Drill chuck

A technology of drill chuck and chuck, which is applied in the direction of chuck, drilling tool accessories, drilling/drilling equipment, etc., which can solve the problems affecting the stability, load capacity and durability of the chuck body, and achieve the improvement of radial runout characteristics, the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

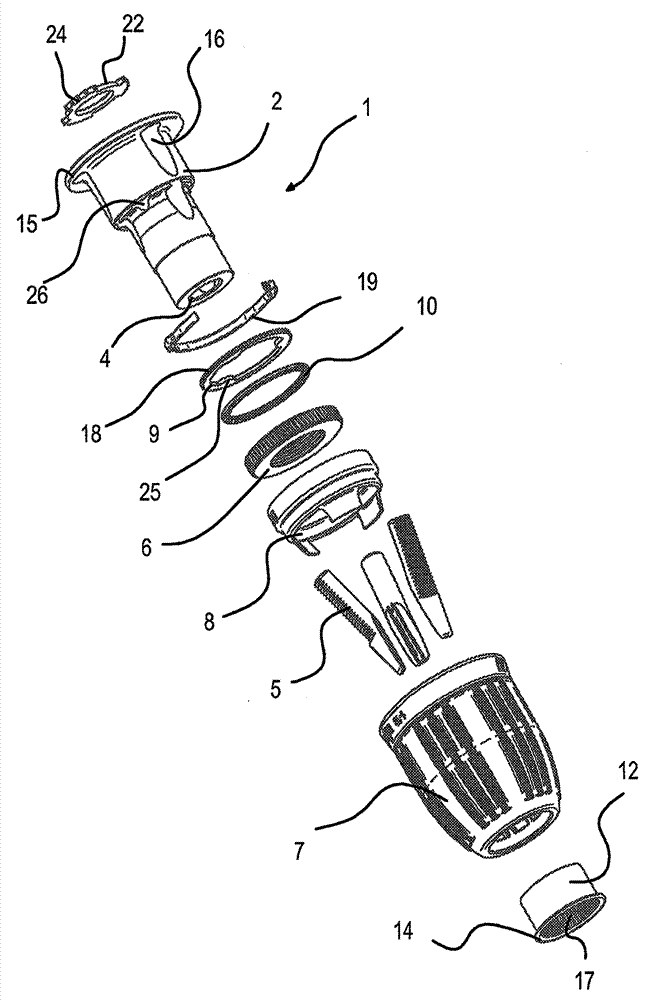

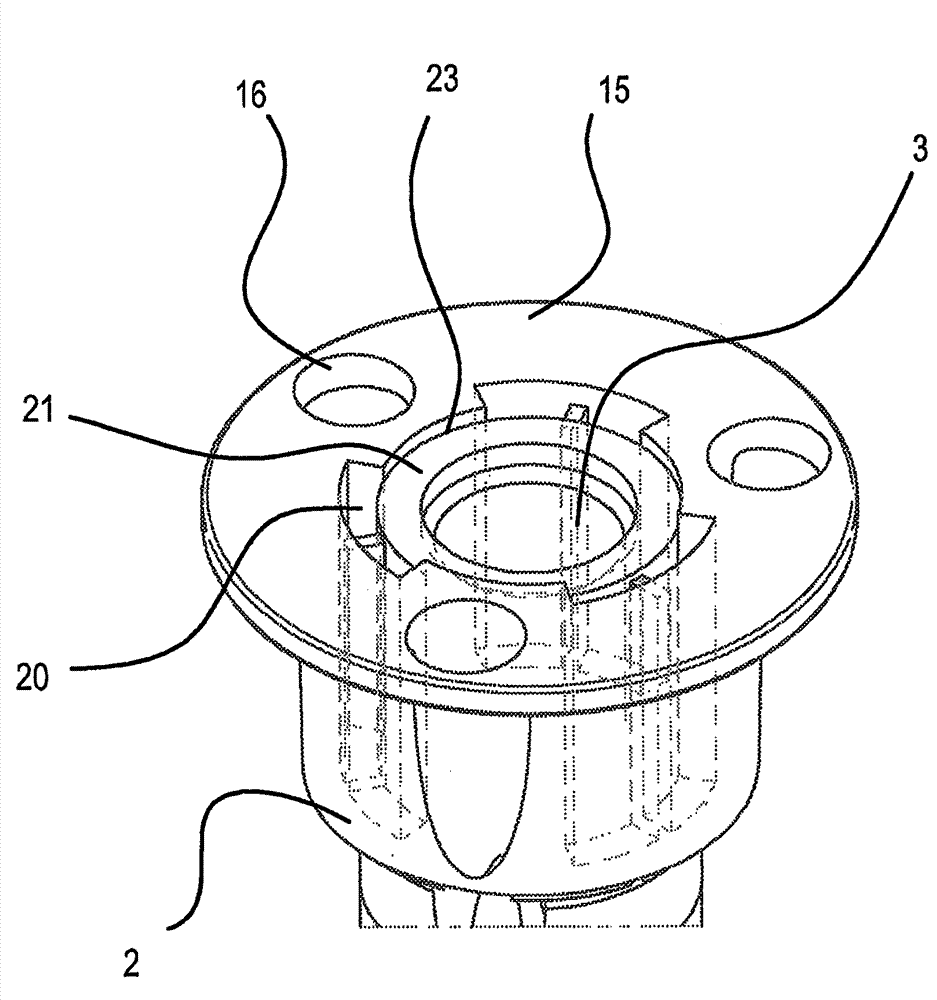

[0050] figure 1 A sectional view of an exemplary embodiment of a drill chuck 1 according to the invention with a chuck body 2 made of fiber-reinforced plastic is shown. The chuck body 2 has a spindle receptacle 3 for receiving a drilling spindle of a drilling machine and, opposite thereto, a tool receptacle 4 . Guided in the chuck body 2 is a caliper 5 , which can be adjusted obliquely to the chuck axis in a guide receptacle in a known manner via a threaded ring 6 . For adjusting the threaded ring 6 , a clamping sleeve 7 is provided, which engages the threaded ring 6 via an intermediate sleeve 8 in the exemplary embodiment shown, but can also bear directly against it. In this case, the threaded ring 6 is supported on the chuck body 2 via the pressure ring 9 and by means of the ball bearing 10 axially rearward in the direction of the spindle receptacle 3 . The threaded ring 6 is supported in the direction of the tool receptacle 4 via a collar-shaped support element 27 which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com