Test tube dryer

A dryer and test tube technology, which is applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems of energy waste, difficult access, and long time required for the dryer, and achieve good drying effect and convenience. The effect of recycling and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

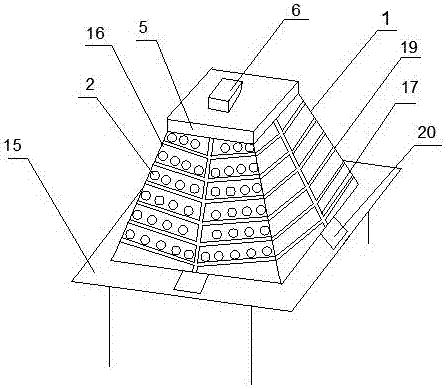

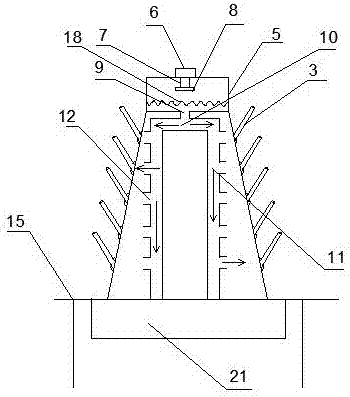

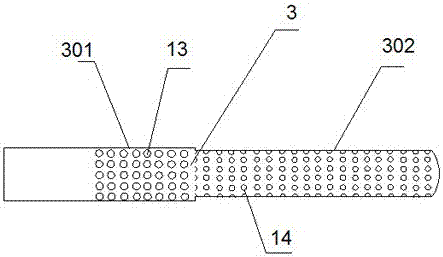

[0025] A test tube dryer, the dryer 1 is a hollow square prism structure, each wall plate 16 of the dryer 1 is provided with a drainage channel, and the drainage channel includes The vertical drainage groove 17 and several branch drainage grooves 19 that are upwardly radiating to both sides of the wall plate 16, the branch drainage groove 19 is connected with the vertical drainage groove 17, and a through hole is provided above each branch drainage groove 19 2. A flanging hole plug 4 is embedded in the through hole 2. The flanging hole plug 4 is a hollow structure with a small diameter at one end and a large diameter at the other end. The end with a small diameter is connected to the drying pipe 3 through threads;

[0026] The top of the dryer 1 is a heating and blowing mechanism, including a housing 5, a motor 6 arranged on the housing, a fan 8 connected to the motor 6 through a rotating shaft 7, and a fan 8 connected to the housing 5 is arranged below the fan 8. The heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com