SnS2 two-dimensional ordered nanopore film as well as preparation method and application thereof

A nanoporous film and thin film technology, applied in coatings, instruments, analytical materials, etc., can solve problems such as difficulty in maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Ultrasonically treat the glass with acetone for 45 minutes, ultrasonically treat with ethanol solution for 45 minutes, ultrasonically clean with deionized water for 30 minutes and change the water repeatedly, soak in the piranha solution for 4 hours and clean with deionized water to complete the hydrophilic treatment of the glass;

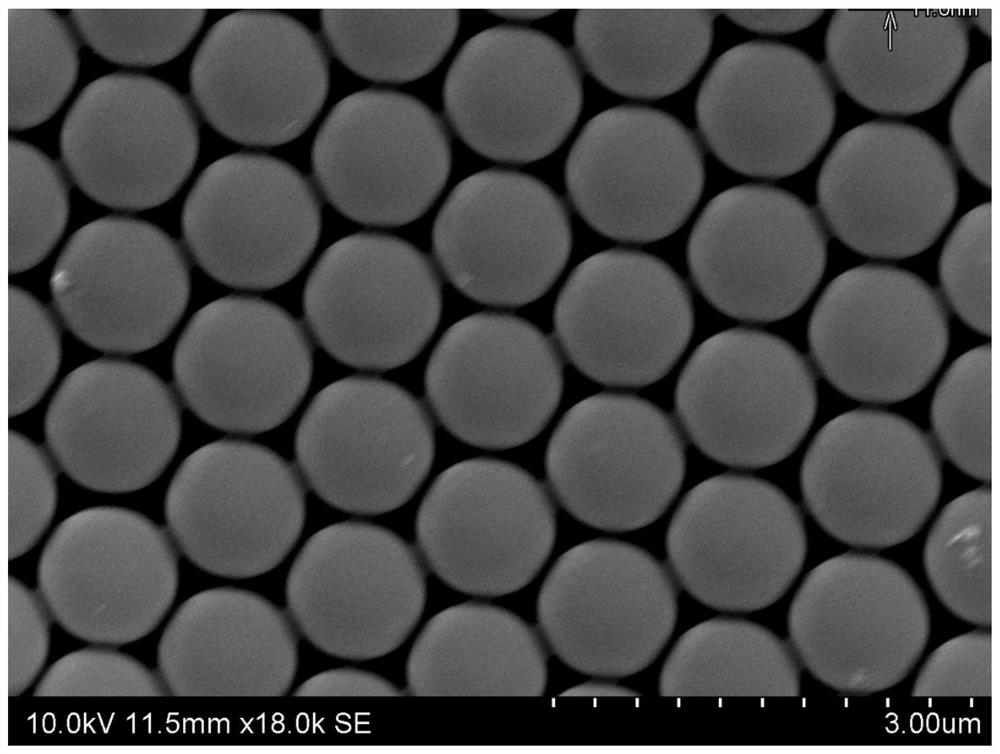

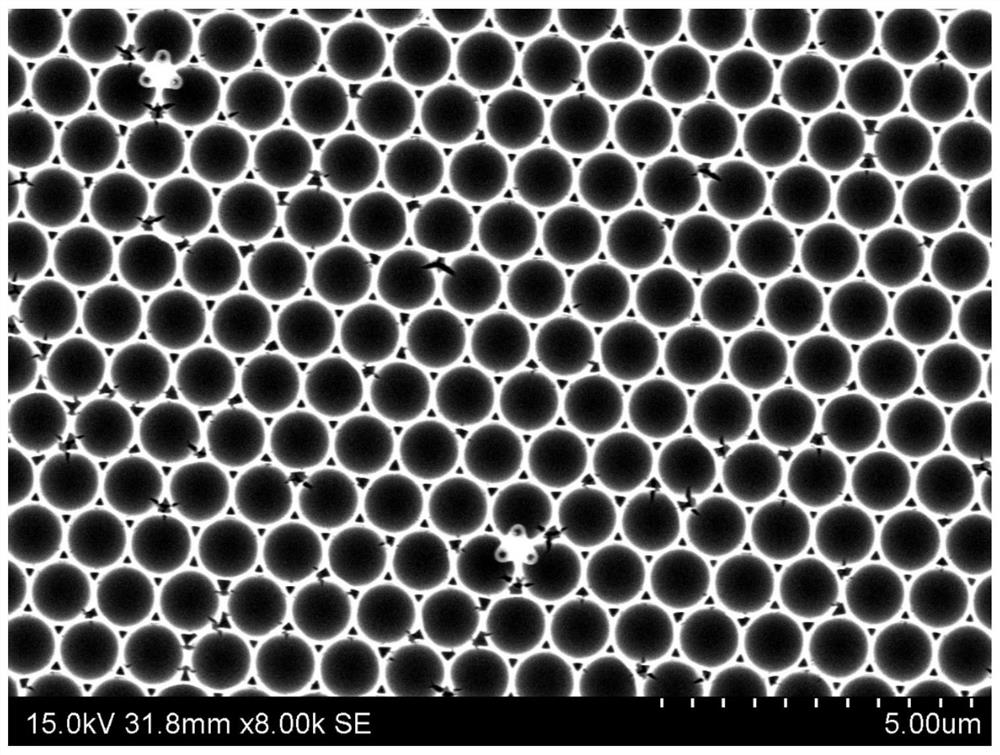

[0044](2) Mix the PS sphere solution and alcohol 1:1 evenly, and after ultrasonic dispersion for 10 minutes, cover the 25mm*75mm glass sheet with hydrophilic treatment with water, and then perform monolayer self-assembly of the PS sphere on the glass substrate;

