Clutch facing

A technology of clutch face and working layer, which is applied in the field of automobile transmission system, can solve the problems of performance loss, not outstanding, and low cost, and achieve the effects of low cost, simple design, and easy manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

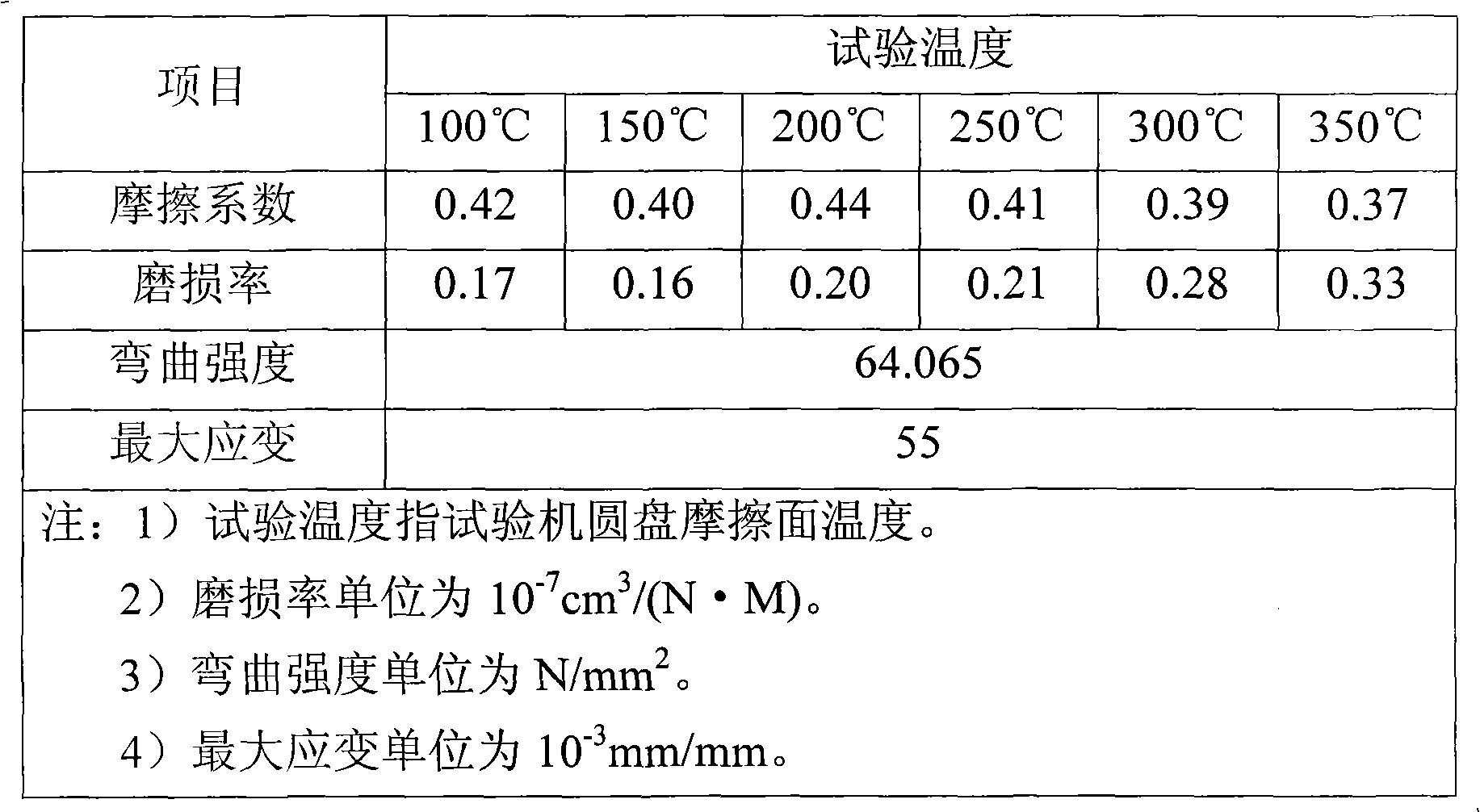

Examples

Embodiment 1

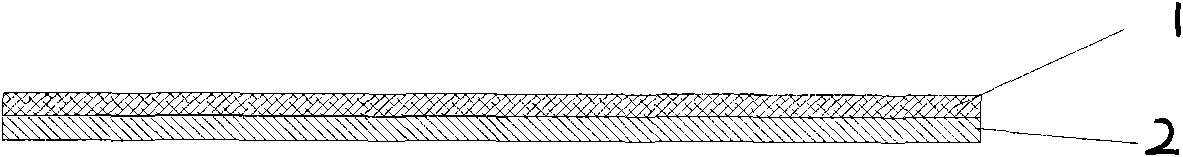

[0028] Implementation example 1 (two layers):

