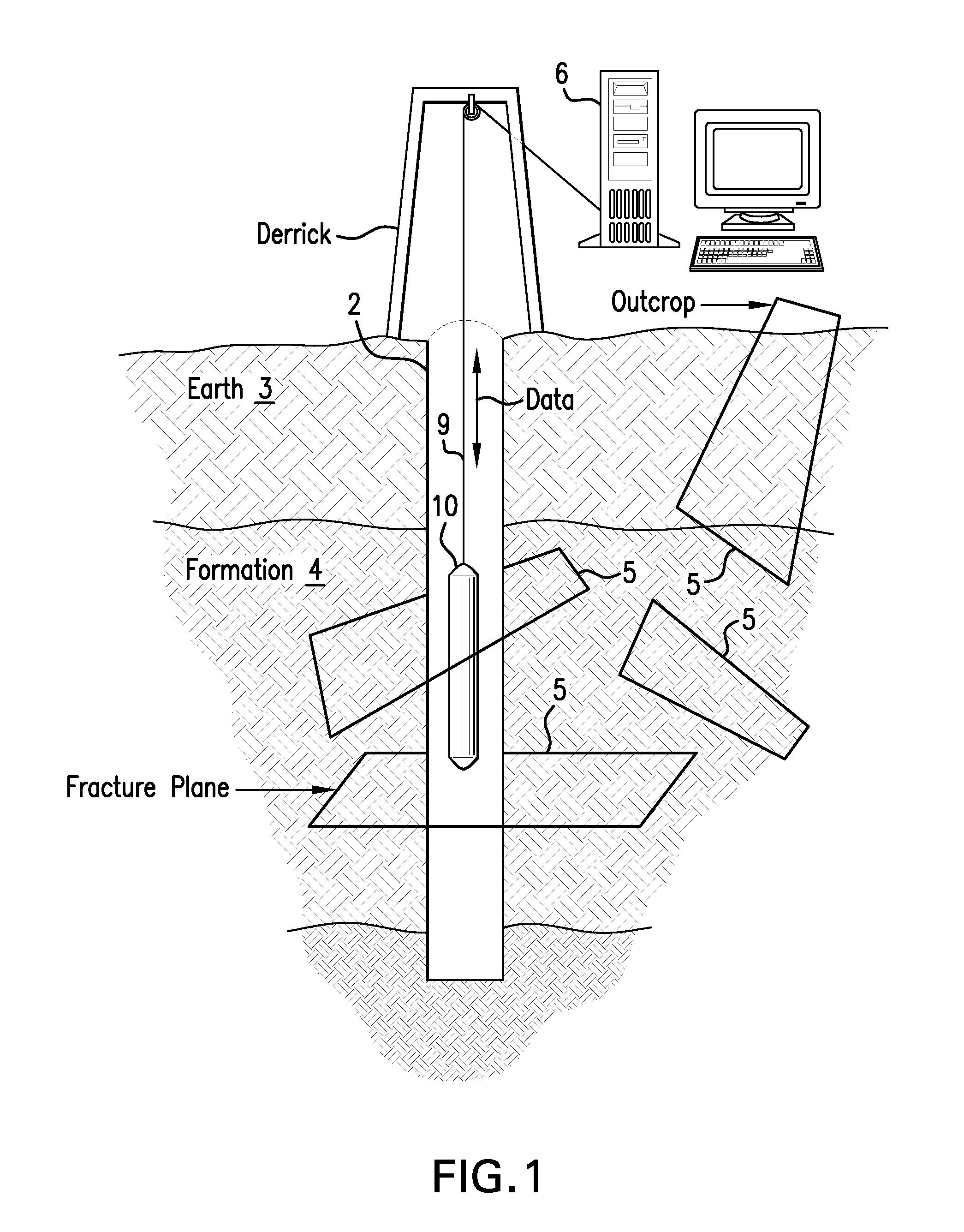

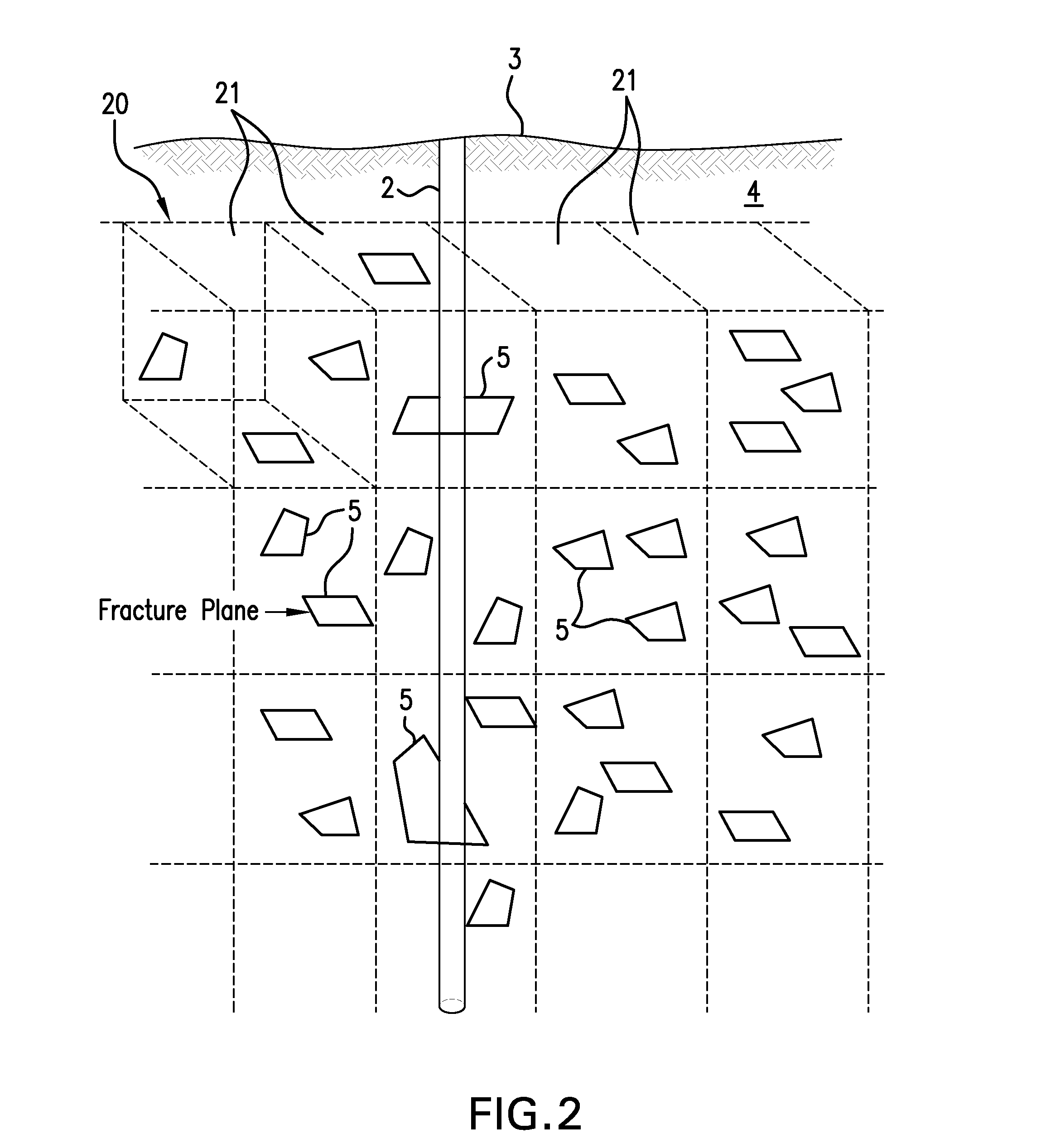

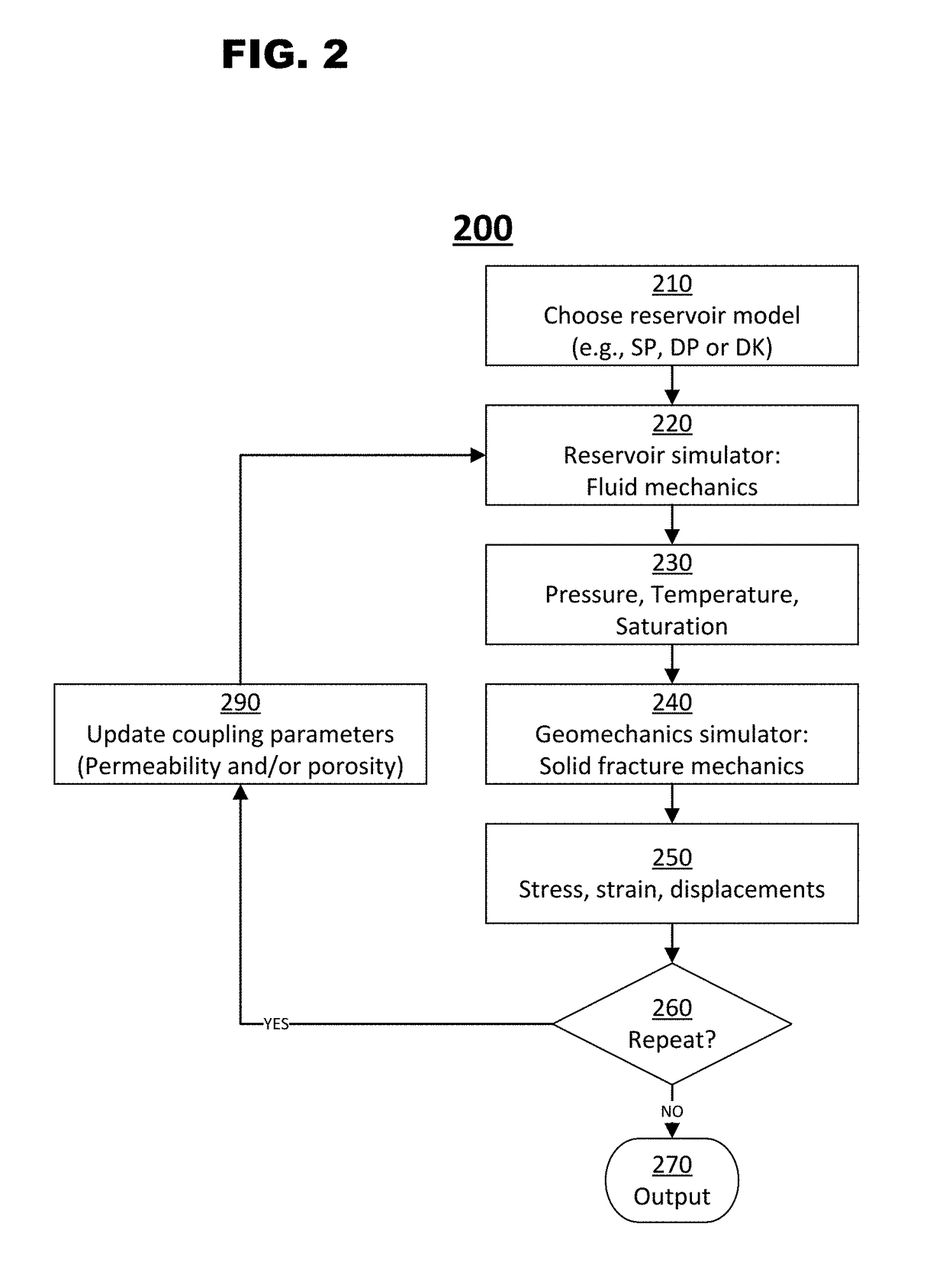

Method to improve reservoir simulation and recovery from fractured reservoirs

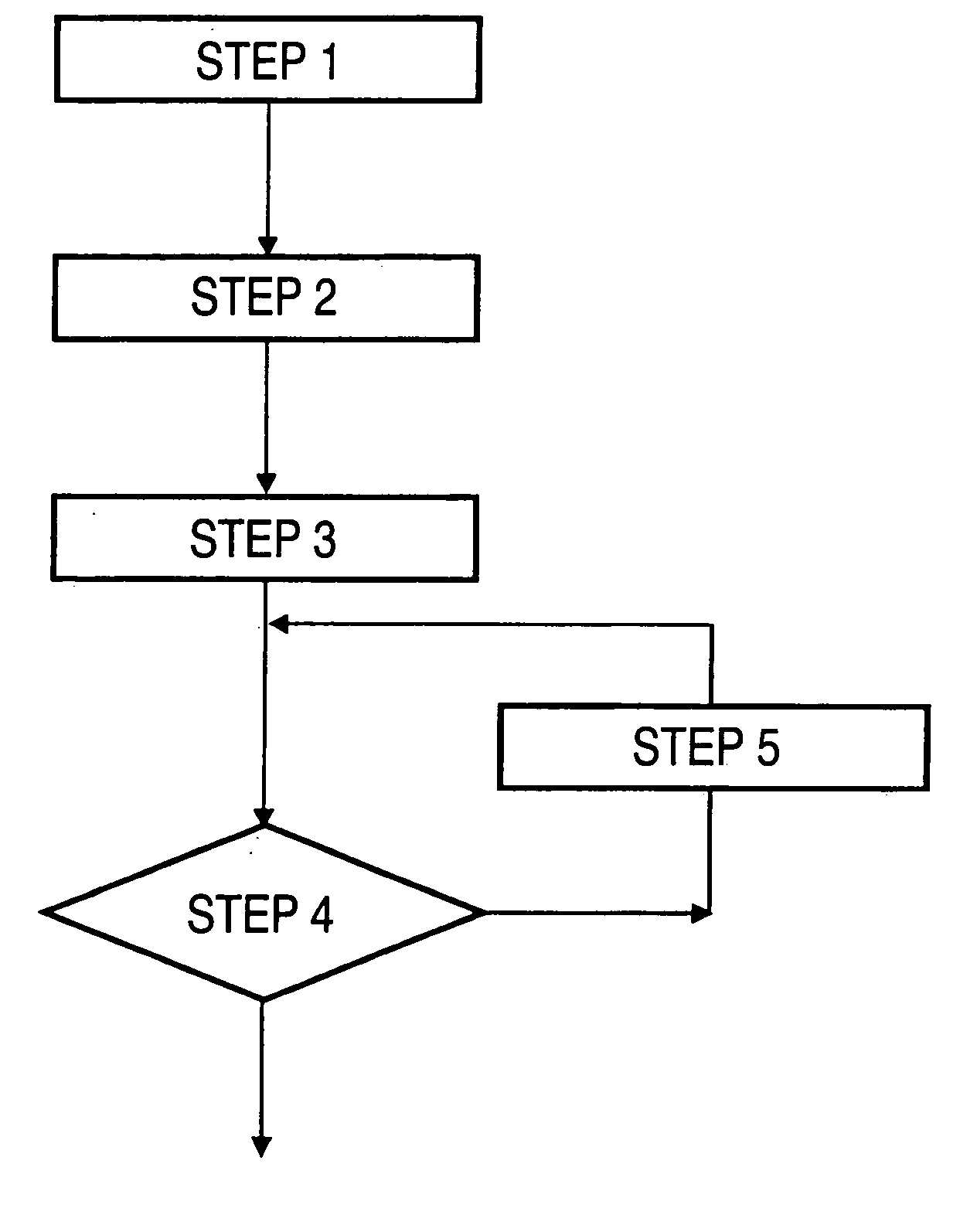

A method for modeling flow properties over a series of time increments of a reservoir in an earth formation having a plurality of fractures is disclosed. The method includes: building a three-dimensional stress field representing stresses in the reservoir; building a three-dimensional discrete fracture network (NFM) having fracture flow properties using information obtained from a tool or changes to the stress field; running a flow simulation of the reservoir for a time increment using the NFM to model the flow properties of the reservoir for that time increment; computing a latest change in the three-dimensional stress field from the flow simulation; and incrementing the time increment and iterating the building the NFM using the latest change in the stress field, the running of the flow simulation using the latest NFM, and the computing a latest change in the stress field from the latest running of the flow simulation.

Owner:BAKER HUGHES INC

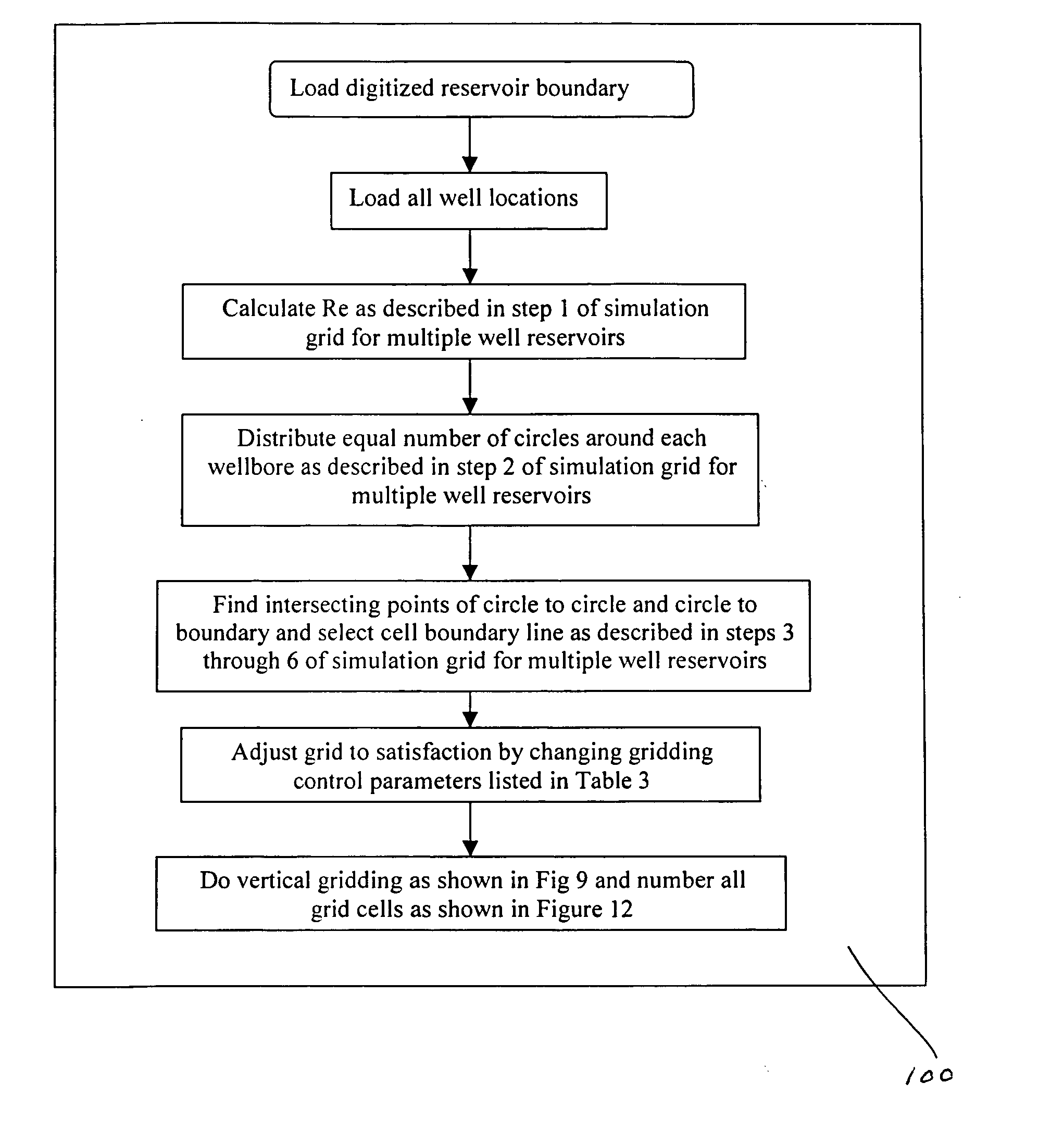

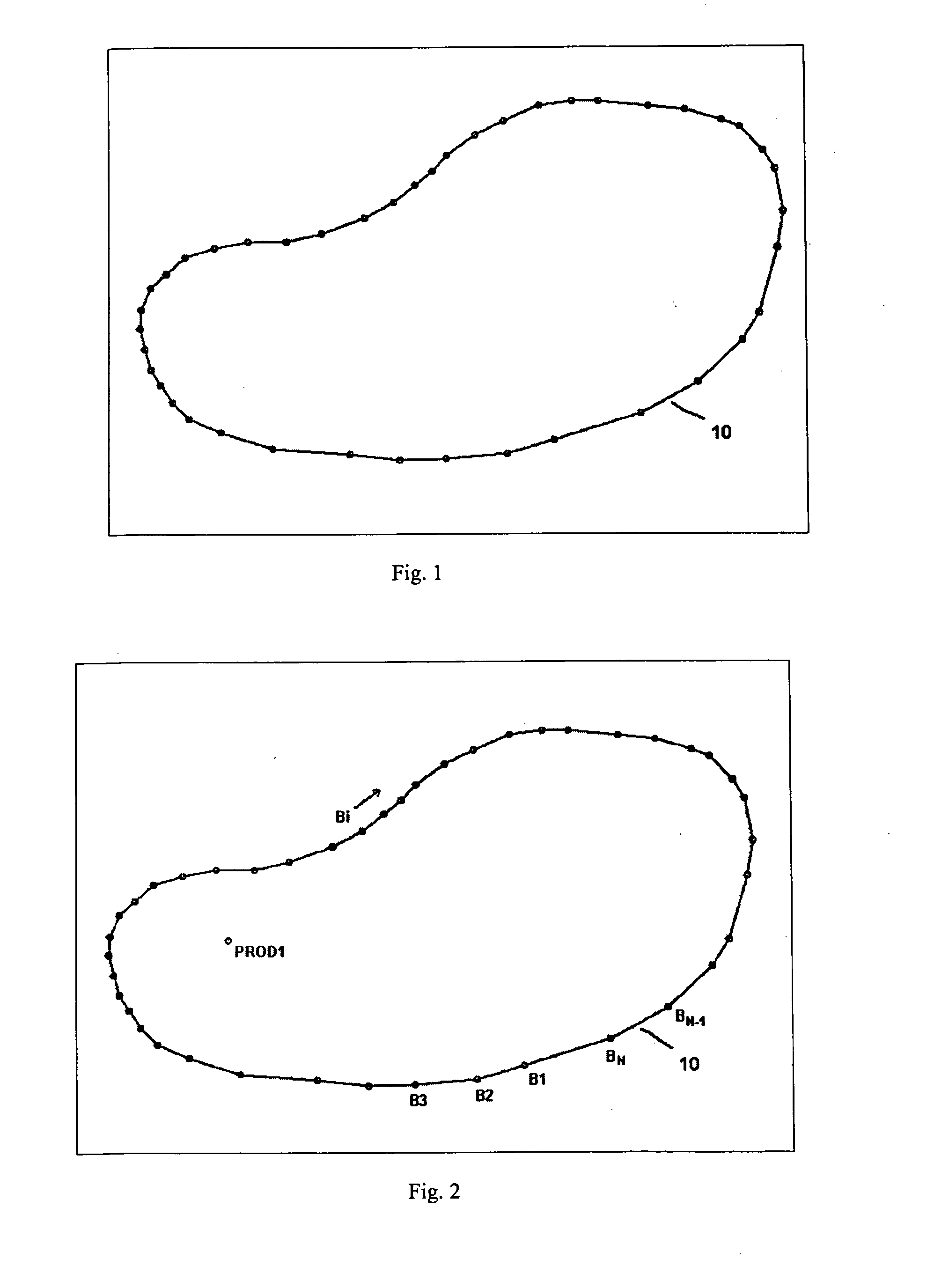

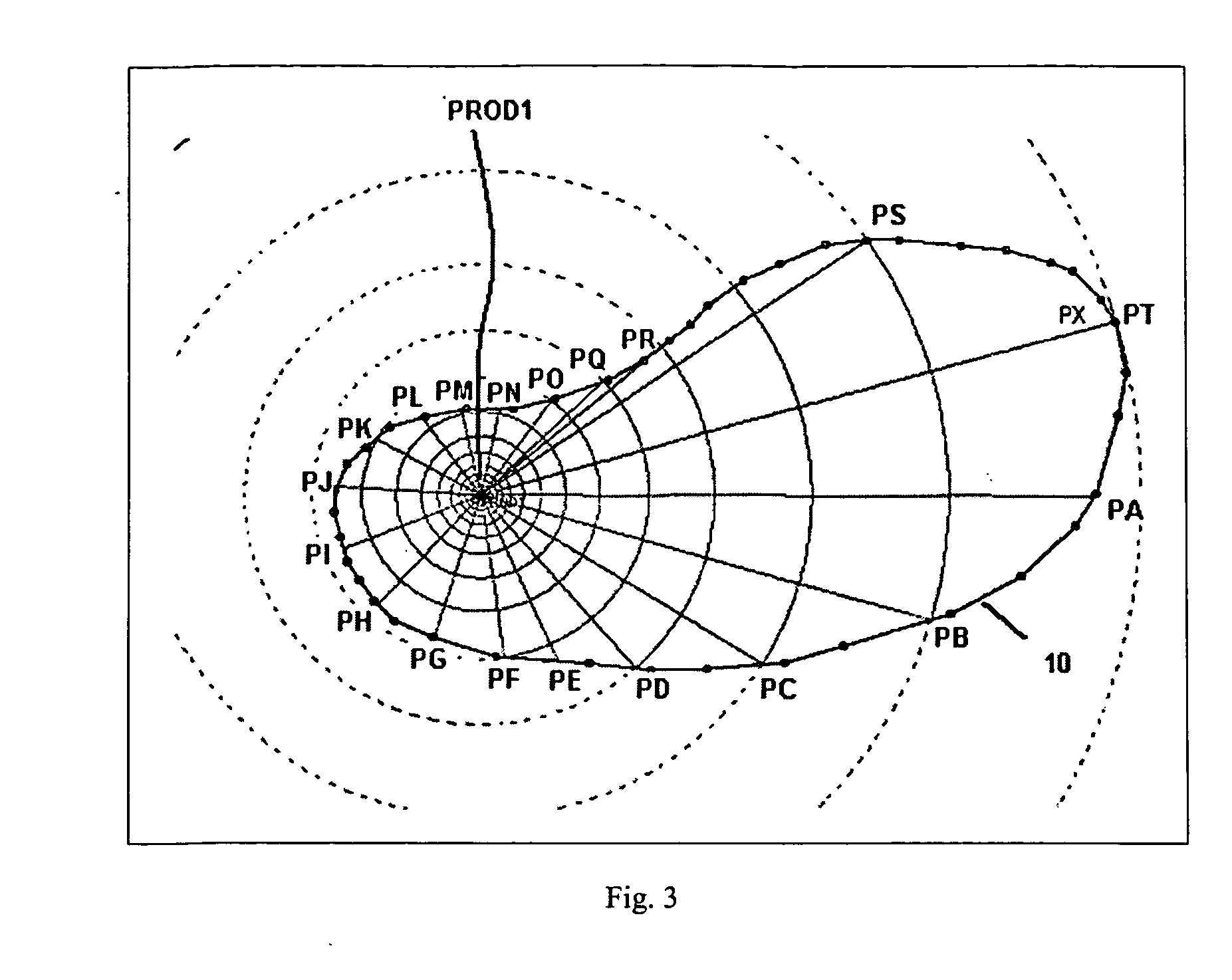

Method for producing full field radial grid for hydrocarbon reservoir simulation

InactiveUS20050021234A1Work flow easyLittle involvementElectric/magnetic detection for well-loggingGeomodellingFull fieldWork flow

