Deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material and preparation method thereof

A friction material and phenolic resin technology, which is applied in the field of material science and processing, can solve the problems of difficult to bear large torsional moment, poor structural integrity of friction materials, easy delamination and damage, etc., to adjust the friction performance and improve the physical and mechanical properties. , The effect of overcoming the delamination problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

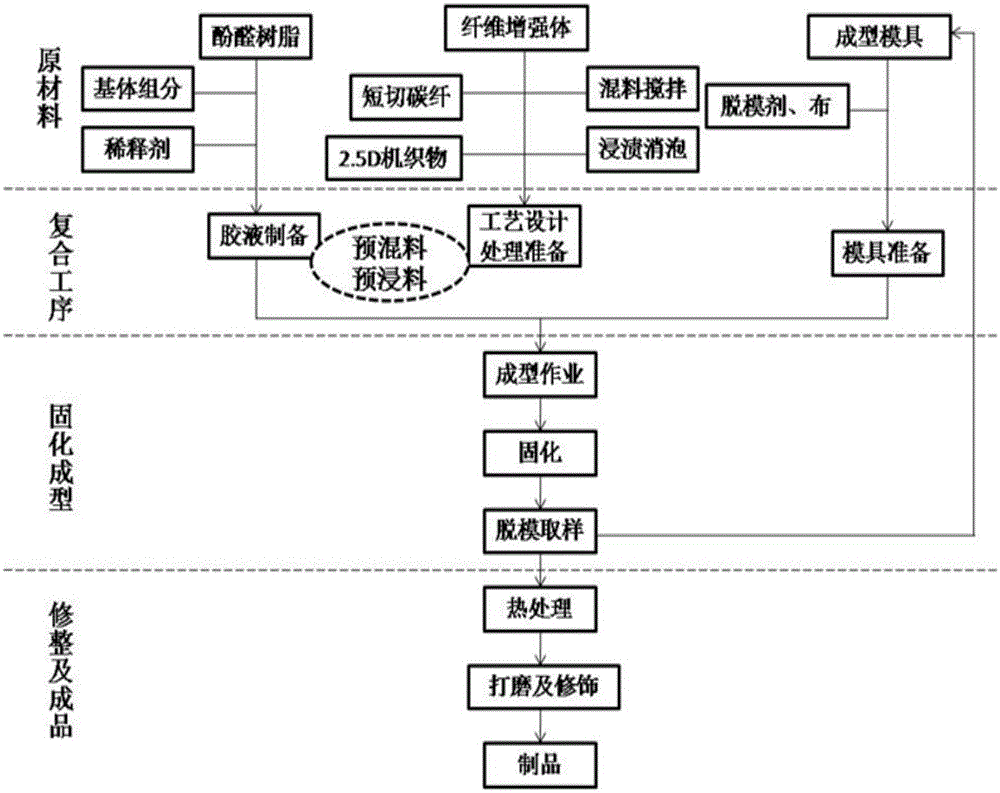

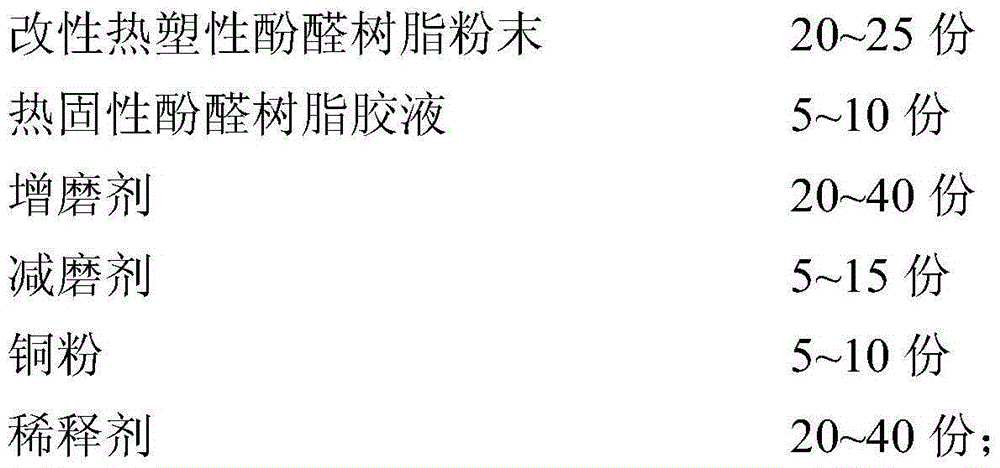

[0026] A carbon fiber reinforced phenolic resin-based friction material with a deep cross-linked structure. The preparation method of the friction material includes three steps of preparing a carbon fiber prefabricated body with a deep cross-linked structure, preparing a matrix glue, and preparing a friction material:

[0027] (1) Preparation of deep crosslinked carbon fiber preform:

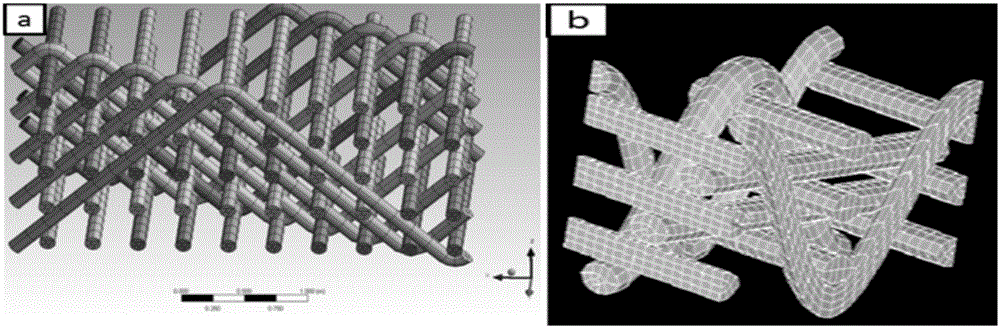

[0028] Weave 2 layers of deep cross-linked carbon fiber woven fabric on a three-dimensional woven prototype machine. The binding warp yarns are arranged at a certain angle to the thickness direction and run through the entire thickness direction of the material. The thickness is about 2mm, the warp density is 20 threads / 10cm, and the weft The density is 80 strands / 10cm, the weaving tension is moderate, and the carbon fiber prefabricated body with deep crosslinking structure is obtained; the carbon fiber is pre-oxidized carbon fiber or oxidized filament, and has certain weavability.

[0029] In t...

Embodiment 2

[0038] A carbon fiber reinforced phenolic resin-based friction material with a deep cross-linked structure. The preparation method of the friction material includes three steps of preparing a carbon fiber prefabricated body with a deep cross-linked structure, preparing a matrix glue, and preparing a friction material:

[0039] (1) Preparation of deep crosslinked carbon fiber preform:

[0040]Weave 4 layers of carbon fiber fabric with deep cross-linked structure on a three-dimensional woven prototype machine. The binding warp yarns are arranged at a certain angle to the thickness direction and run through the entire thickness direction of the material. The thickness is about 4mm, the warp density is 40 threads / 10cm, and the weft density It is 214 strands / 10cm, and the weaving tension is moderate, and a carbon fiber prefabricated body with a deep cross-linked structure is obtained; the carbon fiber is a carbon fiber pre-oxidized filament or an oxidized filament, and has a certain...

Embodiment 3

[0050] A carbon fiber reinforced phenolic resin-based friction material with a deep cross-linked structure. The preparation method of the friction material includes three steps of preparing a carbon fiber prefabricated body with a deep cross-linked structure, preparing a matrix glue, and preparing a friction material:

[0051] (1) Preparation of deep crosslinked carbon fiber preform:

[0052] Weaving 20 layers of deep cross-linked carbon fiber fabrics on a three-dimensional loom, the warp yarns are arranged at a certain angle to the thickness direction, and run through the entire thickness direction of the material, with a thickness of about 18mm, a warp density of 142 threads / 10cm, and a weft density of 658 root / 10cm; the selected carbon fiber is carbon fiber pre-oxidized filament or oxidized filament, which has certain weavability.

[0053] In the deep cross-linked carbon fiber prefabricated body, the carbon fiber runs through each layer along the thickness direction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com