[0029] Friction working layer: the percentage by weight is 17% phenolic resin, 3% nitrile rubber, 10% chalcopyrite powder, 14% magnetite powder, 7% vermiculite powder, 3% aluminum oxide, 7% % wollastonite, 13% graphite, 6% light calcium carbonate, 1% antimony sulfide, 1% carbon black, and 18% barium sulfate are mixed evenly to make a slurry, and then the core-spun yarn Impregnation is carried out, and the impregnated core-spun yarn is dried and wound to form a friction working layer.

[0030] Structural layer: Mix 15% phenolic resin, 8% nitrile rubber, 28% wollastonite, 14% vermiculite powder, and 35% barium sulfate by weight to prepare a slurry, and then make a continuous glass The fibers are impregnated. The impregnated continuous glass fiber is dried and wound to form a support layer.

[0031]In the mold, the friction working layer is laid on the working surface, and the structural layer is laid on the back of the working s...

Embodiment 2

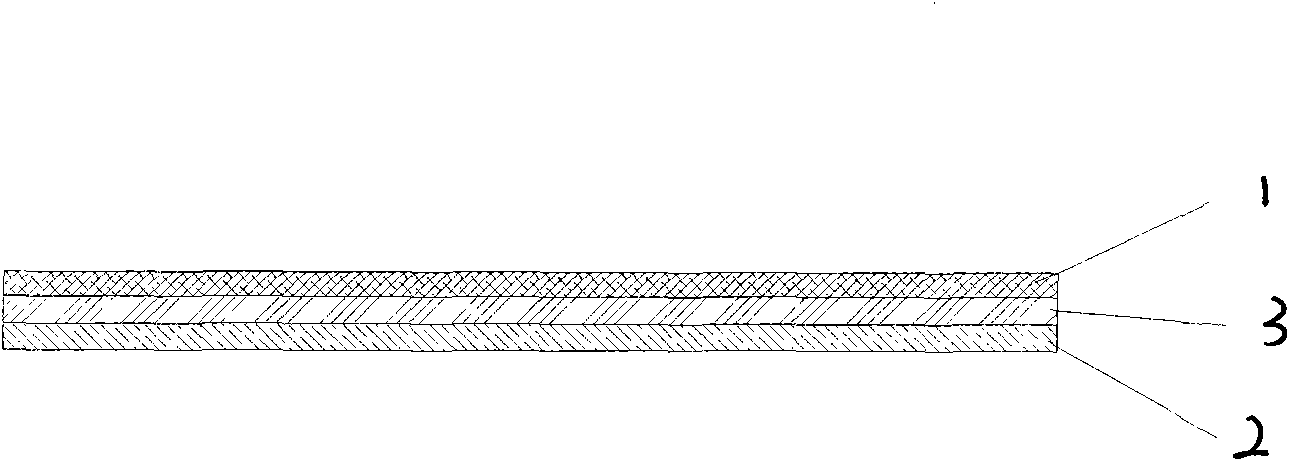

[0034] Implementation example 2 (three layers):

[0035] Friction working layer: the percentage by weight is 17% phenolic resin, 3% nitrile rubber, 10% chalcopyrite powder, 14% magnetite powder, 7% vermiculite powder, 3% aluminum oxide, 7% % wollastonite, 13% graphite, 6% light calcium carbonate, 1% antimony sulfide, 1% carbon black, and 18% barium sulfate are mixed evenly and prepared into a slurry, and then the core-spun yarn Impregnation is carried out, and the impregnated core-spun yarn is dried and wound to form a friction working layer;

[0036] Heat transfer layer: mix 50% steel fiber by weight, 15% phenolic resin, and 35% barium sulfate evenly to make heat transfer layer powder for later use;

[0037] Supporting layer: Mix 15% phenolic resin, 8% nitrile rubber, 28% wollastonite, 14% vermiculite powder, and 35% barium sulfate by weight to prepare a slurry, and then apply continuous glass The fiber is impregnated, and the impregnated continuous glass fiber is dried and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com