A method producing full field radial grid (called here Radial-X Grid) for more accurate and efficient reservoir simulation and improving simulation work flow. The Radial-X Grid method produces both aerial and vertical gridding to divide a reservoir structure into simulation grid cells. The aerial gridding is performed by 1) specifying a reservoir boundary (including faults) and well locations; 2) distributing a set of concentric circles around each well location; 3) determining the circle-circle and circle-boundary intersection locations of these circles; 4) forming the aerial grid by selecting circles, arc segments of intersecting circles and radial lines which connect the ends of these arc segments to the corresponding well center; 5) and forming additional grid lines by selecting the connecting lines of two wells if their circles intersect, adding additional radial lines to certain wells, and connecting end points of certain selected arc segments. Thus, the aerial boundary of each individual grid cell is formed from elements selected from the group of arc segment, well radial line, reservoir boundary, connection line of well to well, arc segment end to arc segment end. The vertical gridding is performed by casting the aerial grid vertically downwardly through all the layers defined in the reservoir structure. The Radial-X Grid method is advantageous for petroleum reservoir simulation applications because it is easy to use, runs fast, produces no grid orientation effect, provides efficient use of grid cells, provides precision modeling and provides better reservoir boundary and fault conformance.

Owner:HAN DIANLI

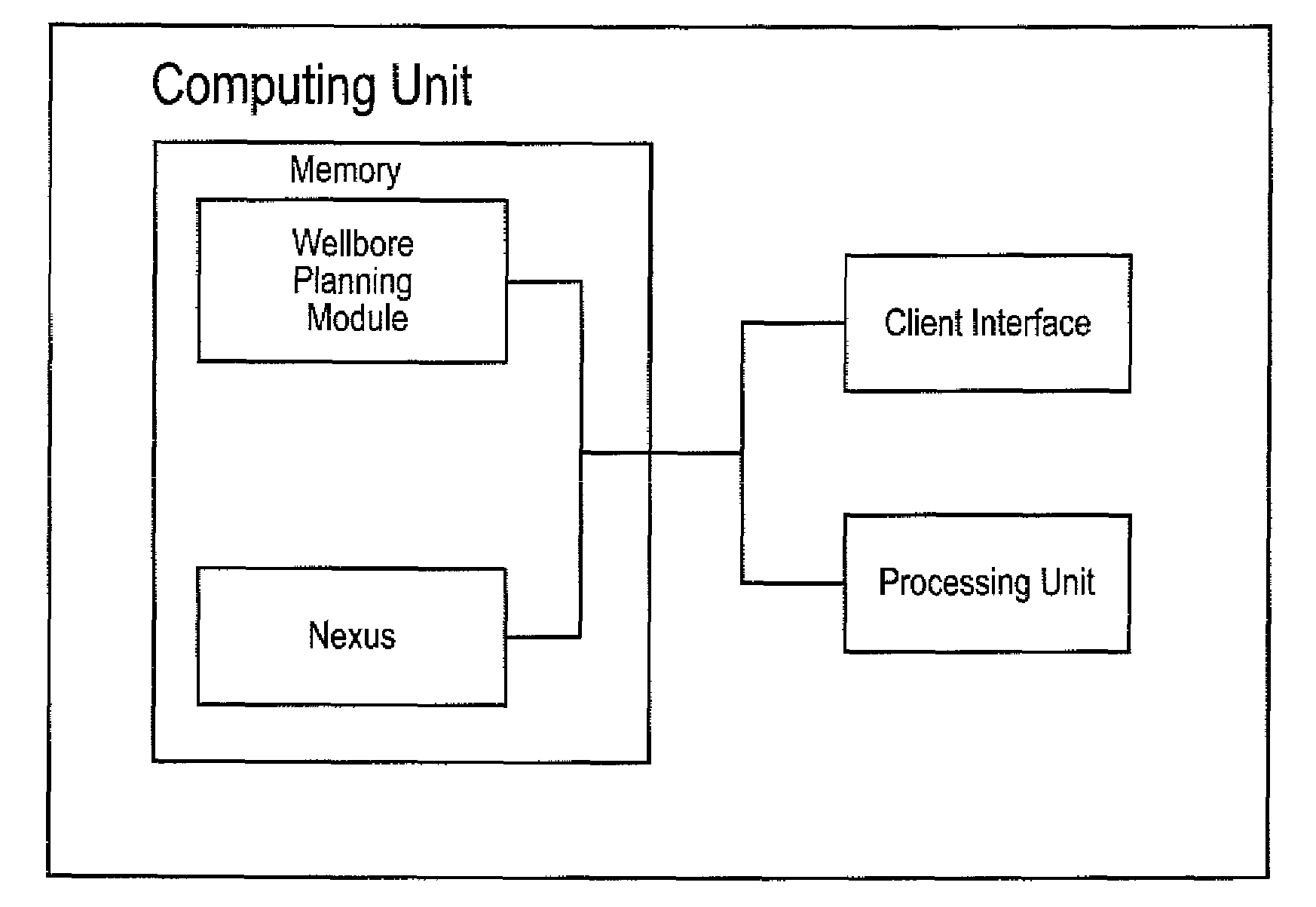

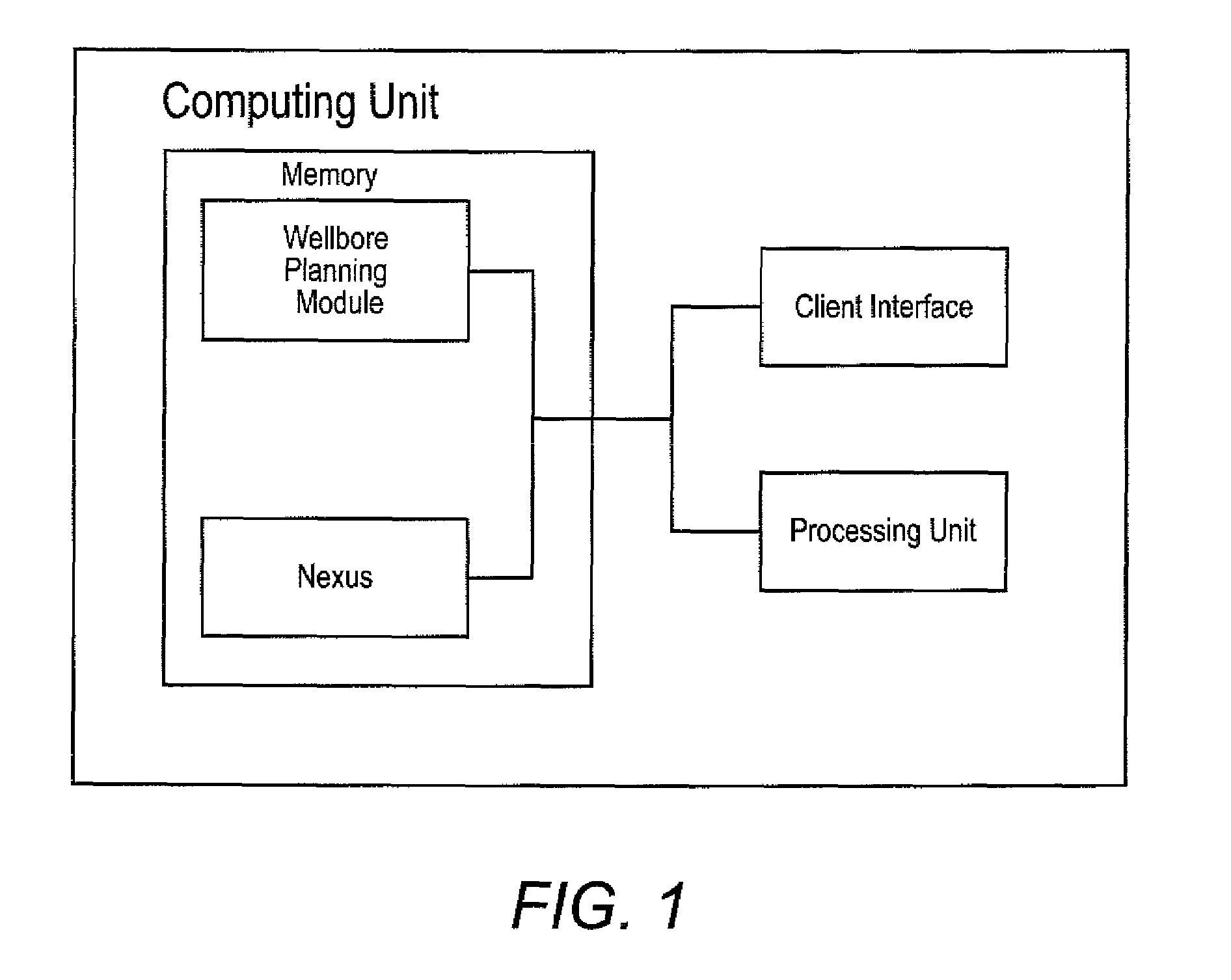

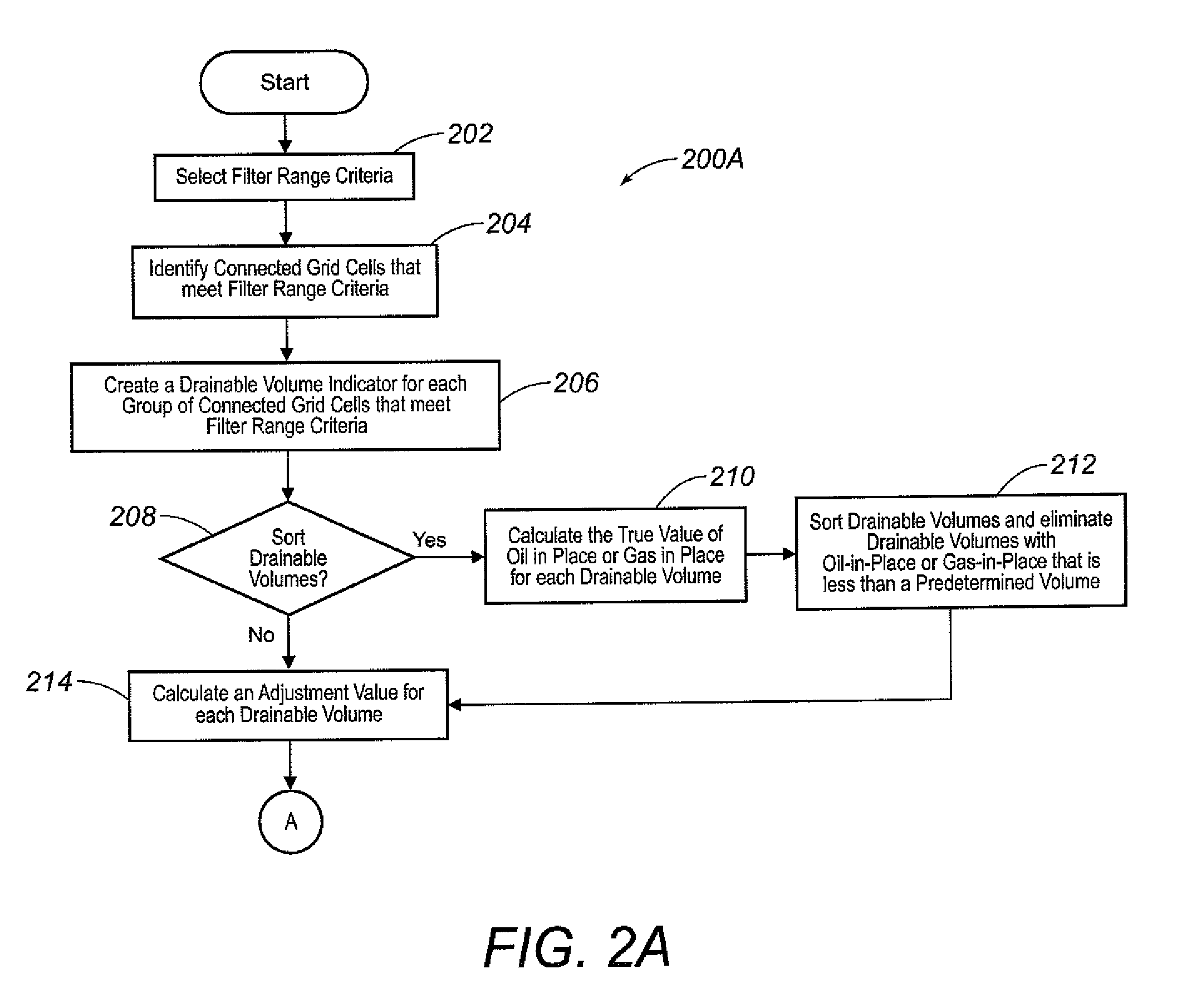

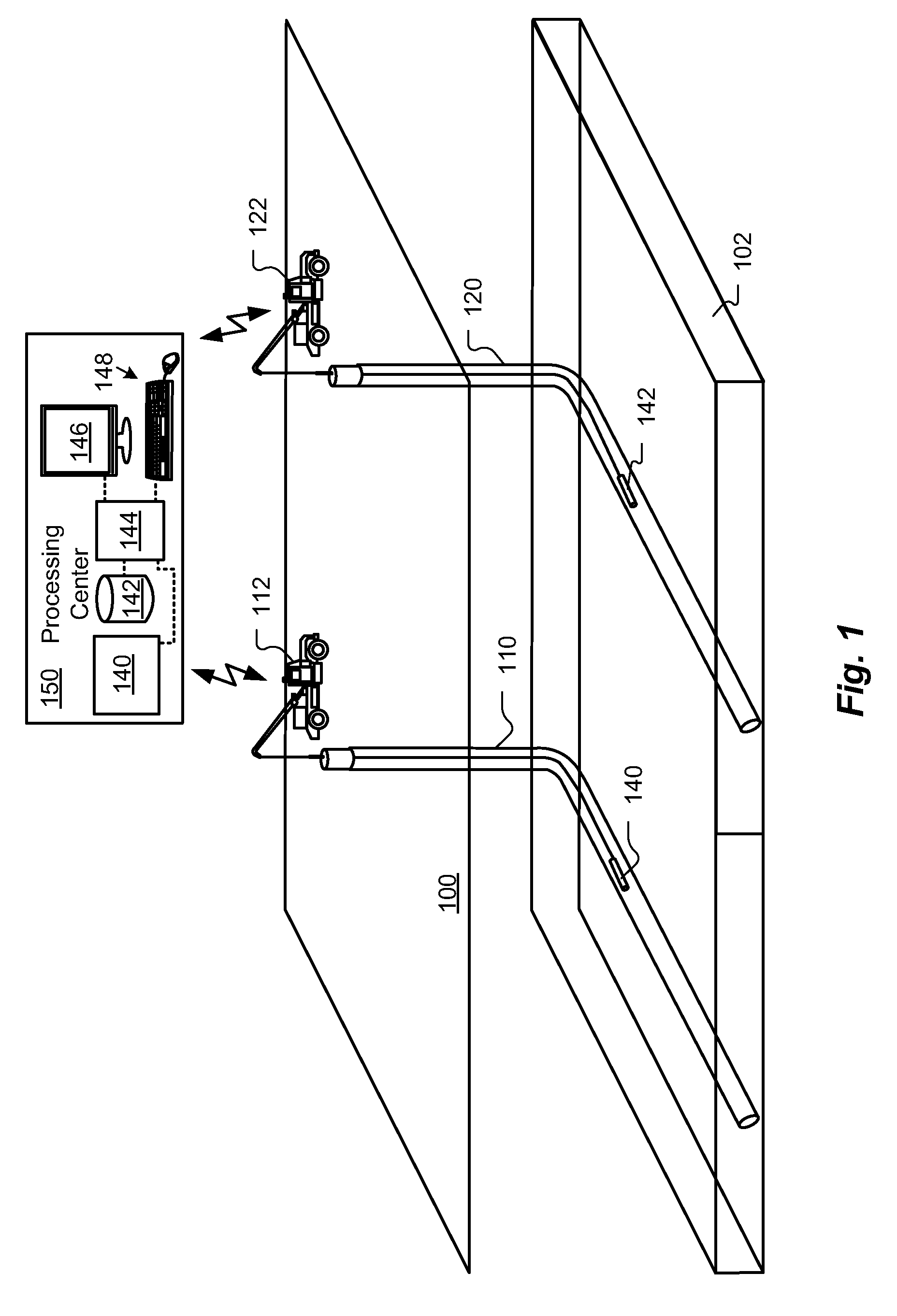

Systems and Methods for Dynamically Developing Wellbore Plans With a Reservoir Simulator

Systems and methods for dynamically developing a wellbore plan with a reservoir simulator. The systems and methods develop a plan for multiple wellbores with a reservoir simulator based on actual and potential reservoir performance.

Owner:LANDMARK GRAPHICS

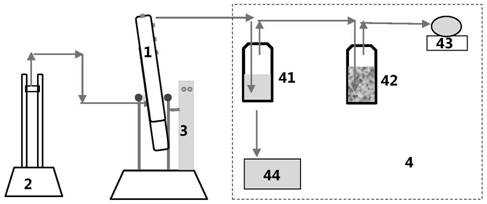

Test simulating device for improving recovery rate of coal bed methane by injecting carbon dioxide

The invention discloses a test simulating device for improving a recovery rate of coal bed methane by injecting carbon dioxide. The test simulating device for improving the recovery rate of the coal bed methane by injecting the carbon dioxide comprises a coal reservoir simulating system, a gas injecting system, a fracture simulating carbon dioxide injecting system, a carbon dioxide absorbing device and a data collection and control system, wherein the coal reservoir simulating system is used for simulating the conditions of pressure and temperature of a coal reservoir, the gas injecting system is used for injecting methane gas or helium gas into the coal reservoir simulating system, the fracture simulating carbon dioxide injecting system is used for injecting high-pressure liquid into the coal reservoir simulating system, enabling the coal reservoir simulating system to simulate the degree of development of fractures, and injecting the carbon dioxide into the coal reservoir simulating system, the carbon dioxide absorbing device is used for absorbing the carbon dioxide exhausted by the coal reservoir simulating system, and the data collection and control system is used for collecting data and carrying out process control. The test simulating device for improving the recovery rate of the coal bed methane by injecting the carbon dioxide is capable of simulating the real conditions of the coal reservoir, simulating on-spot fracturing and the process of pump injection of the carbon dioxide, simulating effects of improvement of the recovery rate of the coal bed methane by injecting different volumes of the carbon dioxide according to different degrees of the development of the fractures and different conditions of the coal reservoir, and achieving an optimal carbon dioxide injection volume aiming at a specific coal reservoir.

