Wood processing thicknesser

A planer and wood technology, which is applied to wood processing appliances, planers, processing machines for manufacturing flat surfaces, etc., can solve the problems of entering the operator and ejecting wood chips, etc., and achieves the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

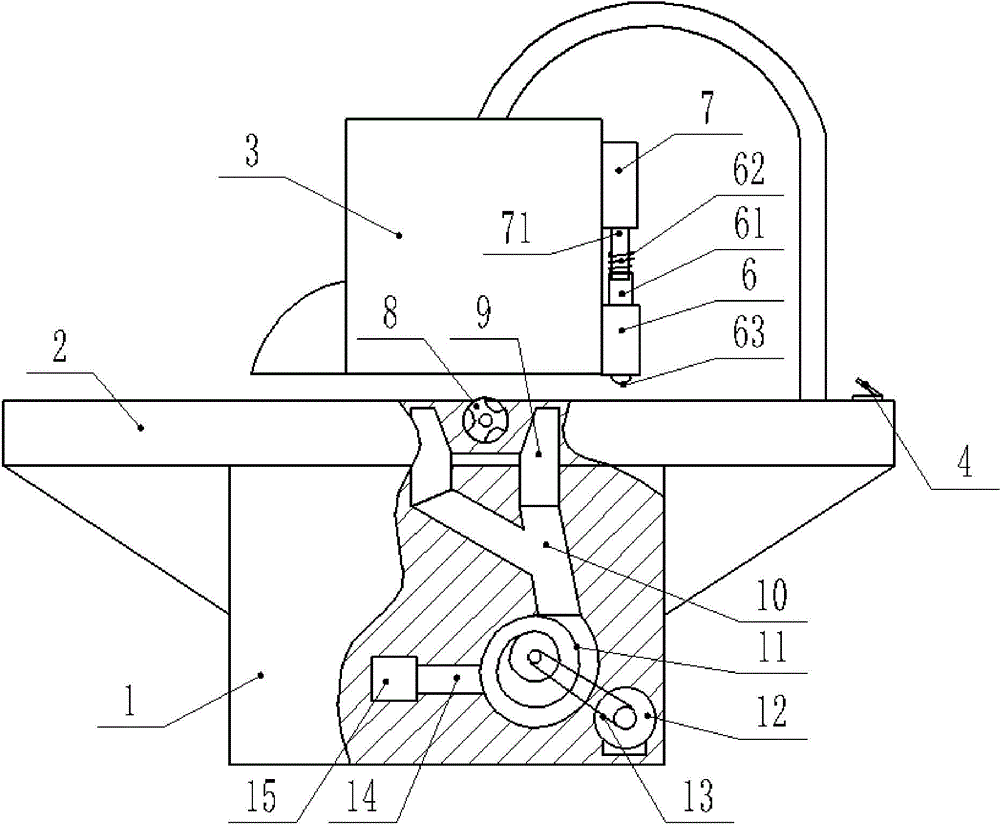

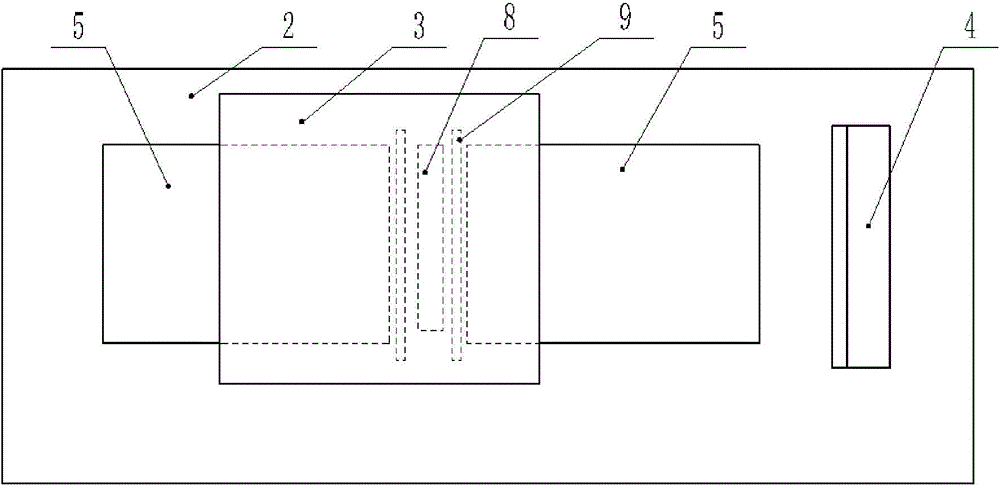

[0012] see Figure 1-2 , a planer for wood processing, comprising a base 1, a chip removal device, a workbench 2 arranged on the abutment and a lower pressing platform 3 positioned above the workbench, the workbench 2 is provided with a conveyor belt device 5, The attachment scraper 4 and the knife shaft 8, the conveyor belt device 5 is a double-segment conveyor belt transmission structure, the conveyor belt device 5 is set in the middle of the workbench 2, the knife shaft 8 is set in the middle of the two conveyor belts of the double-segment conveyor belt, and the knife shaft 8 is set There is a detachable planing tool, and the attachment scraper 4 is set on the right end of the workbench 2; the right end of the pressing table 3 is provided with a front baffle device, and the front baffle device is provided with a baffle 6 and a cylinder 7 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com