Permanent magnet generator for hybrid power motor train unit

A permanent magnet generator and hybrid technology, applied in electric components, magnetic circuits, electrical components, etc., can solve the problems of heavy weight, large volume, and poor heat dissipation of fully enclosed motors, so as to reduce the weight of the motor and improve the operation reliability. and life, the effect of increasing the temperature rise margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

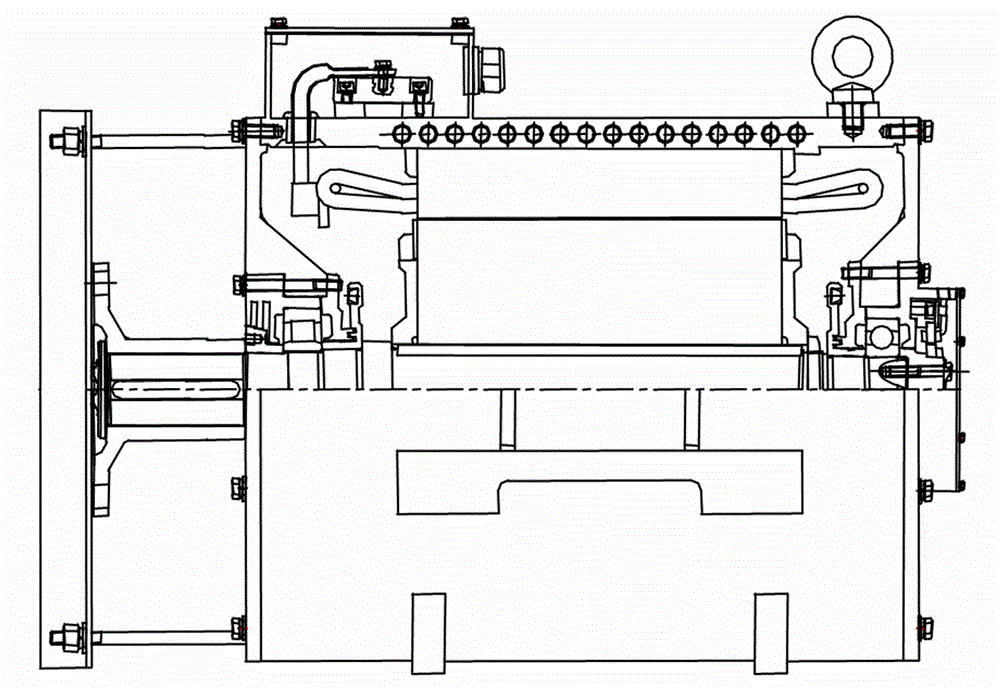

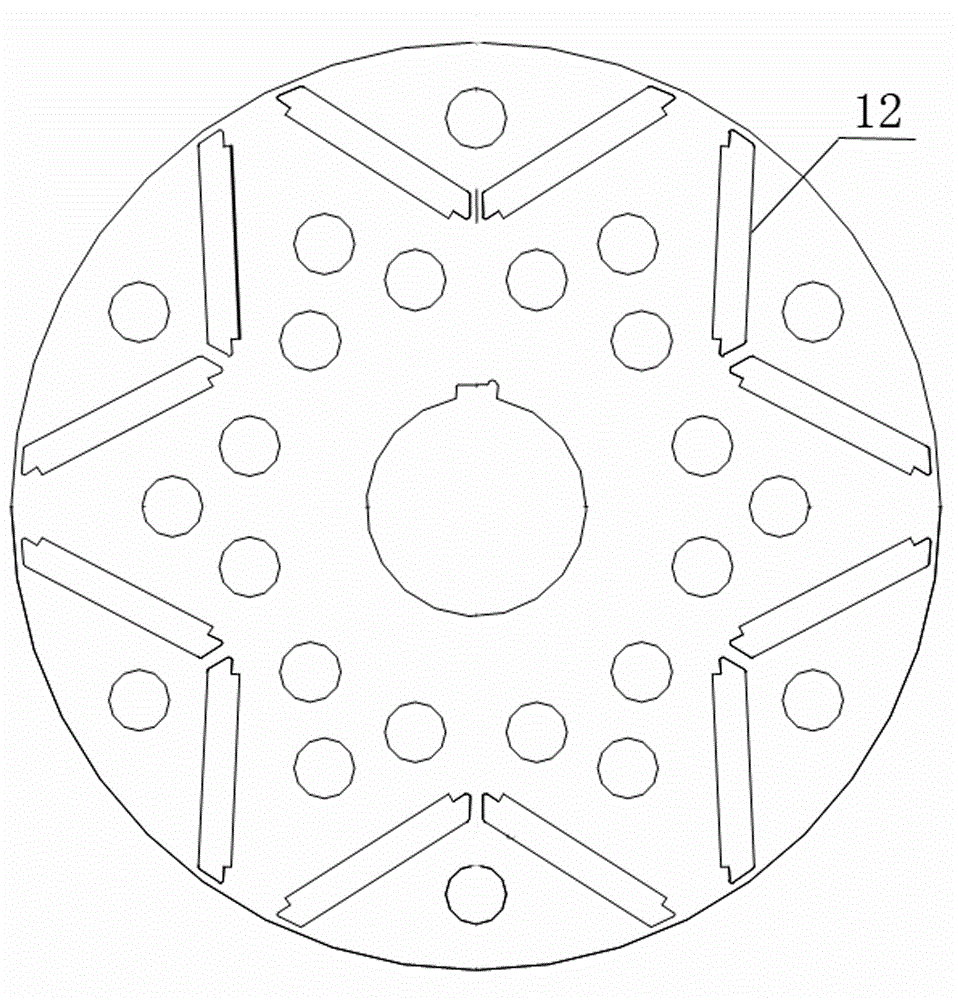

[0020] A permanent magnet generator for a hybrid train set, including a frame 2 and an end cover 1, the frame 2 is provided with a stator assembly 4 containing a stator coil 3 and a rotating shaft, a rotor core 9, a permanent magnet baffle 8, and a permanent magnet baffle The plate pressure ring and the rotor assembly 5 of the permanent magnet, the front inner sealing ring 6 and the rear inner sealing ring 10 are also provided at both ends of the rotating shaft. The baffle pressure ring 7 is a cast aluminum structure, and the magnetic steel assembly and disassembly holes 11 are evenly arranged on the pressure ring.

[0021] In the specific implementation, after the lamination of the stator punching is completed, the stator coil is embedded in the stator core, and the whole is dipped in paint after connecting the wires, and then heat-fitted with the frame; the rotor core punching adopts a V-shaped radial coil with a thicker magnetic steel groove The permanent magnet structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com