Self-growing gel dispersion active fluidity control system and fluid channeling control method for hypotonic-tight reservoir

A jelly dispersion and compact reservoir technology, applied in chemical instruments and methods, mining fluids, earthwork drilling and mining, etc., can solve the problems of unstable product quality, weak flow control ability of polymer microspheres, and the impact of filling and plugging Problems such as fluid production capacity of fracture diversion reservoirs can be solved to improve the effect of enhanced oil recovery, increase the efficiency of crude oil displacement, and improve the effect of matrix oil production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

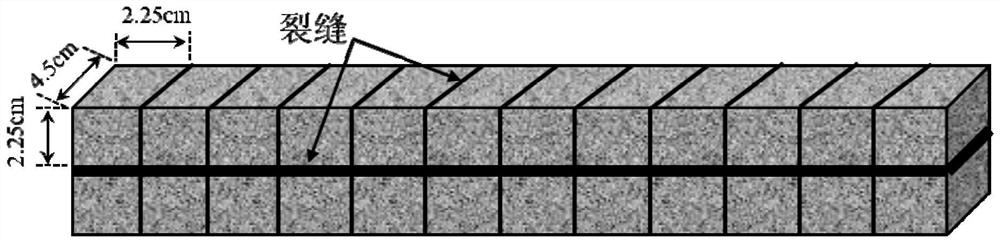

Examples

preparation example Construction

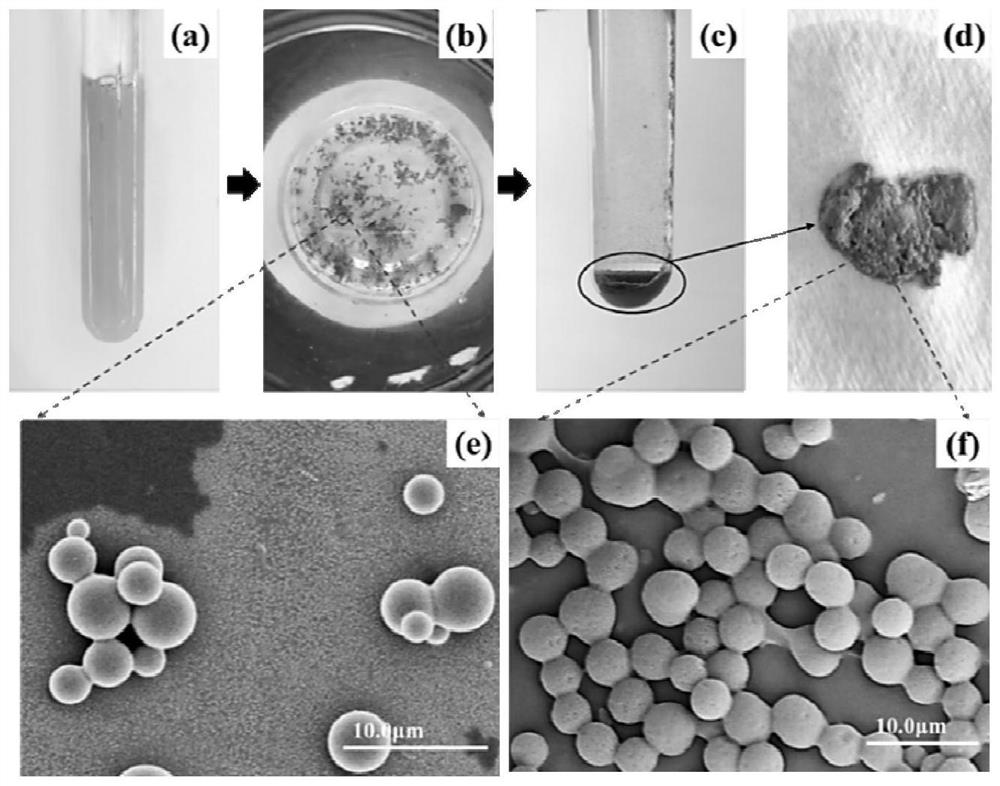

[0064] The preparation method of the nano-strengthened chromium-aldehyde double-group cross-linked integral jelly comprises the following steps: adding functional polymer, phenolic resin cross-linking agent, organic chromium cross-linking agent and nano-strengthening agent into water for mixing, and then curing.

