Low-temperature high-salt-resistant deep profile control and displacement crosslinking system as well as preparation method and application thereof

A technology of cross-linking system and flood control, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor stability, and achieve the effects of good stability, high blocking rate, and adjustable freezing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

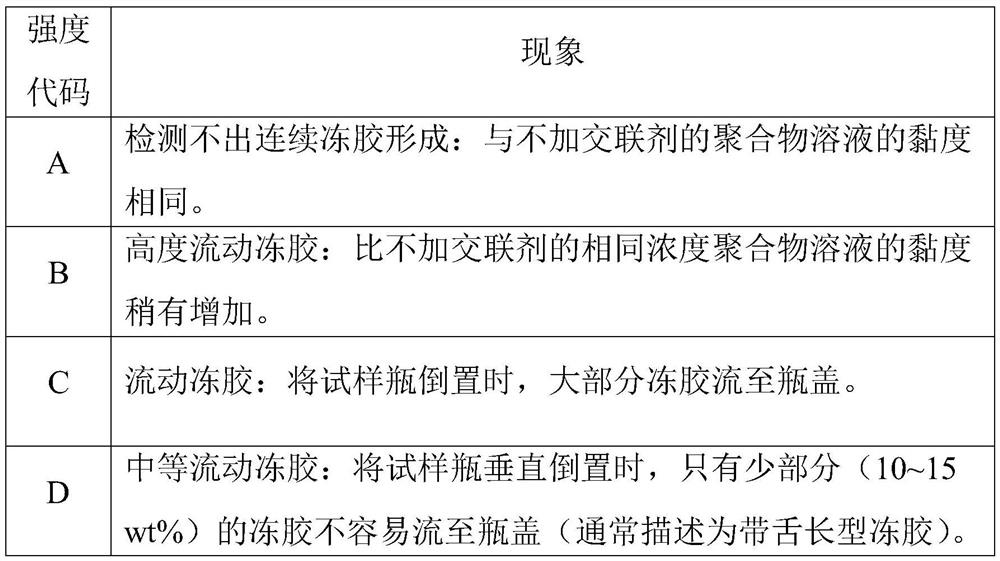

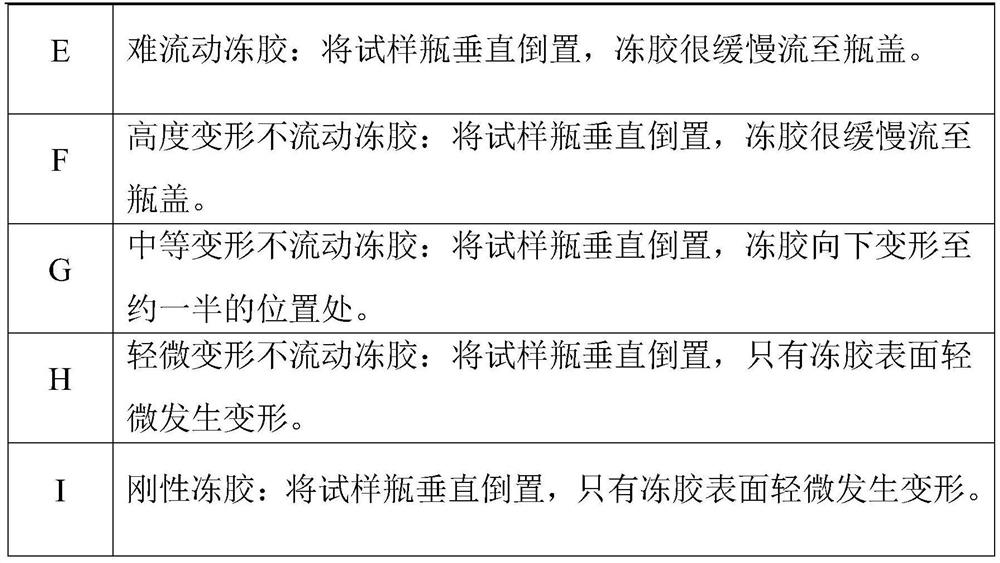

Image

Examples

Embodiment 1

[0031] A cross-linking system suitable for deep control and flooding of low-temperature and high-salt reservoirs, composed of: 0.30% polymer flocculant, 0.40% hexamethylenetetramine, 0.01% resorcinol, 0.10% small molecular organic acid , Water 99.19%. The mass of each component is: polymer flocculant 0.30g; hexamethylenetetramine 0.40g; resorcinol 0.01g; small molecule organic acid 0.10g; water 99.19g.

[0032] Its preparation method is as follows:

[0033] (1) Take 99.19 g of water and add 0.30 g of polymer flocculant to the water while stirring, and continue stirring for 2 to 3 hours to obtain a polymer flocculant solution;

[0034] (2) Then slowly add 0.40 g of hexamethylenetetramine, 0.01 g of resorcinol, and 0.10 g of small molecule organic acid while stirring, and continue stirring for 0.5 h to obtain a gelling solution of the crosslinking system;

[0035] (3) Put the gelling solution in multiple ampoules, sinter and seal it with an alcohol lamp, then place it in an oven...

Embodiment 2

[0041] A cross-linking system suitable for deep control and flooding of low-temperature and high-salt reservoirs, composed of: 0.40% polymer flocculant, 0.50% hexamethylenetetramine, 0.04% resorcinol, 0.15% small molecular organic acid , Water 98.91%. The mass of each component is: polymer flocculant 0.40g; hexamethylenetetramine 0.50g; resorcinol 0.04g; small molecule organic acid 0.15g; water 98.91g.

[0042] Its preparation method is as follows:

[0043] (1) Take 98.91 g of water and add 0.40 g of polymer flocculant to the water while stirring, and continue stirring for 2 to 3 hours to obtain a polymer flocculant solution;

[0044] (2) Then slowly add 0.50 g of hexamethylenetetramine, 0.04 g of resorcinol, and 0.15 g of small molecule organic acid while stirring, and continue stirring for 0.5 h to obtain a gelling solution of the cross-linking system;

[0045] (3) Put the gelling solution in multiple ampoules, sinter and seal it with an alcohol lamp, then place it in an o...

Embodiment 3

[0051] A cross-linking system suitable for deep control and flooding of low-temperature and high-salt reservoirs, composed of: 0.50% polymer flocculant, 0.60% hexamethylenetetramine, 0.05% resorcinol, 0.20% small molecular organic acid , Water 98.65%. The mass of each component is: polymer flocculant 0.50g; hexamethylenetetramine 0.60g; resorcinol 0.05g; small molecule organic acid 0.20g; water 98.65g.

[0052] Its preparation method is as follows:

[0053] (1) Take 98.65 g of water and add 0.50 g of polymer flocculant to the water while stirring, and continue stirring for 2 to 3 hours to obtain a polymer flocculant solution;

[0054] (2) Then slowly add 0.60 g of hexamethylenetetramine, 0.05 g of resorcinol, and 0.20 g of small molecule organic acid while stirring, and continue stirring for 0.5 h to obtain a gelling solution of the regulating and driving cross-linking system;

[0055] (3) Put the gelling solution in multiple ampoules, sinter and seal it with an alcohol lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com