Owner:HENAN POLYTECHNIC UNIV

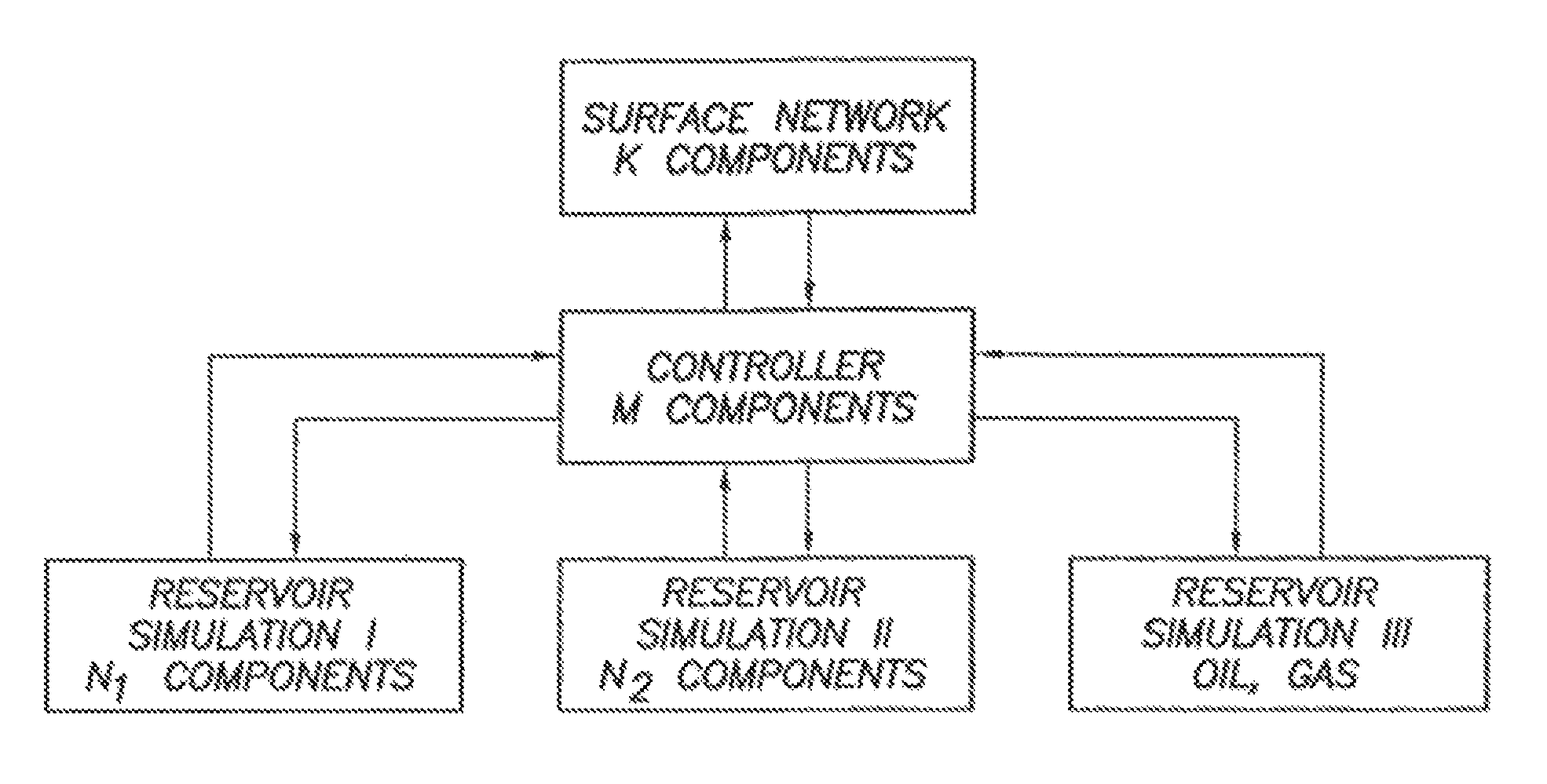

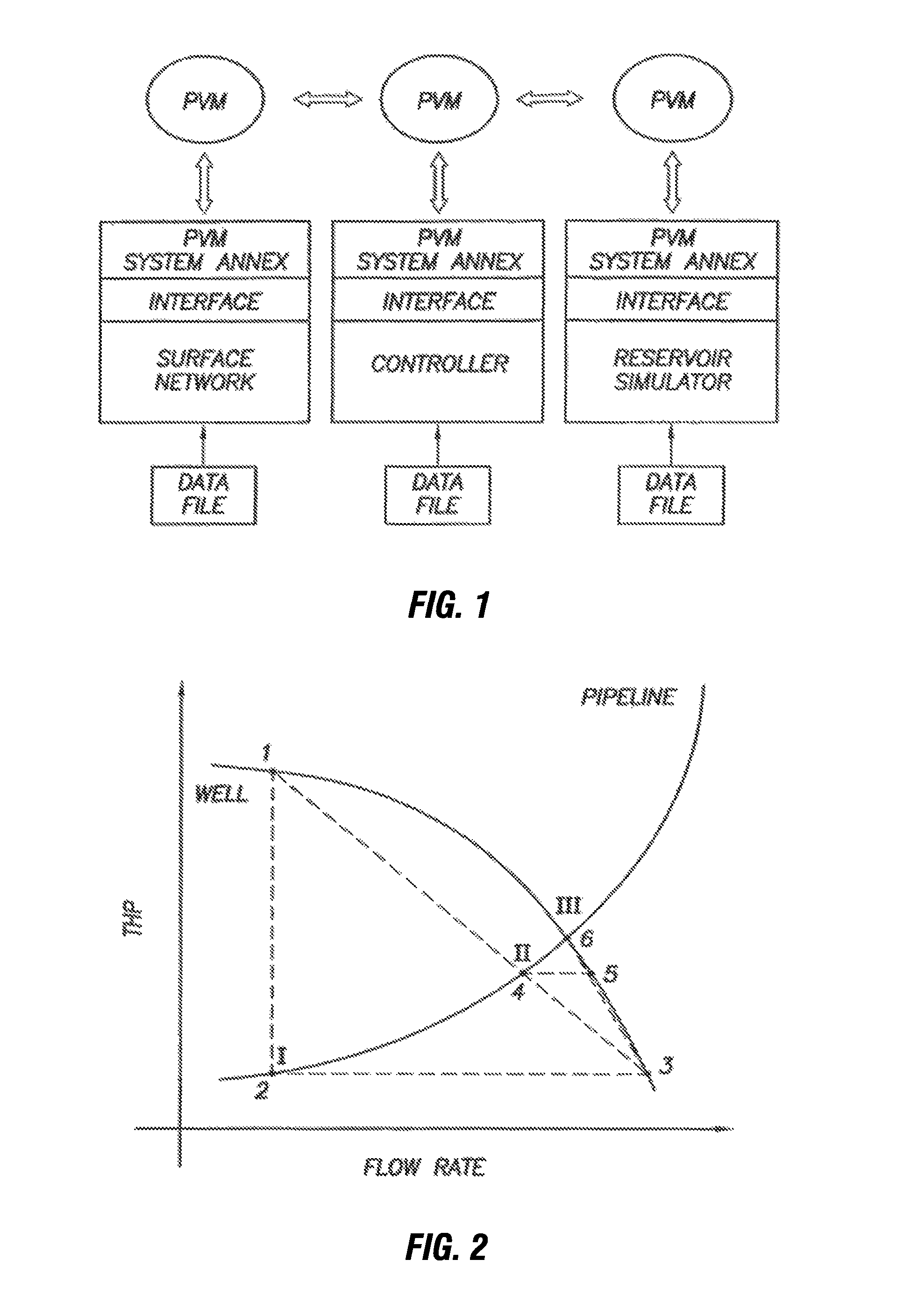

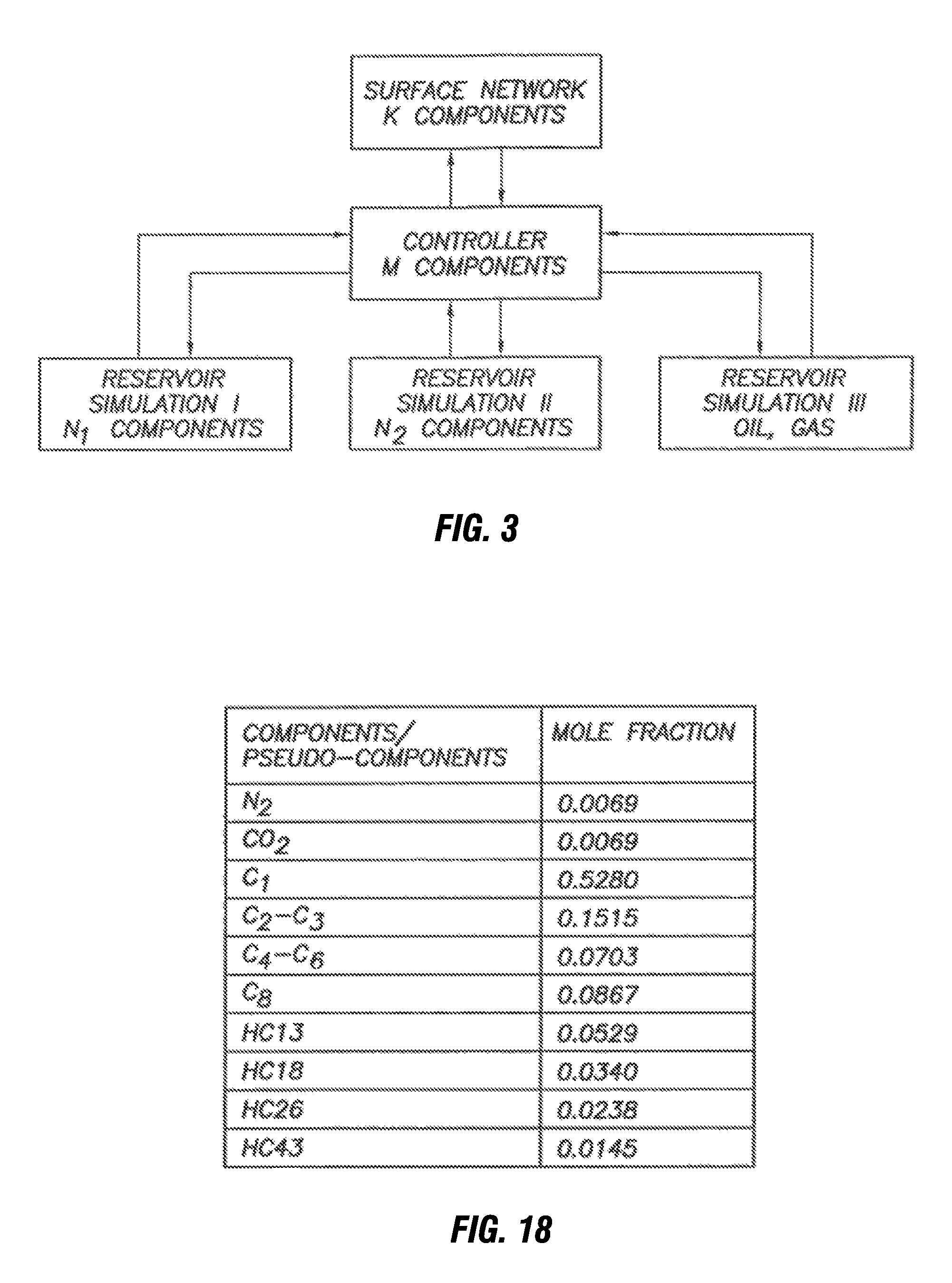

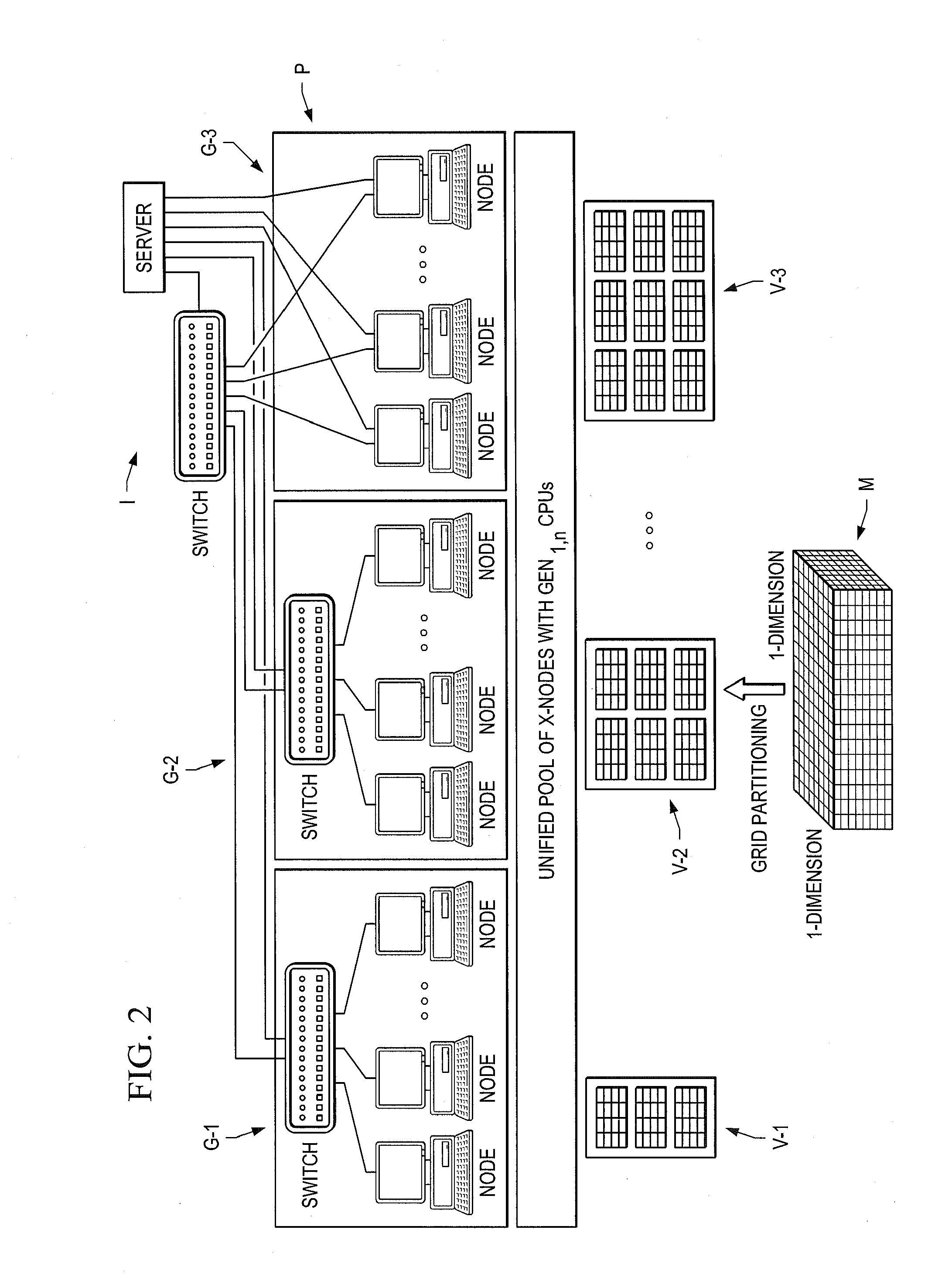

Method and system for integrated reservoir and surface facility networks simulations

InactiveUS8401832B2Design optimisation/simulationConstraint-based CADReservoir modellingParallel computing

A method includes initiating a first reservoir simulation on a first simulator for a first set of physical parameters of a first reservoir. The first reservoir simulator uses a first set of components for a compositional reservoir model. A second reservoir simulation is initiated on a second simulator. A network simulation is initiated on a network simulator to model a network for coupling the first reservoir and the second reservoir to a surface facility. The network simulator uses a second set of components for a compositional network model. The method further includes translating each of a first hydrocarbon fluid stream of the first reservoir simulator and a second hydrocarbon fluid stream of the second reservoir simulator to a common fluid model. Further, network balancing is initiated among the simulators at a corresponding point in each controller time step.

Owner:SCHLUMBERGER TECH CORP

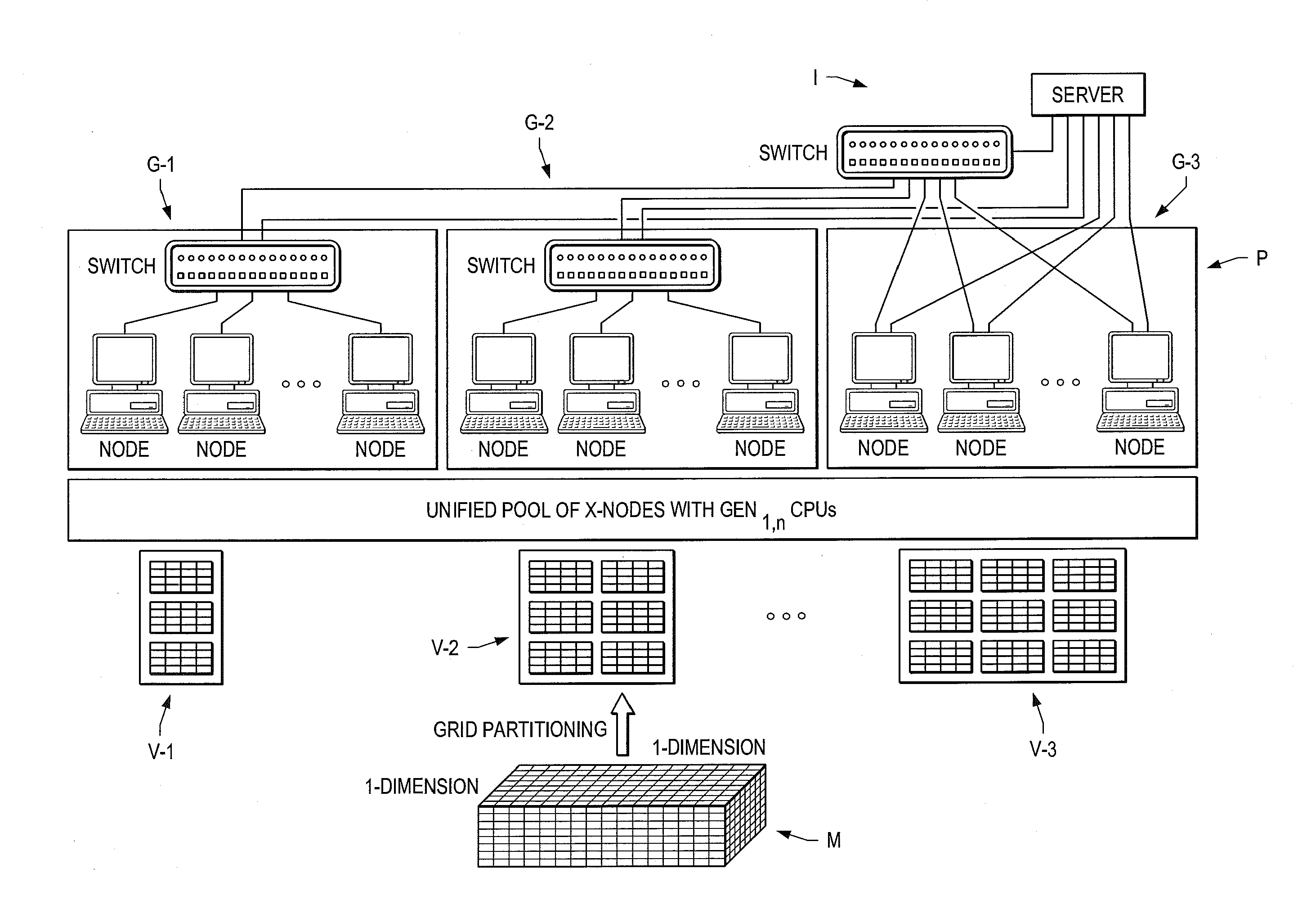

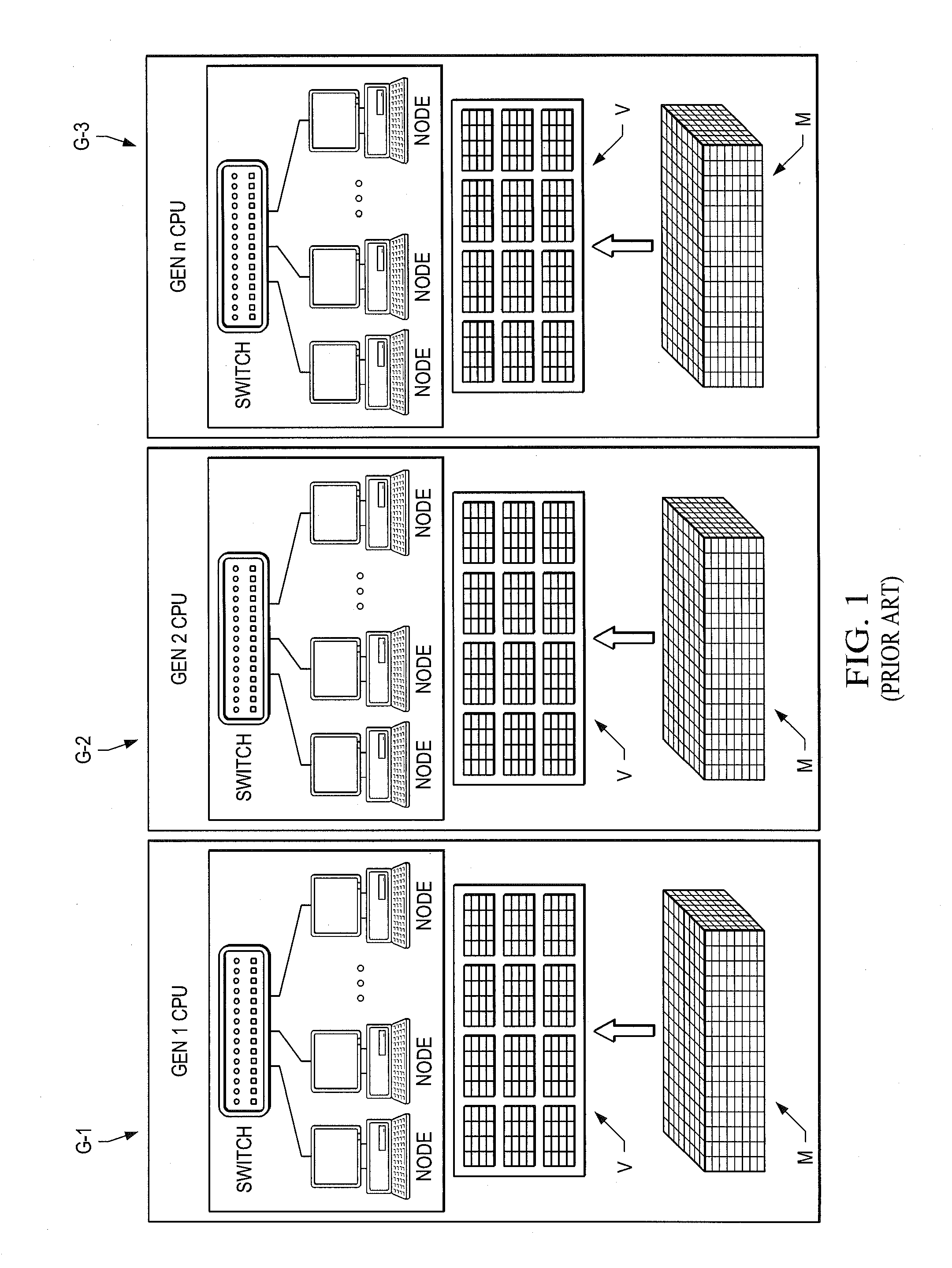

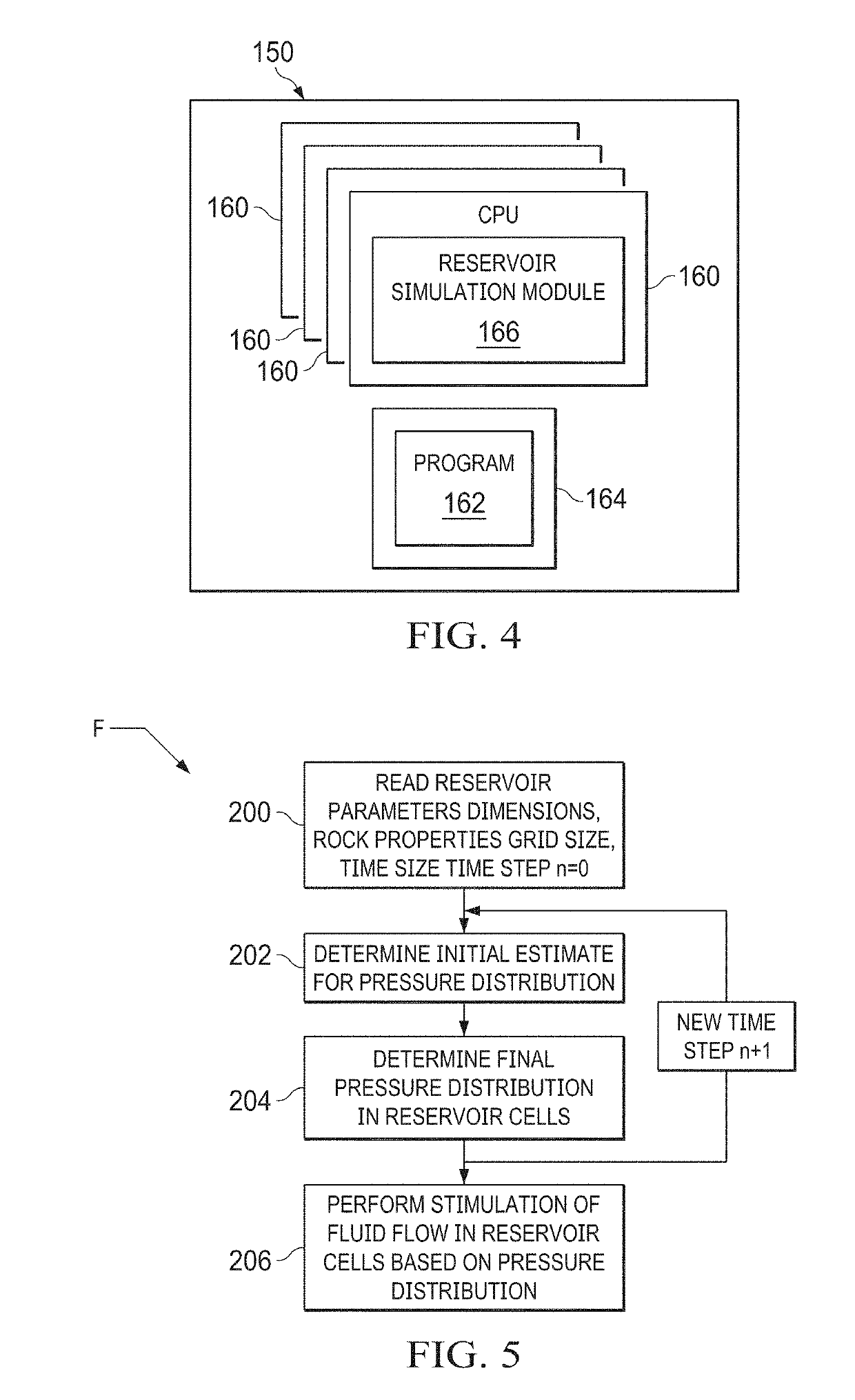

Reservoir simulation with scalable grid computing

ActiveUS20130325419A1SeismologyComputation using non-denominational number representationComputational sciencePerformance computing

Larger, expandable high performance computing (HPC) clusters which are of different generations and performance speeds are provided for reservoir simulation. This provides scalability and flexibility for running computation-intensive reservoir simulation jobs on HPC machines. Availability of larger numbers of processors in a processor pool makes simulation of giant models possible and also reduces fragmentation when multiple jobs are run. A hardware performance based domain decomposition is performed which results in computation load balancing. The reservoir domain is decomposed efficiently to reduce communication overhead. Adaptive detection of the available mix of computation resources is performed, and reservoir simulation decomposition methodology adjusts the distribution of load based on the available hardware and different processor generation resources to minimize the reservoir simulation runtime.

