Full-automatic Pu'er tea pile fermentation and airing production and processing technology

A kind of processing technology, fully automatic technology, applied in the direction of tea processing before extraction, conveyor objects, emptying containers, etc., can solve the problem of difficult discharge, reduce the number of turning over, improve the efficiency of stacking, and use flexible and convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

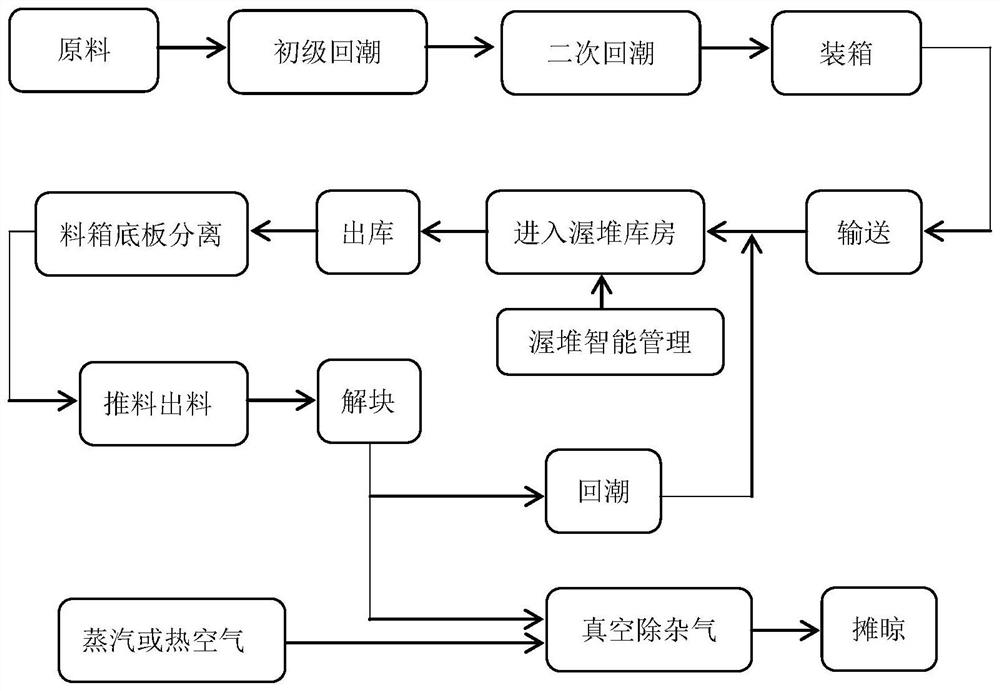

[0029] The fully automatic production and processing technology of Pu-erh tea in piles and air-drying includes the following steps:

[0030] Step S1, pre-treatment of tea raw material stacking: adjusting the moisture content of the tea material includes primary tide water and secondary tide water, ensuring that the moisture content of the tea material is controlled between 34% and 46%;

[0031] Step S2, storage and storage: tea materials are packed and transported into storage into a box-type fermentation warehouse for storage;

[0032] Step S3, stacking management: during the stacking process, intelligent sensors are used to obtain and adjust the stacking conditions in the stacking warehouse, and manage the time points and times of stacking in the stacking process; the intelligent sensors include temperature and humidity sensors, which are set at In the Wodui warehouse, it is uniformly monitored and processed by the controller to keep it in a state of constant temperature and...

Embodiment 2

[0037] On the basis of Example 1, preferably, in step S1, the primary dampening is tunnel-type dampening, and the moisture of the tea material is increased by 5% to 10%, so that the tea material is softened and softened, and the moisture content of the material after the initial dampening is obtained. Moisture content, after the second moisture regain, the moisture content of the tea material is precisely controlled between 20% and 25%.

