Fabricated ceramic tile wall surface and construction method thereof

A prefabricated and ceramic tile technology, applied in covering/lining, construction, building construction, etc., can solve problems such as long construction period, wall damage, construction site pollution, etc., and achieve the effect of improving installation quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

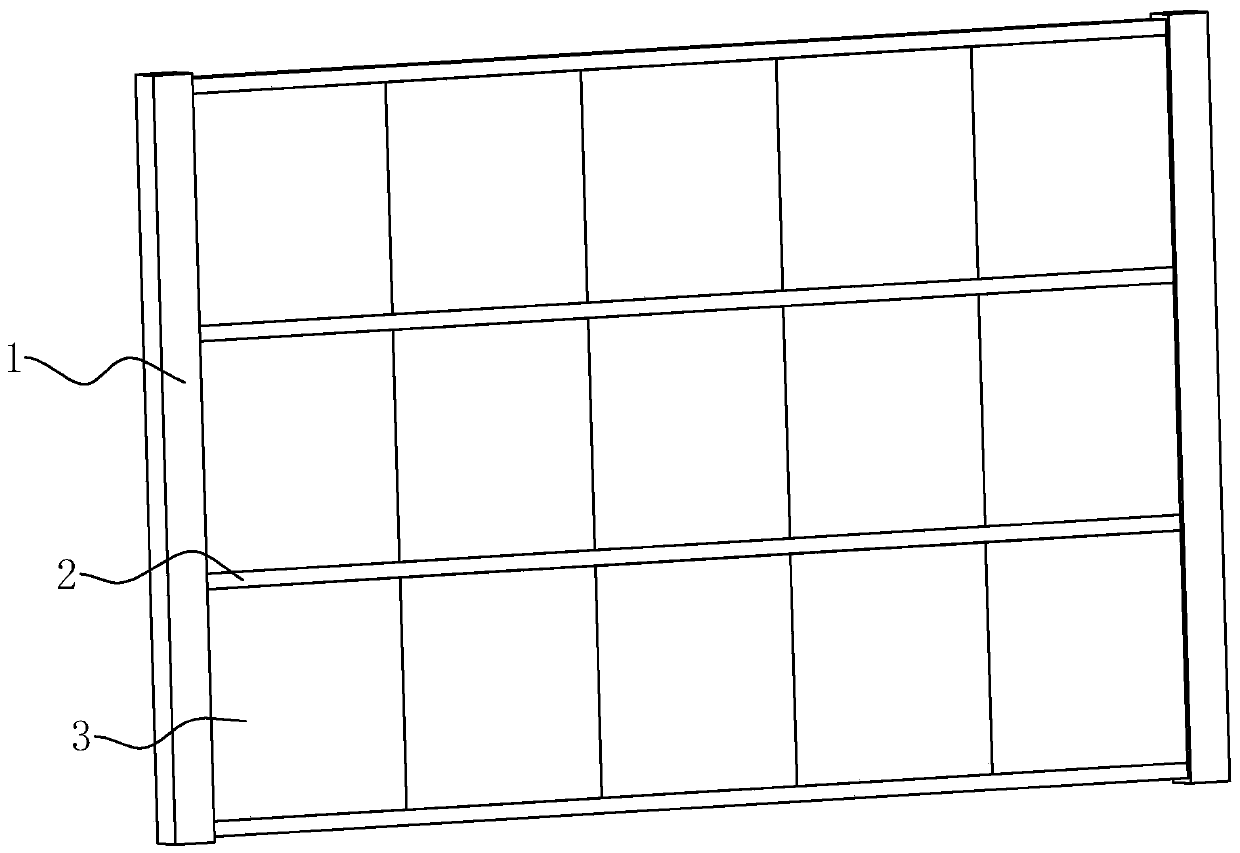

[0037] Embodiment 1: A kind of prefabricated ceramic tile wall surface, such asfigure 1 As shown, it includes the main joist 1 installed on the wall on the inner surface, a plurality of load-bearing joists 2 arranged horizontally and equidistantly on the main joist 1, and a plurality of tile templates 3 installed outside the main joist 1. The load-bearing joists 2 are all connected with Ground-parallel setup.