[0045] According to the self-transfer characteristics of the PS ball monolayer film, transfer it to a 25mm*30mm glass sheet;

[0046] Place the self-assembled PS single-layer template in a blast drying oven at 90°C for 90 minutes to dry, so that the PS template and the 25mm*30mm glass substrate are more tightly combined;

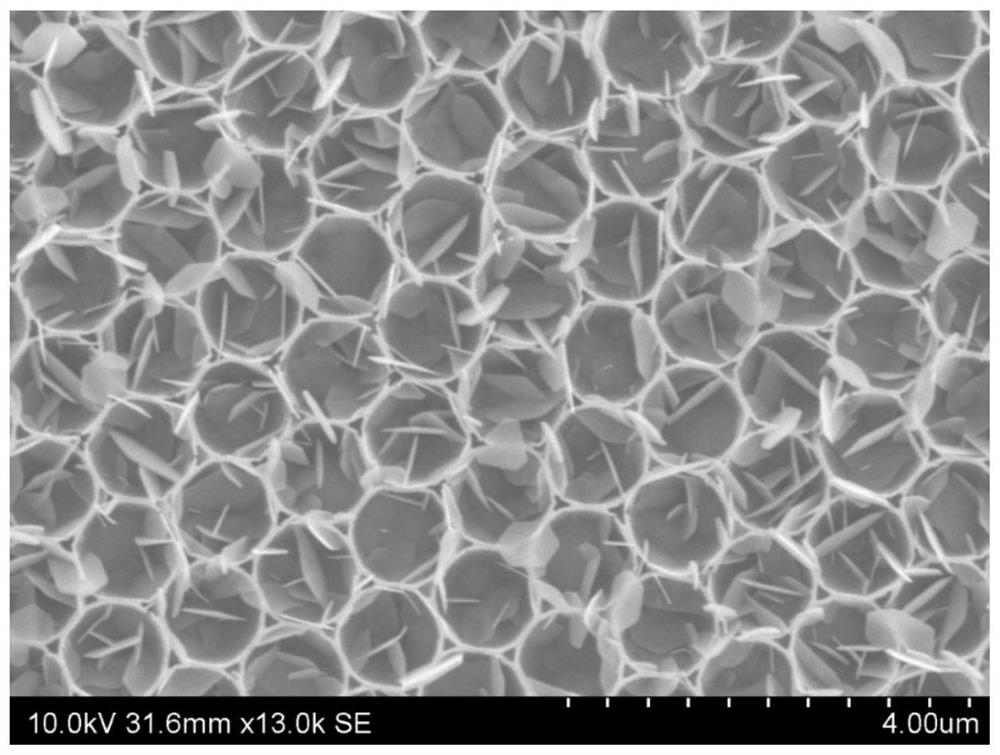

[0047] (3) With 0.2mol / L SnCl 4 ·5H 2 O solution is th...

Embodiment 2

[0056] (1) Ultrasonically treat the glass with acetone for 45 minutes, ultrasonically treat with ethanol solution for 45 minutes, ultrasonically clean with deionized water for 30 minutes and change the water repeatedly, soak in the piranha solution for 4 hours and clean with deionized water to complete the hydrophilic treatment of the glass;

[0057] (2) Mix the PS sphere solution and alcohol 1:1 evenly, and after ultrasonic dispersion for 10 minutes, cover the 25mm*75mm glass sheet with hydrophilic treatment with water, and then perform monolayer self-assembly of the PS sphere on the glass substrate;

[0058] According to the self-transfer characteristics of the PS ball monolayer film, transfer it to a 25mm*30mm glass sheet;

[0059] Place the self-assembled PS single-layer template in a blast drying oven at 90°C for 90 minutes to dry, so that the PS template and the 25mm*30mm glass substrate are more tightly combined;

[0060] (3) With 0.2mol / L SnCl 4 ·5H 2 O solution is t...

Embodiment 3

[0065] (1) Ultrasonically treat the glass with acetone for 45 minutes, ultrasonically treat with ethanol solution for 45 minutes, ultrasonically clean with deionized water for 30 minutes and change the water repeatedly, soak in the piranha solution for 4 hours and clean with deionized water to complete the hydrophilic treatment of the glass;

[0066] (2) Mix the PS sphere solution and alcohol 1:1 evenly, and after ultrasonic dispersion for 10 minutes, cover the 25mm*75mm glass sheet with hydrophilic treatment with water, and then perform monolayer self-assembly of the PS sphere on the glass substrate;

[0067] According to the self-transfer characteristics of the PS ball monolayer film, transfer it to a 25mm*30mm glass sheet

[0068] Place the self-assembled PS single-layer template in a blast oven at 90°C to dry for 90 minutes, so that the PS template and the 25mm*30mm glass substrate are more tightly bonded.

[0069] (3) With 0.05mol / L of SnCl 4 ·5H 2 O solution is the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com