Discrete element analysis method for propagation and damage of coating crack in cutting process of coated cutting tool

A technology of crack propagation and cutting process, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of reducing the number of units, the amount of calculation and the calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

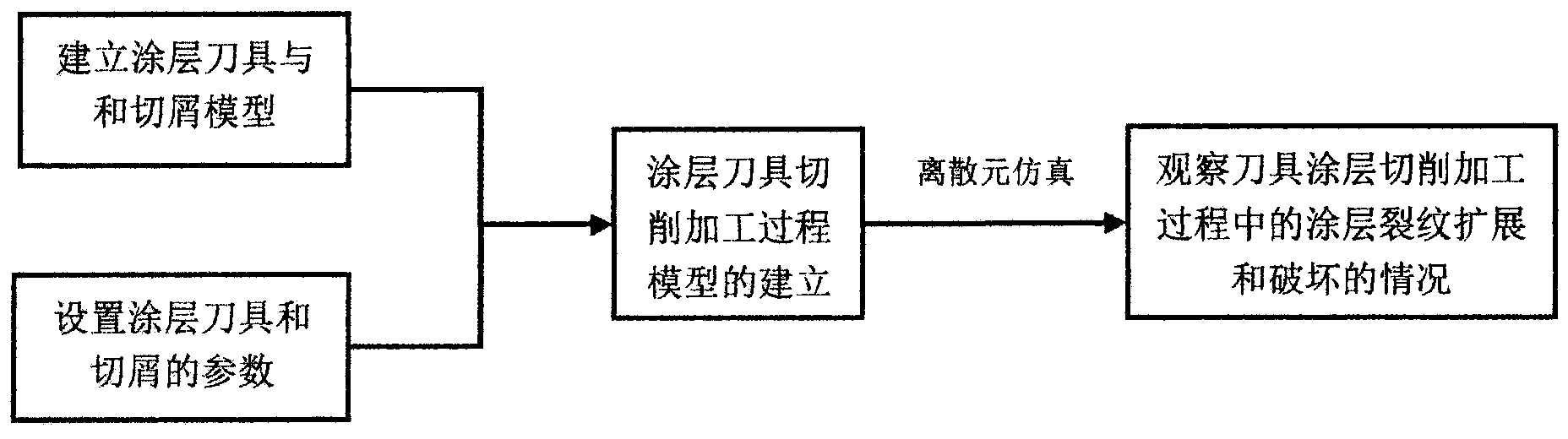

[0028] A discrete element analysis method for coating crack growth and damage during the cutting process of a coated tool, including: 1 establishment of a discrete element model for the coated tool and chip; 2 setting of the microscopic parameters of the coated tool and chip; 3 coating tool The establishment of the discrete element model of the cutting process; 4. Apply the established discrete element model to simulate and observe the crack growth and damage of the coating during the cutting process of the tool coating.

[0029] The discrete element analysis method of the present invention is as figure 1 shown.

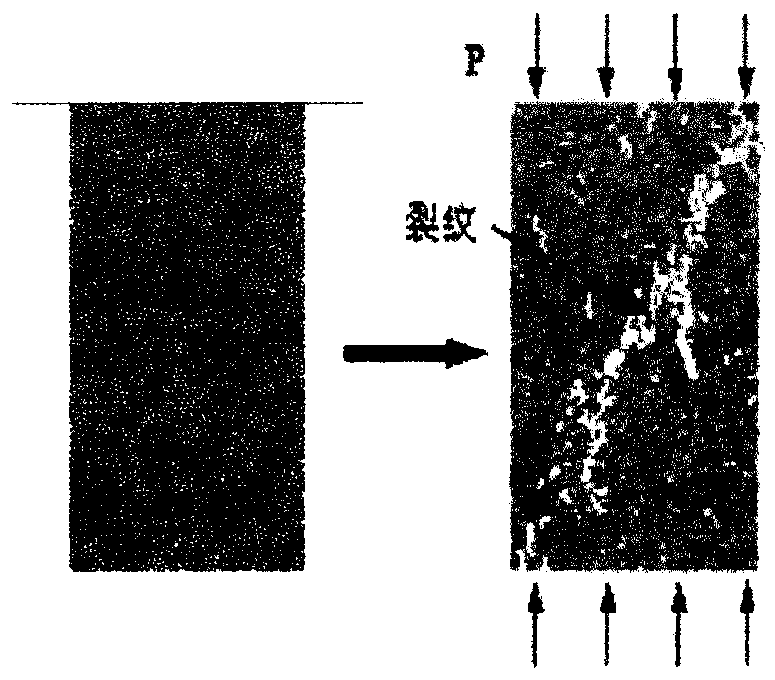

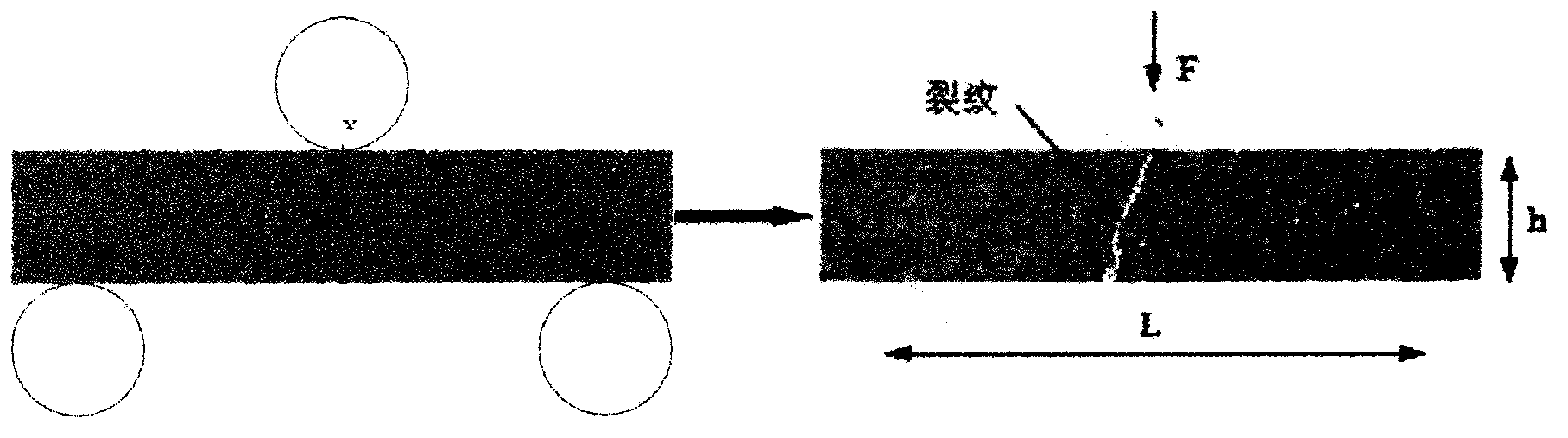

[0030] 1. Establishment of discrete element model of coated tool and chips;

[0031] When using PFC2D software to generate a discrete element model, it usually includes the following three steps:

[0032] 1) In the specified area, by giving porosity, particle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com