Anti-shear fatigue double-layer asphalt mixture grading and optimizing method based on virtual repeated penetration test

A technology of asphalt mixture and penetration test, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of poor comprehensiveness, inability to optimize the gradation of asphalt mixture, and relying on indoor test methods, etc. The effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below according to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0030] A method for optimizing the gradation of double-layer asphalt mixtures resistant to shear fatigue based on virtual repeated penetration tests, the method specifically includes the following steps:

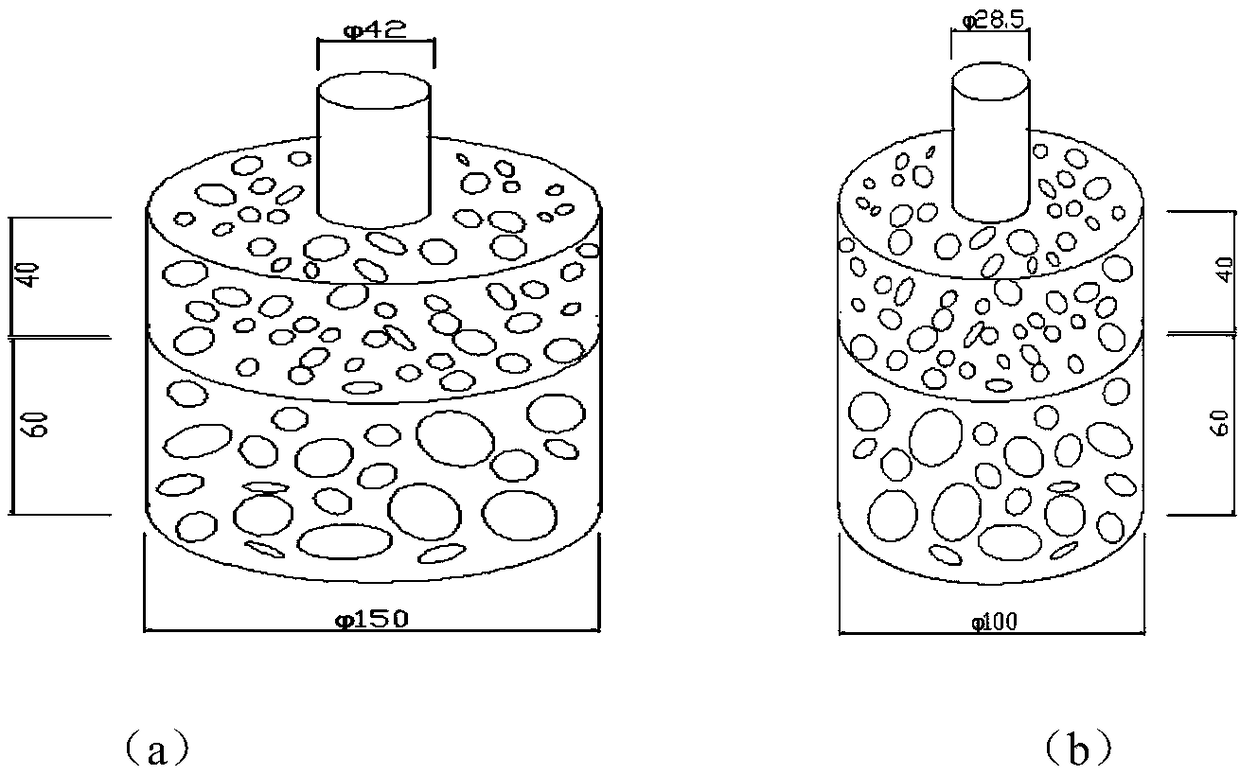

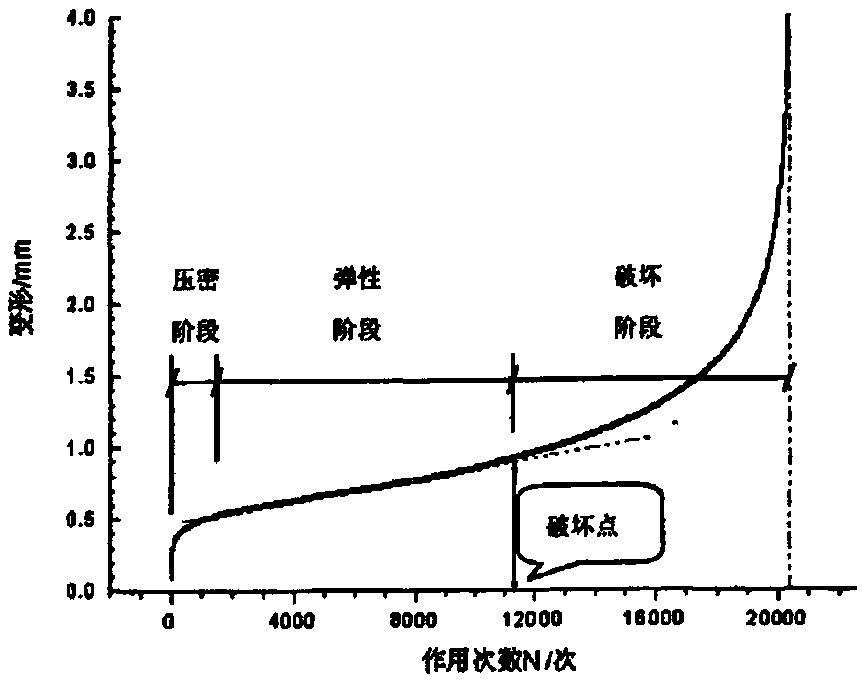

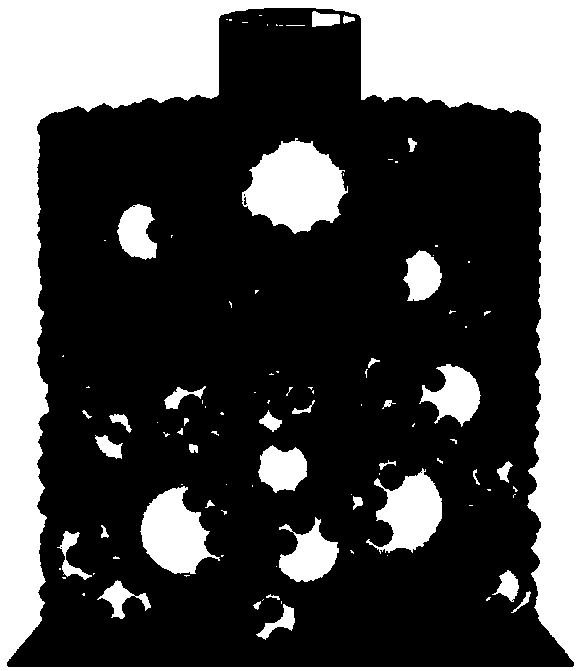

[0031] S1: First, the uniaxial creep compression test of asphalt mortar is carried out to obtain the viscoelastic parameters of asphalt mortar at 30°C in the contact model, as shown in Table 1; The penetration test is used to determine the failure times N of the asphalt mixture under repeated penetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com