Molybdenum disulfide/tungsten disulfide multi-layer tantalum-doped thin film and preparation method and application thereof

A technology of tungsten disulfide and molybdenum disulfide, which is used in coatings, metal material coating processes, ion implantation plating, etc., can solve the mechanical properties requirements such as oxidation resistance, humidity sensitivity, high temperature oxidation performance and hardness that are not met. and other problems, to meet the requirements of stable lubrication and long service life, good temperature adaptive performance, and good friction and wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

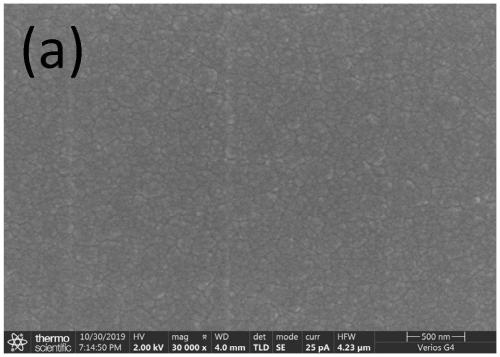

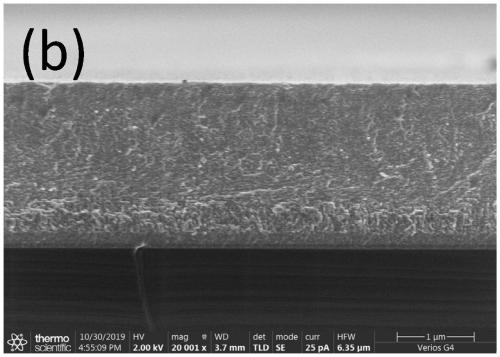

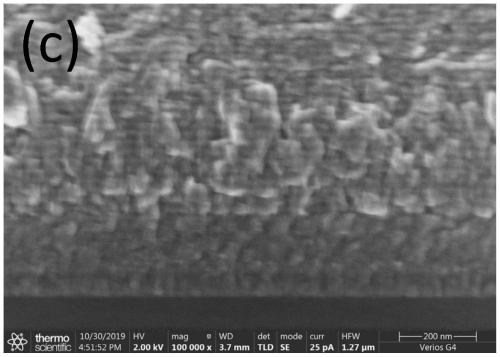

[0030] As another aspect of the technical solution of the present invention, it relates to the preparation method of the aforementioned molybdenum disulfide / tungsten disulfide multilayer tantalum-doped film, which includes: adopting magnetron sputtering technology to sequentially deposit a titanium transition layer on the surface of the substrate , a titanium / tantalum / molybdenum disulfide / tungsten disulfide multilayer gradient transition layer and a molybdenum disulfide / tungsten disulfide multilayer tantalum doped layer to obtain the molybdenum disulfide / tungsten disulfide multilayer tantalum doped film.

[0031] In some embodiments, the method for preparing a titanium transition layer includes: using magnetron sputtering technology, using a titanium target as a cathode target, using a protective gas as a working gas, applying a target current to the titanium target, and applying a negative bias to the substrate pressure, thereby depositing a titanium transition layer on the su...

Embodiment 1

[0059] In this embodiment, the base material is nickel-based 718 high temperature steel and silicon wafer. Using magnetron sputtering technology to prepare a molybdenum disulfide / tungsten disulfide multilayer tantalum-doped film on the surface of the substrate, mainly including the following steps:

[0060] Perform mechanical polishing on the surface of the substrate, put the substrate material into an acetone solution for 15 minutes of ultrasonic cleaning, blow dry with nitrogen, put it in absolute ethanol solution for 15 minutes of ultrasonic cleaning, blow dry with nitrogen and take it out.

[0061] Put the cleaned substrate into the magnetron sputtering chamber, and evacuate until the vacuum degree is lower than 3×10 -5 Pa, and then sputtering and cleaning the target for 5 minutes, applying a bias voltage of -400V to the substrate sample, and performing plasma etching for 30 minutes, and the substrate temperature was 100°C.

[0062] Preparation and deposition of molybdenu...

Embodiment 2

[0073] In this embodiment, the base material is nickel-based 718 high temperature steel and silicon wafer. Using magnetron sputtering technology to prepare a molybdenum disulfide / tungsten disulfide multilayer tantalum-doped film on the surface of the substrate, mainly including the following steps:

[0074] Perform mechanical polishing on the surface of the substrate, put the substrate material into an acetone solution for 15 minutes of ultrasonic cleaning, blow dry with nitrogen, put it in absolute ethanol solution for 15 minutes of ultrasonic cleaning, blow dry with nitrogen and take it out.

[0075] Put the cleaned substrate into the magnetron sputtering chamber, and evacuate until the vacuum degree is lower than 3×10 -5 Pa, and then sputtering and cleaning the target for 5 minutes, applying a bias voltage of -450V to the substrate sample, and performing plasma etching for 20 minutes, and the substrate temperature is 150°C.

[0076] Preparation and deposition of molybdenum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com