Optical coating material guiding and drying device

A technology of optical coating and drying device, applied in drying, drying machine, granular material drying and other directions, can solve the problems of low degree of material dispersion, unable to effectively dry coating materials, etc., to promote rapid drying, The effect of promoting moisture evaporation and improving looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

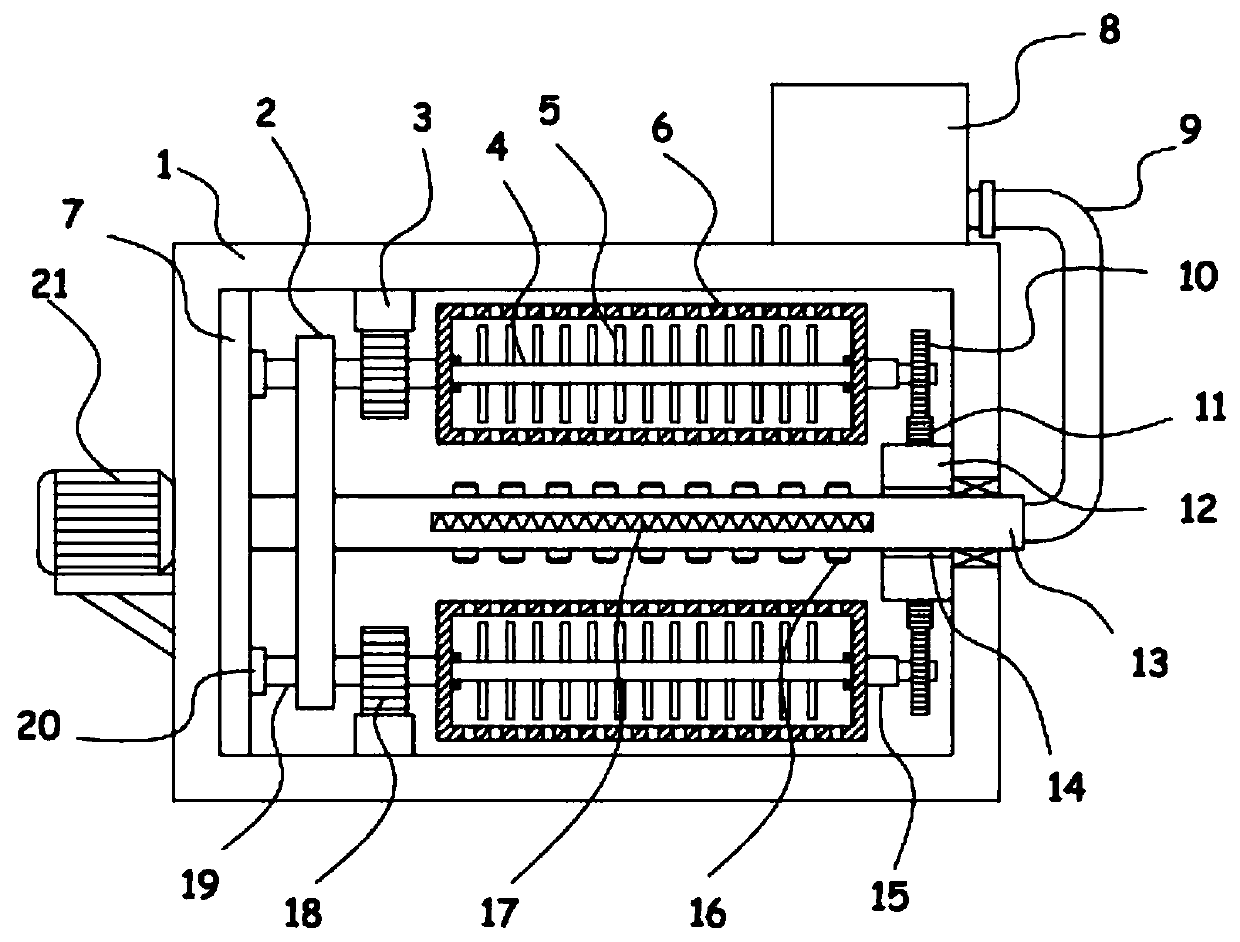

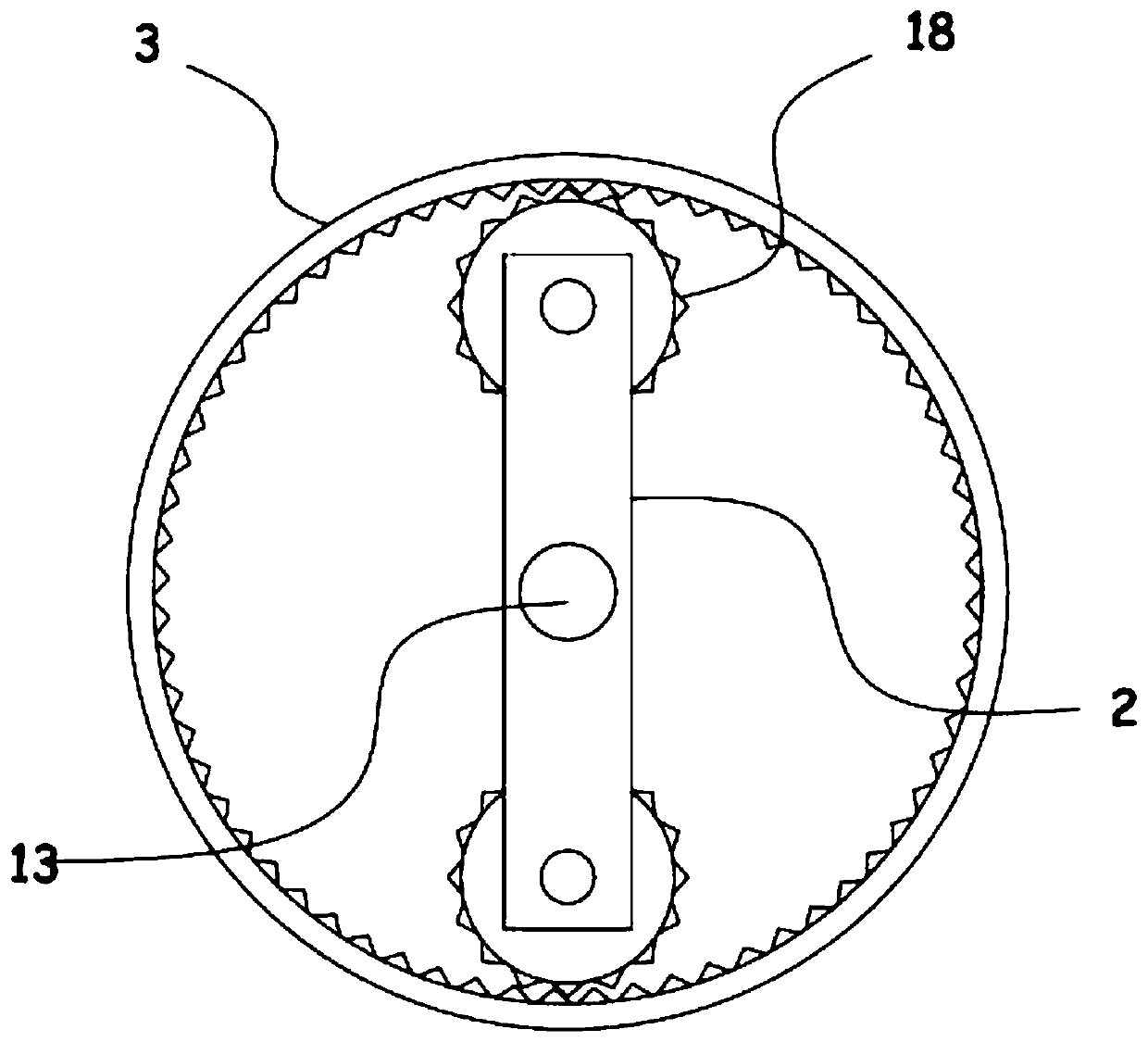

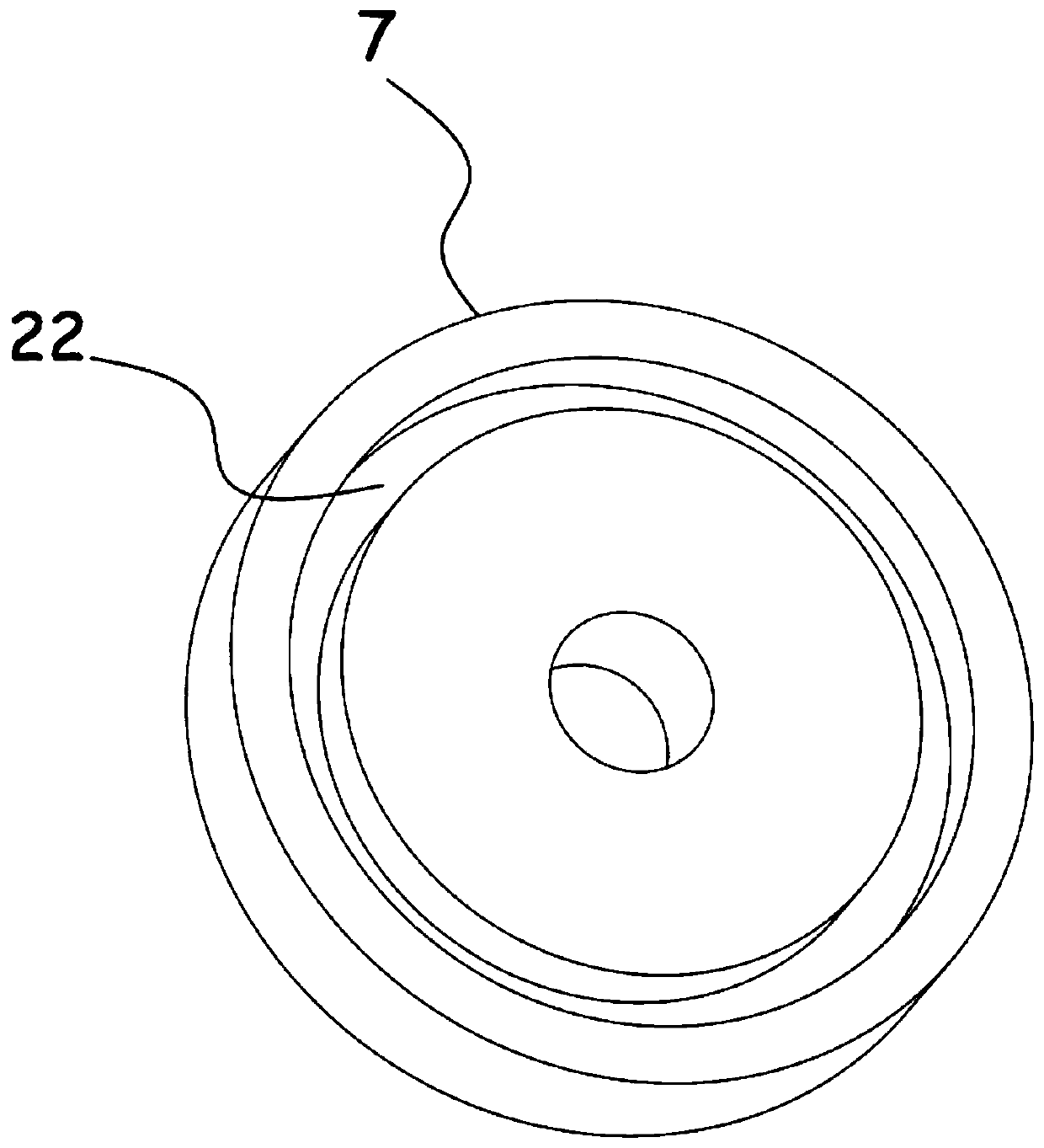

[0022] see Figure 1-4 , a kind of optical coating material guide material drying device, comprising a support frame 1, a servo motor 21 and a hot air blower 8 are fixed on the support frame 1, a mesh cylinder 6 for storing coating materials is provided on the support frame 1, and the support frame 1 A