Injection mold with high-strength ejection lifter

An injection mold and high-strength technology, which is applied in the field of injection molds, can solve problems such as the length of the slanted ejector rod, the insufficient strength of the slanted ejector, and the breaking of the slanted ejector, achieving low cost, reduced labor costs, and easy assembly. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

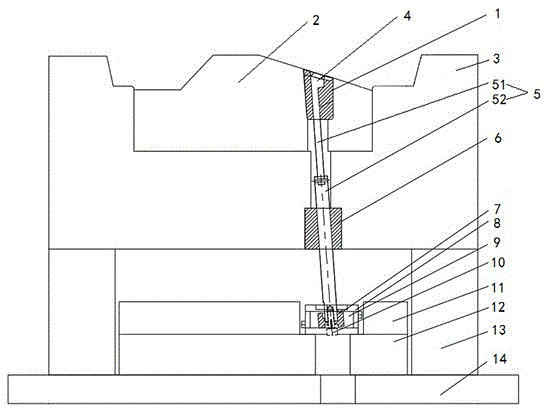

[0017] A kind of injection mold with high-strength ejection inclined roof according to the present invention, such as figure 1 As shown, it includes an insert 1, a movable mold core 2, a movable template 3, an inclined ejector head 4, an inclined ejector rod 5, an inclined ejector guide block 6, an inclined ejector rod fixing block 7, an inclined ejector seat 8, an inclined ejector sliding piece 9, Inclined top fixing screw 10, upper ejector plate 11, lower ejector plate 12, mold foot 13 and lower fixed plate 14, the movable mold core 2 shown is set inside the movable template 3; wherein the inclined ejector rod 5 includes the ends connected to each other Push rod 51 and tail push rod 52; the diameter of the tail push rod 52 is greater than the end push rod 51; the inclined head 4 is arranged on the top of the end push rod 51, and the two are integrally formed, which is an integral structure; shown The inclined plug head 4 is set inside the insert 1, wherein the movable mold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com