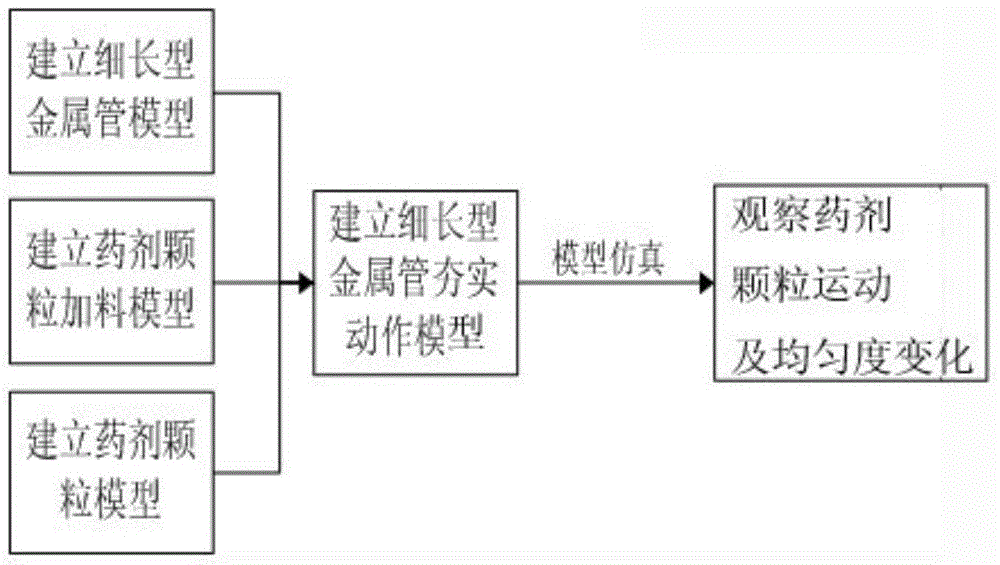

Method for establishing multi-scale model of medicament particles during powder compaction process of long thin metal pipe

A technology of model building and metal tubes, which is applied in the fields of instruments, calculations, and electrical digital data processing, can solve the problems of low production efficiency, multi-scale modeling of pharmaceutical particles, high labor intensity, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

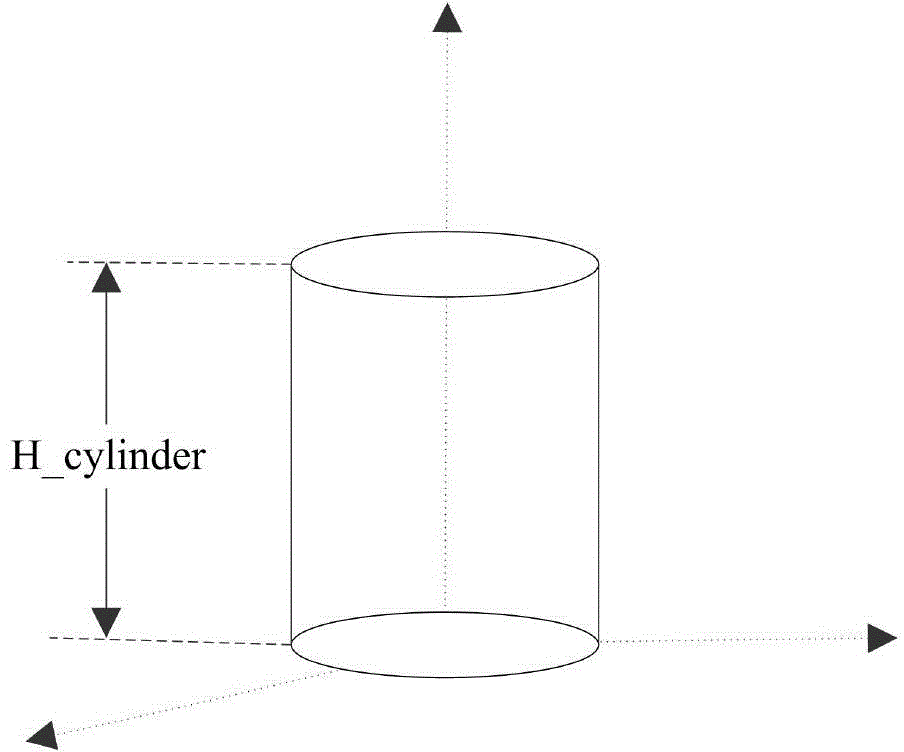

[0114] Step 1: Establishment of the slender metal tube model

[0115] Establish a hollow cylindrical wall to simulate a slender metal pipe, set the effective side of the cylindrical wall to point to the inner wall of the cylindrical wall, and the ID number of the inner wall is 1; establish a bottom wall at the bottom of the cylindrical wall The plug is simulated, and the effective side of the bottom wall is set as the upper surface, and the ID number of the upper surface wall is 2; the slender metal tube is easy to deform, so its stiffness setting order of magnitude is lower than that of the ground infinite plane. A slender metal tube model such as image 3 As shown, its specific parameters are as follows:

[0116] The height of the cylindrical wall is H_cylinder=0.5m;

[0117] The radius of the bottom surface of the cylindrical wall is rad=0.05m;

[0118] Step 2: Establishment of drug particle feeding model

[0119] Establish a funnel-shaped wall to simulate the feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com