Construction method for two-dimensional discrete element model of mother rock and particle material thereof

A two-dimensional discrete, construction method technology, applied in CAD numerical modeling, special data processing applications, instruments, etc., can solve problems such as large funds and manpower investment, achieve good detailed characteristics and good simulation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

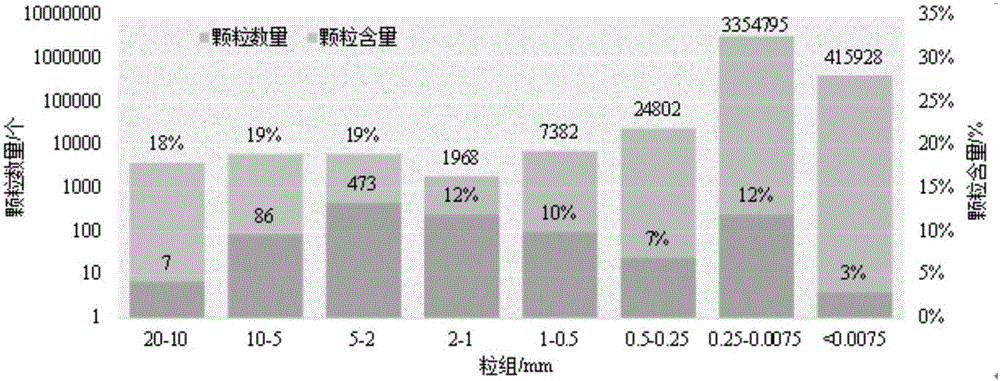

[0047] The concept of "fine particles" in the present invention is different from concepts such as "fine particle soil" or "fine particle sandstone" in geotechnical tests. It is a relative concept, and the object it describes is: when using particle flow software (PFC 2D ) in the process of modeling or calculation, the part of particles in the sample that has "small particle size, low total mass content, but a large number of total particles".

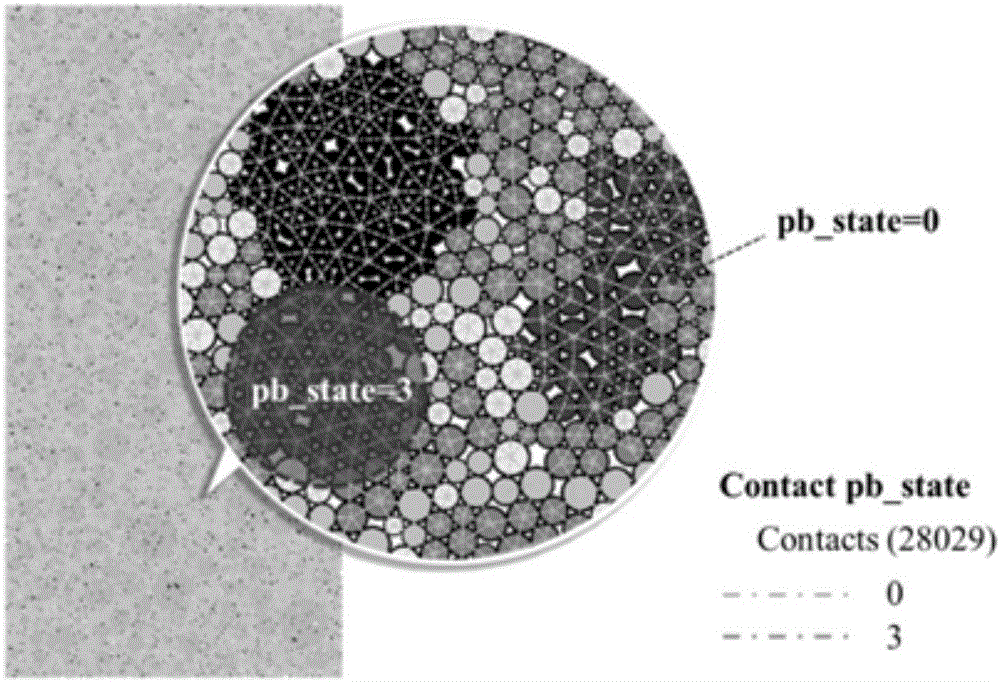

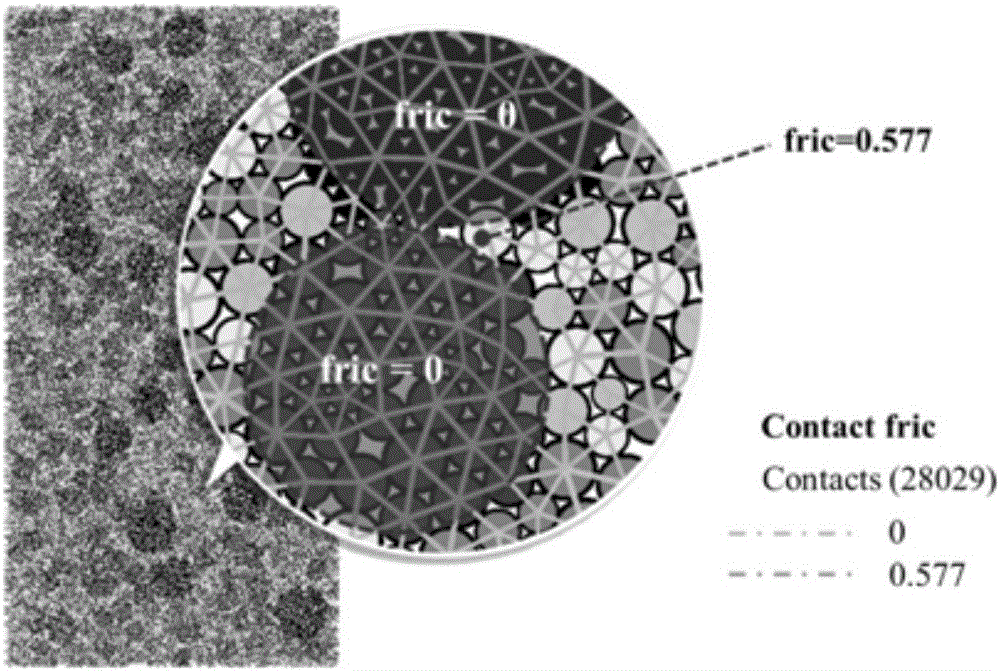

[0048] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com