Voice Coil Motor (VCM) magnetic sheet assembly device

A technology for assembling equipment and magnetic sheets, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of complicated production equipment structure, complicated replacement work, and increased assembly processes, saving assembly time, sending The effect of smooth entry and increased assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

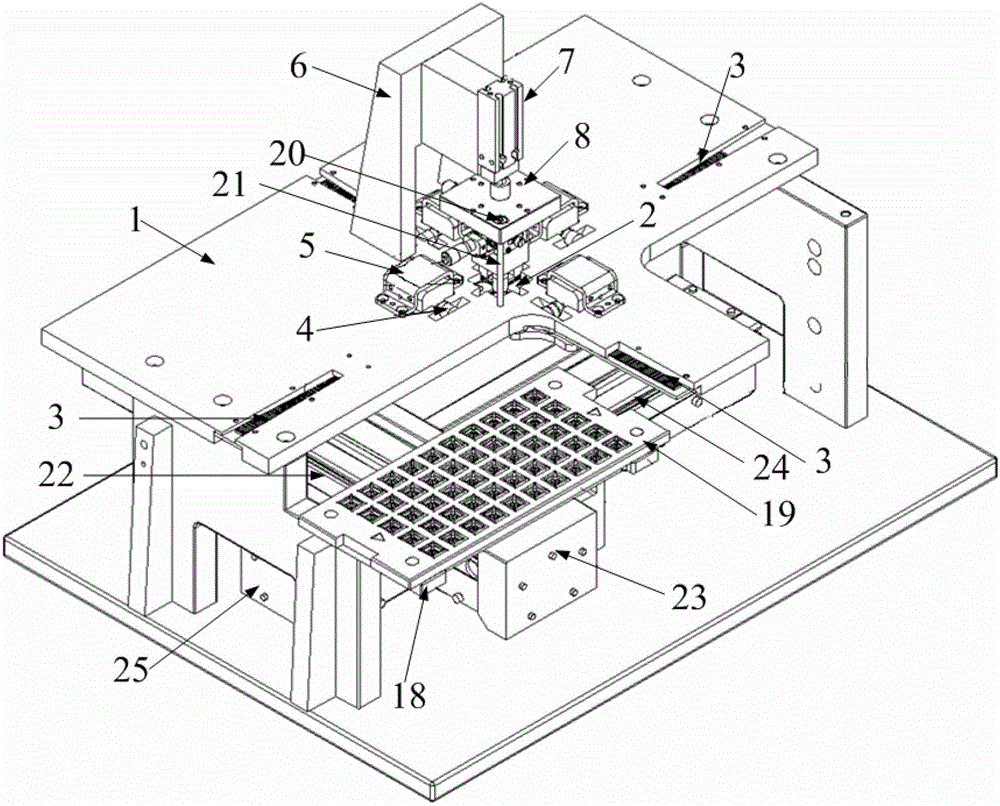

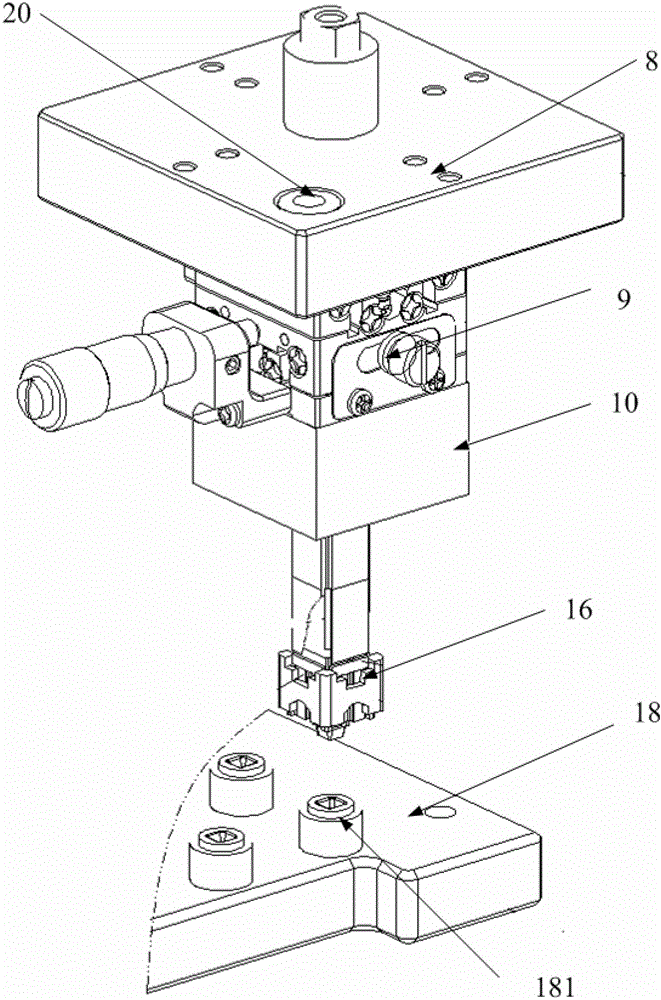

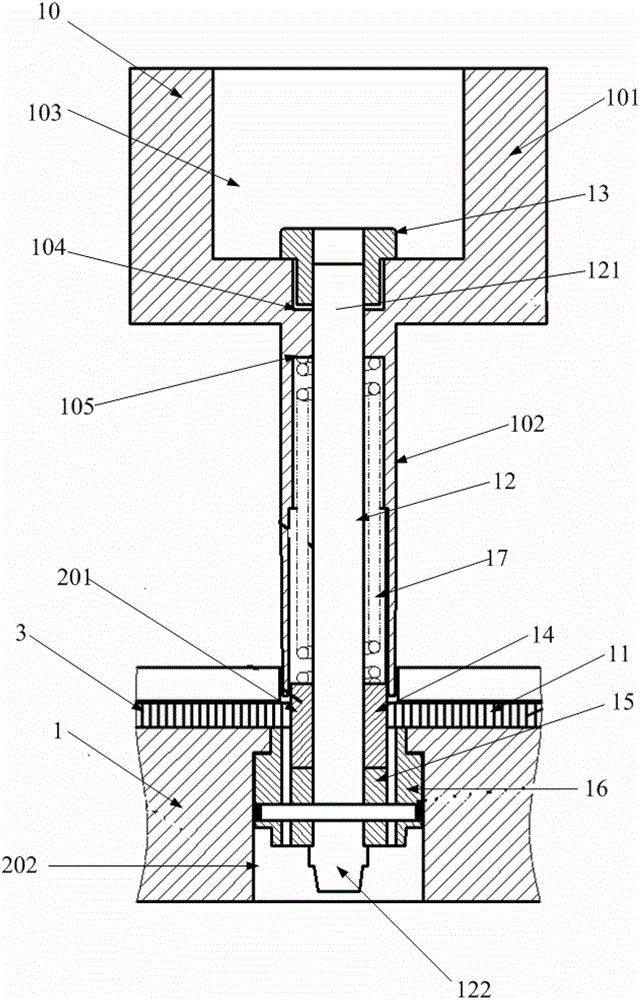

[0051] Such as Figure 1~4 As shown, a kind of VCM motor magnetic sheet assembly equipment described in this embodiment includes a workbench 1, and a feeding hole 2 is arranged in the center of the workbench 1, and in the workbench 1, the corresponding magnetic sheet installation position is set for The feeding system that feeds the magnetic sheet 11 into the feeding hole 2, the feeding system includes four magnetic strip slides 3 arranged inside the workbench 1, and the four magnetic strip slides 3 are all connected to the feeding hole 2, and each magnetic strip One end of the slideway 3 close to the feeding hole 2 is provided with a feeding wheel 4, and the feeding wheel 4 performs intermittent work through the power device 5 of the feeding wheel, so that the magnetic sheets 11 can be sent into the feeding hole 2 one by one for assembly work. And every adjacent magnetic stripe slideway 3 is vertically arranged, and feed wheel 4 comprises the first feed wheel and the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com