Metallic transfer printing film

A transfer film and metal technology, applied in the direction of metal layered products, printing, copying/marking methods, etc., can solve problems such as shedding, inconvenient use, PVC toxicity, etc., and achieve the effect of simple steps and excellent convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the features of the present invention, the following preferred embodiment will be described with reference to the accompanying drawings.

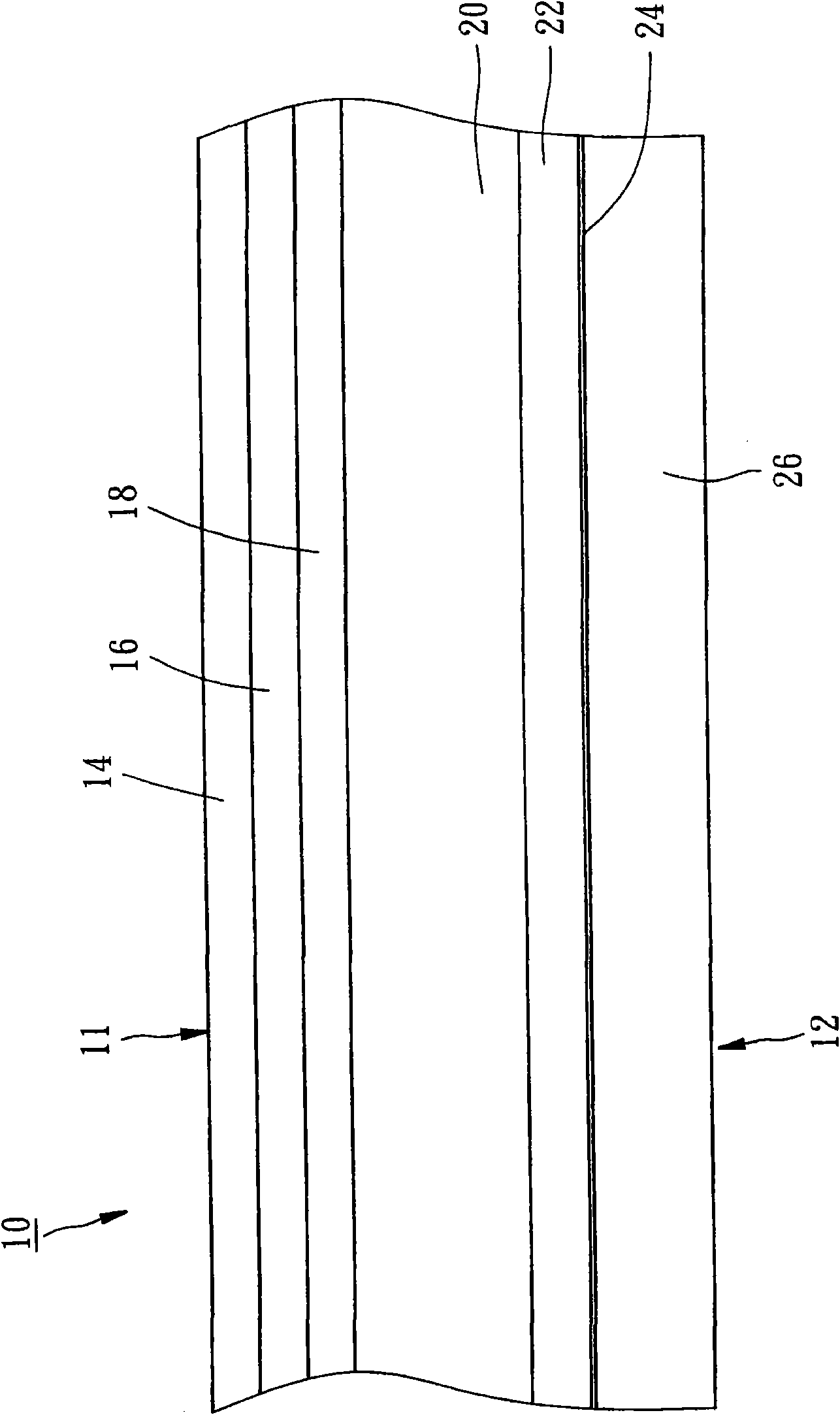

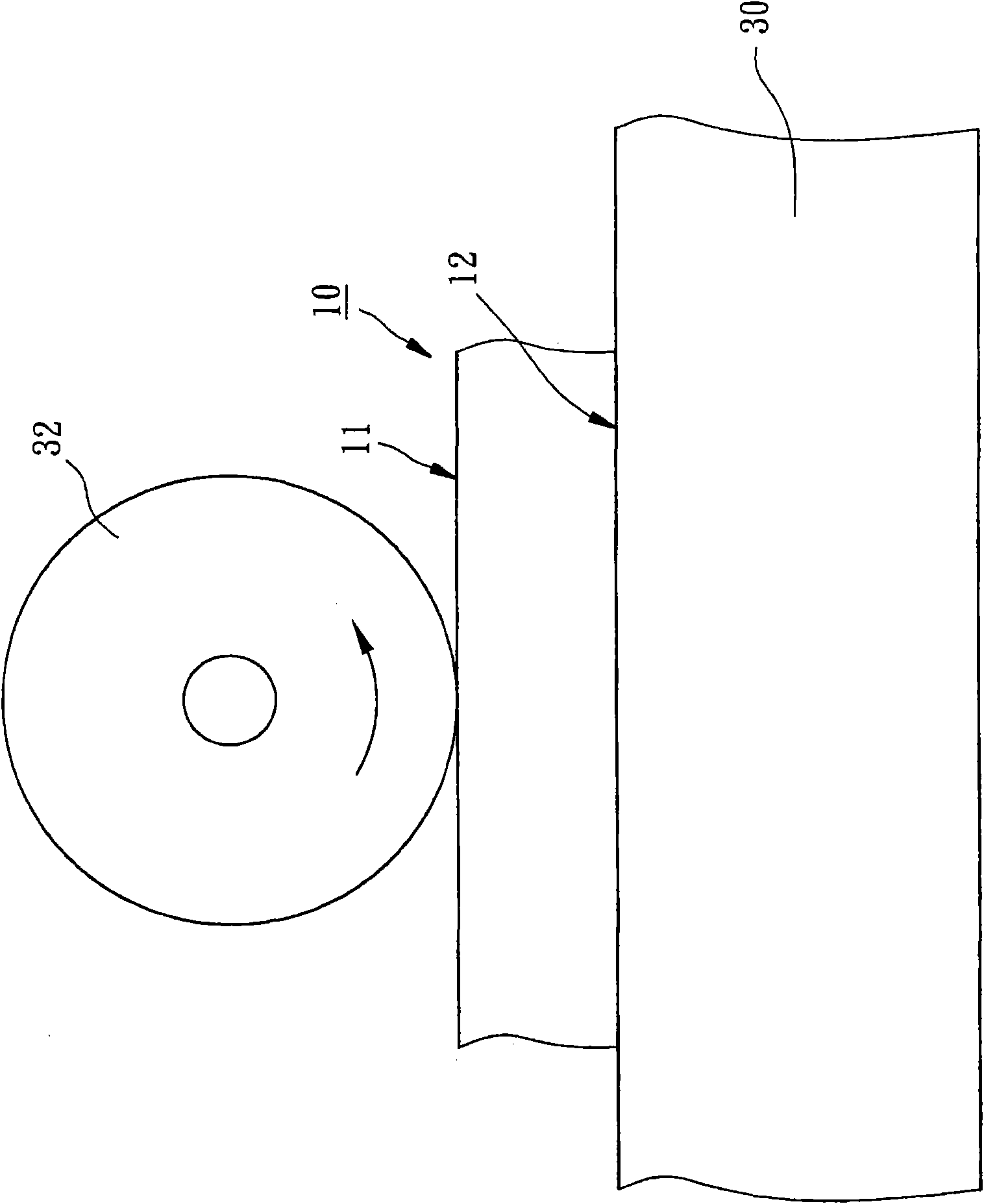

[0041] see figure 2 , the metal transfer film 10 provided by a preferred embodiment of the present invention has a first side 11 and a second side 12, from the first side 11 to the second side 12 sequentially includes an anti-adhesion layer 14 , a PET layer 16 , a release layer 18 , a protective layer 20 , a resin layer 22 , a metal layer 24 and an adhesive layer 26 .

[0042] Wherein, PET is the abbreviation of polyethylene terephthalate (Poly(ethylene terephthalate)). Since the PET layer 16 has good toughness, it is used as the base material of the metal transfer film 10 in this embodiment, and the remaining layers are respectively overlaid on them.

[0043] The release layer 18 is made of acrylic resin or fiber bundle resin, and its function is to make the protection layer 20 easy to separate from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com