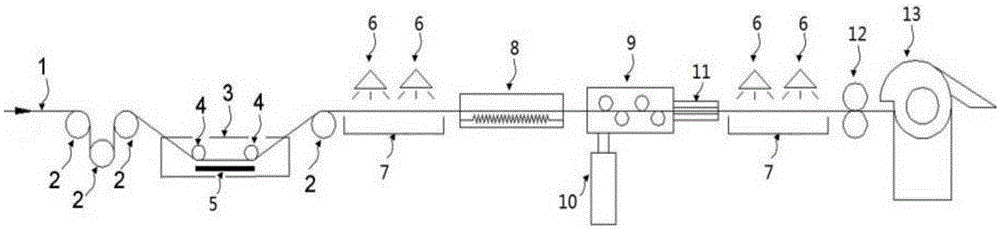

Preparation method and device for carbon fiber-reinforced thermoplastic resin composite material

A technology of resin composite material and reinforced thermoplastic, applied in the direction of coating, can solve the problems of low mechanical performance, uneven dispersion of metal powder, unstable electromagnetic shielding performance, etc., to improve mechanical performance, reduce equipment investment, and achieve excellent electromagnetic protection. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

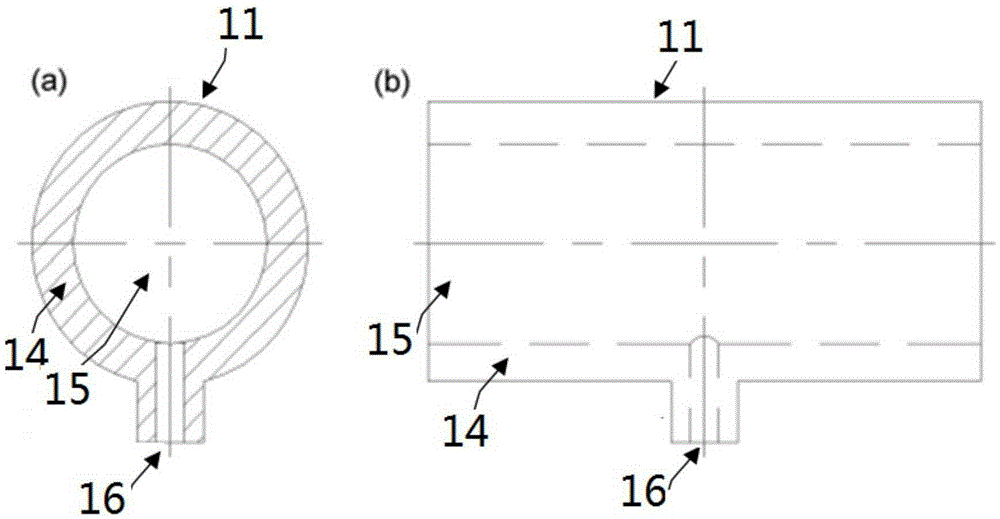

[0047] A heating export device 11 is arranged at the outlet of the molten impregnation die head 9, which includes a heating device 14, an inner cavity body 15 and a resin discharge port 16, the heating device 14 is located on the outer wall of the inner cavity body 15, and the resin discharge port 16 is located at the inner cavity body 15 directly below the . The heating device 14 is a resistance wire.

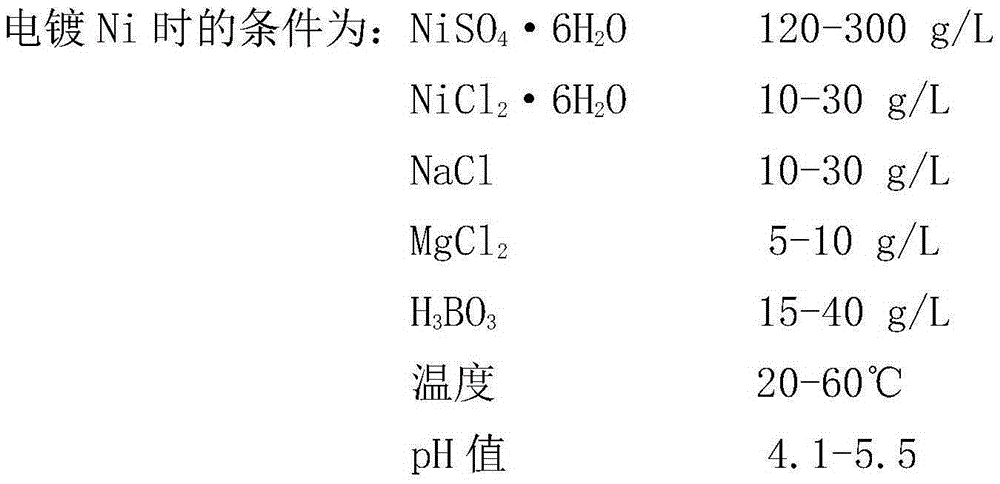

[0048] The polyacrylonitrile (PAN)-based high-strength 12K carbon fiber was heat-treated in a desizing furnace at 450°C for 20 minutes, and the atmosphere was nitrogen; then the carbon fiber was used as the cathode, and the electroplated anode plate was a nickel plate for continuous nickel plating. The formula of the electroplating solution is: NiSO 4 ·6H 2 O240g / L, NiCl 2 ·6H 2 O30g / L, NaCl15g / L, MgCl 2 15g / L,H 3 BO 3 30g / L, the pH value is controlled at 4.2-5.0, and the temperature is 40°C. The current through the carbon fiber tow is 2A, and the total electroplating ...

Embodiment 2

[0053] The structure of the heating exporting device 11 is shown in Embodiment 1.

[0054] The polyacrylonitrile (PAN)-based high-strength 12K carbon fiber was heat-treated in a desizing furnace at 550°C for 12 minutes, and the atmosphere was nitrogen; after that, the carbon fiber was used as the cathode, and the electroplated anode plate was a nickel plate for continuous nickel plating. The formula of the electroplating solution is: NiSO 4 ·6H 2 O120g / L, NiCl 2 ·6H 2 O30g / L, NaCl10g / L, MgCl 2 10g / L,H 3 BO 3 40g / L, the pH value is controlled at 4.8-5.5, and the temperature is 20°C. The current through the carbon fiber tow is 2A, and the total electroplating time is 6min. The metal-plated carbon fiber was washed with deionized water, the washing temperature and time were 30°C and 5min, respectively, and the nickel ion content in the washing water was detected to be 0.021g / L; the cleaned nickel-plated carbon fiber was put into a 400°C heat treatment furnace for 4 minutes,...

Embodiment 3

[0058] At the outlet of the molten impregnation die 9, a heating export device 11 is arranged, which includes a heating device 14, an inner cavity body 15 and a resin discharge port 16, the heating device 14 is located at the outer wall of the inner cavity body 15, and the resin discharge port 16 is located at the inner cavity body 15 directly below the . The heating device 14 is hot air.

[0059] The polyacrylonitrile (PAN)-based high-strength 12K carbon fiber was heat-treated in a desizing furnace at 650°C for 5 minutes, and the atmosphere was argon; then the carbon fiber was used as the cathode, and the electroplated anode plate was a nickel plate for continuous nickel plating. The formula of the electroplating solution is: NiSO 4 ·6H 2 O300g / L, NiCl 2 ·6H 2 O10g / L, NaCl30g / L, MgCl 2 5g / L,H 3 BO 3 15g / L, the pH value is controlled at 4.4-5.2, and the temperature is 50°C. The current through the carbon fiber tow is 2A, and the total electroplating time is 6min.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com