Low-cost environment-friendly surfactant and preparation method thereof

A surfactant and environment-friendly technology, applied in the field of low-cost environment-friendly surfactants and their preparation, can solve the problems of poor salt resistance, poor calcium and magnesium ion resistance, insufficient temperature resistance, etc., and achieve low cost and molecular weight. Low, low interfacial tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

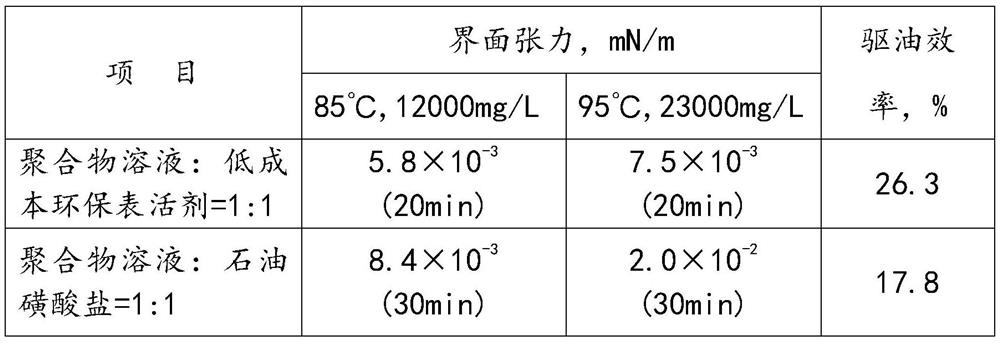

Embodiment 1

[0026] The embodiment of the present invention provides a kind of low-cost environment-friendly surfactant, wherein the material is made up of following components by weight: ricinoleamidopropyl betaine (effective content 98%) 100g, lauric acid diethanolamide (effective content 99%) %) 20g, dirhamnolipid (effective content 50%) 50g, tap water 180g.

[0027] Wherein the preparation method is as follows:

[0028] S1. Select ricinoleamidopropyl betaine and lauric acid diethanolamide according to the weight ratio and place them in a 500ml beaker and stir for 20-30min with a magnetic stirrer;

[0029] S2. After stirring evenly, add dirhamnolipids of equal weight ratio and continue stirring for 10 minutes;

[0030] S3. Finally, add tap water in an equal weight ratio and stir for 10-20 minutes to obtain the finished product.

[0031] Wherein the preparation method of ricinoleamidopropyl betaine is:

[0032] S1. Based on the total mass of 200g, measure 80g of castor oil and 105g of...

Embodiment 2

[0038] The embodiment of the present invention provides a kind of low-cost environment-friendly surfactant, wherein the material is made up of following components by weight: ricinoleamidopropyl betaine (effective content 98%) 100g, lauric acid diethanolamide (effective content 99%) %) 20g, dirhamnolipid (effective content 50%) 50g, tap water 180g.

[0039] Wherein the preparation method is as follows:

[0040] S1. Select ricinoleamidopropyl betaine and lauric acid diethanolamide according to the weight ratio and place them in a 500ml beaker and stir for 20-30min with a magnetic stirrer;

[0041] S2. After stirring evenly, add dirhamnolipids of equal weight ratio and continue stirring for 10 minutes;

[0042] S3. Finally, add tap water in an equal weight ratio and stir for 10-20 minutes to obtain the finished product.

[0043] Wherein the preparation method of ricinoleamidopropyl betaine is:

[0044]S1. Based on the total mass of 200g, measure 85g of castor oil and 100g of ...

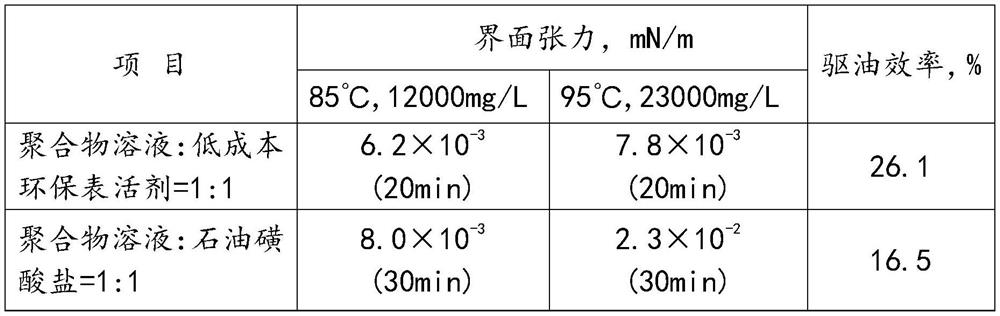

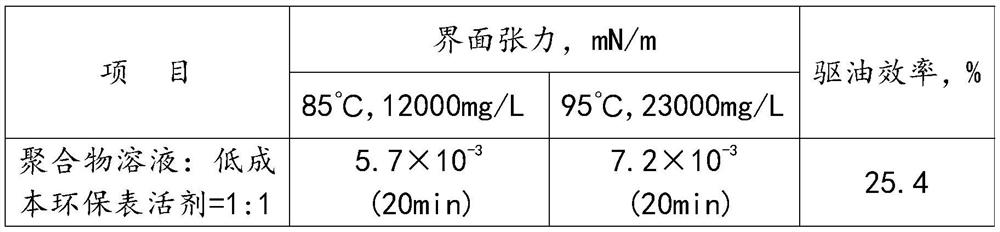

Embodiment 3

[0050] The embodiment of the present invention provides a kind of low-cost environment-friendly surfactant, wherein the material is made up of following components by weight: ricinoleamidopropyl betaine (effective content 98%) 100g, lauric acid diethanolamide (effective content 99%) %) 20g, dirhamnolipid (effective content 50%) 50g, tap water 180g.

[0051] Wherein the preparation method is as follows:

[0052] S1. Select ricinoleamidopropyl betaine and lauric acid diethanolamide according to the weight ratio and place them in a 500ml beaker and stir for 20-30min with a magnetic stirrer;

[0053] S2. After stirring evenly, add dirhamnolipids of equal weight ratio and continue stirring for 10 minutes;

[0054] S3. Finally, add tap water in an equal weight ratio and stir for 10-20 minutes to obtain the finished product.

[0055] Wherein the preparation method of ricinoleamidopropyl betaine is:

[0056] S1. Based on the total mass of 200g, measure 90g of castor oil and 95g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com