Owner:SAUDI ARABIAN OIL CO

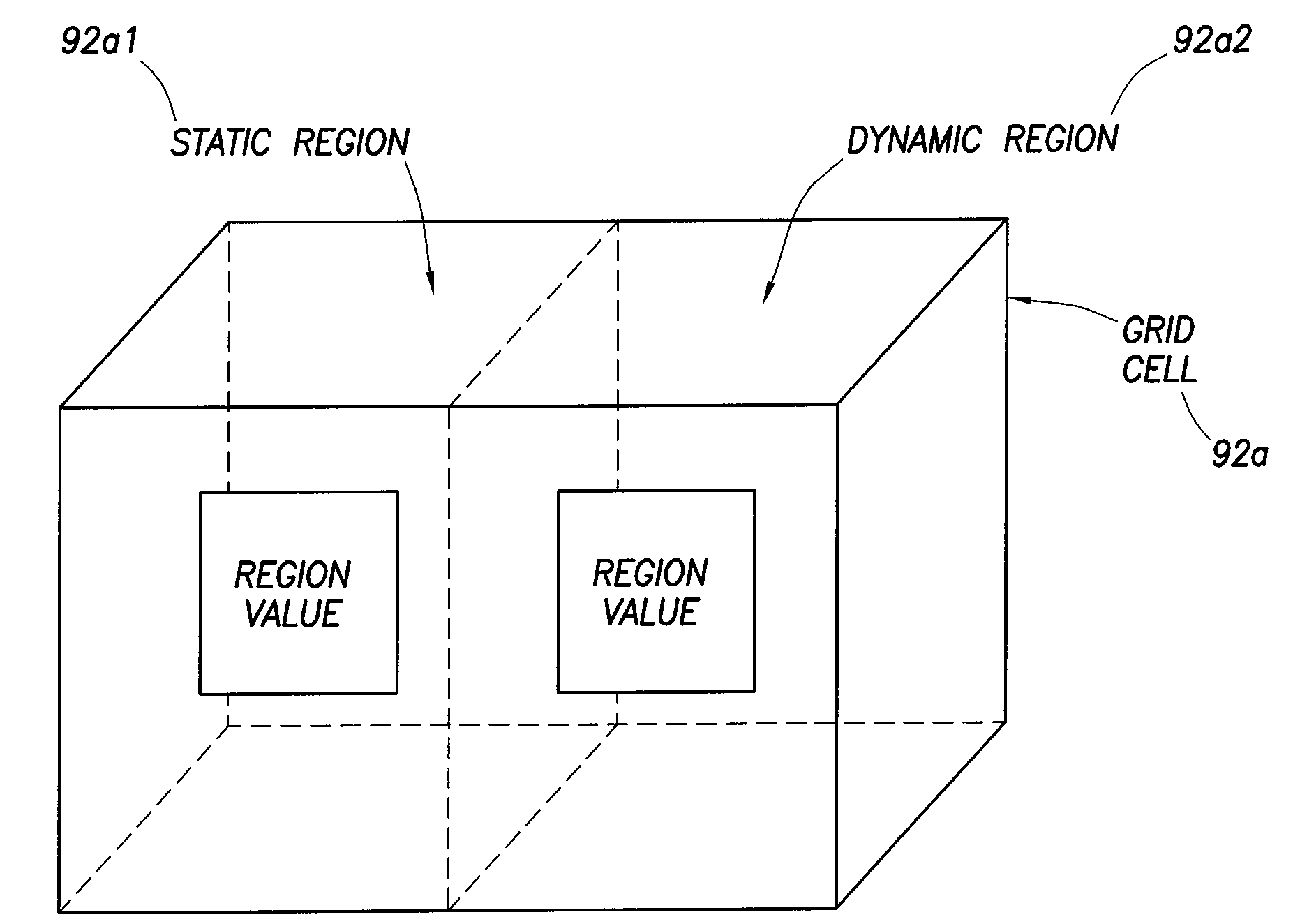

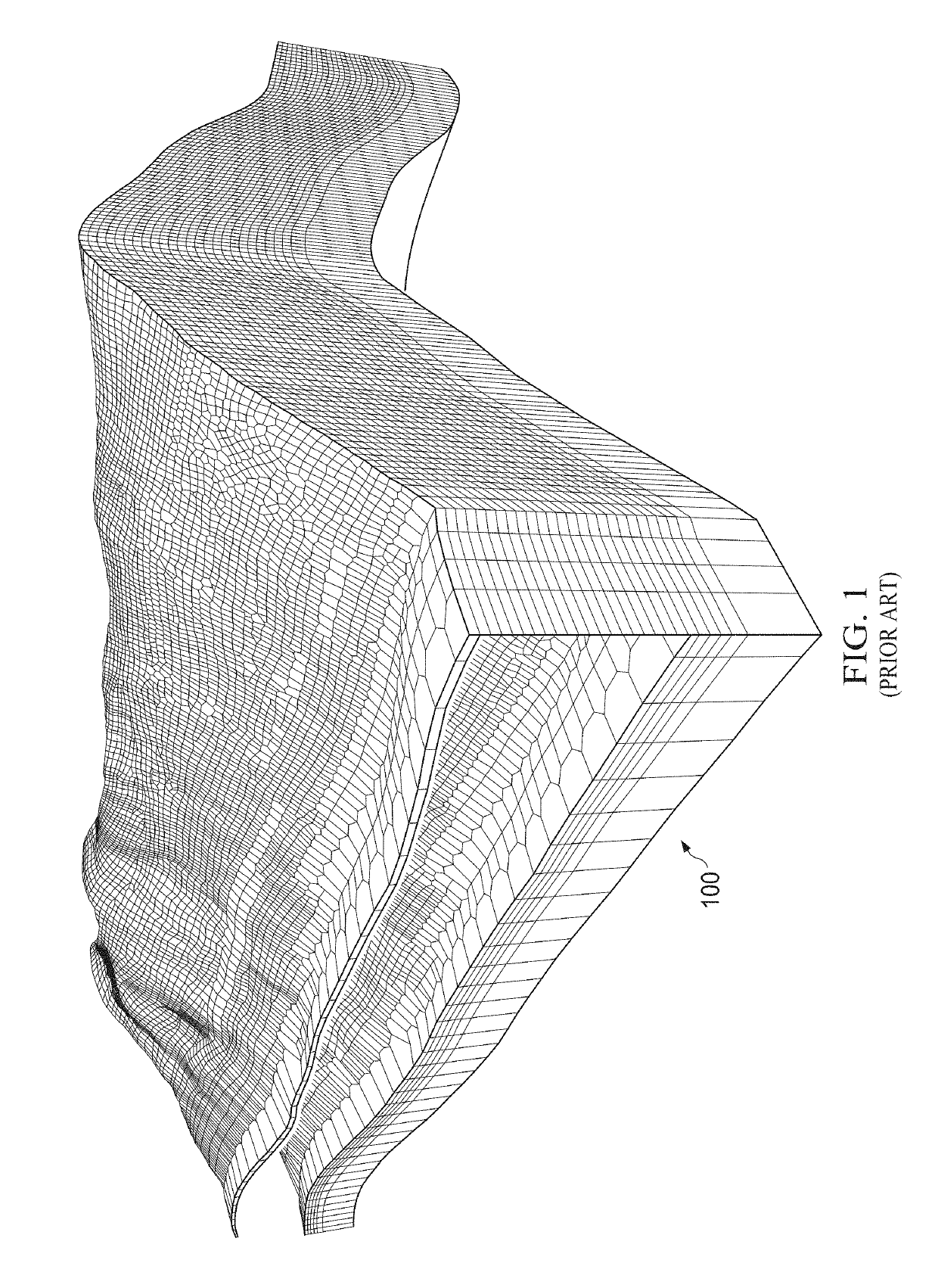

Method for defining regions in reservoir simulation

ActiveUS20090254324A1Electric/magnetic detection for well-loggingComputation using non-denominational number representationReservoir modellingGrid cell

A method is disclosed, which is practiced by a reservoir simulator, for simulating a reservoir and generating a set of simulation results, the simulation results including a framework, the framework further including a plurality of grid cells, comprising: generating one or more static and dynamic regions within the grid cells of the framework of the simulation results, the static and dynamic regions each having region values, wherein the region values of the static regions cannot be allowed to change dynamically, and wherein the region values of the dynamic regions can be allowed to change dynamically.

Owner:SCHLUMBERGER TECH CORP

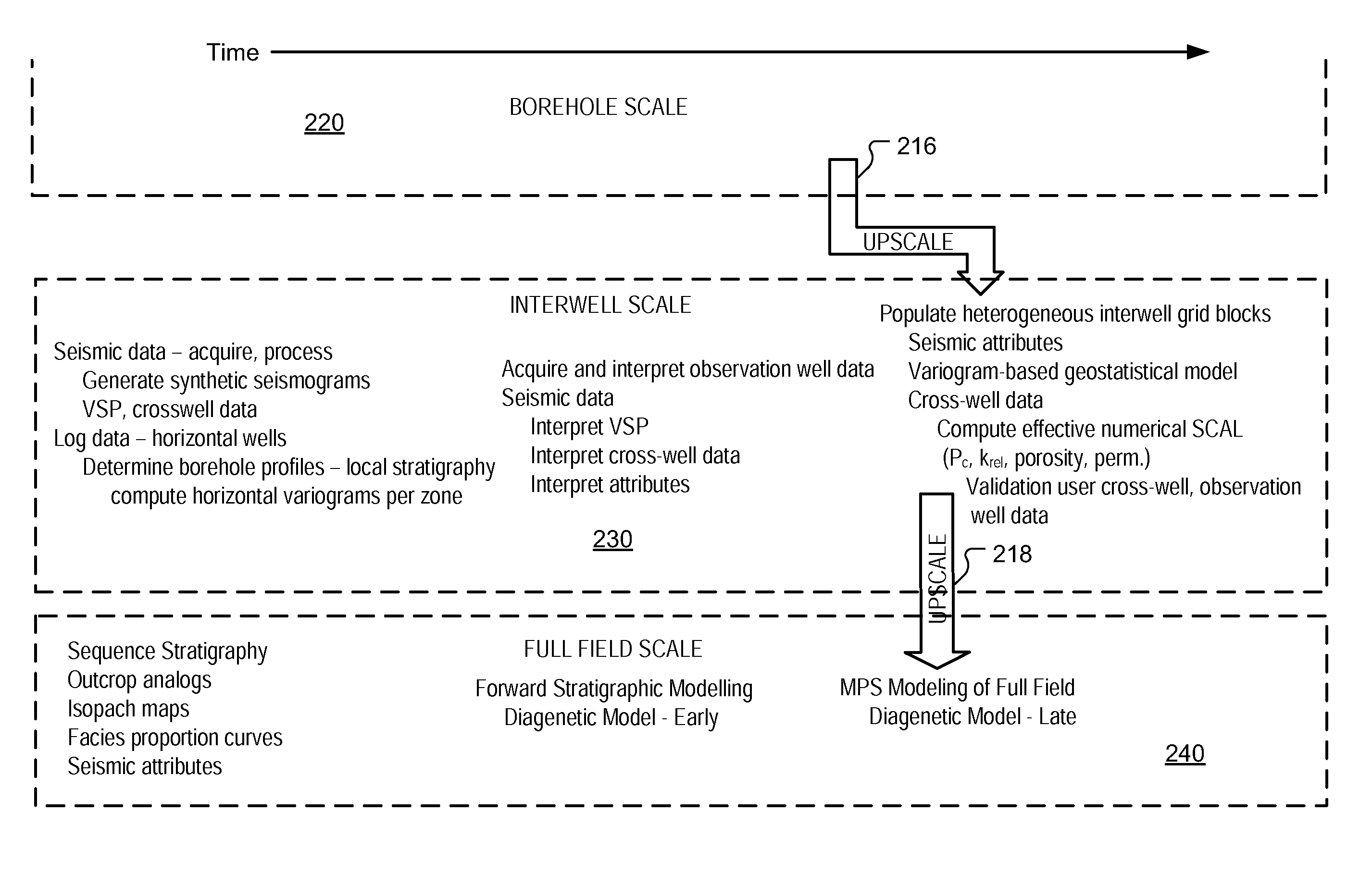

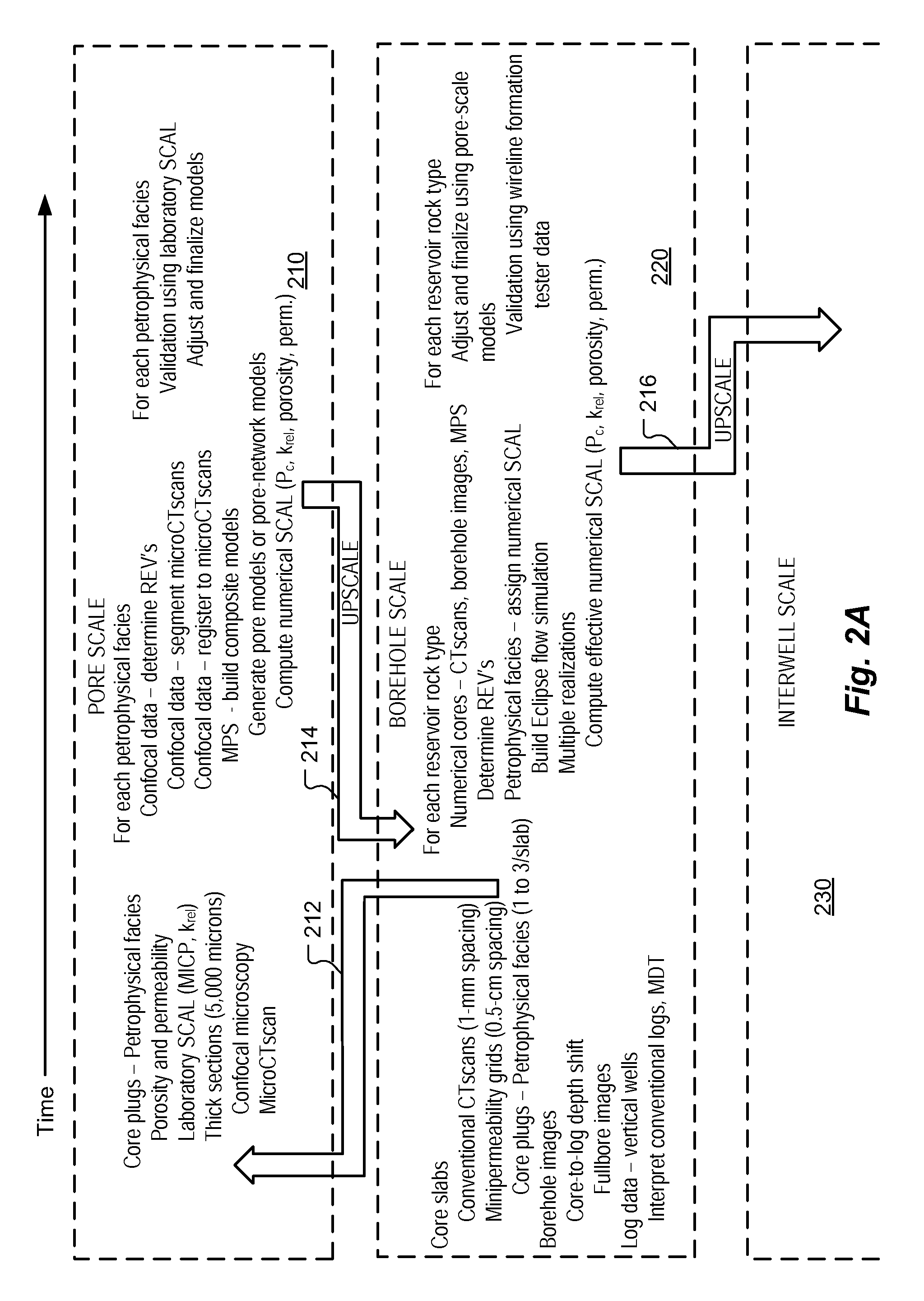

Multiscale digital rock modeling for reservoir simulation

Methods for upscaling digital rock modeling data are described. Core-plug samples for pore-scale modeling are chosen using whole-core mini-permeability grids and conventional CT scans. Pore models or pore-network models are used for flow modeling. Borehole-scale models use MPS (Multi-Point Statistics) to combine mini-permeability grids and conventional CTscans of whole core with electrical borehole images to create 3D numerical pseudocores for each RRT (Reservoir Rock Type). Effective SCAL properties computed from various MPS borehole-scale realizations or models are used to populate interwell-scale models for each RRT. Effective properties computed from flow simulations for interwell volumes are used to populate full-field scale models. At the full-field scale, outcrop analogs, sequence stratigraphy, forward stratigraphic models, diagenetic models, and basin-scale models are combined using MPS to improve flow simulations. At every stage, REVs (representative element volumes) are computed to be certain rock heterogeneities have been captured.

Owner:SCHLUMBERGER TECH CORP

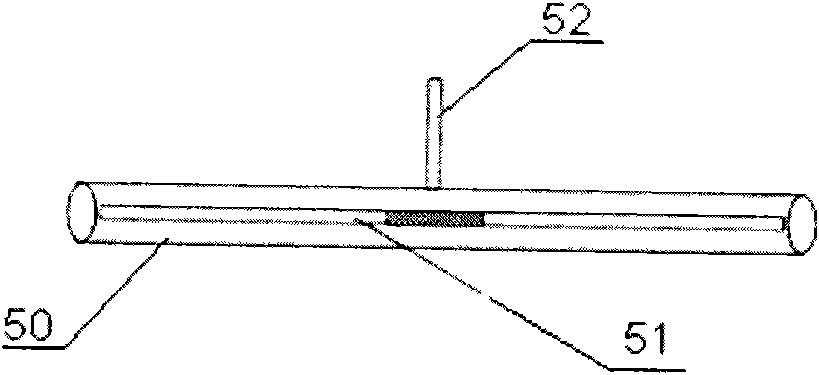

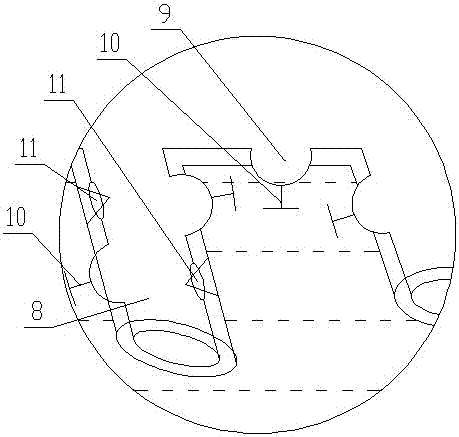

Device for observing transportation of propping agent in fracturing process of coal reservoir

A device for observing transportation of a propping agent in a fracturing process of a coal reservoir comprises a coal reservoir simulating system, a confining pressure loading system, a fracturing fluid pumping-in system, a data acquiring and analyzing system and a waste treatment system, wherein the fracturing fluid pumping-in system is connected with a liquid inlet of the coal reservoir simulating system; and the waste treatment system is connected with a liquid outlet of the coal reservoir simulating system. For solving the problems that distribution conditions of a fractured propping agent in fracture channels of coal beds are unclear under different fracturing operational discharge capacity, propping agent concentration, liquid levels and fracture development of the coal reservoir, and field fracturing design cannot be guided effectively, a visualized device which simulates transportation and laying of the propping agent in a fracturing process under different fracture development degrees of the coal reservoir and different pumping-in diameters is designed. By the device, the laying condition of the propping agent fractured under different conditions can be observed clearly, so that experimental basis can be provided for field fracturing design.

