Grinding wheel discrete element modeling method with consideration of abrasive particle shape and distribution randomness

A modeling method and random technology, applied in the research field of modeling method of grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the drawings.

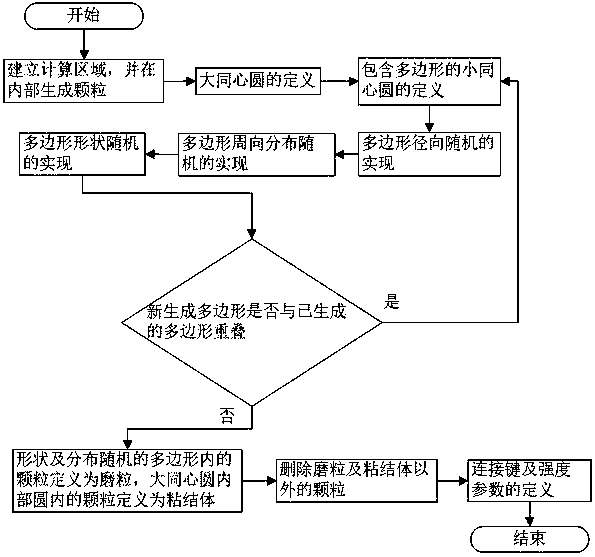

[0065] A discrete element modeling method for grinding wheels considering the shape of abrasive grains and the randomness of their distribution is characterized in that the steps are as follows:

[0066] (1) Establish a square boundary and use it as a calculation area to generate tightly arranged particles inside.

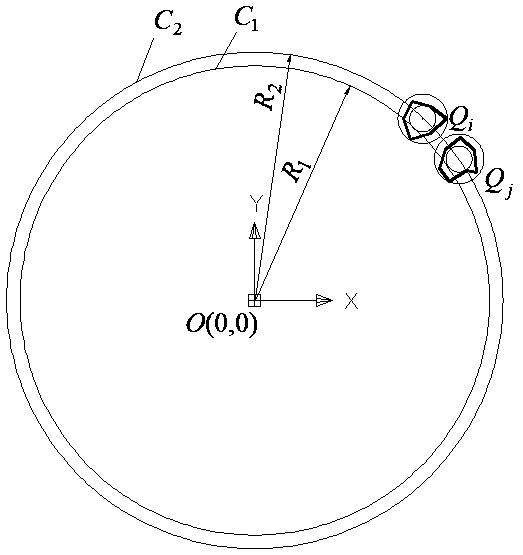

[0067] (2) Define two large concentric circles in the center of the square area, and the inner circle is recorded as C 1 , The outer circle is recorded as C 2 To round C 1 As the contour of the bonded body of the grinding wheel, the polygon that characterizes the contour of the abrasive grain is denoted as Q i , Distributed in the circle C 1 And circle C 2 The area between.

[0068] (3) Polygons representing the contours of abrasive particles Q i Realization of the randomness of radial distribution: define two small concentric circles containing a polygon, and the inner circle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com