Double-seam submerged-arc welding pipe with petroleum and natural-gas transfer and its production

A technology of submerged arc welded pipe and production method, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of insufficient capacity of pipe-making steel plates, achieve good appearance and internal quality of welds, reduce steel plate width, The effect of improving the conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

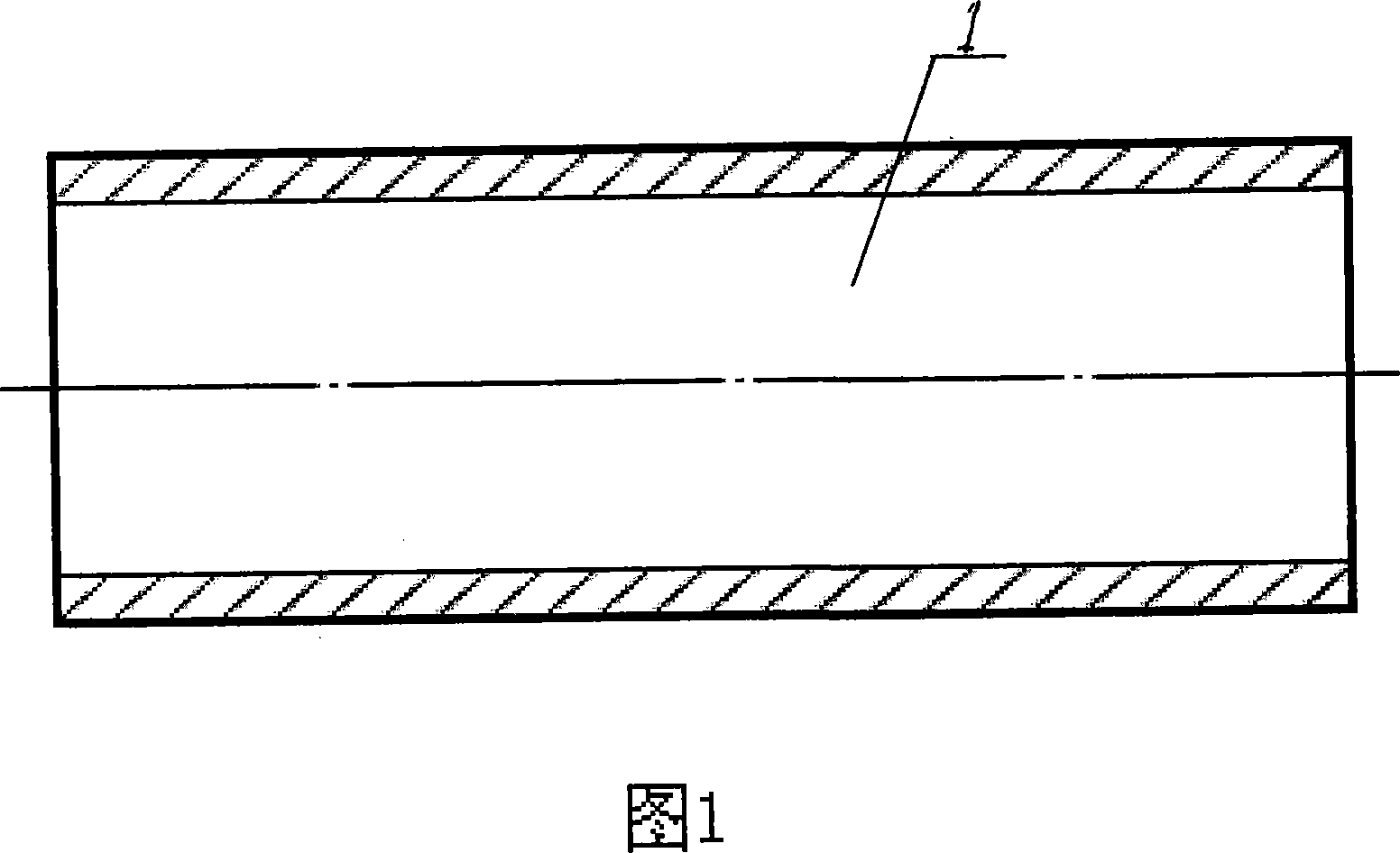

[0029] Embodiment 1: refer to accompanying drawing. Taking the production method of a double seam submerged arc welded steel pipe for oil and natural gas transportation with an outer diameter of 1016mm and a wall thickness of 29mm as an example, further explanation is given.

