A kind of halbach magnetic steel structure permanent magnet synchronous motor and assembly method

A technique for permanent magnet synchronous motors and assembly methods, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, electromechanical devices, etc. Unable to meet the requirements of product use, the magnetic steel is prone to bumps and cracks, etc., to achieve the effect of improving engineering efficiency, facilitating high-precision coaxial assembly, and facilitating batch assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

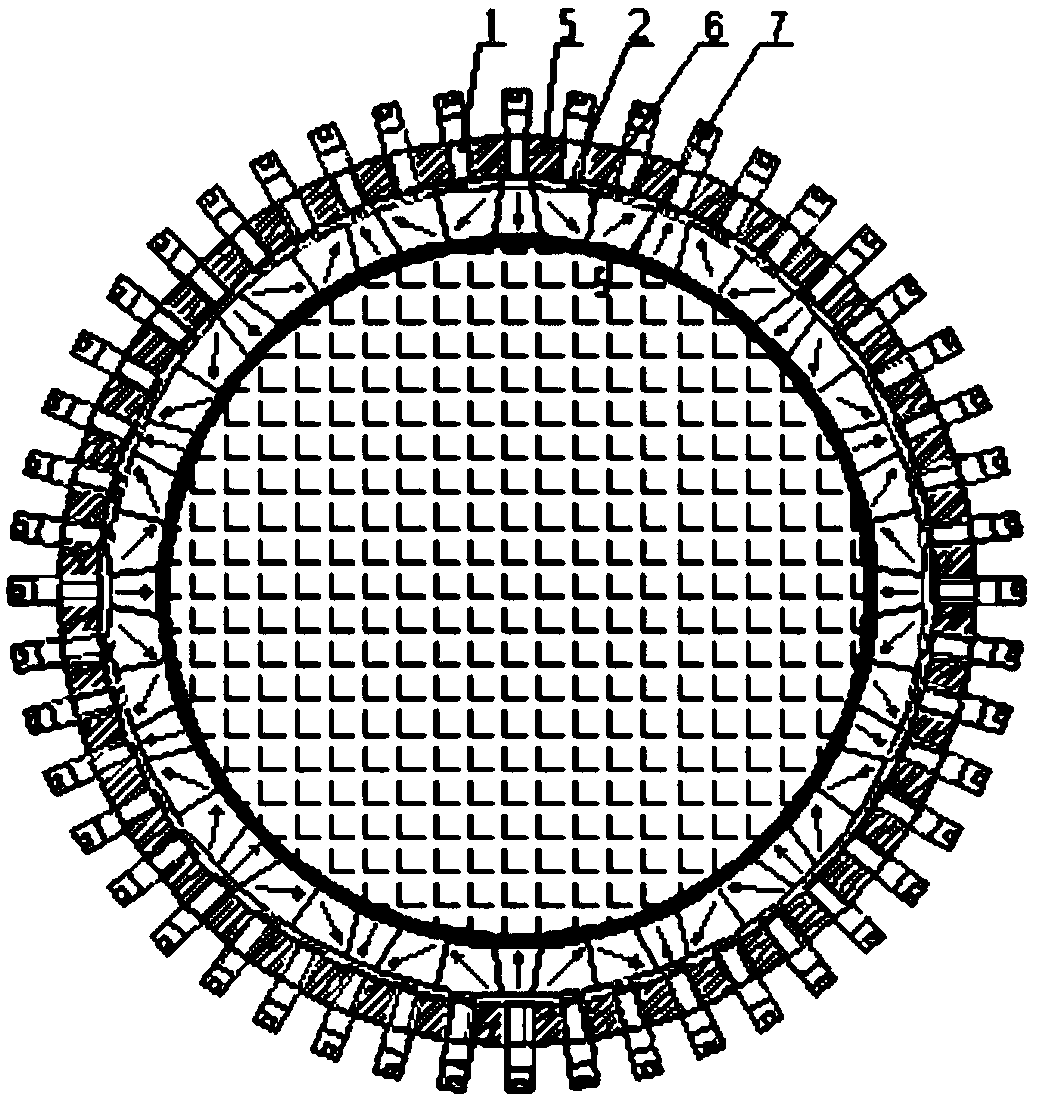

[0039] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

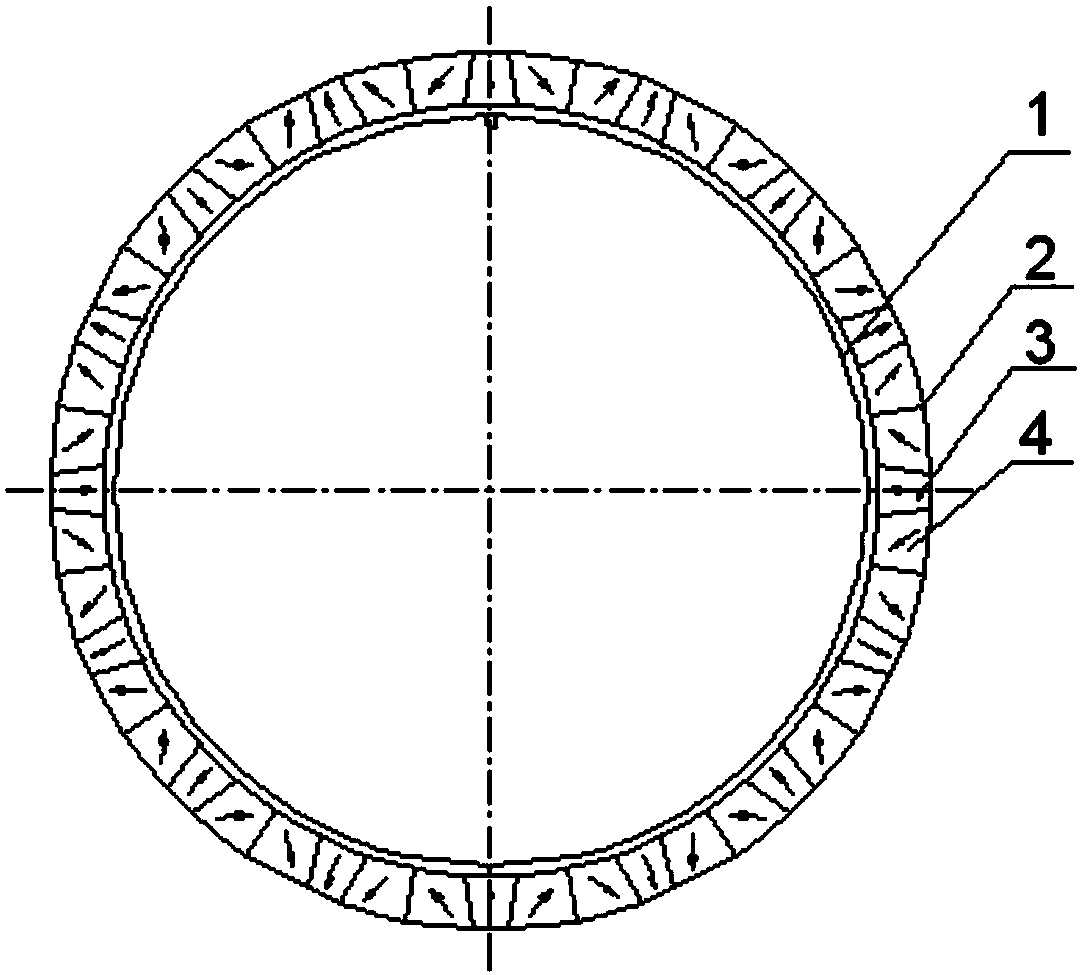

[0040] Such as figure 1 As shown, the three Halbach magnets in the same direction (arrow direction) are used as a magnetic