Arc-shaped wood veneer dyeing device for forestry processing

A wood veneer and dyeing device technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of uneven spraying of paint, general dyeing effect of wood board, lack of rotating wood board frame, etc., to achieve reasonable structure and increase dyeing Efficiency and uniformity of dyeing, the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

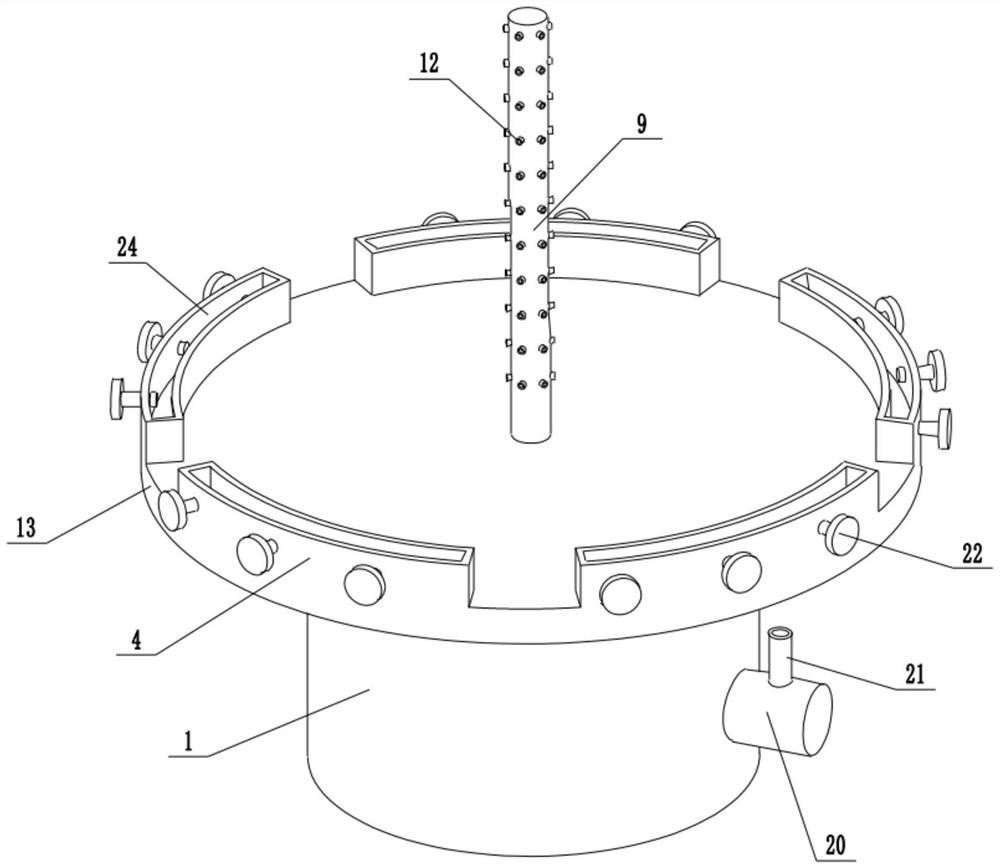

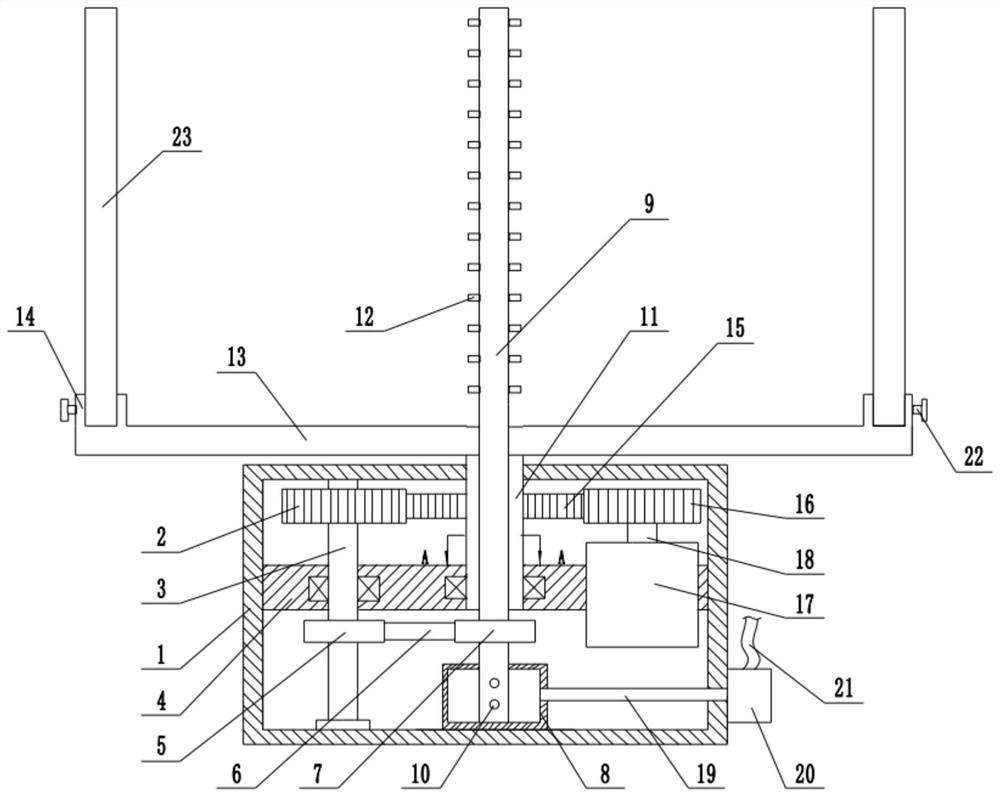

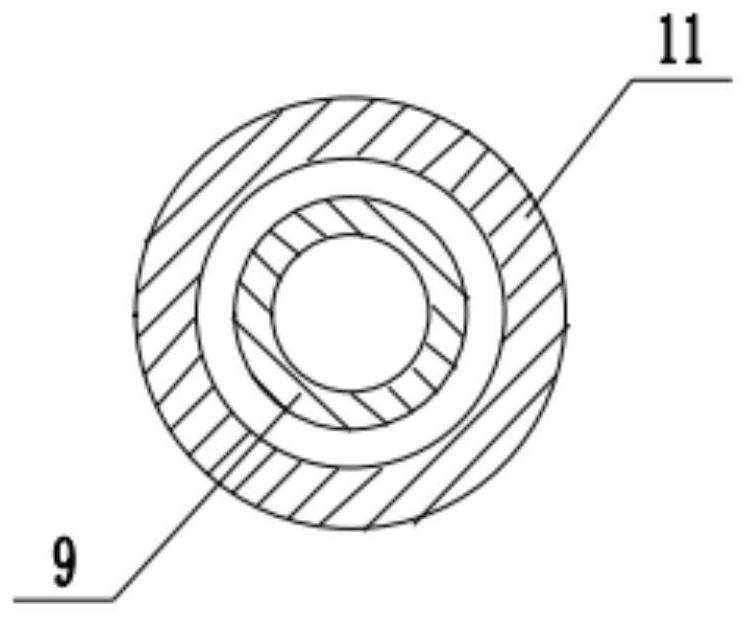

[0027] refer to Figure 1~3 , in an embodiment of the present invention, an arc-shaped wood veneer dyeing device for forestry processing includes a fixed box 1, and a baffle plate 4 is installed inside the fixed box 1 to realize the installation and fixation of the drive motor 17, and the rotation The position-limiting guiding installation of shaft 11 and rotating shaft 3, driving motor 17 is installed in the middle part of baffle plate 4 right sides, and described driving motor 17 is double-turning stepper motor, thus has guaranteed the bidirectional rotation of driving gear 16, and the driving motor 17 Output shaft 18 is connected with driving gear 16, and driving gear 16 left side is meshed with intermediate gear 15, and rotating shaft 11 is installed in the middle part of intermediate gear 15, and rotating shaft 11 inside is provided with cavity, and cavity interior is provided with color-spraying post 9, and setting cavity The cavity ensures that the color spraying column...

Embodiment 2

[0029]In another embodiment of the present invention, 1. A curved wood veneer dyeing device for forestry processing, comprising a fixed box 1, a baffle 4 is installed inside the fixed box 1, and a drive motor 17 is installed in the middle of the right side of the baffle 4, and the drive motor 17 is a double-turn stepper Motor, the output shaft 18 of the driving motor 17 is connected with a driving gear 16, the left side of the driving gear 16 is meshed with an intermediate gear 15, the middle part of the intermediate gear 15 is equipped with a rotating shaft 11, and the inside of the rotating shaft 11 is provided with a cavity. Color column 9, the bottom end of the color spray column 9 is rotated at the bottom of the feed box 8, the interior of the color spray column 9 is a hollow structure, the top of the rotating shaft 11 is equipped with a rotating seat 13, and the outer side of the upper end of the rotating seat 13 is provided with Clamping block 14, described clamping blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com