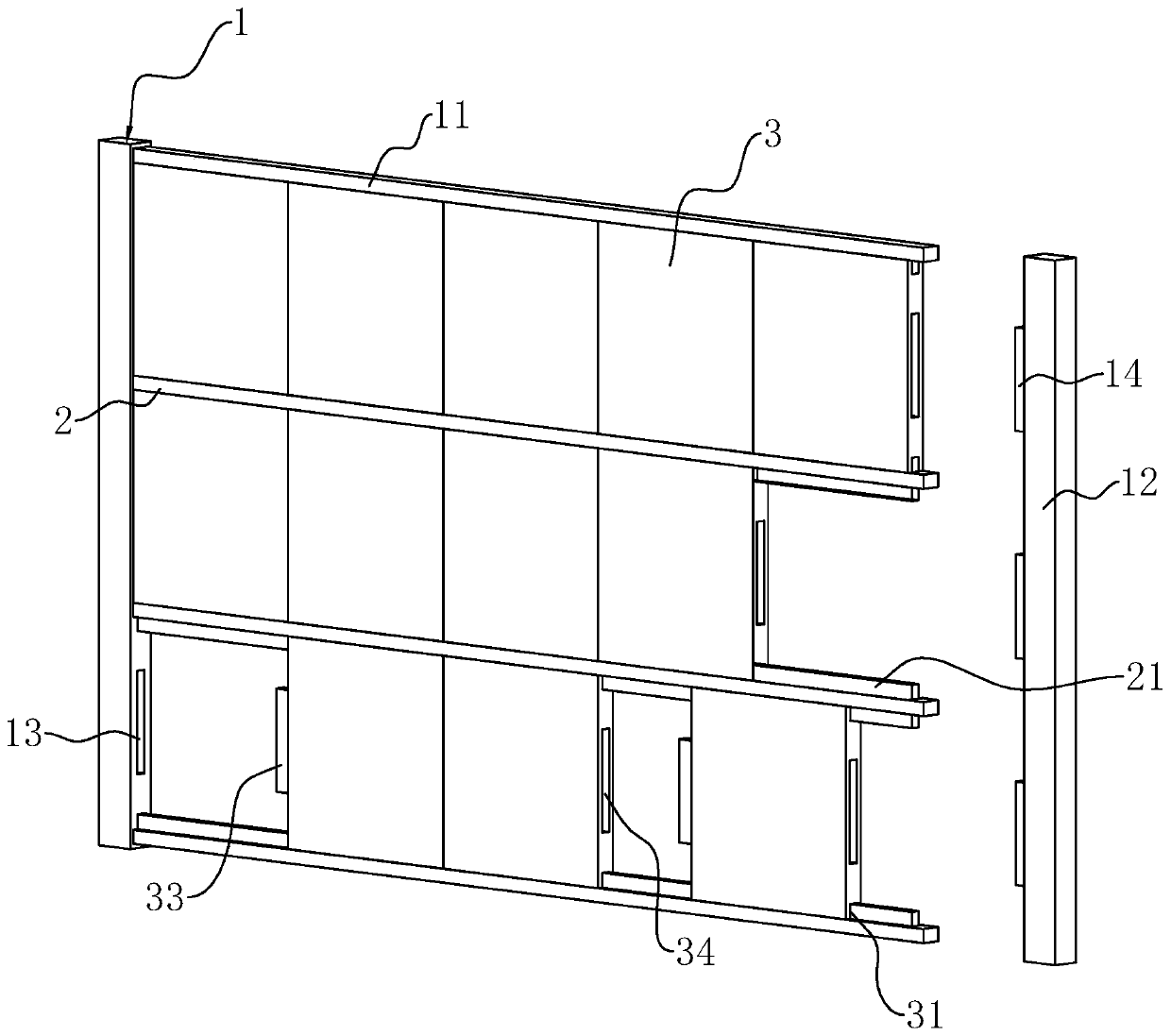

[0038] Such as figure 2 As shown, the main keel 1 includes a door frame 11 and an installation keel 12 that is fixed on the door frame 11 by self-tapping screws and forms a ring-shaped installation area. And in the door frame 11; a plurality of tile templates 3 are spliced with each other and are all slid and arranged between the upper and lower bearing joists 2 along the length direction of the bearing joists 2, so that they form tile walls.