Owner:HENAN POLYTECHNIC UNIV

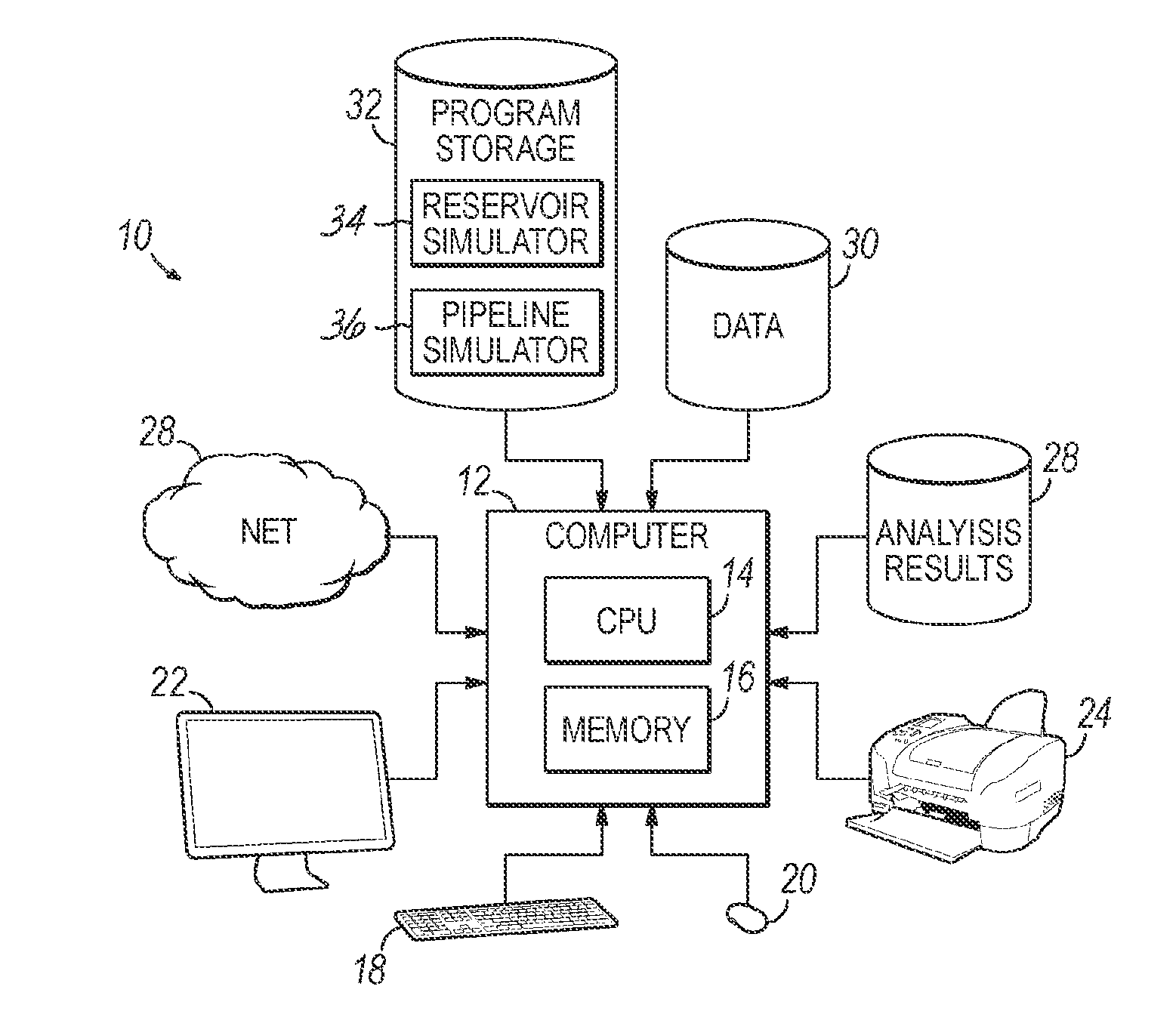

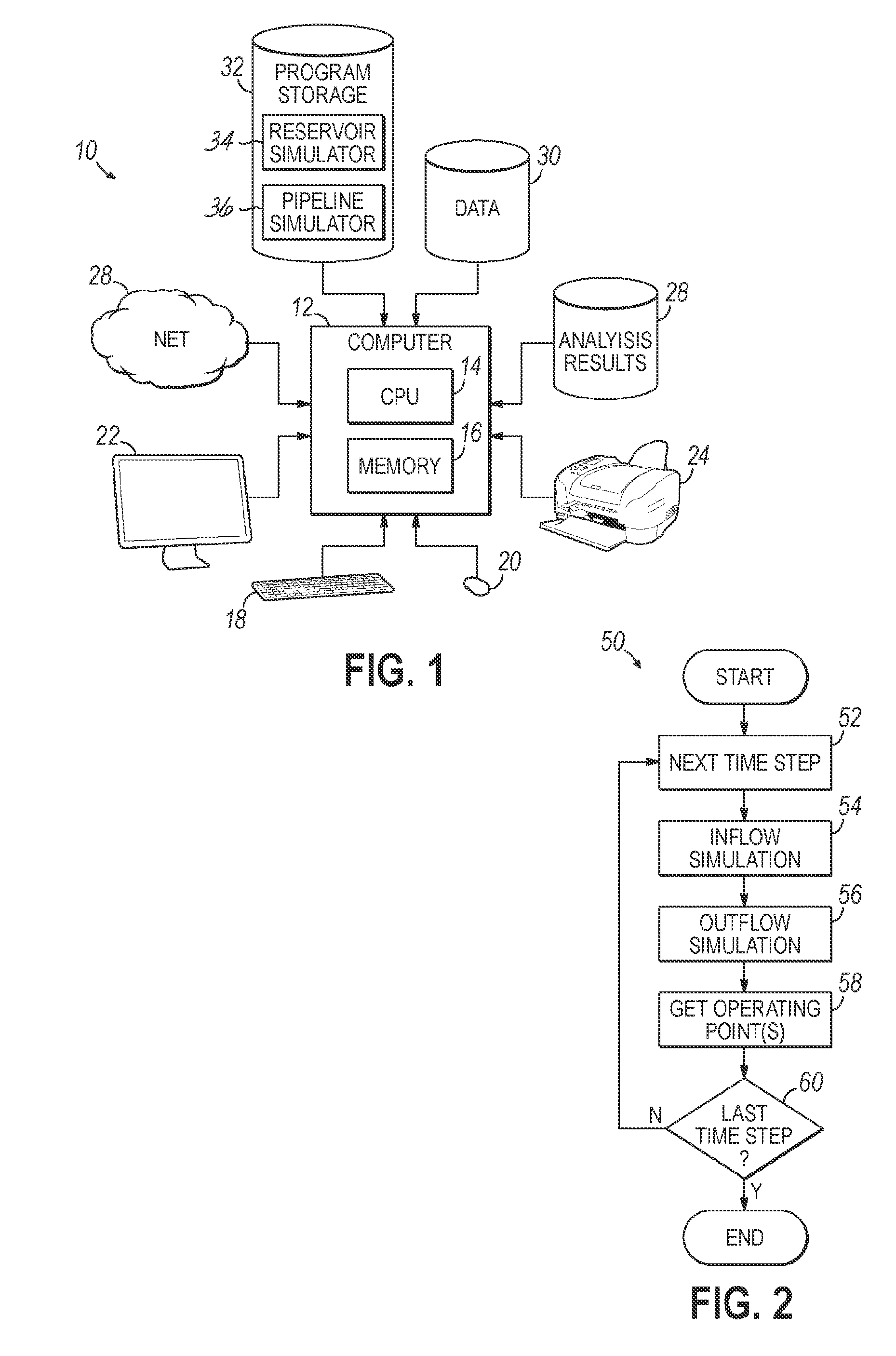

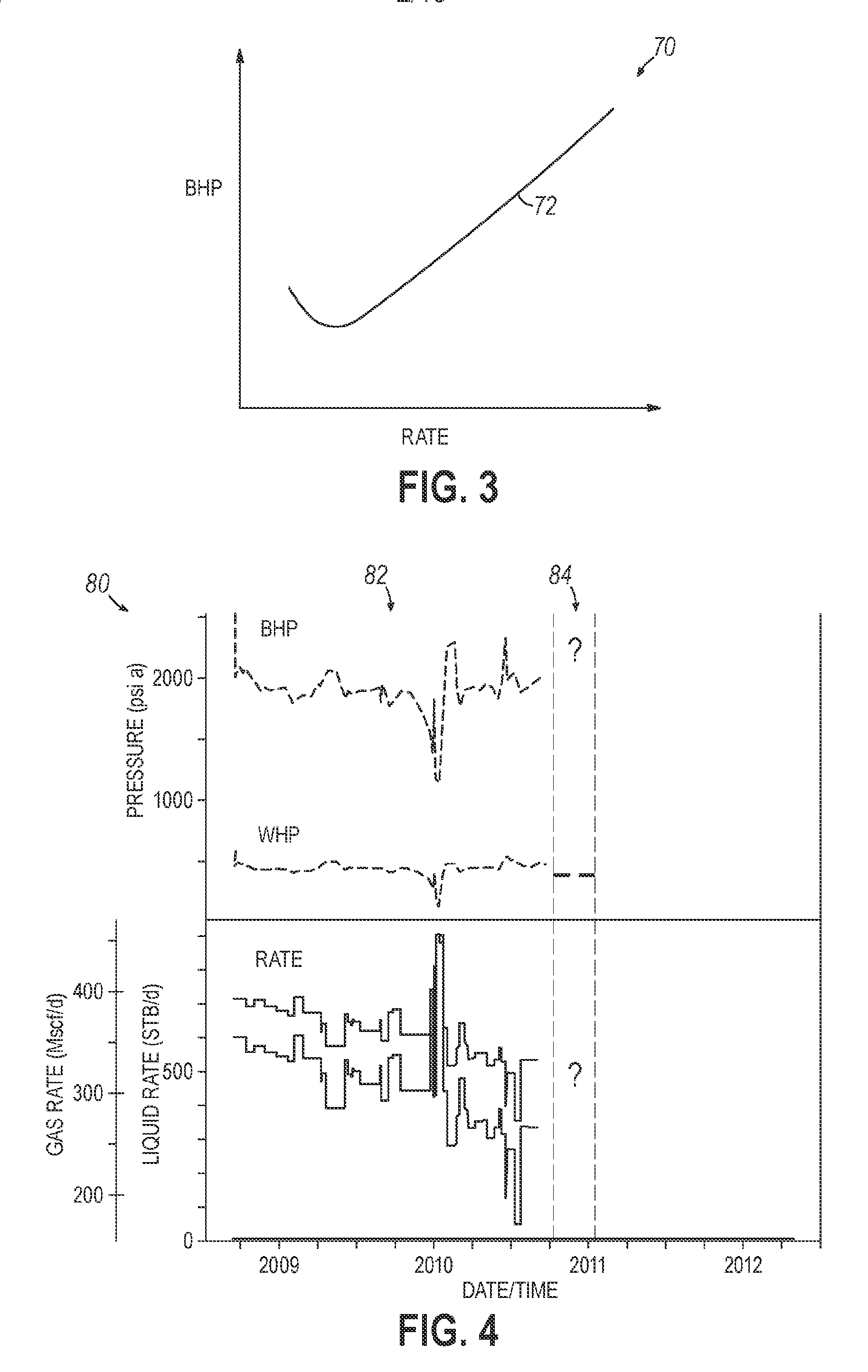

Multi-well time-lapse nodal analysis of transient production systems

ActiveUS20120101787A1Fluid removalComputation using non-denominational number representationNODALSimulation

A method, apparatus and program product utilize an analytical reservoir simulator to perform inflow simulation for a node during nodal analysis in a multi-well petroleum production system. By doing so, time-lapse nodal analysis may be performed of a transient production system in a multi-well context, often taking into account production history and the transient behavior of a reservoir system. Moreover, in some instances, an interference effect from different wells in a multi-well production system may be considered, and in some instances nodal analysis may be performed simultaneously for multiple wells. Multi-layer nodal analysis may also be performed in some instances to account for the pressure loss in a wellbore between multiple layers.

Owner:SCHLUMBERGER TECH CORP

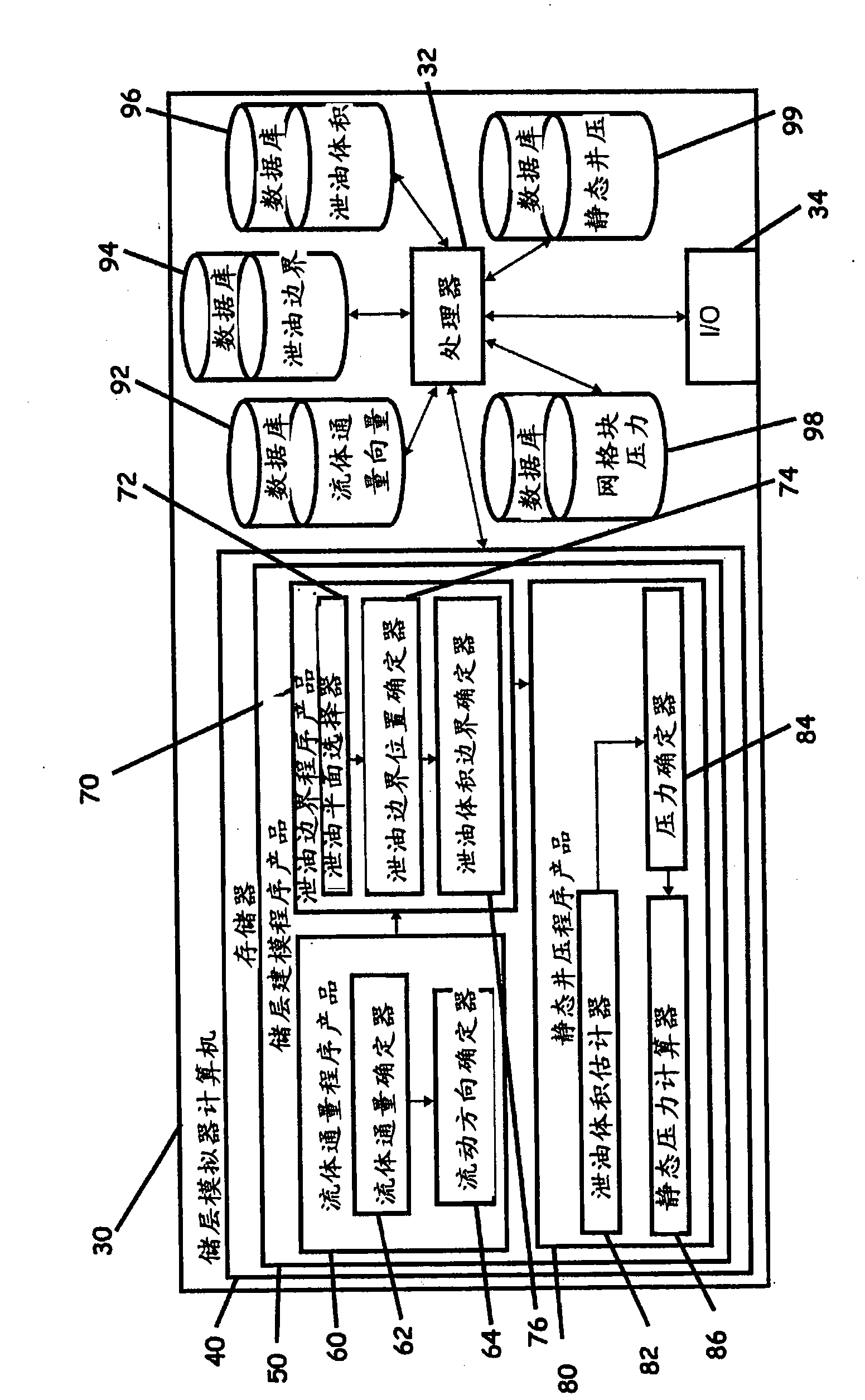

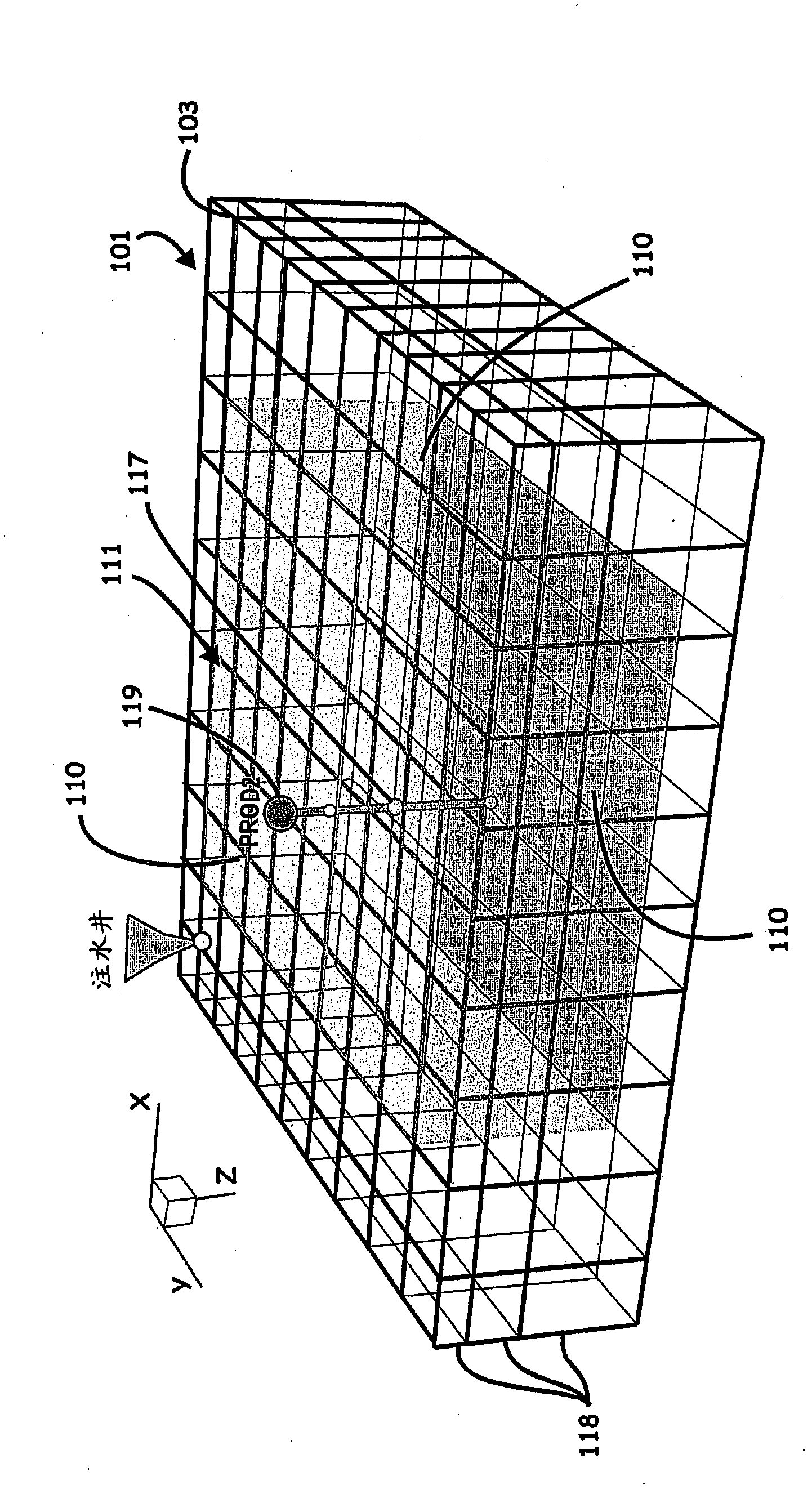

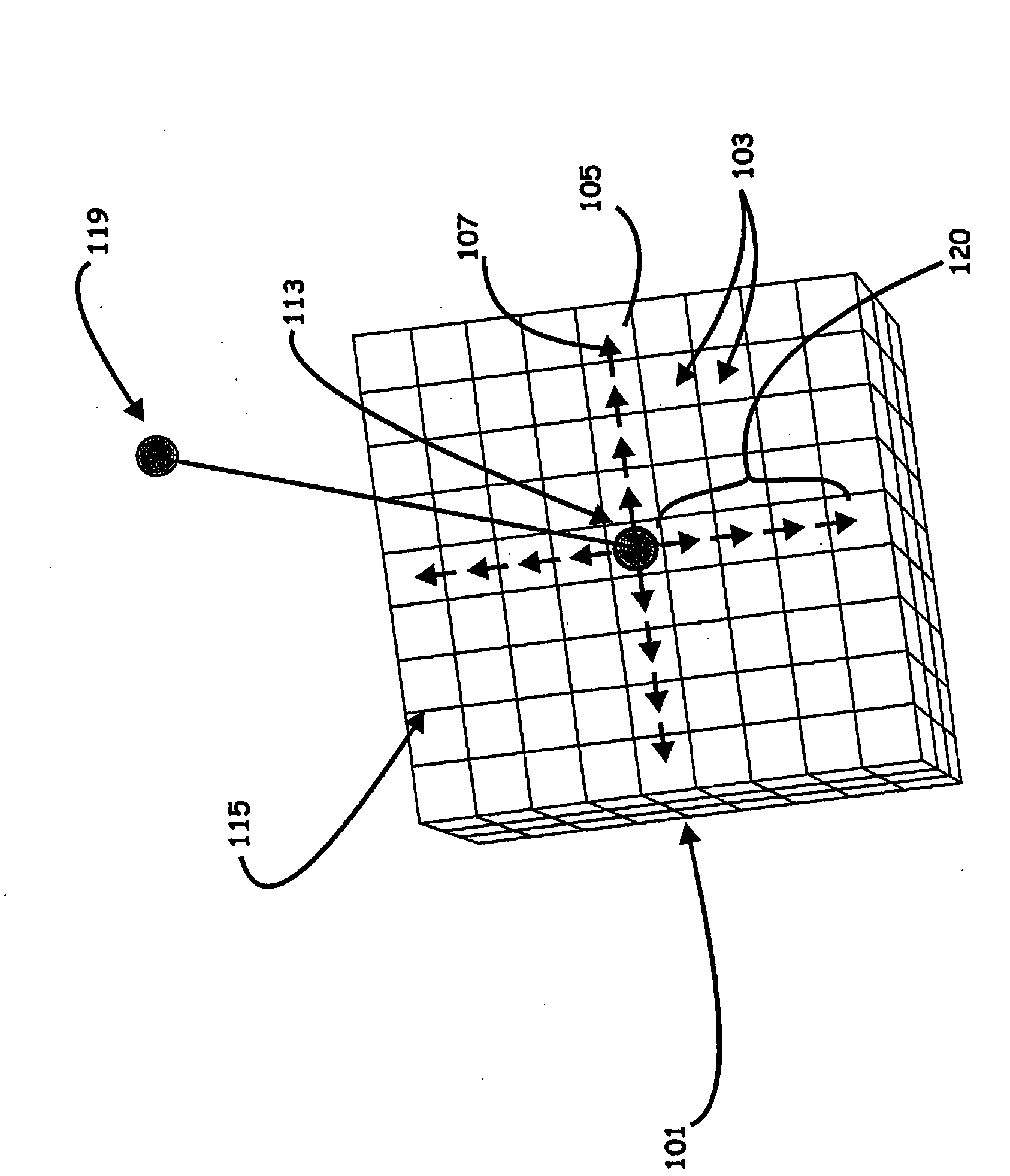

Systems, computer implemented methods, and computer readable program products to compute approximate well drainage pressure for a reservoir simulator

Systems, computer implemented methods, and program products to determine approximate static well pressures for one or more arbitrary shaped wells (119) by estimating the drainage volume (111) of the one or more wells (119), are provided. The drainage volume (111) of the one or more wells (119), for example, can be estimated from the one or more computed fluid flow flux vectors (107), and the approximate static well pressures for the one or more wells (119) can be subsequently calculated by taking the pore volume average of the dynamic grid block pressures within the drainage volume (111) of the one or more wells (119).; The one or more fluid flow flux vectors (107) can be calculated at each iteration in a numerical reservoir simulator as a part of standard simulator computations, negating a need for additional, extraneous computations to calculate effective drainage volume (111) of the one or more wells (119).

Owner:SAUDI ARABIAN OIL CO

Method for uncertainty quantification in the performance and risk assessment of a carbon dioxide storage site

ActiveUS8548785B2Other gas emission reduction technologiesSeismologyNormal densityReservoir modelling

A CO2 sequestration site is evaluated by incorporating a consistent petrophysical framework having uncertainties expressed in the form of probability density functions of wellbore measurements, by systematically propagating the uncertainties in generating probability density functions or cumulative distribution functions of the parameters used in a reservoir simulation, by using the reservoir simulation to transform the first set of parameters into output variables with uncertainties, and by using the output variables and uncertainties to generate an answer product from which uncertainty levels of performance metrics can be ascertained.

