Test simulating device for improving recovery rate of coal bed methane by injecting carbon dioxide

A carbon dioxide and coal bed methane technology, applied in the fields of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems in the exploration stage, on-site application, on-site promotion restrictions, and increased project investment risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

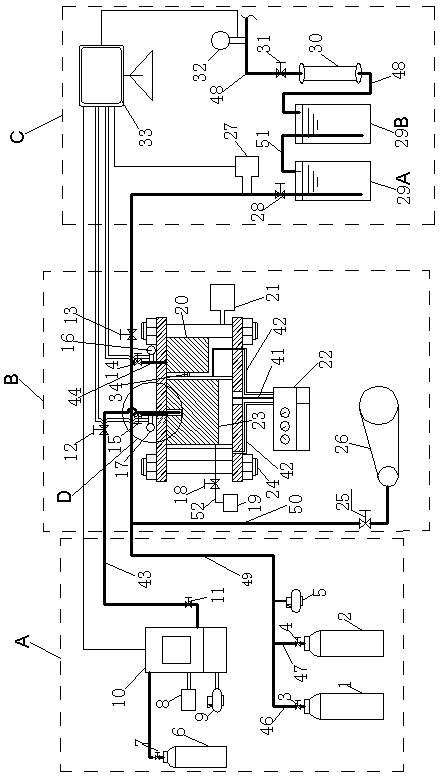

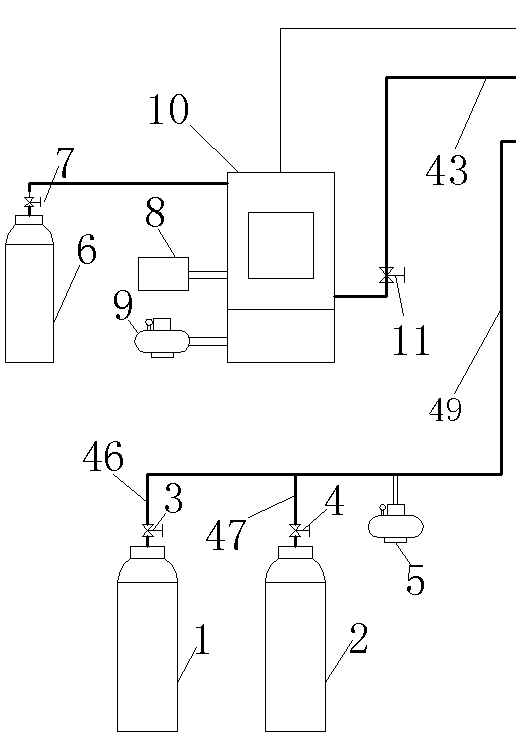

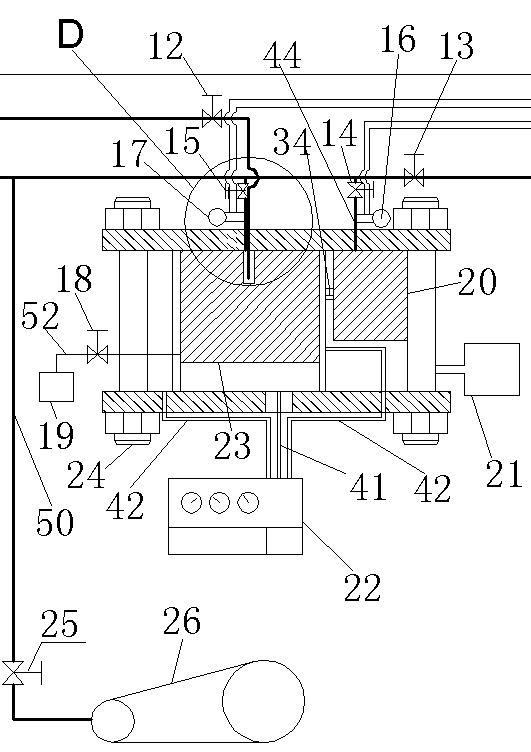

[0019] Figure 1 to Figure 5 The thicker lines in the middle show the fluid lines, and the thinner lines to the computer show the signal (control) lines.

[0020] Such as Figure 1 to Figure 5 As shown, the test simulation device of carbon dioxide injection to enhance coal bed methane recovery of the present invention includes the following systems and devices:

[0021] Coal reservoir simulation system for simulating coal reservoir pressure and temperature conditions;

[0022] A gas injection system for injecting methane gas or helium gas into the coal reservoir simulation system through the gas main pipe 49;

[0023] A fracturing simulation carbon dioxide injection system for injecting high-pressure liquid into the coal reservoir simulation system through the fracturing pipeline 43, enabling the coal reservoir simulation system to simulate the degree of fracture development, and injecting carbon dioxide into the coal reservoir simulation system;

[0024] A carbon dioxide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com