Seat waist support and automobile seat with same

A lumbar support and seat technology, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problem that the lumbar support structure cannot be adjusted in height, inclination angle, etc., and achieve a reasonable design of the lumbar support structure and improve comfort. performance, easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described below in conjunction with embodiments and drawings.

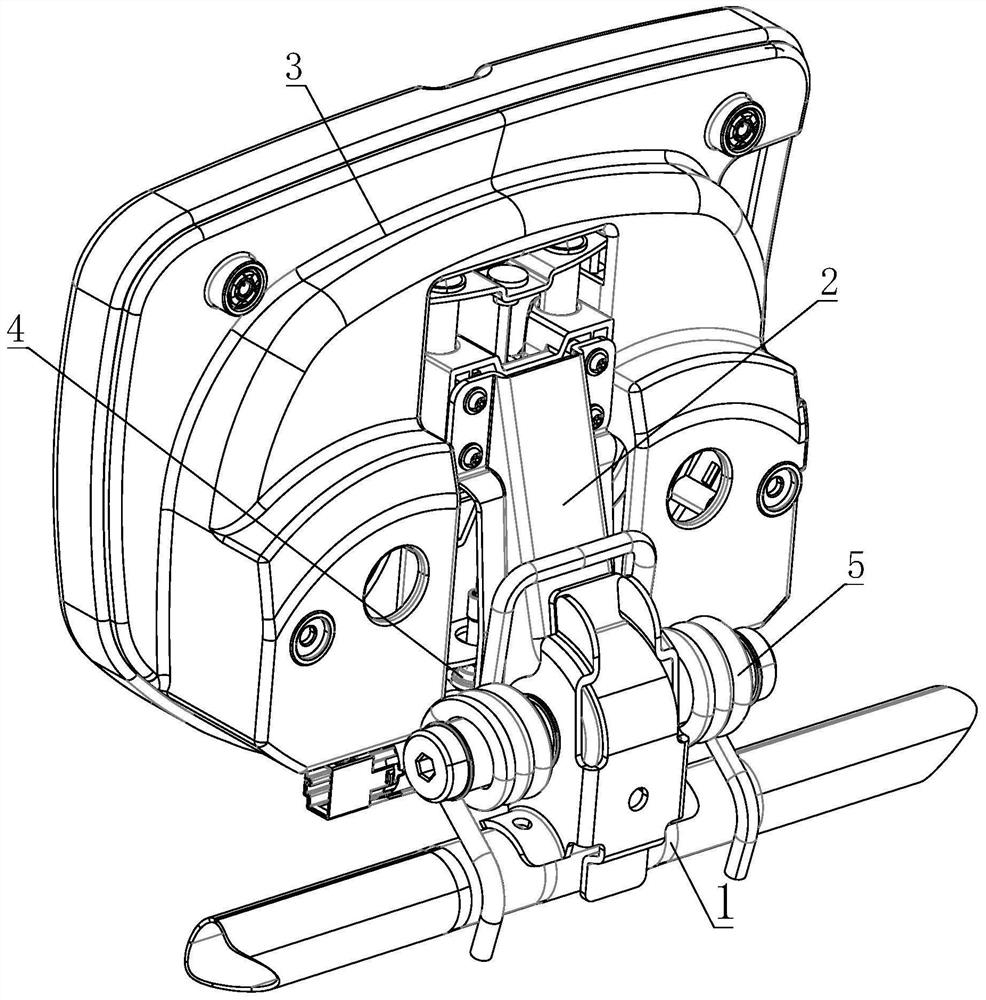

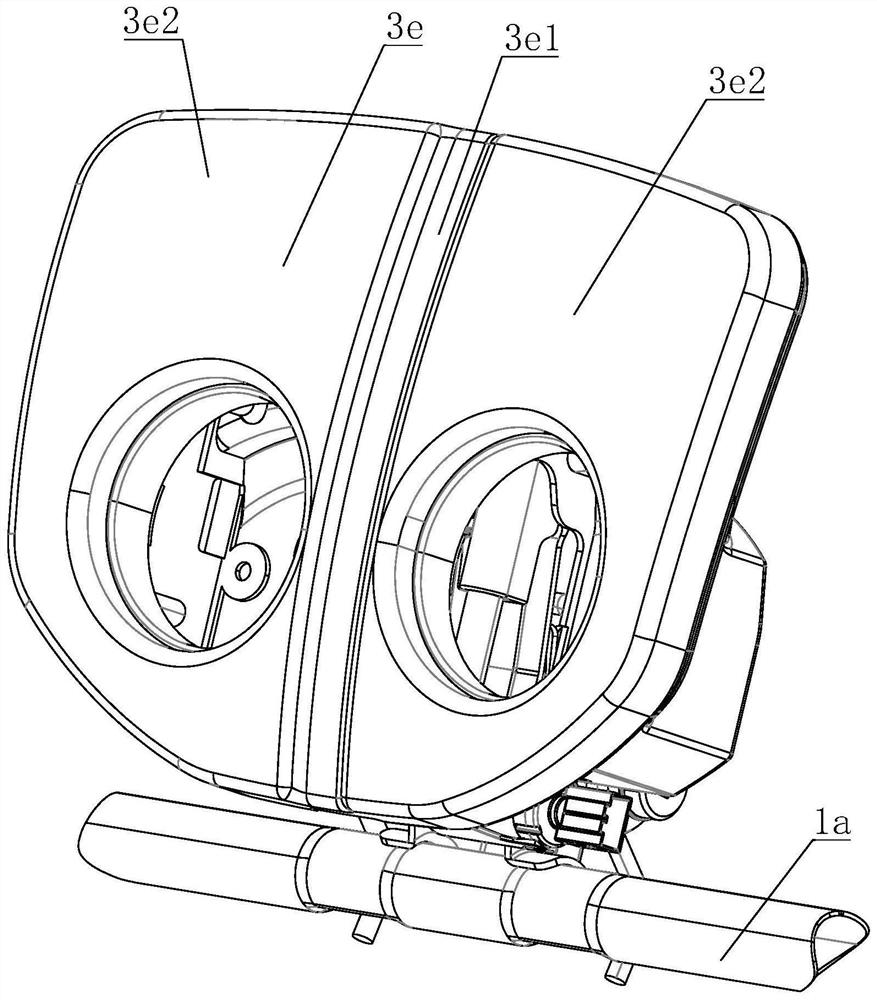

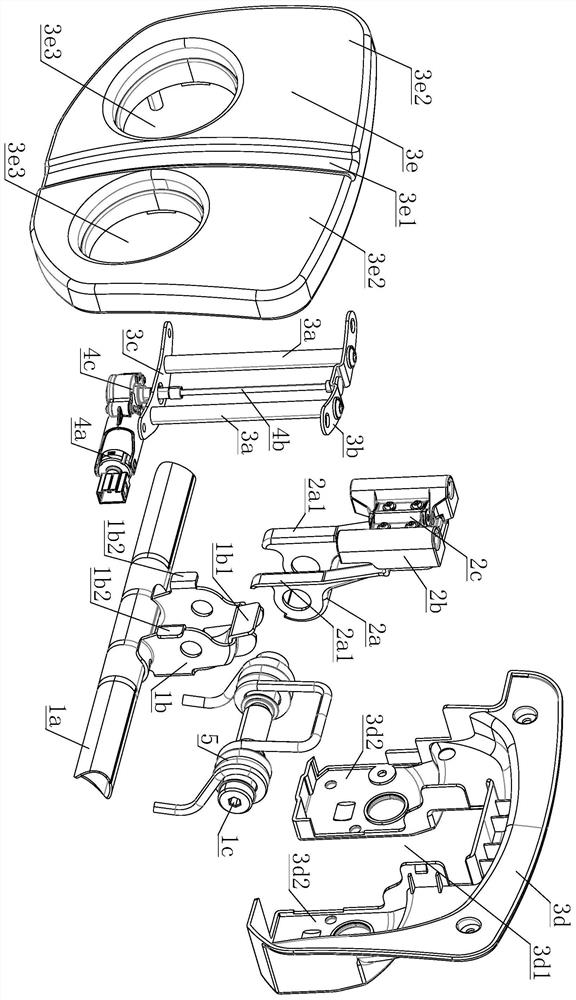

[0034]Such asFigure 1 to 3As shown, a seat lumbar support, the main components involved in the lumbar support include: a connecting component 1, a seat body component 2, a waist support component 3, a driving mechanism 4 and an elastic element 5. The further assembly relationship of these five components is : The base assembly 2 is rotatably assembled on the connecting assembly 1. The lumbar support assembly 3 is mounted on the base assembly 2 in a liftable manner. The driving mechanism 4 is arranged between the lumbar support assembly 3 and the base assembly 2, and can drive the lumbar support assembly 3 During the lifting movement, the elastic element 5 is installed between the base assembly 2 and the connecting assembly 1.

[0035]Further, the connecting assembly 1 is composed of a connecting shaft 1a and an angle limiting seat 1b fixedly installed in the middle of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com