Owner:SCHLUMBERGER TECH CORP

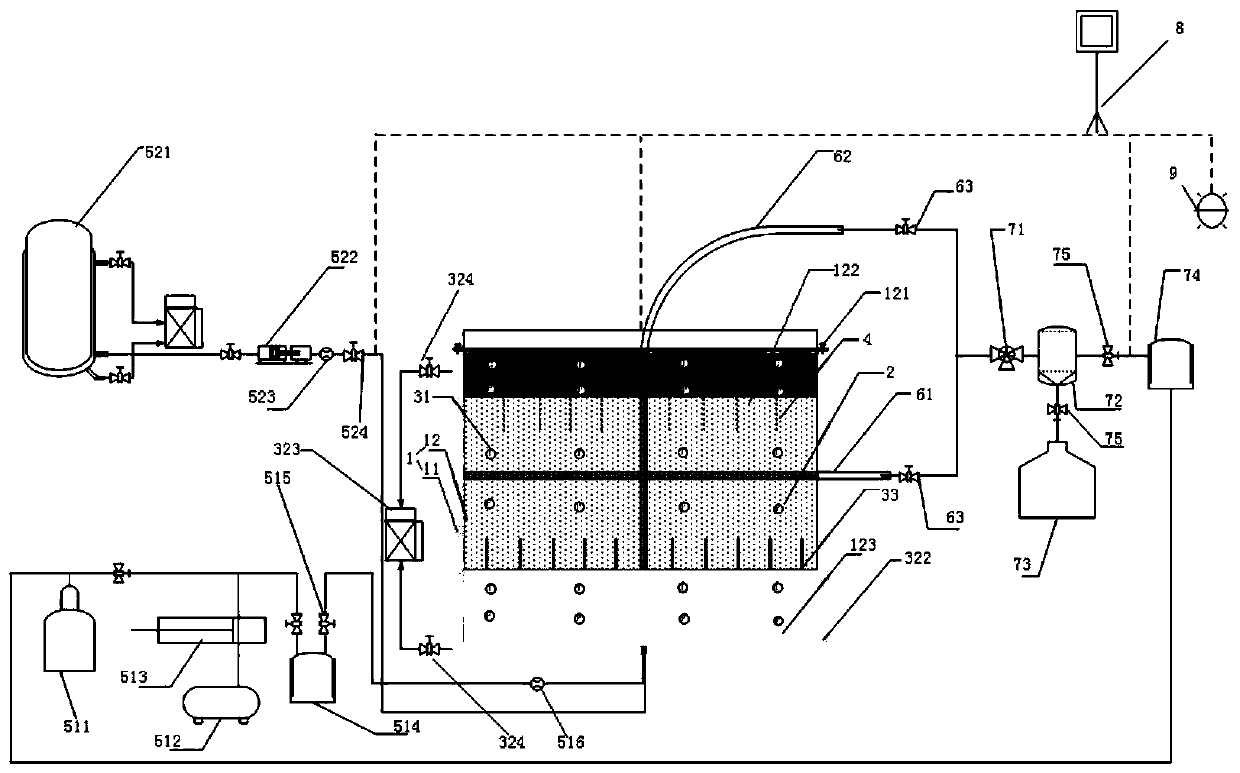

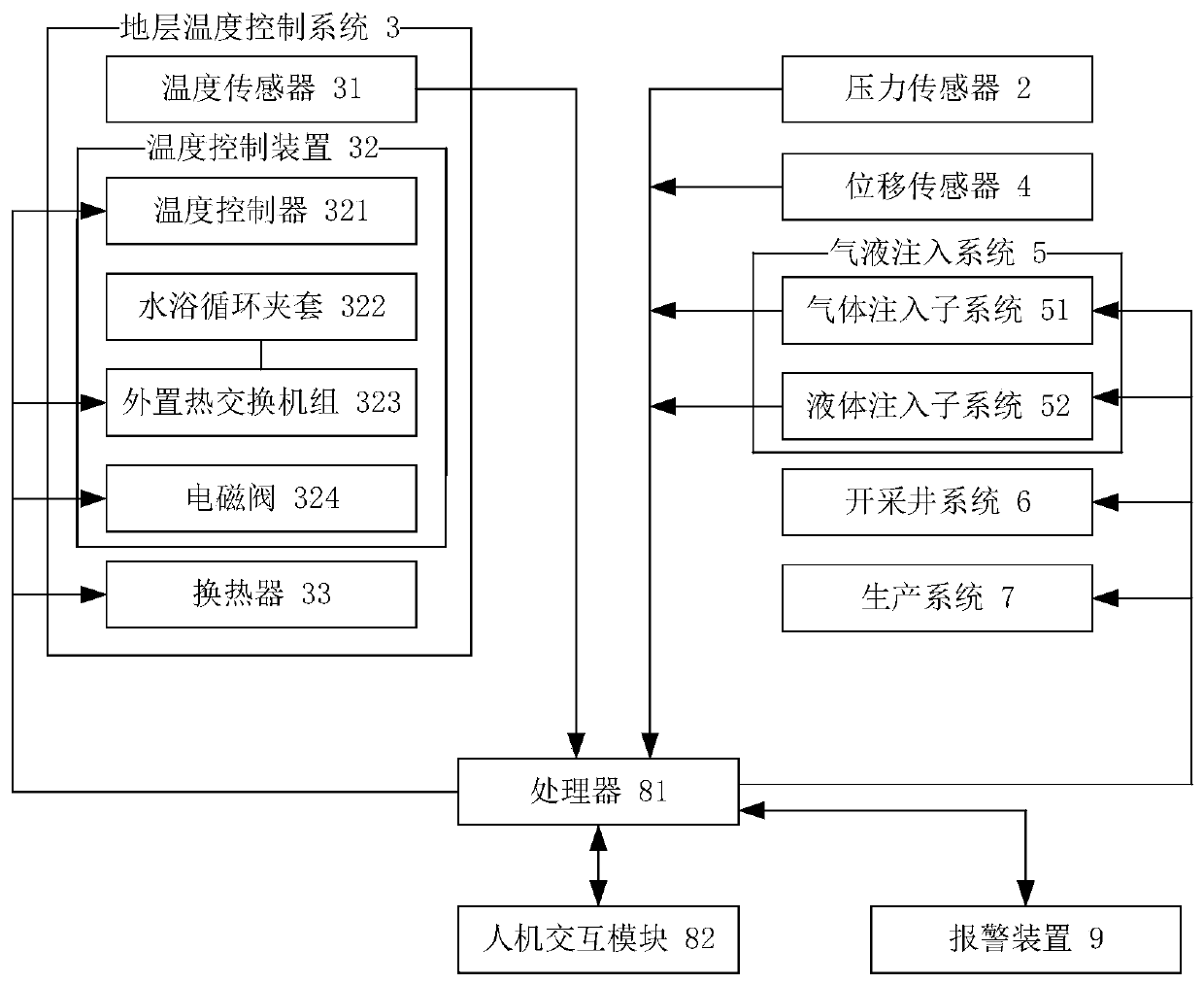

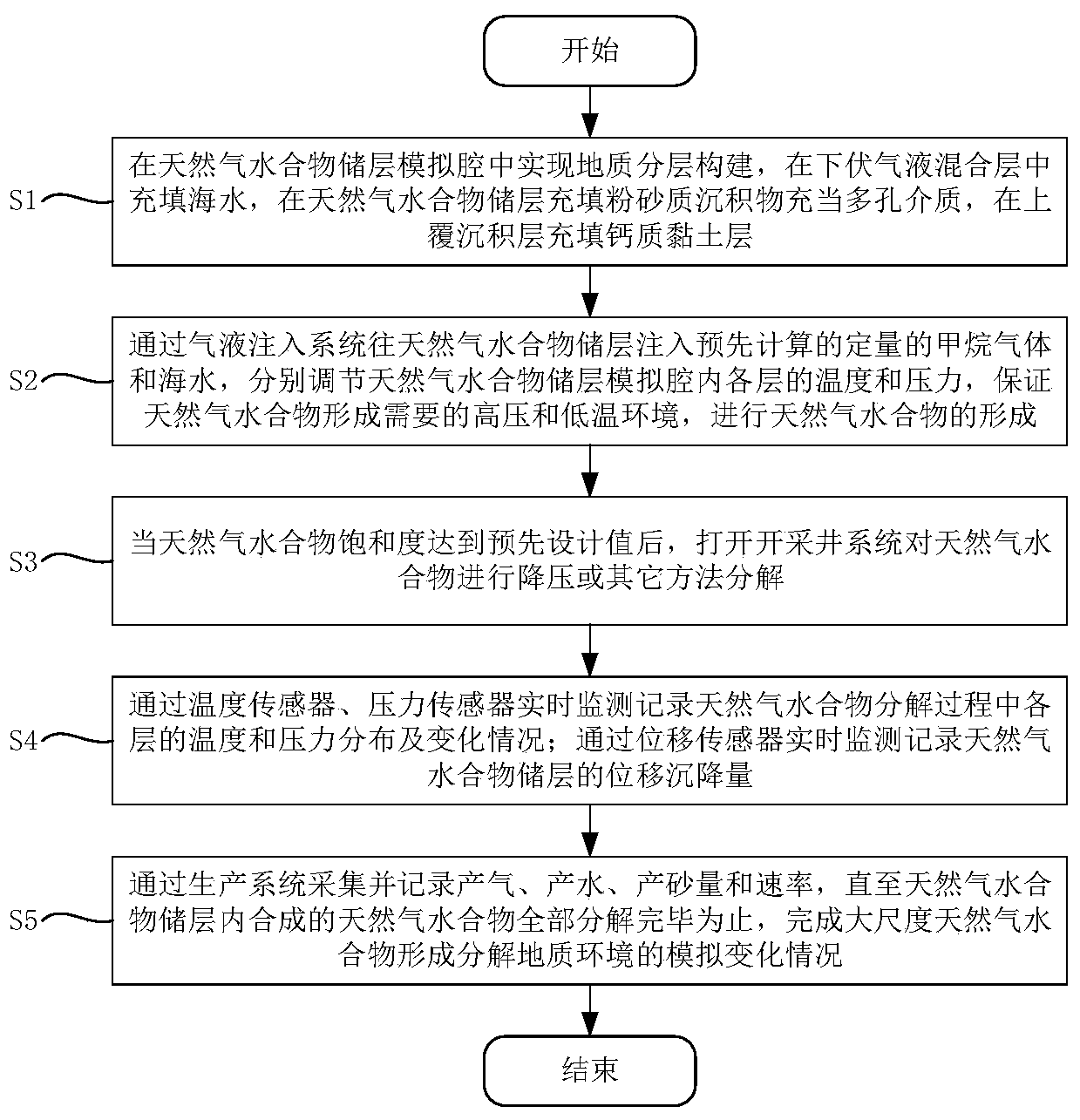

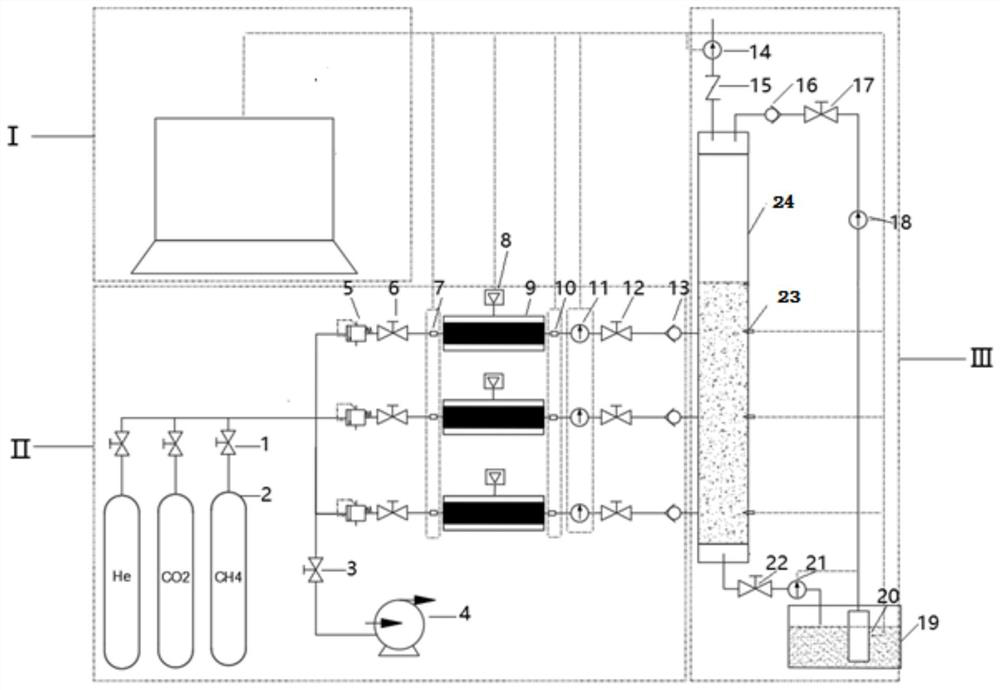

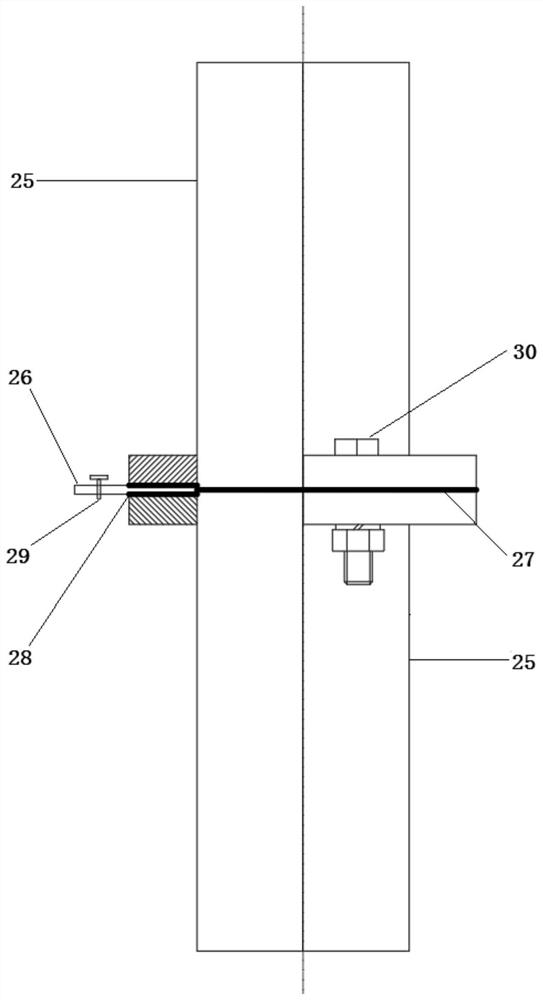

Large-scale natural gas hydrate formation and decomposition geological environment simulation system and method

InactiveCN111577212AReduce the risk of impactMake up for the shortcoming that it is difficult to realize the pressure gradient change in the real gas hydrate reservoirSurveyConstructionsDecompositionEngineering

The invention provides a large-scale natural gas hydrate formation and decomposition geological environment simulation system. The large-scale natural gas hydrate formation and decomposition geological environment simulation system comprises a natural gas hydrate reservoir simulation cavity, a stratum temperature control system, a gas-liquid injection system, an exploitation well system, a production system, a pressure sensor, a displacement sensor and an information acquisition control system; the gas-liquid injection system is in communication with the bottom of a cavity; the exploitation well system is arranged inside the cavity; the production system is connected with the output end of the exploitation well system; the output end of the production system is connected with the input endof the gas-liquid injection system; the pressure sensor is arranged in a simulation layer; the displacement sensor is arranged in the simulation layer; and the information acquisition control systemis electrically connected with the pressure sensor, a temperature control device, the gas-liquid injection system, the production system and the displacement sensor. The invention further provides a simulation method, in-situ geological stratification construction of the natural gas hydrate reservoir in the sea area is achieved, the geological environment system simulation requirement in the large-scale natural gas hydrate forming and decomposing process is met, and the defect that a small-scale simulation system is difficult to achieve pressure gradient changes in a real natural gas hydrate reservoir is overcome.

Owner:GUANGDONG LAB OF SOUTHERN OCEAN SCI & ENG GUANGZHOU +1

Experimental device for coal seam gas multi-layer co-production

PendingCN111706321AIn line with production statusSurveyFluid removalMining engineeringReservoir modelling

The invention discloses an experimental device for coal seam gas multi-layer co-production. The experimental device comprises a reservoir simulation system, a wellbore simulation system and a controland data collection system, wherein the reservoir simulation system comprises a plurality of coal seam simulation components connected in parallel and is used for simulating the reservoir condition ofmultiple coal seams; the wellbore simulation system comprises a cylinder for simulating the drainage and gas production process of a wellbore; the coal seam simulation components are respectively connected to different height positions of the cylinder, so that the wellbore simulation system simulates the output characteristics and pressure differences among coal seams in the wellbore of a coal seam gas well; and the control and data collection system is respectively connected with the reservoir simulation system and the wellbore simulation system and is used for sending control instructions and collecting simulated data. The experimental device can simulate the flow condition of multi-phase flow in the wellbore during multiple coal seam co-production. Reservoir simulation is associated with wellbore simulation, so that the experimental device can accurately simulate the real situation of a reservoir and can simulate and study the condition in the wellbore during production.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT +1

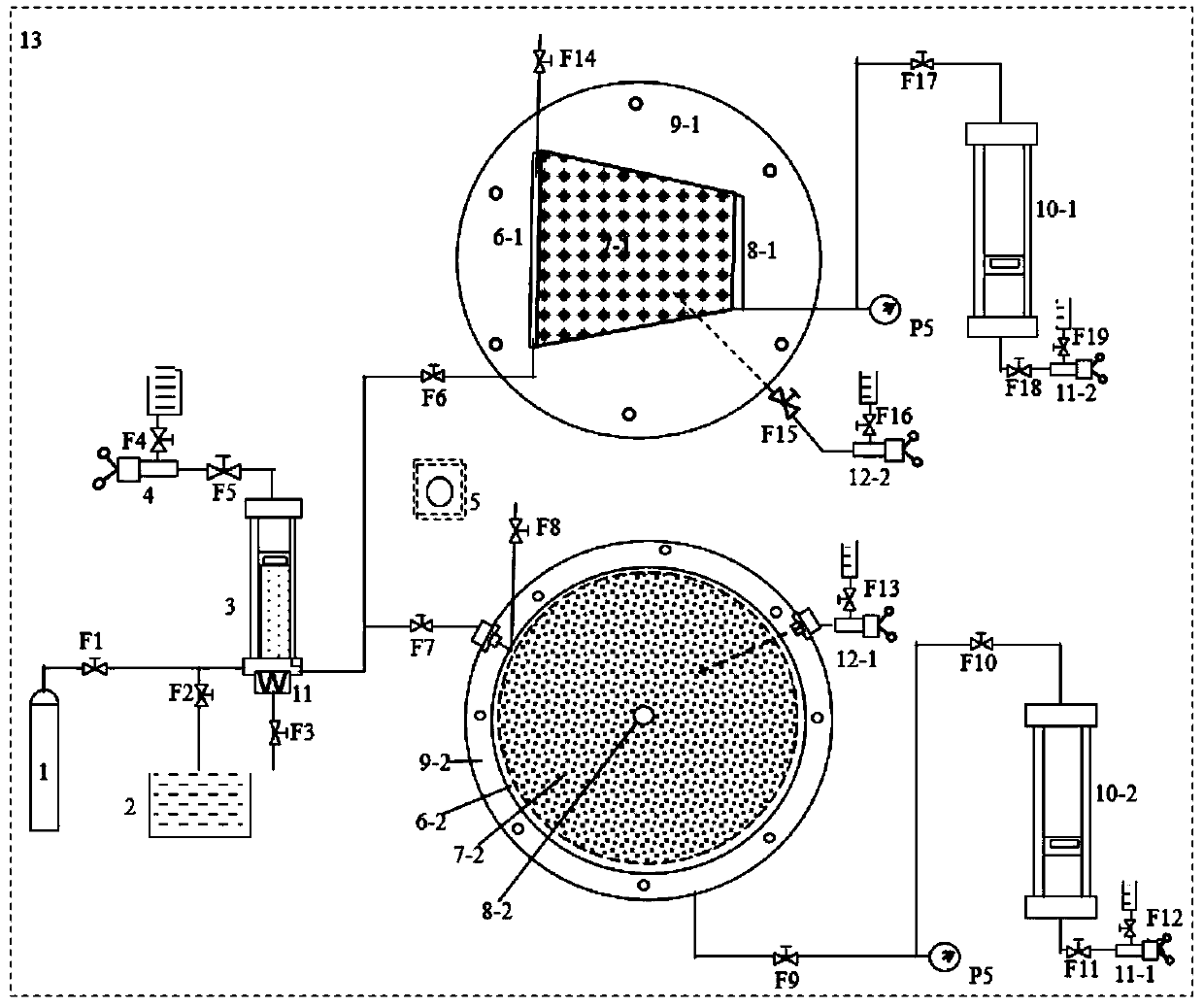

Simulation method and device for stripping and transporting hydrate reservoir sediment during depressurization

ActiveCN110361158AExclude the influence of analysis resultsEliminate the effects ofHydrodynamic testingEngineeringDistribution law

The invention discloses a simulation method and device for stripping and transporting hydrate reservoir sediment during depressurization. The simulation device comprises a reservoir simulation module,a supply module, a pressure control module, a temperature control module and a recovery module. The reservoir simulation module is used for loading loose deposits, forming a hydrate reservoir and observing a sediment stripping initiation process and comprises a microscopic visual module, a pure radial flow reservoir simulation module and a non-radial flow reservoir simulation module. The influences of the different streamline patterns and a hydrate distribution law on the initiation and migration process of hydrate reservoir sands are considered, hydrate reservoirs under different hydrate saturations and different hydrate distribution patterns are prepared through the reservoir, that the hydrate is in an undecomposed state in a subsequent sand production mechanism analysis experiment is guaranteed, a critical pressure drop condition of sand production and an sand production pattern evolution law are discussed, and a technical support is provided for the prediction of a sand productionlaw in an actual production well.

Owner:QINGDAO INST OF MARINE GEOLOGY

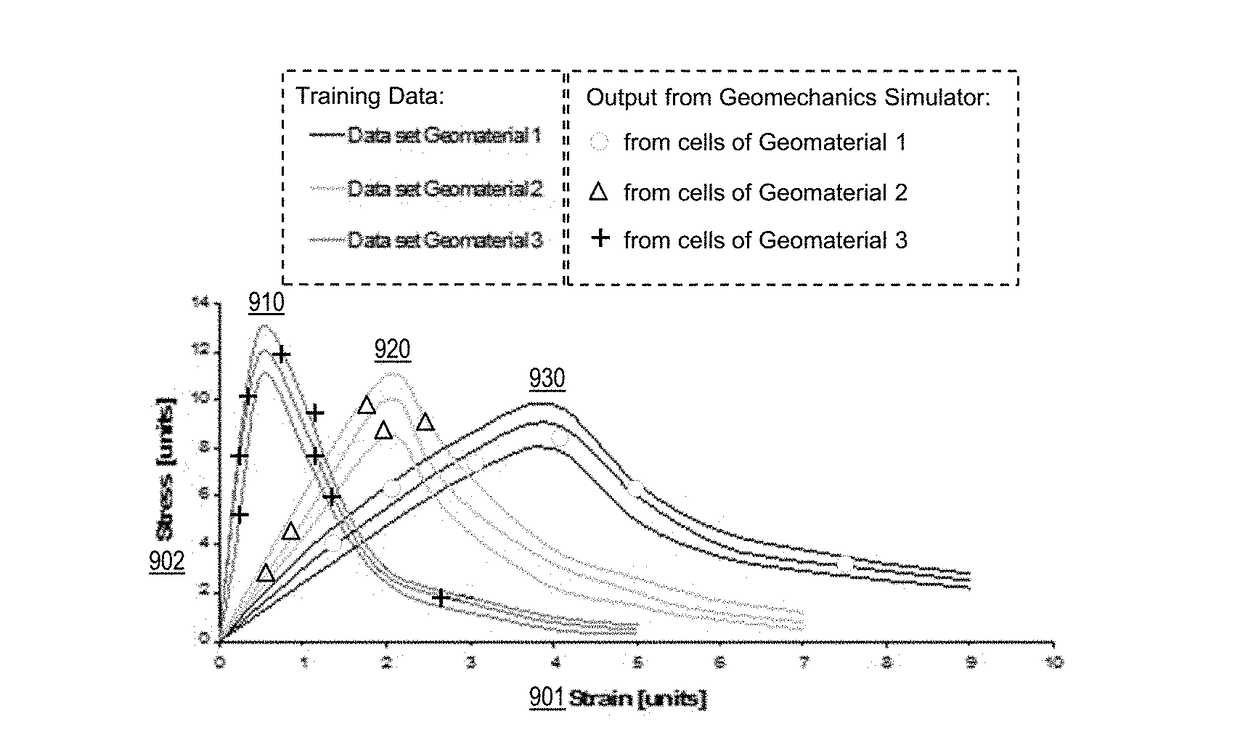

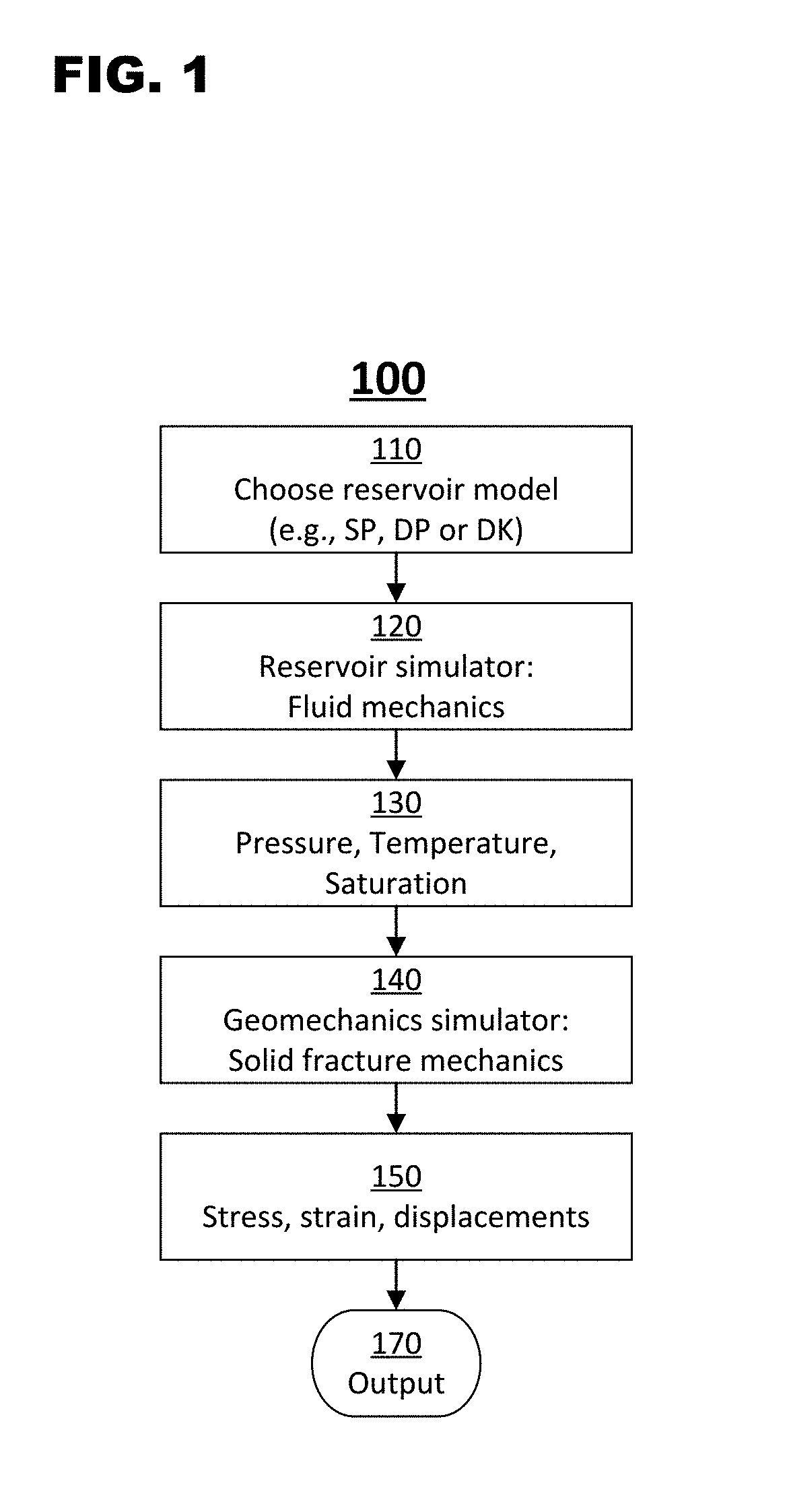

Machine learning assisted reservoir simulation

ActiveUS20180004865A1Substantial beneficial technical effectGeomodellingDesign optimisation/simulationMachine learningReservoir simulation

An embodiment includes a method for use by at least one machine learning classifier. The method comprises the machine learning classifier obtaining one or more recent results from at least one geomechanical simulation; the machine learning classifier comparing the recent results to stored historical data; and, based on the comparing, the machine learning classifier deciding at least one reservoir model for use by at least one reservoir simulation.