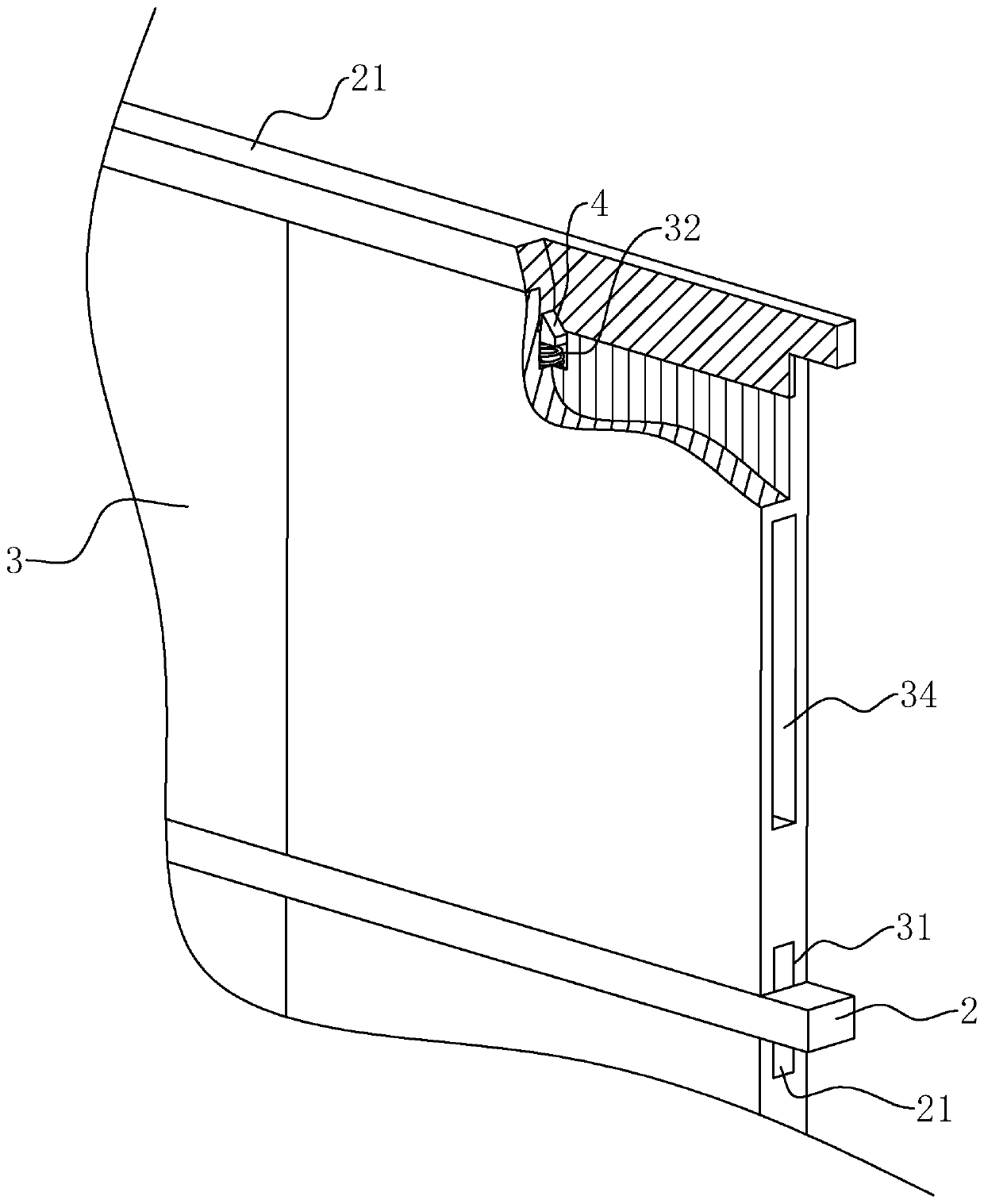

[0039] Such as image 3 As shown, positioning grooves 31 are provided on the upper and lower sides of the tile template 3 ...

Embodiment 2

[0044] Embodiment 2: a kind of construction method of prefabricated ceramic tile wall, comprises the following steps:

[0045] S1. Pre-design step: according to the size of the wall, determine the installation interval of the main keel 1, the installation interval of the bearing keel 2, the thickness and size of the wall module, and the size of the ceramic tile;

[0046] S2. Production of ceramic tile formwork 3: batch production of ceramic tile formwork 3 according to design requirements;

[0047] S3. The installation step of the bearing keel 2: fix and install a plurality of bearing keels 2 on the door frame 11 horizontally, equidistantly, and in parallel;

[0048] S4. Installation of tile formwork 3: slide the tile formwork 3 from between the upper and lower two bearing keels 2, so that multiple tile formworks 3 are sequentially spliced in a row, and connected to the keyhole 22 on the bearing keel 2 through the telescopic buckle 4 Inside, multiple rows of tile templates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com