[0030] The production process of spliced plate double seam submerged arc welded pipe, the main process is as follows:

[0031] A. Use two steel plates with a width of 1596mm, a length of 12000mm, and a thickness of 29mm. Each steel plate is processed with welding grooves along the two edges of the length direction, and the two steel plates are welded along one end of the length direction by double-sided submerged arc welding. Splicing together, the width of the spliced steel plates reaches the width requirement for manufacturing steel pipe 1 with an outer diameter of 1050 mm, ie 3192 mm.

[0032] B. UOE straight seam submerged arc welding steel pipe production process is used to manufacture steel pi...

Embodiment 2

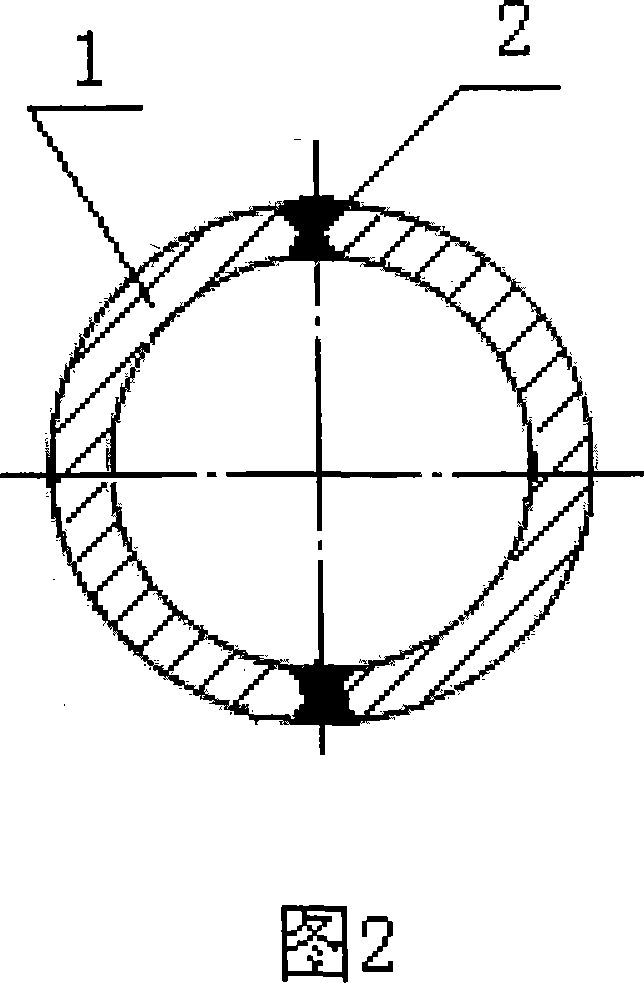

[0035] Embodiment 2: refer to accompanying drawing. Taking the production method of a double seam submerged arc welded steel pipe for oil and natural gas transportation with an outer diameter of 1219mm and a wall thickness of 32mm as an example, further explanation is given.

[0036] Formed double seam submerged arc welded pipe production process (called COE double seam submerged arc welded pipe production process), the main process is as follows:

[0037] A. Two steel plates with a width of 1915mm, a length of 12000mm, and a thickness of 32mm are used to process welding grooves on their longitudinal edges, and each steel plate is pressed into a "C" shape with a press and a forming die to make two " C" shaped half pipe.

[0038] B. Two C-shaped semi-pipes are positioned and welded along the longitudinal welding groove group on the mold to form an "O"-shaped round pipe, and then two welds 2 are formally welded. The welding method is double-sided submerged arc welding.

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com