[0065] In the present invention, the mobility control system has the function of self-growth, and the nano-strengthened chromium-aldehyde double-group cross-linked integral jelly can be sheared and ground into jelly dispersion particles by a colloid mill, and then the jelly dispersion particles can be prepared in water. Dilute into jelly dispersion particle suspension, add surfactant, and mix well before use. During use, the jelly dispersion particles prepared from nano-strengthened chromium-aldehyde double-group cross-linked monolithic jelly can control fluid mobility after self-growth in the fractures of low-permeability-tight reservoirs; Active agents can act as o...

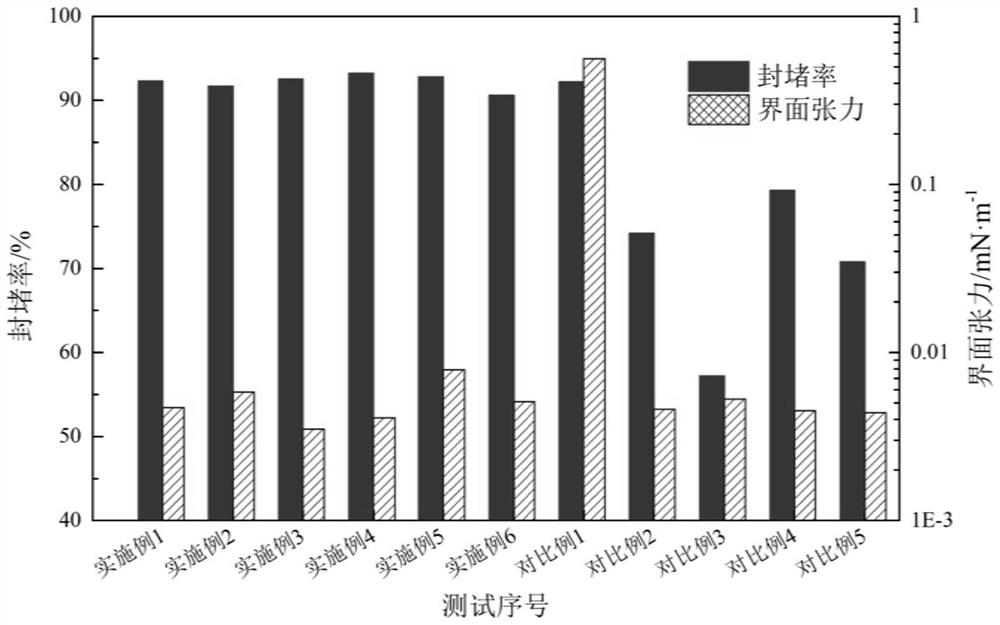

Embodiment 1

[0106] Active fluidity control system S1: containing 100 parts by weight of self-growing jelly dispersion and 0.35 parts by weight of surfactant;

[0107] Wherein, the self-growing jelly dispersion is prepared by shearing and grinding of nano-strengthened chromium-aldehyde double-group cross-linked integral jelly by a colloid mill. The preparation method of the nano-strengthened chromium-aldehyde double-group cross-linked integral jelly comprises the following steps: mixing acrylamide / vinyl sulfonate / acrylamide methyl propane sulfonate terpolymer (with a relative molecular mass of 5 ×10 6 ), phenolic resin precondensation polymer, chromium acetate and hydrophilic nano-silica (particle size: 20-30nm) were added to water and mixed well, and then aged at 90°C for 2h; with acrylamide / vinylsulfonate / propylene The total weight of amidomethyl propanesulfonate terpolymer, phenolic resin pre-condensation polymer, chromium acetate, hydrophilic nano-silica and water is 100%, the acrylam...

Embodiment 2

[0110] Active fluidity control system S2: containing 100 parts by weight of self-growing jelly dispersion and 0.35 parts by weight of surfactant;

[0111] Wherein, the self-growing jelly dispersion is prepared by shearing and grinding of nano-strengthened chromium-aldehyde double-group cross-linked integral jelly by a colloid mill. The preparation method of the nano-strengthened chromium-aldehyde double-group cross-linked integral jelly comprises the following steps: mixing acrylamide / vinyl sulfonate / acrylamide methyl propane sulfonate terpolymer (with a relative molecular mass of 5 ×10 6 ), phenolic resin precondensation polymer, chromium acetate and hydrophilic nano-silica (particle size: 20-30nm) were added to water and mixed well, and then aged at 90°C for 2h; with acrylamide / vinylsulfonate / propylene The total weight of amidomethyl propanesulfonate terpolymer, phenolic resin pre-condensation polymer, chromium acetate, hydrophilic nano-silica and water is 100%, the acrylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com