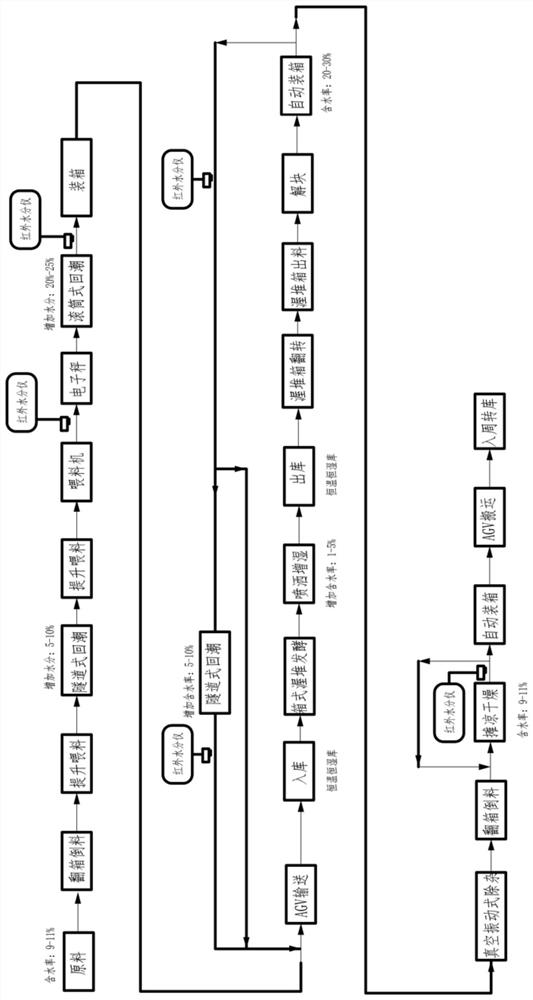

[0038] The material box used in steps S2-S4 is a barreled material barrel with a detachable bottom plate, and several meshes or through holes are opened on the wall and bottom of the barrel; the material box used in steps S5-S6 is a square or rectangular material box.

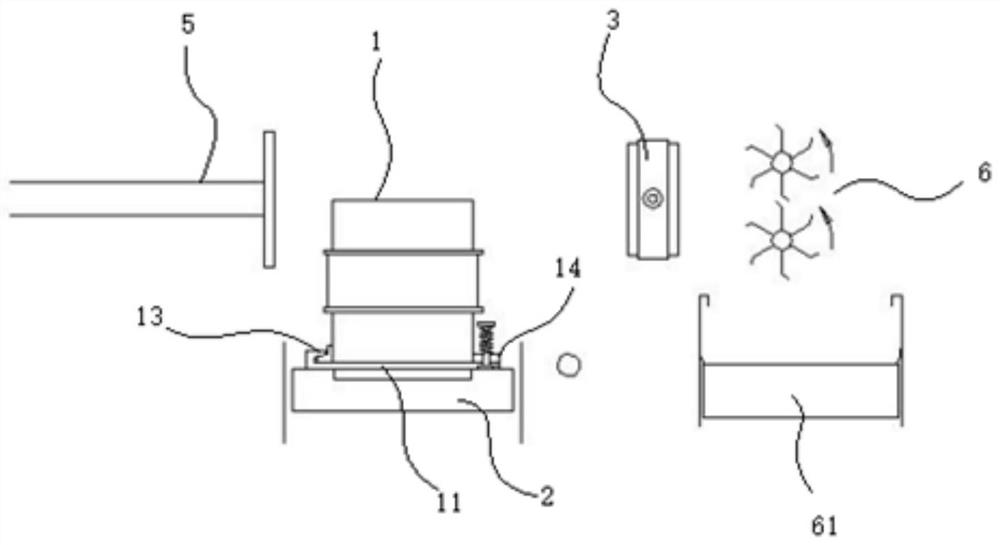

[0039] Step S4 comprises the following steps: as image 3 As shown, the movable floor at the bottom of the barrel and the barrel body remain fixed and enter the discharging and unblocking station. After entering the station, they drive into the reversible and reversible convey...

Embodiment 3

[0056] On the basis of Example 1 or 2, the following steps are also included: the tea material is pre-steamed for 2-5 minutes; then the tea material is placed in a vacuum environment, and the ambient pressure is kept between 50-70kPa for a continuous 1-3 minutes; after step S2 is completed, inject negative pressure steam to contact the tea material, and keep the temperature of the negative pressure steam between 70-85°C for 1-3 minutes; or replace the negative pressure steam with hot air, inject The hot air with a temperature between 70-85°C is in contact with the tea material for 1-3 minutes; stop injecting steam or hot air, and gradually release the negative pressure until the standard atmospheric pressure is restored.

[0057] The specific steps of vacuum deodorization are as follows:

[0058] Step (1), pre-steaming the tea material before discharging and cooling after stacking or fermentation, the pre-steaming time is 1-5 minutes; the moisture content of the tea material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com