Flanging and riveting self-locking nut and machining method thereof

A technology of self-locking nuts and processing methods, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems of low efficiency, troublesome processing, high cost and unable to meet the needs of rapid development, and achieve high safety and reliability, convenient maintenance, and locking good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The manufacturing method of the present invention is that the bar is directly molded and pressed to form a blank, which is machined and cold deformed. The theoretical basis is to use a material with good plasticity, whose grains will not break after die forging, and whose grains are arranged in a linear shape, that is, the grain streamlines are uniform, complete and highly oriented. This kind of material has good upsetting processability and can obtain any shape blanks. Commonly used materials are carbon structural steel (such as: ML30, ML35), alloy structural steel (such as: 30CrMnSiA, 40CrNiMoA) and so on.

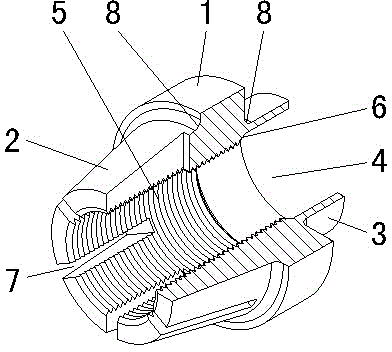

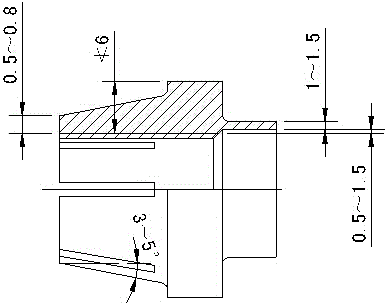

[0027] The turning riveting self-locking nut that the present invention processes, as figure 1 and 2 As shown, the shape of the turning riveting self-locking nut is a variable diameter cylinder, the middle section of the variable diameter cylinder is a large cylinder 1, one end of the large cylinder 1 is a cone 2, and the other end of the large cylinder 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com