Visual uniaxial penetrating test-based bituminous mixture homogeneity evaluation method

An asphalt mixture, uniaxial penetration technology, applied in the analysis of materials, material analysis using radiation, material analysis using wave/particle radiation, etc., can solve the problem of unscientific selection and determination of uniformity index parameters, asphalt mixture Difficult to obtain, difficult to determine the uniformity of asphalt mixture, etc., to achieve the effect of representative selection of uniformity parameters, strong industrial practicability and operability, and scientific selection of uniformity parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention provides a virtual penetration test asphalt mixture homogeneity evaluation method based on discrete element simulation, combined with the accompanying drawings, the specific implementation steps are as follows:

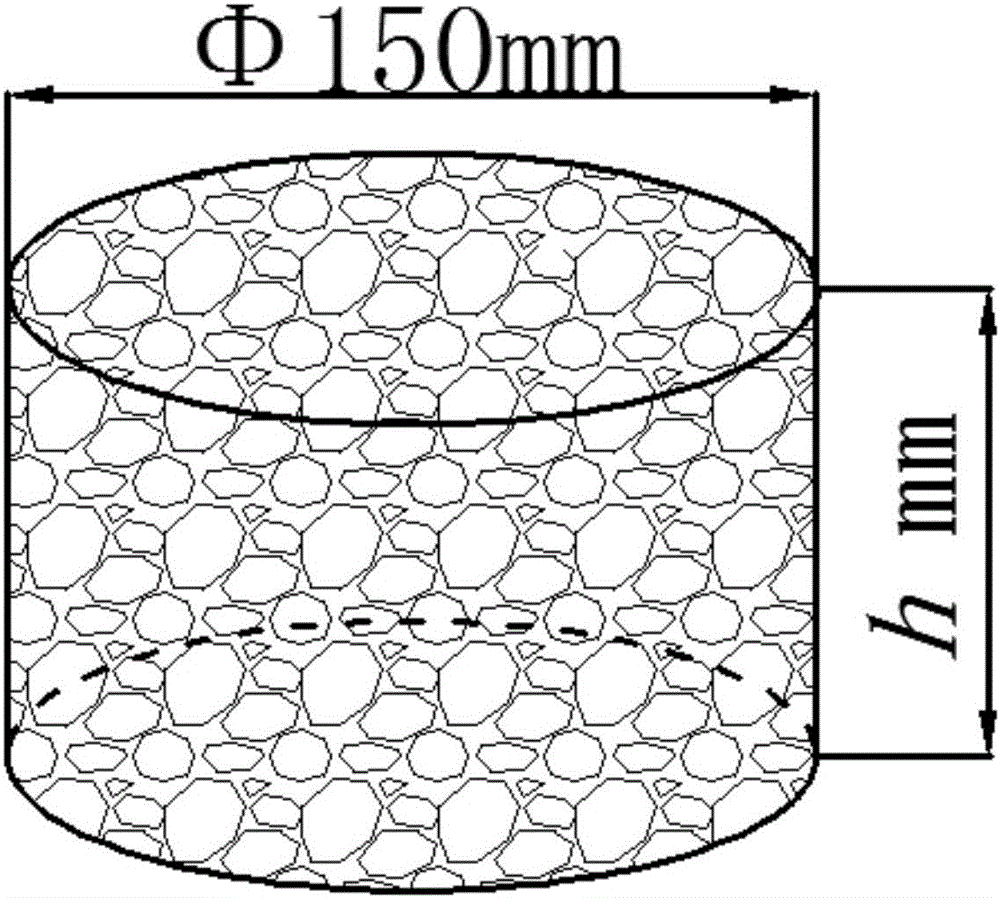

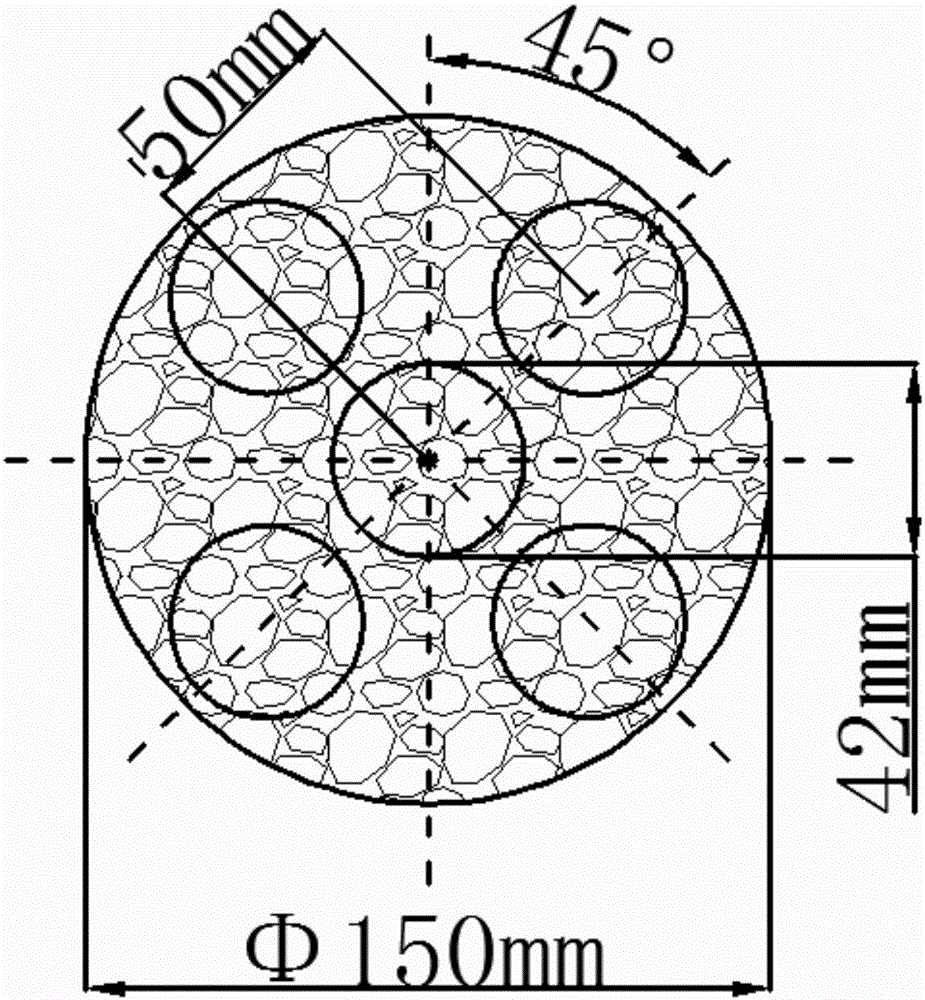

[0035] (1) Indoor molding or on-site drilling of cylindrical core samples to provide cylindrical asphalt mixture specimens required for analysis, with a diameter of Φ150mm and a height of hmm (due to the differences in the thickness of each structural layer of the asphalt pavement, on-site drilling The height of the test piece cannot be guaranteed to be consistent, so the variable h is used to uniformly represent the height of the test piece), such as figure 1 shown. Refer to "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" T0736-2011, and use a rotary compactor (SGC) to form Φ150mm cylindrical asphalt mixture specimens indoors, or refer to "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering"...

Embodiment 2

[0056] Using the quantitative evaluation method of asphalt mixture uniformity of the applicant's invention title "a method for evaluating the uniformity of asphalt mixture" with the application number "CN201310542528.7", the uniformity of asphalt mixture specimens with different gradations is calculated, and the asphalt mixture The material gradation type is AK13, AC16(A), AC16(B), AC16(C), and its gradation composition is shown in Table 2:

[0057] Table 2 Gradation Composition

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com