Method for welding automotive anti-rolling steel tube and A column reinforcement plate

A welding method and reinforcing plate technology are applied in welding equipment, arc welding equipment, metal processing equipment, etc., which can solve the problems that the process cannot meet the requirements and the welding accuracy requirements are high, meet the performance requirements of the whole vehicle, improve the welding strength, welding solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

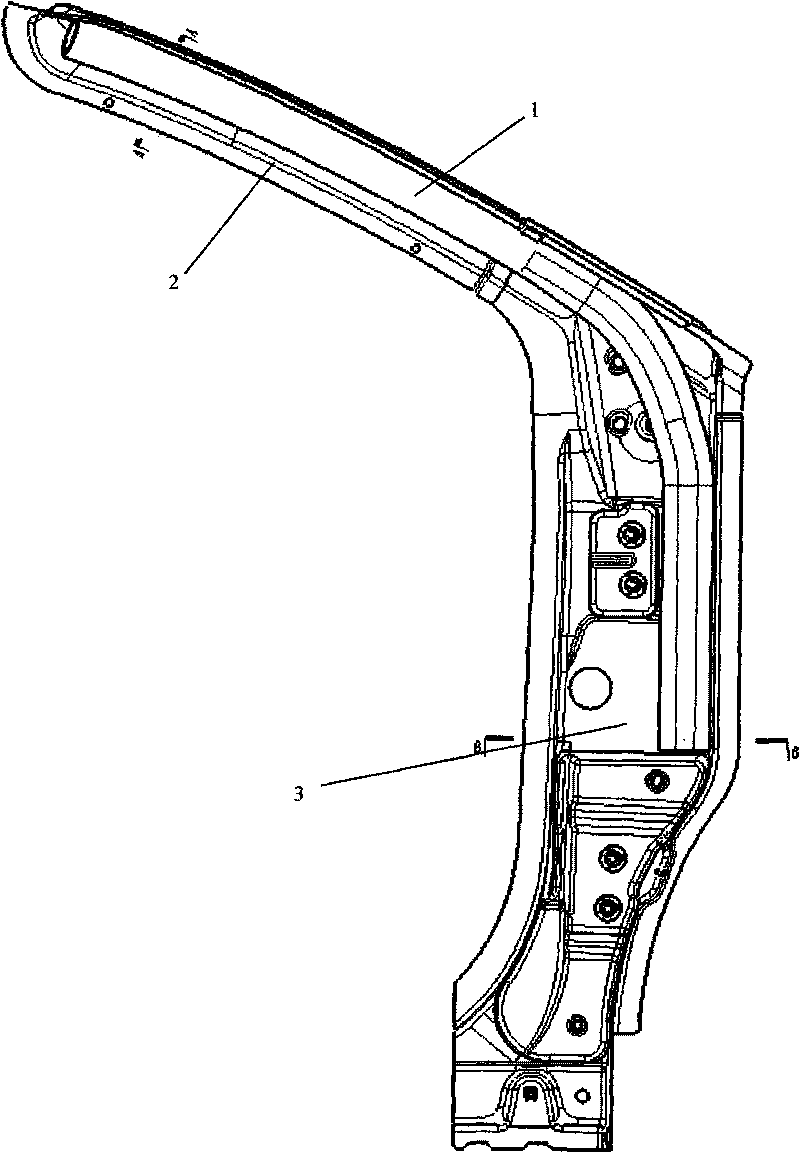

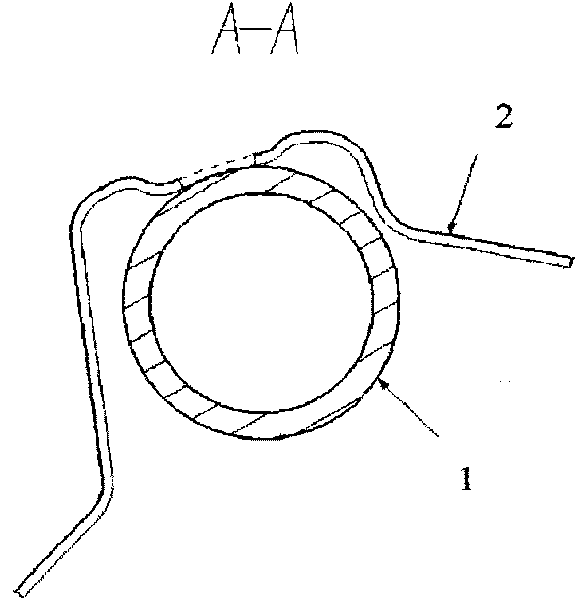

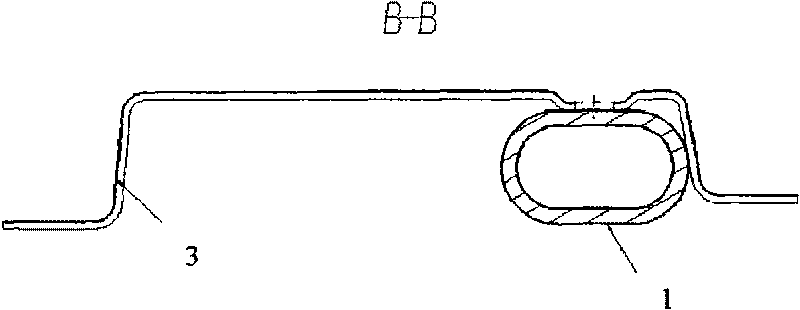

[0013] As shown in the attached figure, the A-pillar reinforcement plate includes the upper reinforcement plate 2 and the lower reinforcement plate 3. In order to weld the anti-rollover steel pipe 1 of the automobile to the A-pillar reinforcement plate, the A-pillar reinforcement plate and the steel pipe are positioned to ensure their welding. Accuracy, the A-A section shows that there is a certain welding manufacturing gap between the steel pipe 1 and the upper reinforcement plate 2, and the back of the A-pillar reinforcement plate is provided with a plug welding port, and the back is in the form of plug welding. The B-B section shows that the lower reinforcement plate 3 is in contact with the steel pipe 1 on one side, and has no contact with the steel pipe 1 on the other side. The opening form is designed. At this time, the steel pipe is welded to the A-pillar reinforcement plate, which is beneficial to the steel pipe welding adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com