Intermittent rotating tray

A technology for turning material trays and trays, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve the problem of high cost of manipulators and achieve the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

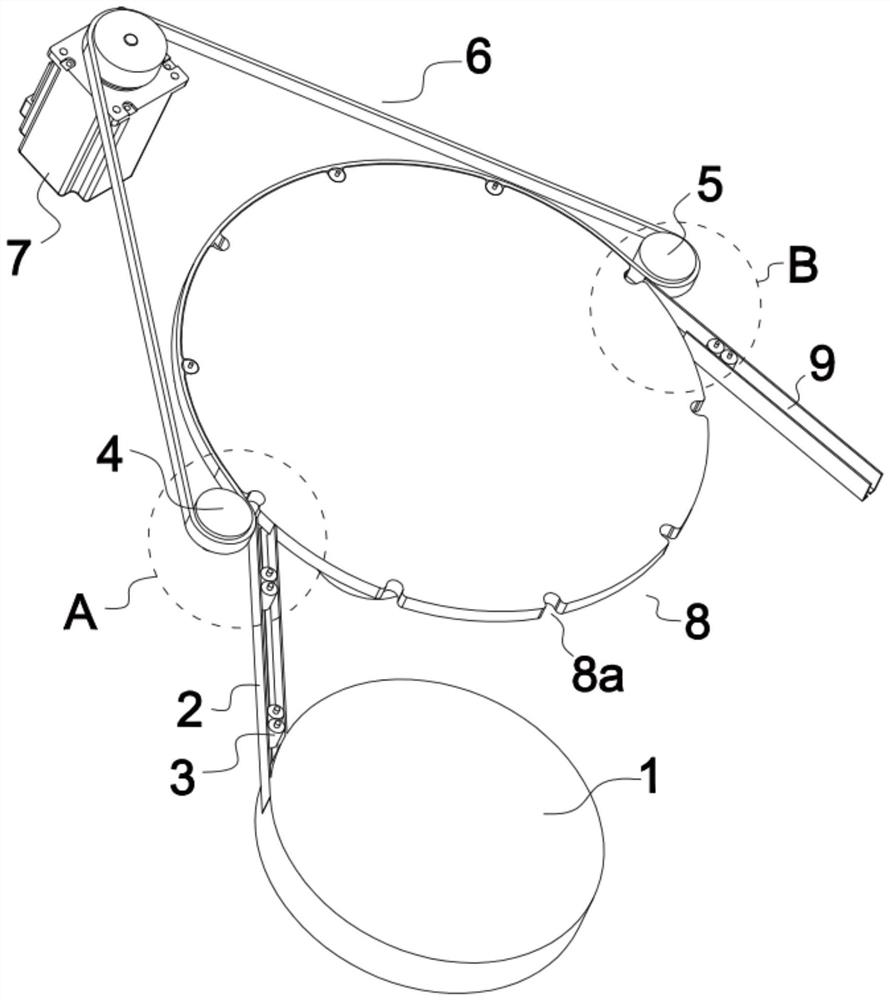

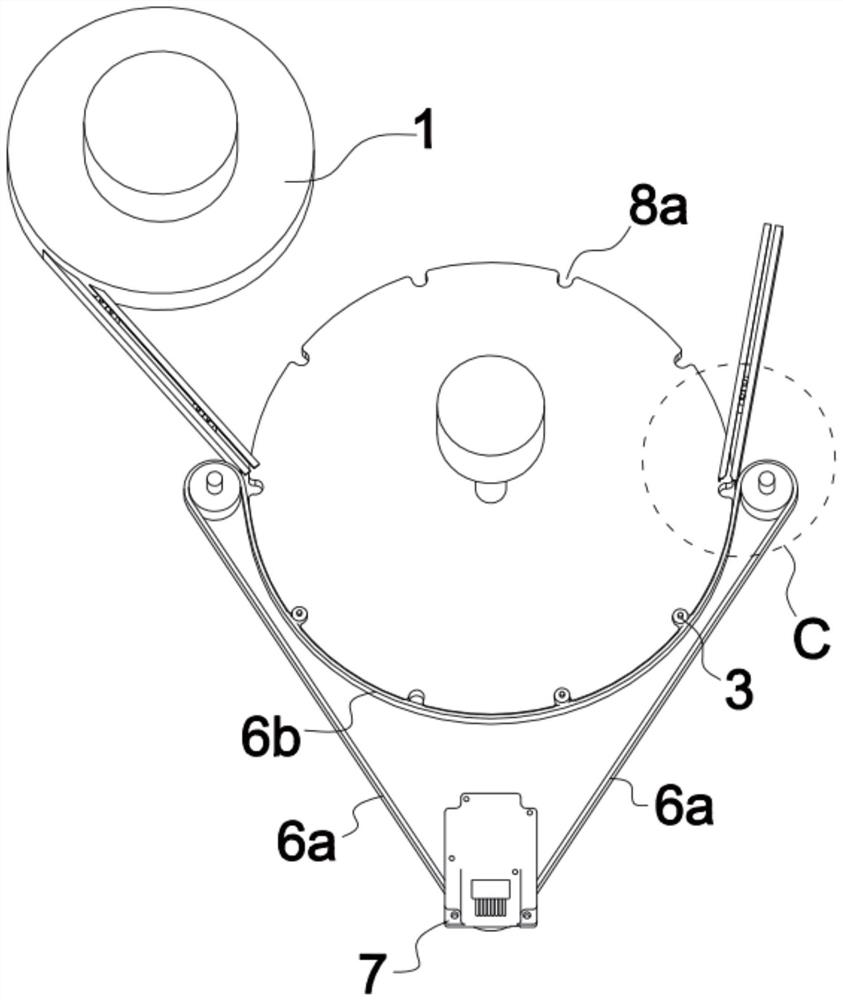

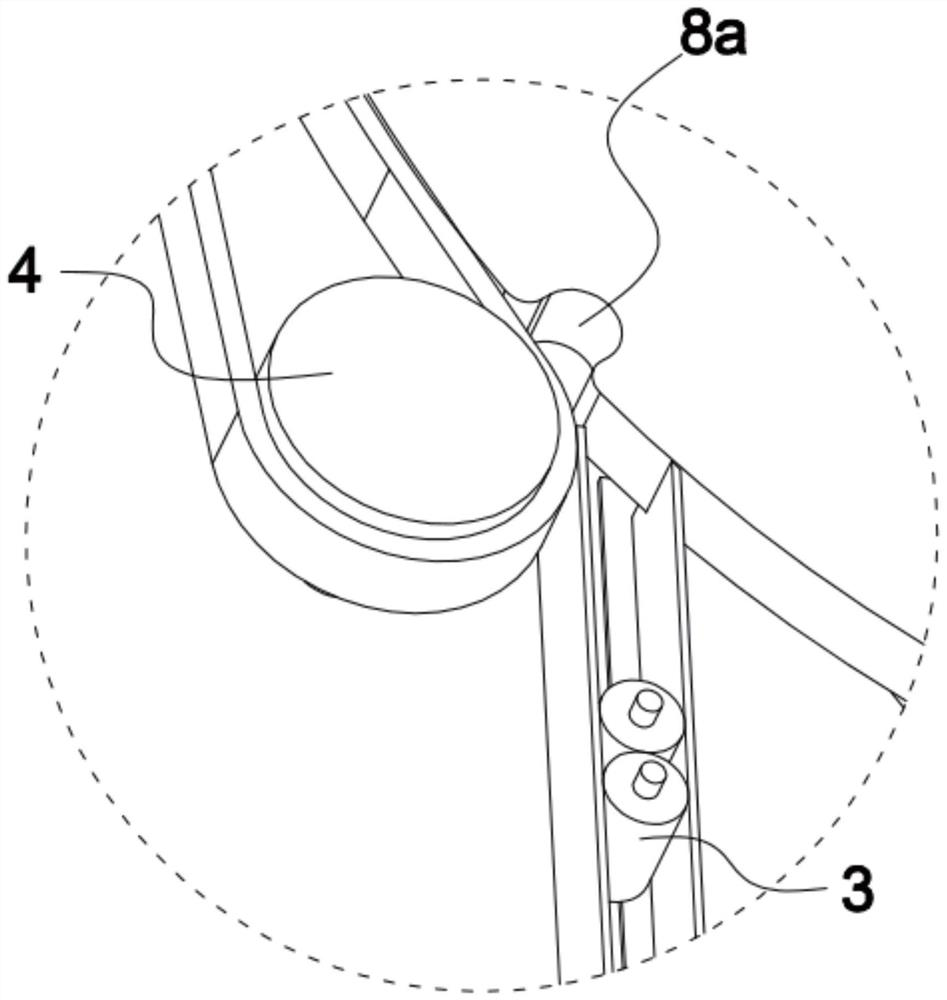

[0033] In order to achieve the purpose of the present invention, an intermittent rotating tray includes: a turning tray 8, which has a degree of freedom of rotation around its own axis, and a number of gaps 8a for accommodating products 3 are arranged at intervals on the edge of the turning tray 8; The vibration plate 1 is in contact with the transfer plate 8 through the feeding track 2, and the vibration plate 1 conveys the product 3 to the transfer plate 8; the transmission belt 6 is in contact with the edge of the transfer plate 8, and the inner wall of the transmission belt 6 is in contact with the active motor 7, The first driven wheel 4, the second driven wheel 5, on the transmission belt 6 except the position that contacts with the driving motor 7, the first driven wheel 4, and the second driven wheel 5 form an arc segment 6b, two straight line segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com