Owner:IBM CORP

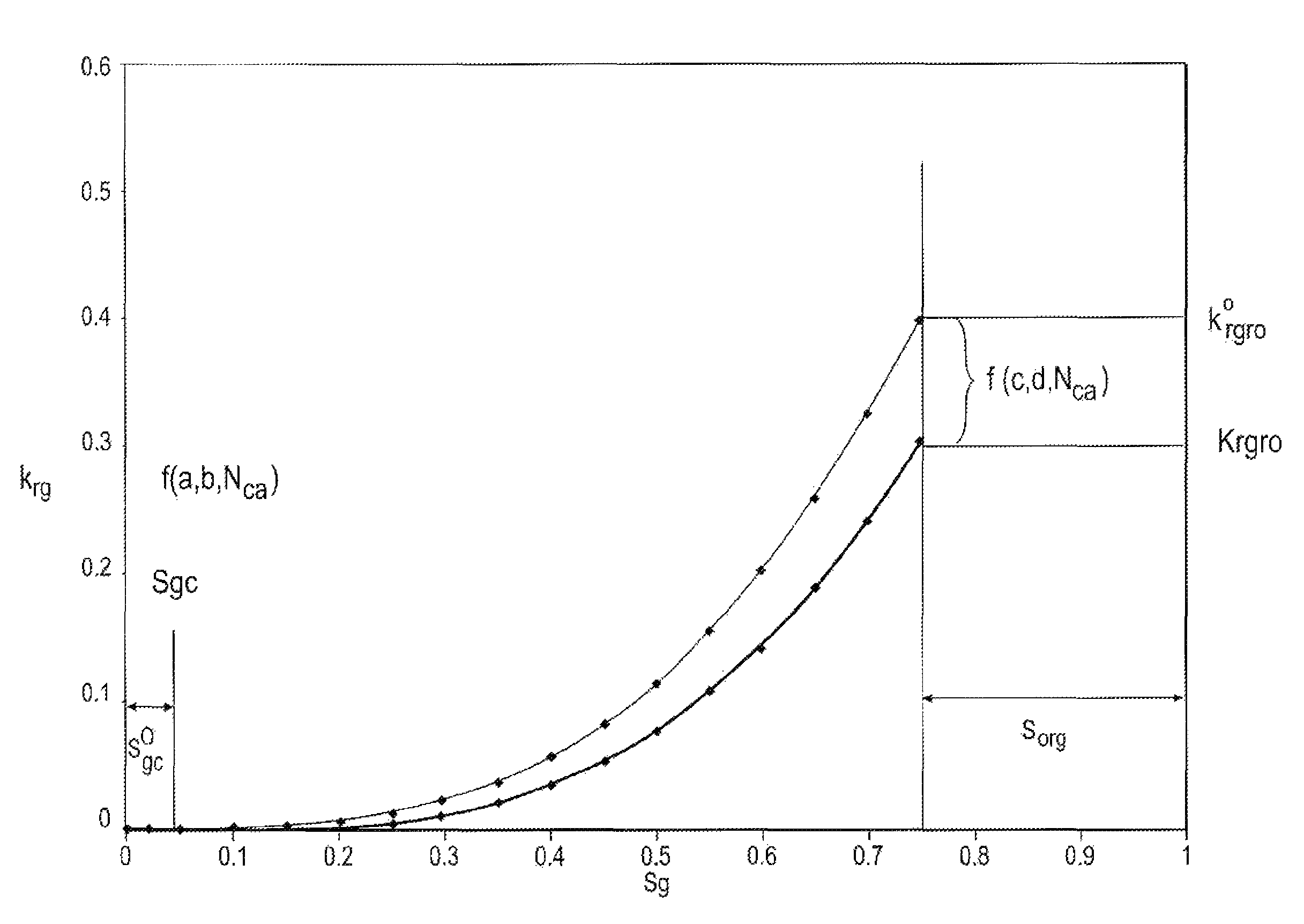

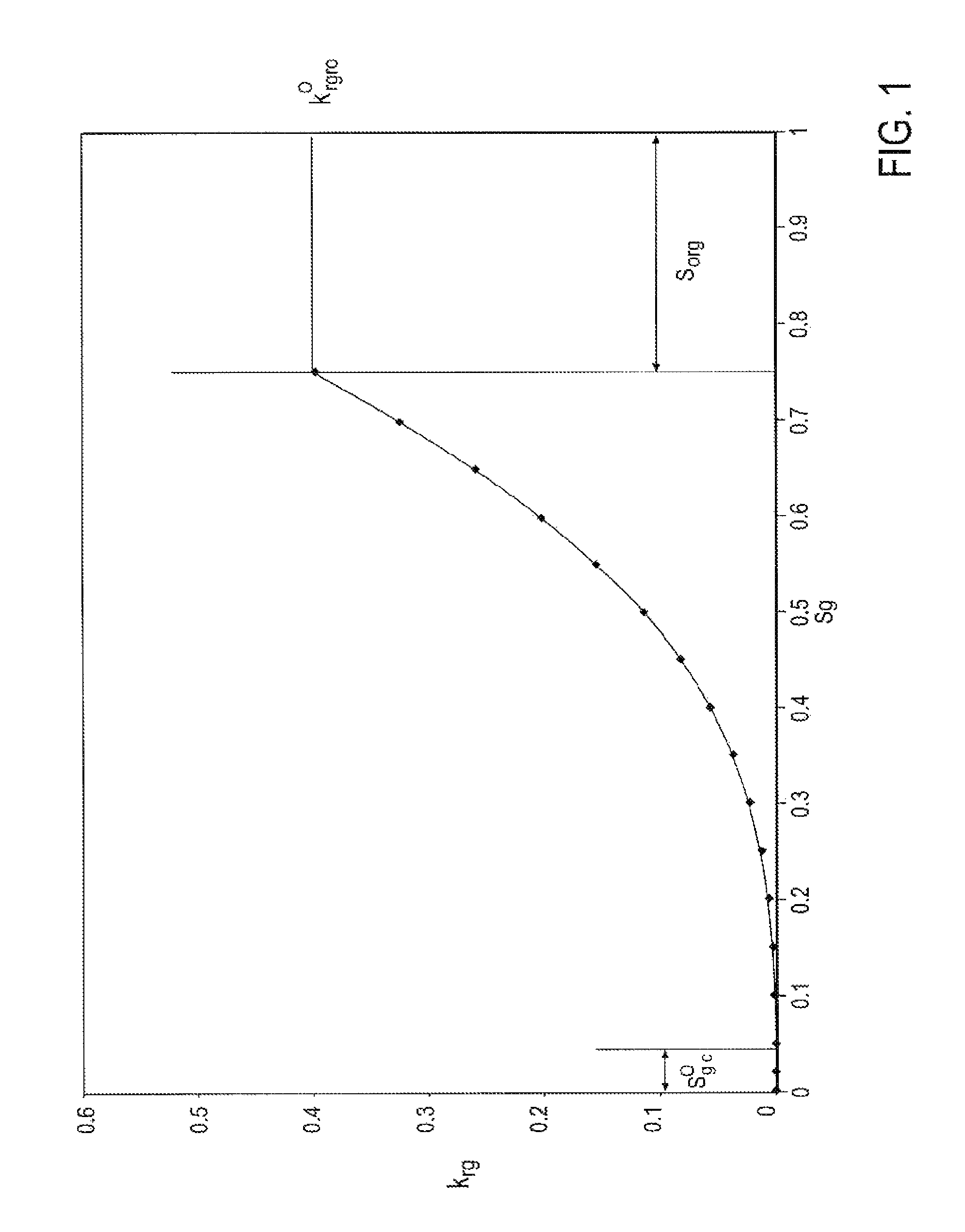

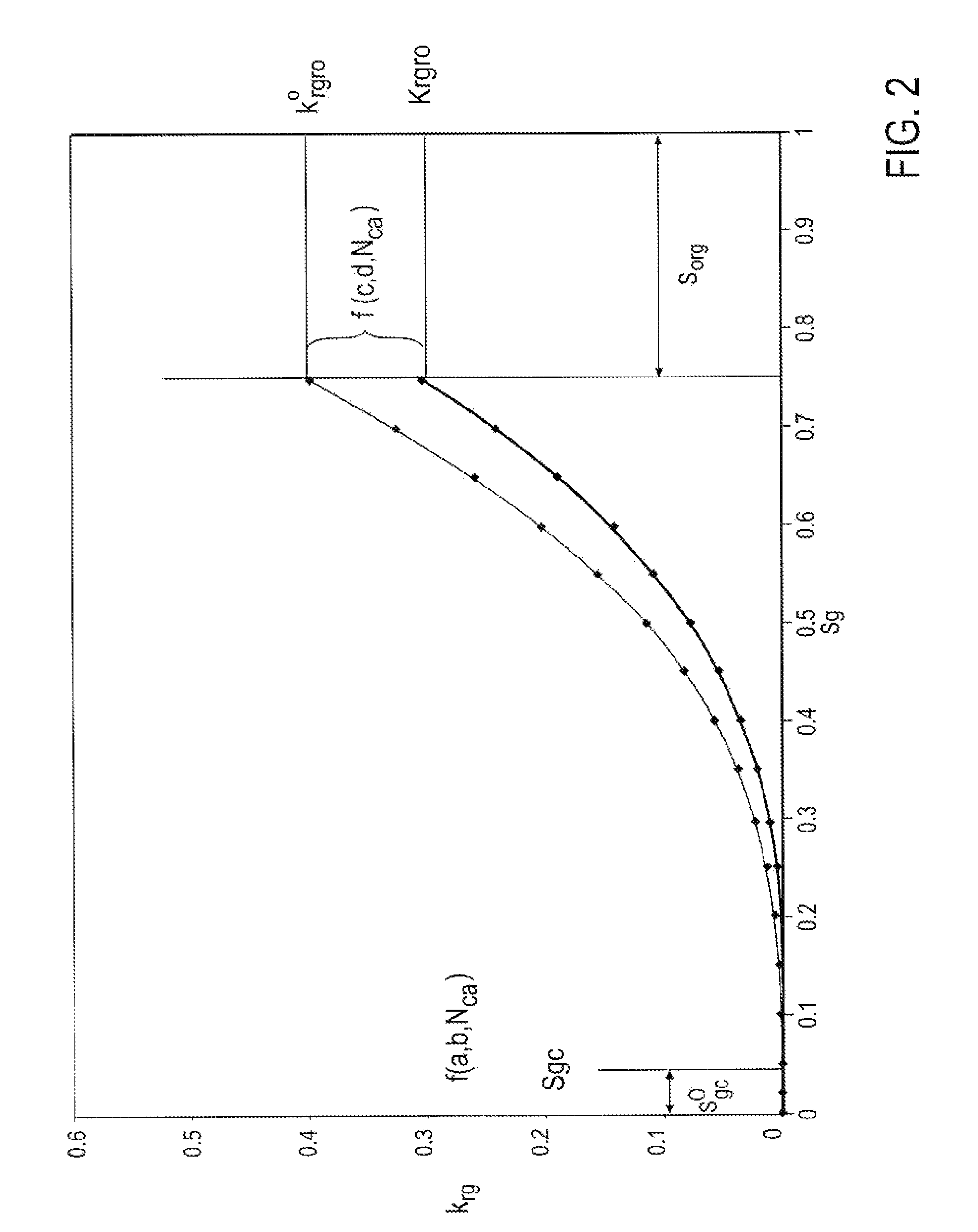

Method, system and program storage device for reservoir simulation utilizing heavy oil solution gas drive

ActiveUS9020793B2Maintain relatively stableImprove predictive performanceFluid removalDesign optimisation/simulationProduct gasFuel oil

A method, a system and a program storage device for predicting a property of a fluid, such as fluid production from a subterranean reservoir containing heavy oil entrained with gas is described. The method includes developing a baseline correlation of gas relative permeability krg versus gas saturation Sg. A capillary number dependent correlation is determined capturing the relationship between at least one of critical gas saturation Sgc and capillary number Nca and gas relative permeability krgro and capillary number Nca phased upon a plurality of depletion rates. Capillary numbers Nc are calculated for a plurality of cells in a reservoir model representative of the subterranean reservoir. The baseline correlation is then adjusted to comport with at least one of Sgc and krgro selected from the capillary number dependent correlation to produce a plurality of corresponding adjusted baseline, correlations. Gas relative permeabilities krg for the plurality of cells are selected from the corresponding adjusted baseline correlations. A reservoir simulation is then run utilizing the selected relative permeabilities krg to predict a property of at least one fluid in a subterranean reservoir containing heavy oil entrained with gas.

Owner:CHEVROU USA INC

Horizontal well sand-water co-production and control and mining well completion multifunctional experimental system and experimental method thereof

ActiveCN111411934AComprehensive experimental simulation functionsSmall sizeSurveyFluid removalMathematical simulationHorizontal wells

The invention discloses a horizontal well sand-water co-production and control and mining well completion multifunctional experimental system and an experimental method thereof. The experimental system comprises a central control system and further comprises a liquid storage tank, a water pump, a reservoir simulation unit, a transparent shaft, a sand-liquid separation sand collector and a backflowpump which are sequentially connected through pipelines. The experimental method comprises a horizontal well non-uniform water outlet profile and a dynamic evolution simulation experiment and a horizontal well sand-water control horizontal well comprehensive flow simulation experiment thereof, a horizontal well sand-water co-production profile and a dynamic evolution simulation experiment thereof, a horizontal well non-uniform sand production profile and a dynamic evolution simulation experiment thereof, a horizontal well circulating gravel packing sand prevention process simulation experiment and various experiments, a series of experiments are carried out, more accurate mathematical simulation calculation results are obtained, important scientific value and engineering guiding significance are provided for improving horizontal well development effects of oil and gas reservoirs, and important reference values are provided for horizontal well development of unconventional oil gas andnatural gas hydrate reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

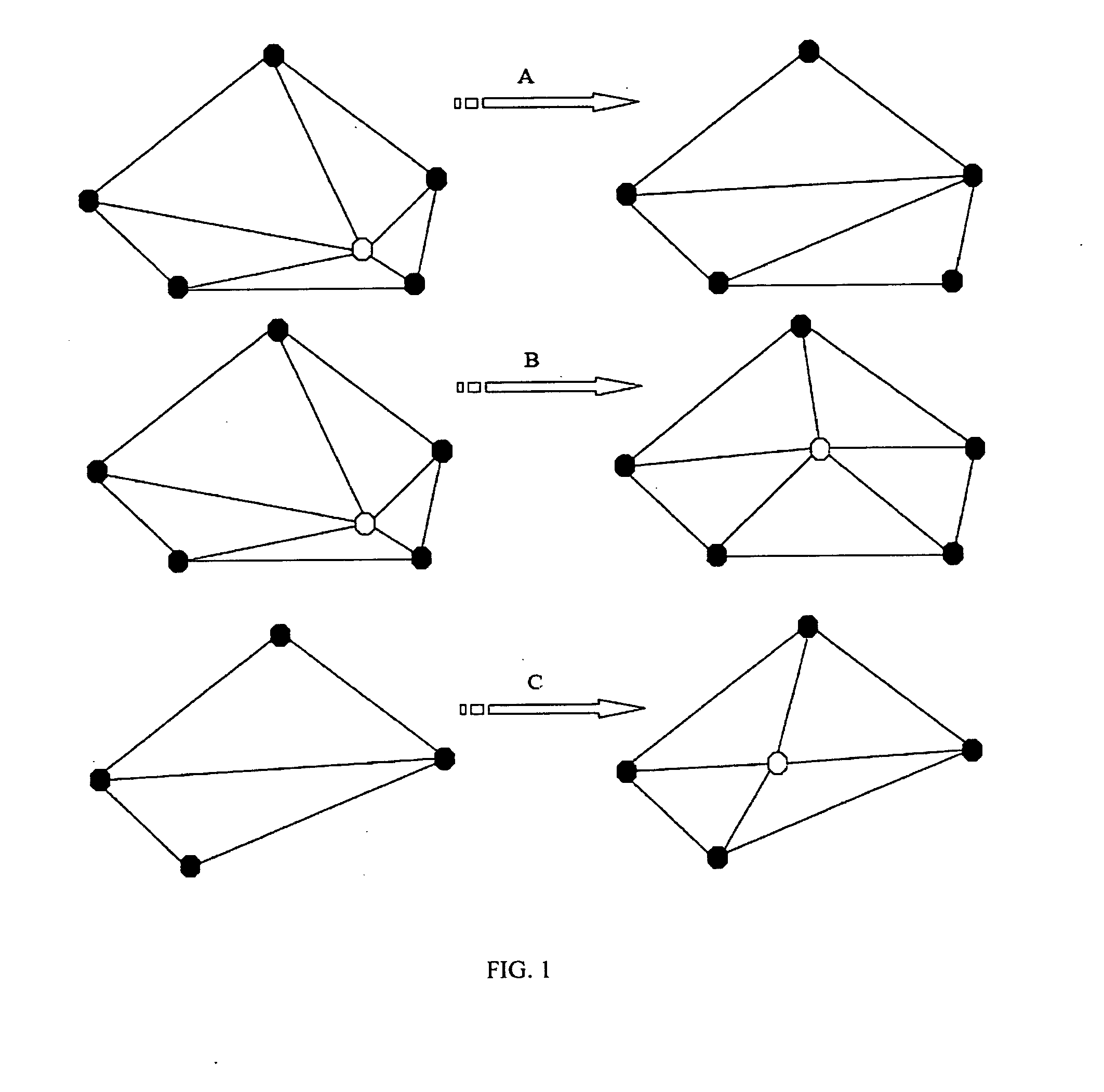

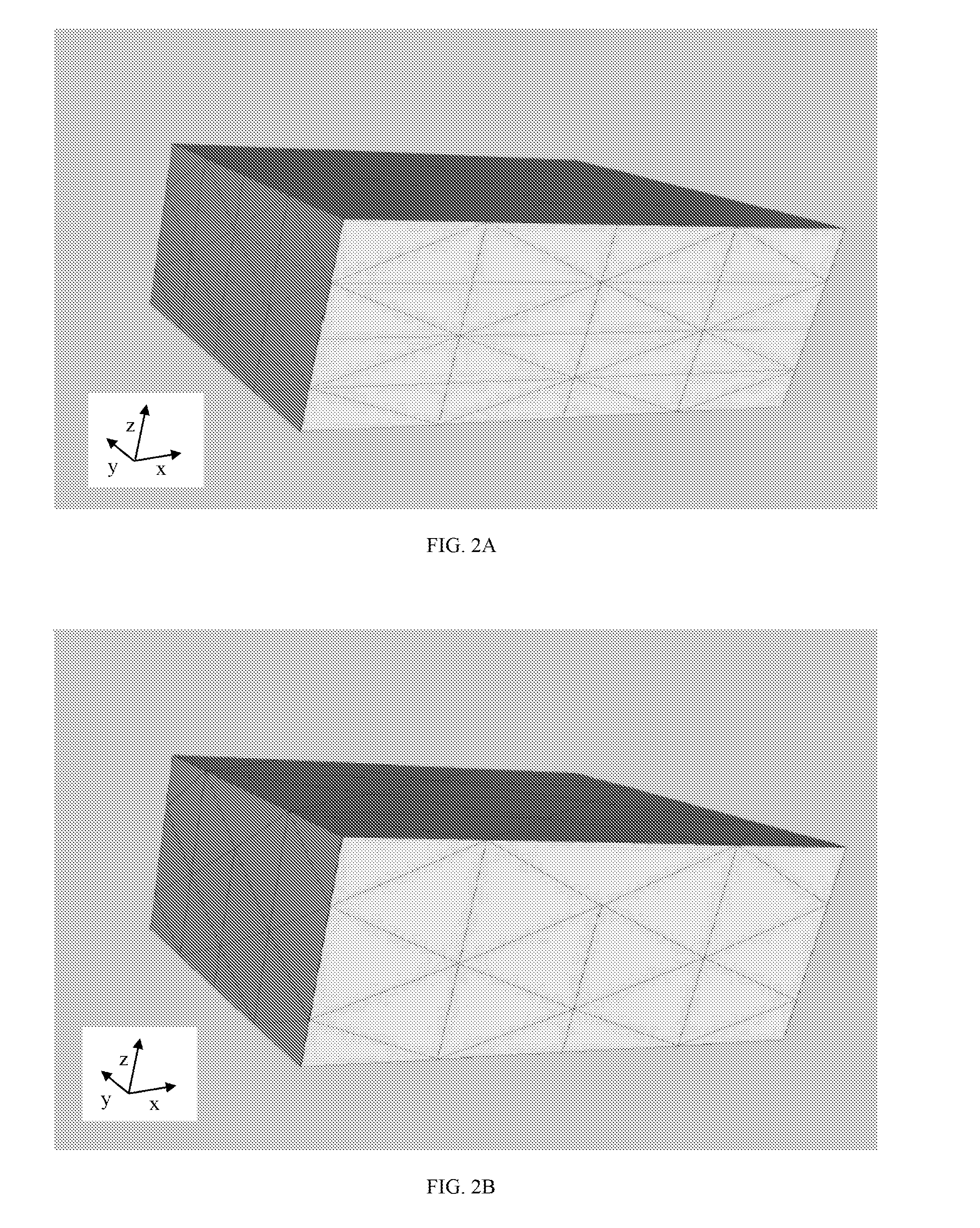

Method of constructing an optimized mesh for reservoir simulation in a subterranean formation

The invention is a method of constructing an optimized mesh for reservoir simulation in a subterranean formation useful for exploration in exploitation of oil deposits. At an instant T of the reservoir simulation, a size function is estimated, characterizing the initial mesh representative of the subterranean formation being studied. Next the flow of the fluids within the formation at this instant T is simulated by use of a reservoir simulator and of the initial mesh. An optimized size function is thereafter computed by use of the size function estimated on the initial mesh and of at least one parameter deduced from the reservoir simulation. And finally, an optimized mesh is constructed by modifying the initial mesh as a function of the optimized size function.