revolving mechanism for driving the net cylinder 6 to rotate is provided, and a self-rotation mechanism for driving the net cylinder 6 to rotate is provided in the support frame 1. A hollow shaft 13 is installed on the center of the support frame 1, and the hollow shaft 13 is provided with a A drying mechanism for drying materials in the mesh cylinder 6, and an agitating mechanism for dispersing the coating material is installed in rotation inside the mesh cylinder 6.

[0023] The net cylinder 6 of this device is filled with the coated granular material to be dried, and the net cylinder 6 is driven to revolve while rotating through the set rotation mechanism and revolution mecha...

Embodiment 2

[0027] On the basis of Embodiment 1, in addition, the drying mechanism of the device includes a heating rod 17 fixed on the side wall of the hollow shaft 13, and several nozzles 16 are uniformly installed on the hollow shaft 13, and the outlet end of the hot air blower 8 is connected with The air guide tube 9 is arranged in communication with the hollow shaft 13 through a rotary joint.

[0028] The hot air generated by the hot air blower 8 is sent to the inside of the hollow shaft 13 through the air duct 9, the hot air is sprayed out through the nozzle 16, and the hot air enters the inside of the mesh cylinder 6 to realize the drying effect on the material, and the heating rod 17 provided can dry the hollow shaft 13. The air flow inside the shaft 13 is reheated to ensure that the hot air ejected from the nozzle 16 has a higher temperature and speed up the drying of the material.

[0029] Further, the device is also provided with a stirring mechanism, including a limit tube 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com