pole, and the three opposite Halbach magnets form an N-S magnet pair, and the magnetic poles meet the requirements of the tile-shaped structure.

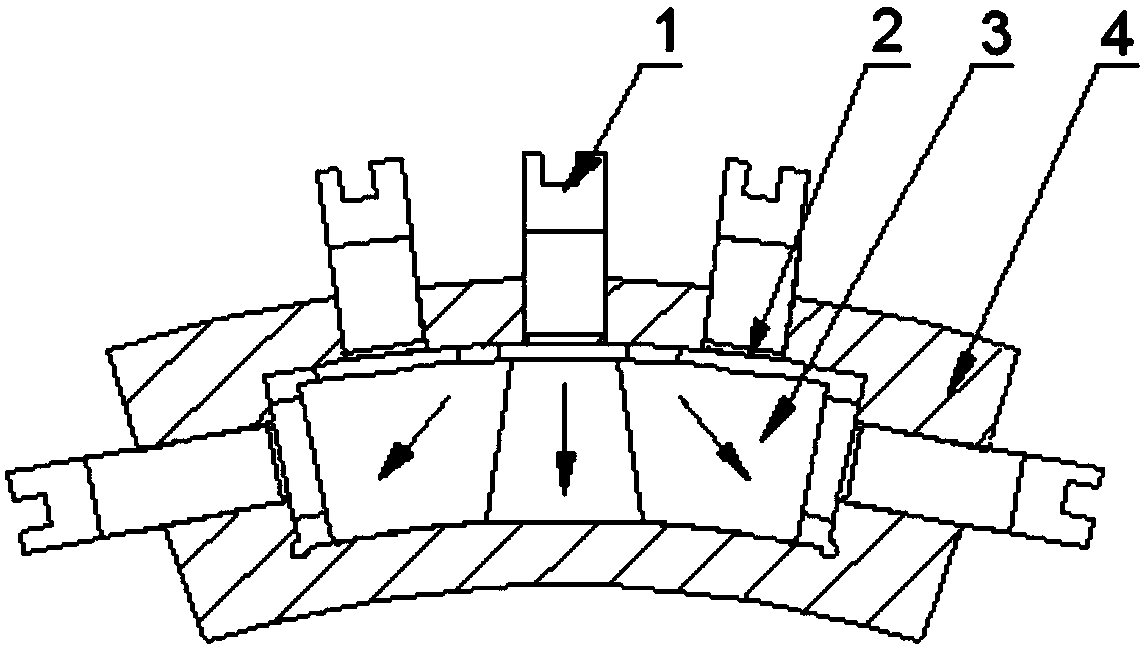

[0041] Such as figure 2 as shown,

[0042] Step 1: Install three magnetic steel analog blocks 3 with the same shape as Halbach magnetic steel in the composite mold case 4 according to the Halbach magnetic steel structure permanent magnet synchronous motor rotor single magnetic pole assembly rule, and fix them with locking screws 1 on the end and both sides , so that the magnetic steel analog block 3 and the synthetic mold cover 4 are closely matched;

[0043] Step 2: Take out a magnetic steel analog block 3 at the left or right end, apply glue on the surface of a Halbac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com