Owner:INST FR DU PETROLE

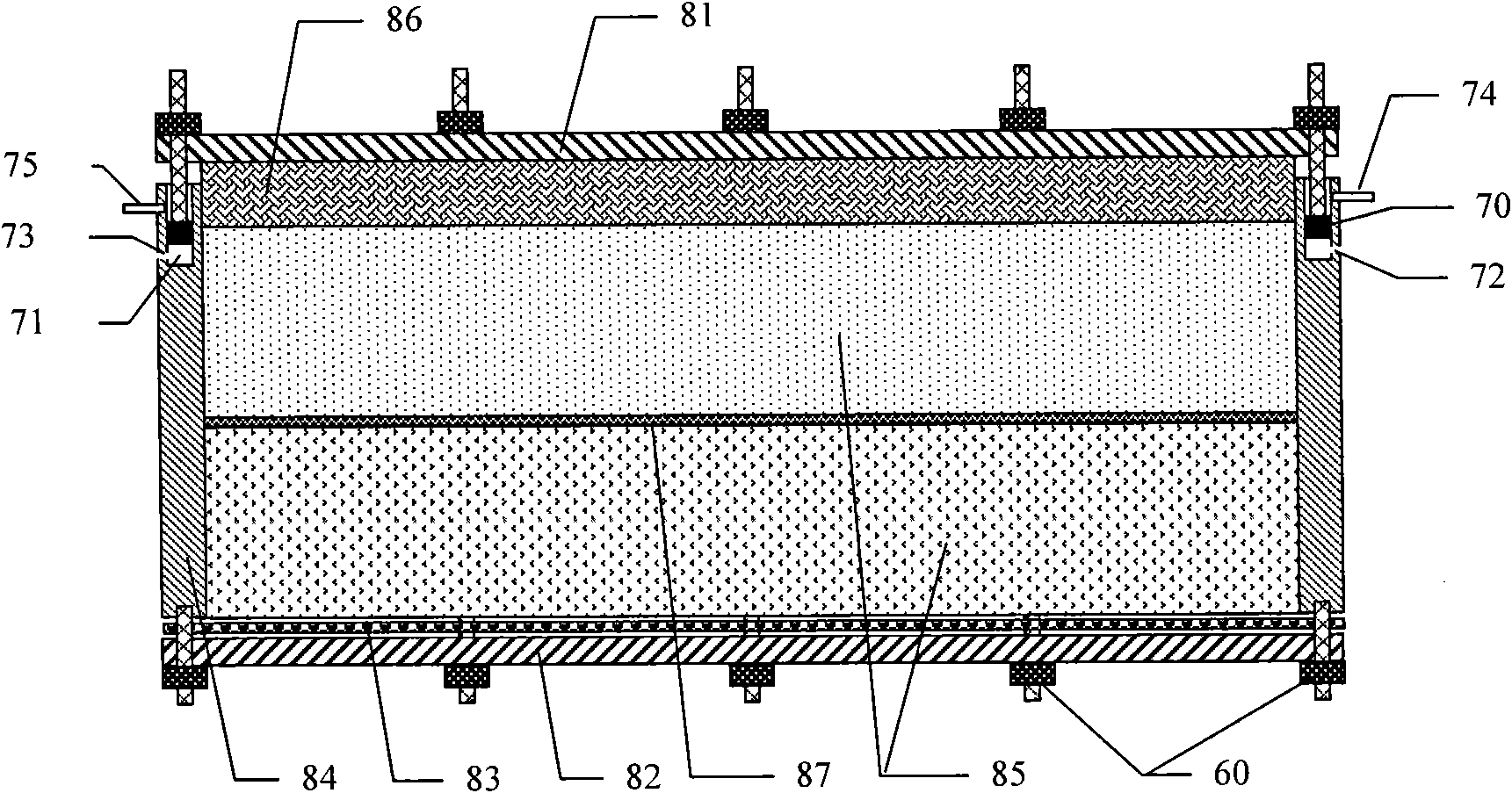

Three-dimensional heterogeneous oil-reservoir multi-well-pattern mode water flooding physical simulation experiment device

ActiveCN111022010AReduce the difficulty of filling and fillingStable in natureFluid removalWater storage tankWater production

The invention discloses a three-dimensional heterogeneous oil-reservoir multi-well-pattern mode water flooding physical simulation experiment device. The three-dimensional heterogeneous oil-reservoirmulti-well-pattern mode water flooding physical simulation experiment device comprises a reservoir simulation system, an injection system and an experimental measurement system, wherein the injectionsystem and the experimental measurement system are separately connected with the reservoir simulation system. The reservoir simulation system comprises an experiment box, an insulating filter screen and a measurement electrode. The insulating filter screen is detachably arranged to divide the experiment box into multiple layers; the injection system comprises an injection pump, an oil-and-water storage tank, a pressure gauge and a multiported valve, wherein the injection pump, the oil-and-water storage tank, the pressure gauge and the multiported valve are connected in sequence; the oil-waterstorage tank is connected with each layer of the experiment box through the multiported valve and an injection pipeline; and the experimental measurement system comprises a multi-channel resistance measurement instrument and a flow measurement system, wherein the multi-channel resistance measurement instrument is connected with the measuring electrode, and the flow measurement system is connectedwith each layer of the experiment box through discharging pipelines. According to the three-dimensional heterogeneous oil-reservoir multi-well-pattern mode water flooding physical simulation experiment device, multi-layer filling and leveling degree is ensured, the development of an interlayer can be more accurately simulated, the oil-and-water production can be measured in layers under the simulated multi-well-pattern mode, and the resistance is measured in real time to obtain the saturation distribution.

Owner:SOUTHWEST PETROLEUM UNIV

Method for operating a substerranean formation from which a fluid is produced

ActiveUS20160003010A1Easy to operateLow costFluid removalDesign optimisation/simulationReservoir modellingReservoir simulation

A method for operating an oil deposit based on a technique of positioning wells to be drilled is disclosed. Based on a grid representative of the petrophysical properties of a subterranean formation through at least one well is drilled, a reservoir simulation is performed up to a time for which production of the formation being studied is to be predicted. Then, attributes are selected that are representative of the flows in the formation and a classification of these attributes is performed. Then, a quality indicator is computed for each of the classes and at least one class is selected such that its quality indicator is greater than a first threshold.

Owner:INST FR DU PETROLE

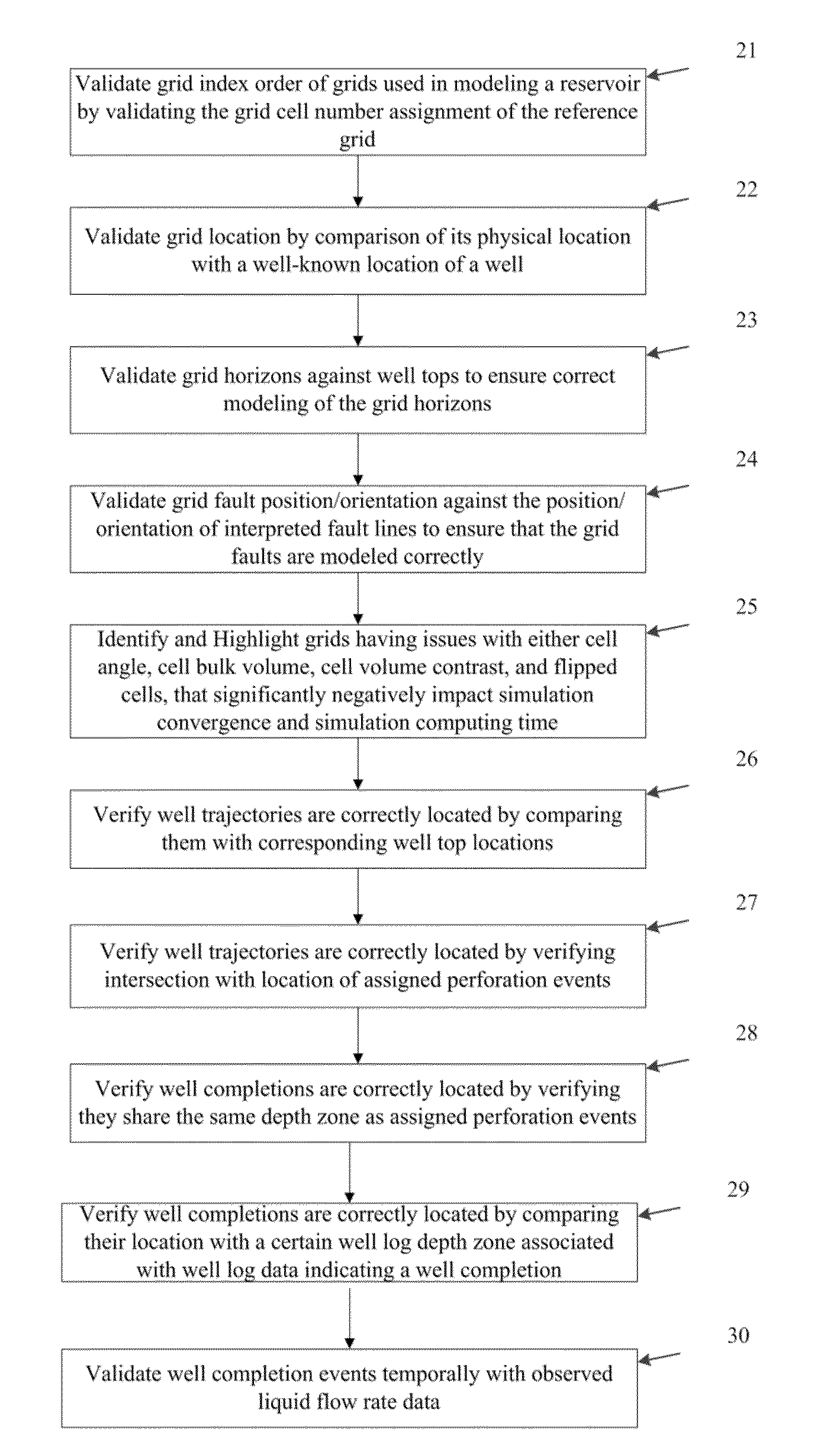

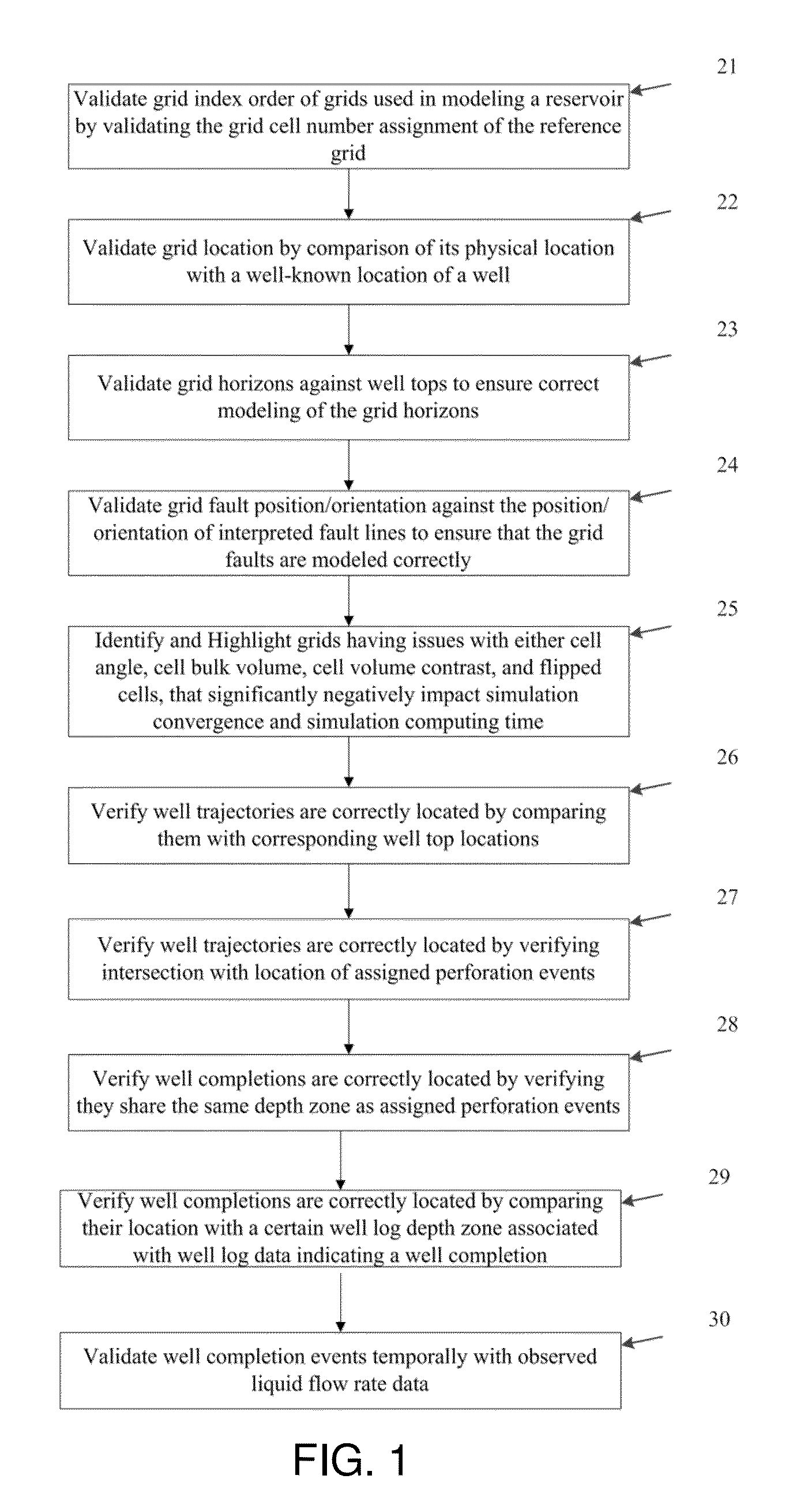

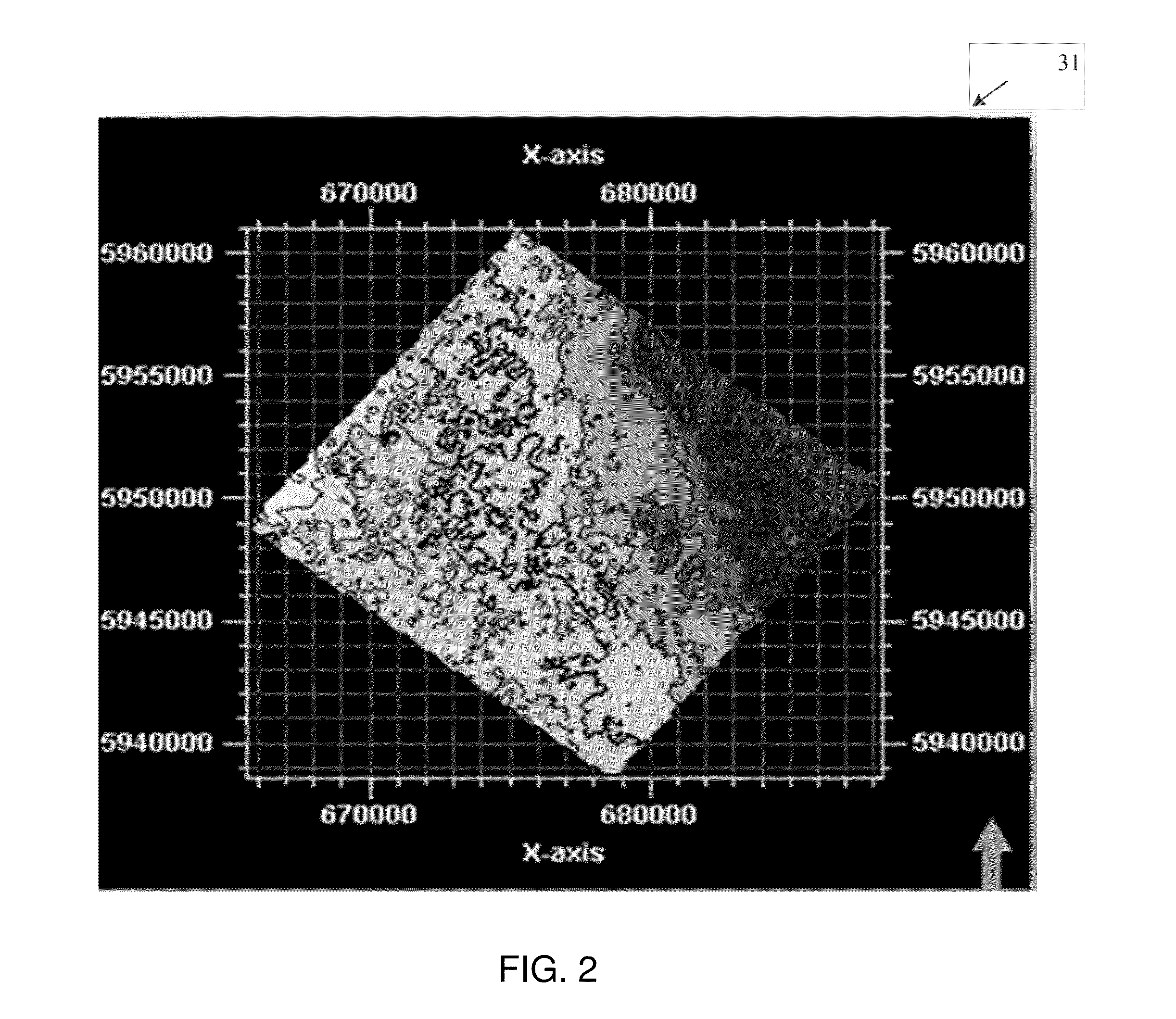

Computer-implemented methods for reservoir simulation with automated well completions and reservoir grid data quality assurance

ActiveUS20150185361A1Eliminate tedious manual non-formal effortReduce decreaseSeismic data acquisitionGeomodellingReservoir modellingData quality

Machine, computer readable medium, program code, and computer-implemented methods for performing a reservoir simulation with well completion and reservoir grid data quality assurance, are provided. An exemplary embodiment can include a data quality analyzing machine having memory containing data quality analyzing instructions configured to simulate a reservoir model with automated well completion and reservoir grid data quality assurance.

Owner:SAUDI ARABIAN OIL CO

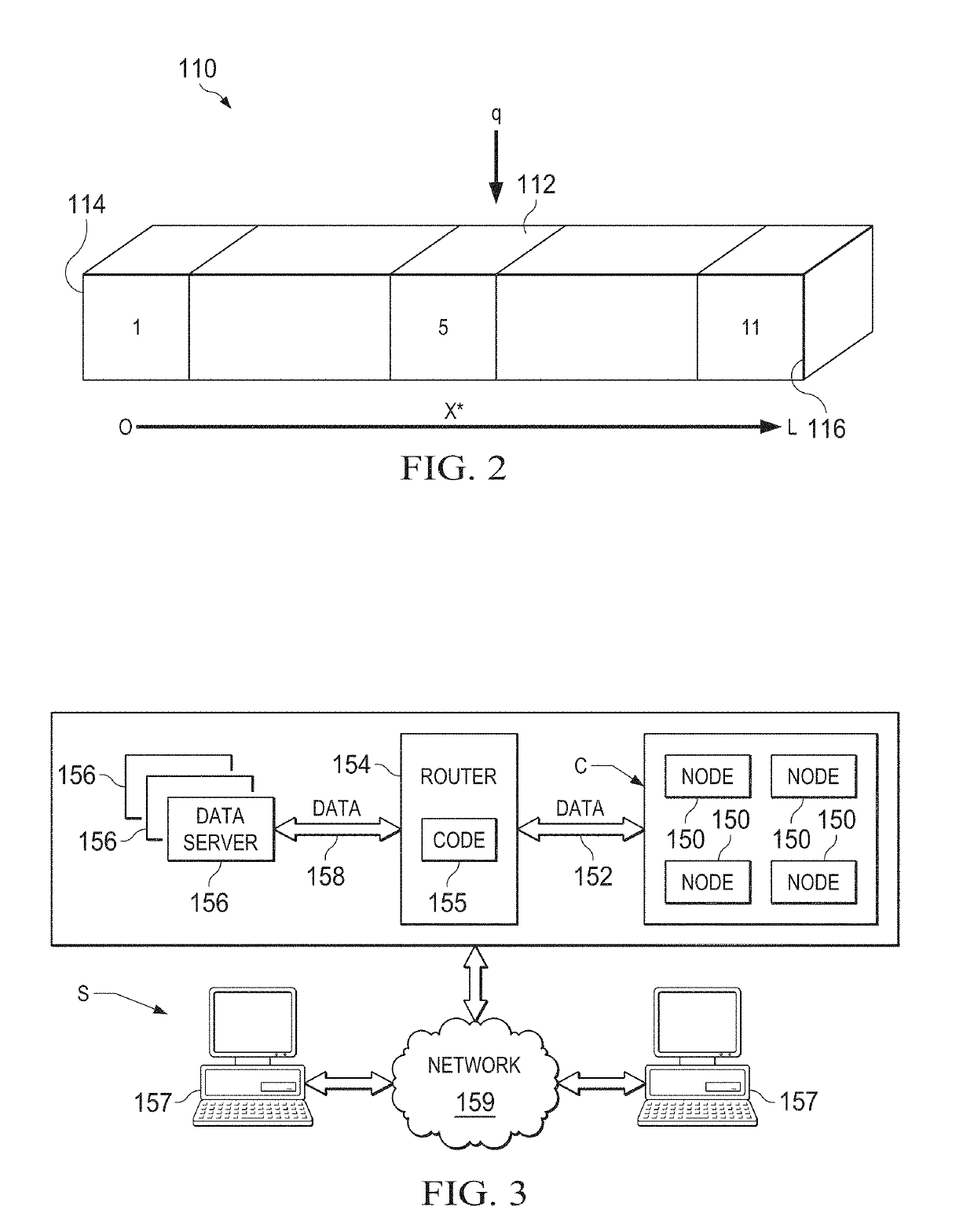

Determining pressure distribution in heterogeneous rock formations for reservoir simulation

ActiveUS20190330959A1Fast convergenceSurveyDesign optimisation/simulationPorosityRate of penetration

Computer system performance is improved during reservoir simulation runs where heterogeneous rock formations suffer from convergence problems. Convergence problems are affected by accurate determination of pressure distribution for reservoir simulation, which is very complex when properties or attributes of reservoir rock formations are heterogeneous. In heterogeneous reservoir rock formations, pressure distribution is affected over three dimensions by variations of rock permeability and porosity. The difficulty in convergence of the simulation runs results in increased computer operation and processing time and consequent computer usage costs. Improved determination of pressure distribution in heterogeneous rock formations permits acceptable initial pressure measures for pressure determination during reservoir simulation and to reduce convergence problems with existing reservoir simulation.

Owner:SAUDI ARABIAN OIL CO

Reservoir simulation unit and gas dissolution distribution evaluation device and method thereof

PendingCN113266345AFast heating rateExcellent temperature uniformityFluid removalFlue gasReservoir modelling

The invention discloses a reservoir simulation unit and a CO2 dissolution distribution evaluation device and method thereof, and belongs to the technical field of oilfield development. The reservoir simulation unit comprises a container capable of being closed; a partition communication component is arranged in the container and divides the container into a sand filling chamber and a bottom water chamber, and the sand filling chamber and the bottom water chamber are communicated through the partition communication component; the sand filling chamber is located on the upper portion of the bottom water chamber; and a plurality of injection and production openings are formed in the container wall, corresponding to the area where the sand filling chamber is located, of the container at different heights. The reservoir simulation unit and the CO2 dissolution distribution evaluation device and method thereof are suitable for CO2 gas injection dissolution evaluation and can effectively meet the experimental requirements for gas injection dissolution evaluation of N2, CO2+ N2 composite gas, flue gas and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com