Method for assembling forming of cockpit glass and cockpit special-shaped opening frame of aircraft

A cockpit and glass technology, which is applied in the field of assembling and forming of special-shaped cockpit hatch frames, can solve the problems affecting the reliability and service life of cockpit glass, the inability to guarantee the sealing of the cockpit, and the existence of assembly stress, and achieve strong convenience. and practicality, improving production efficiency, and the effect of production process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

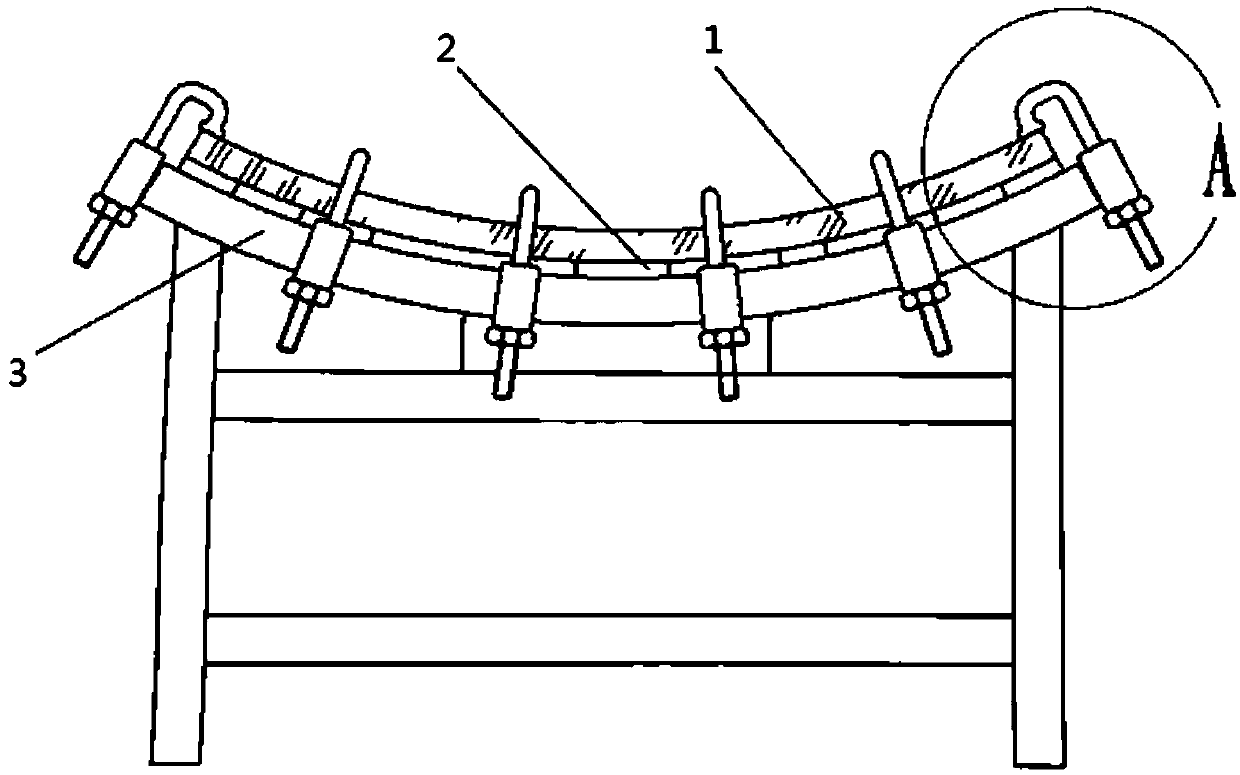

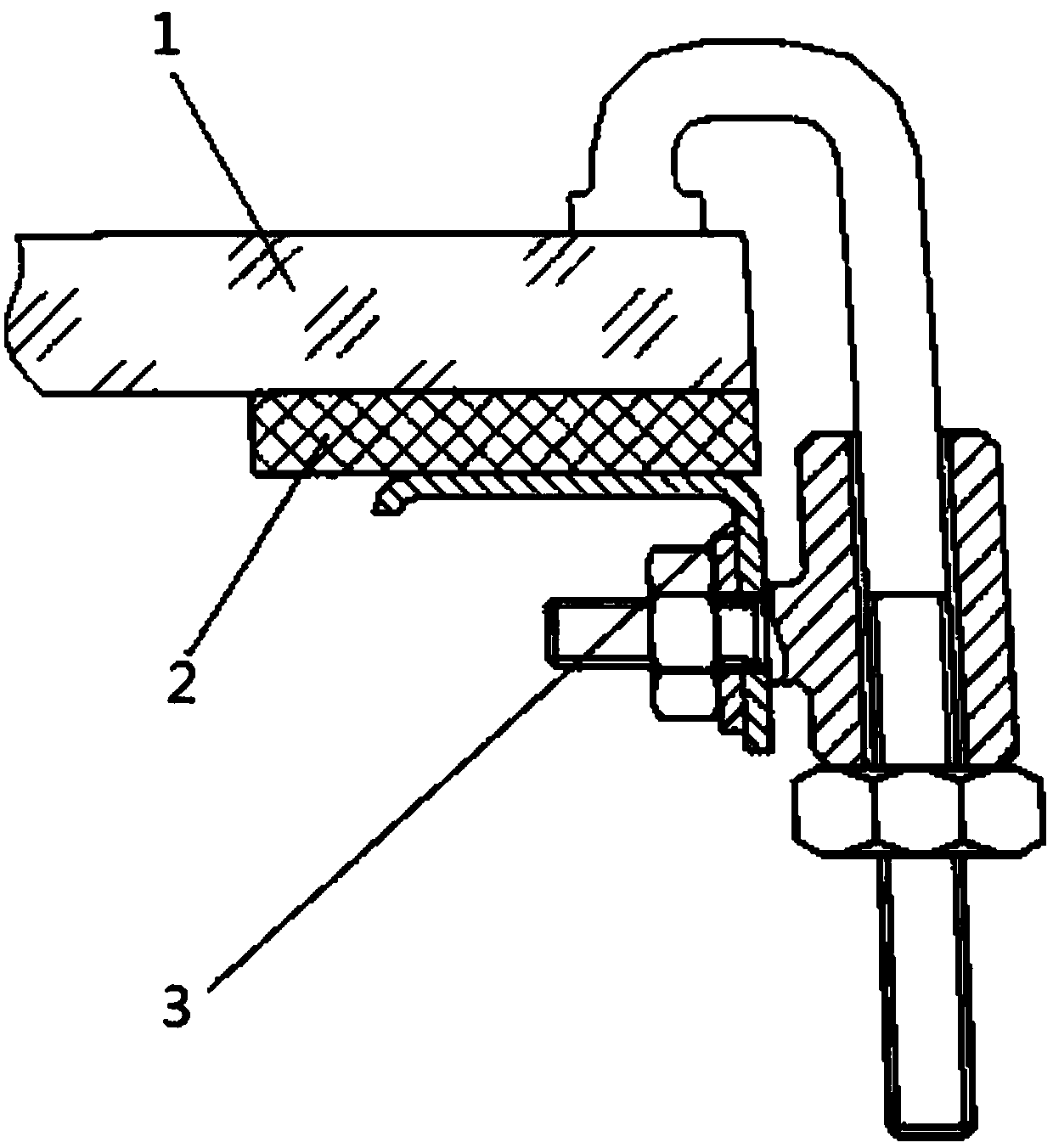

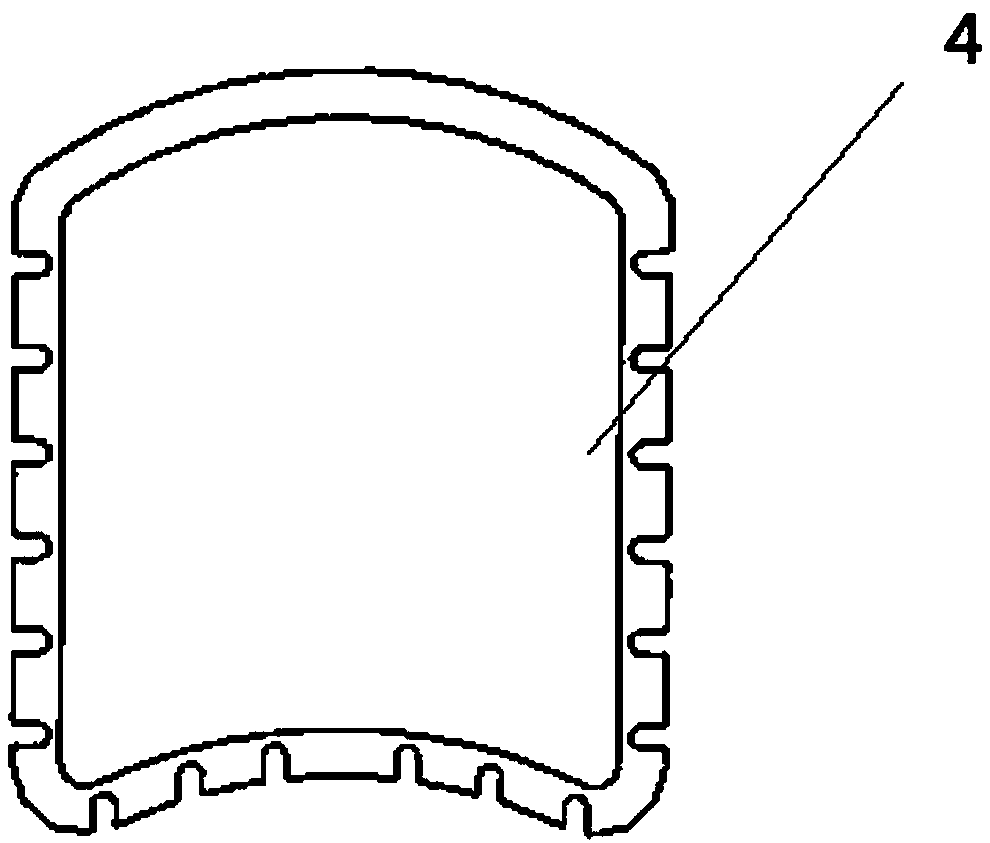

[0052] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

[0053] The present invention is based on aviation plexiglass heating and tempering batch molding technology, through the statistics, analysis and summary of the deformation of the cockpit hatch frame during the aircraft overhaul process, and the requirements for glass "personalized" molding tooling, process methods and process control At the same time, it also fully demonstrated the optimization and adjustment of the synergistic process flow, and determined and proposed the cockpit glass manufacturing assembly molding control technology in the process of aircraft overhaul.

[0054] Among them, the "personalized" assembly molding process method: according to the actual shape and size of the cockpit hatch frame of a single aircraft, during the molding process of the cockpit glass, gaskets of different specifications and sizes are laid on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com