Locking structure of slotted nut

A technology for locking structures and nuts, which is applied in the direction of nuts, threaded fasteners, locking fasteners, etc., which can solve the problem of lack of locking effect, unfixed size of channel nuts, and small size of locking clips that cannot be fixed and other problems to achieve the effect of avoiding insufficient locking, simple locking method and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

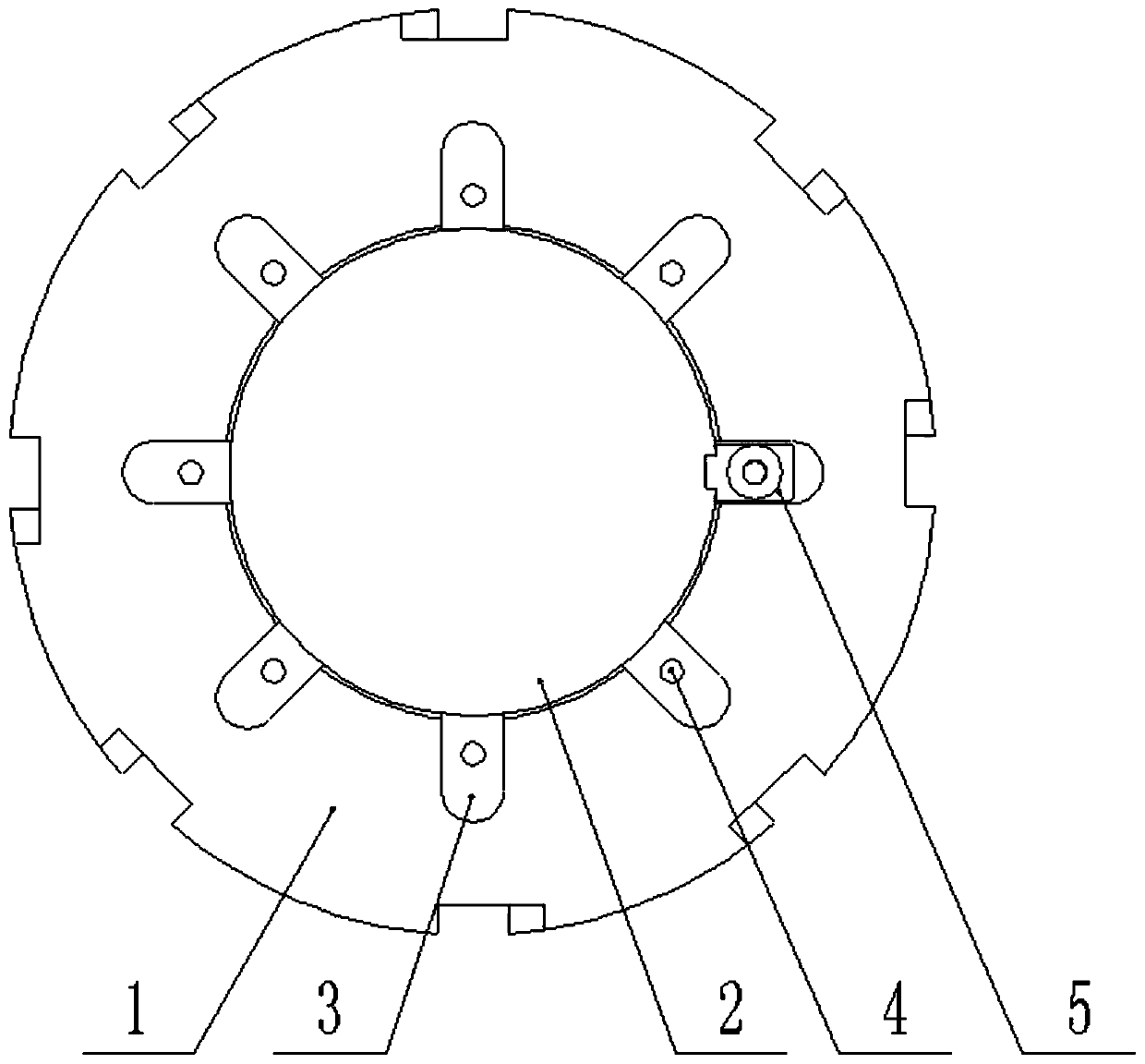

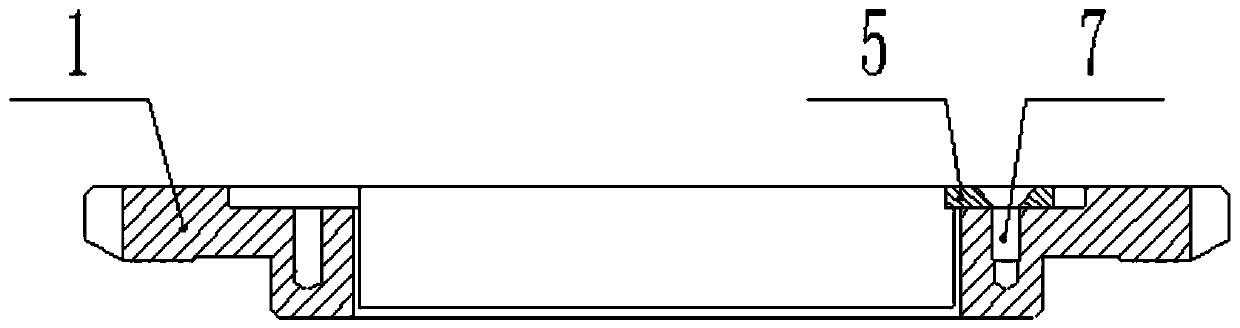

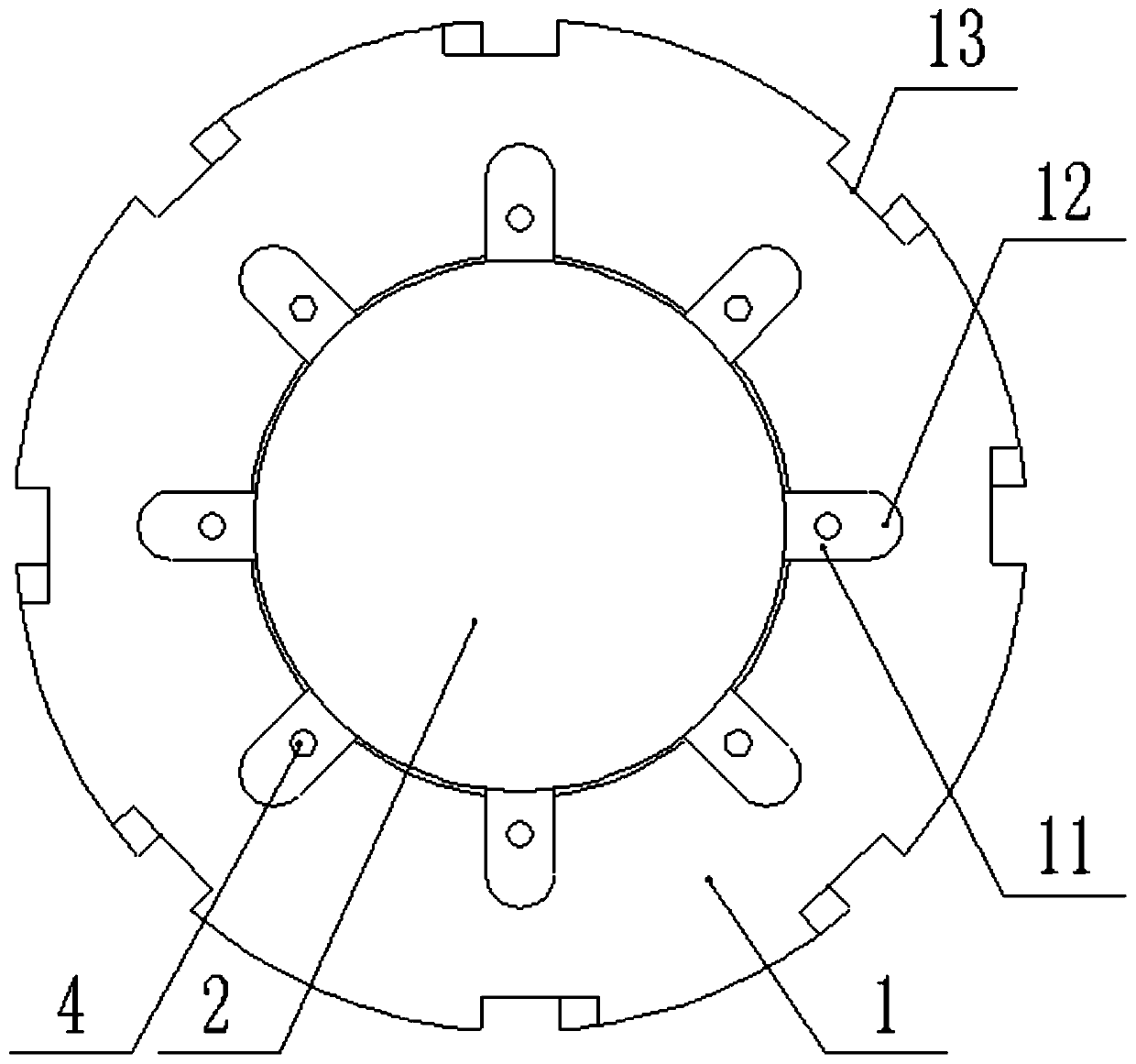

[0023] Such as Figure 1 to Figure 5 As shown,

[0024] A locking structure for a trough nut includes a trough nut 1, a threaded hole 2 penetrates through the center of the trough nut 1, a connecting shaft is screwed in the threaded hole 2, and a locking vertical is provided on the connecting shaft. A groove, the upper surface of the groove nut 1 is provided with a number of grooves 3 along the outer edge of the threaded hole 2, one end of the groove 3 is communicated with the threaded hole 2, and a connecting threaded hole 4 is provided in the groove 3 , The groove 3 corresponding to the vertical slot on the connecting shaft is provided with a locking piece 5, and the locking piece 5 is provided with a counterbore 6 corresponding to the connecting threaded hole 4, and the counterbore 6, connecting A countersunk screw 7 is screwed into the threaded hole 4, and a side surface of the locking piece 5 facing the threaded hole 2 is provided with a protruding portion 8 which is clampe...

specific Embodiment 2

[0026] Such as Figure 1 to Figure 5 As shown,

[0027] A locking structure for a trough nut includes a trough nut 1, a threaded hole 2 penetrates through the center of the trough nut 1, a connecting shaft is screwed in the threaded hole 2, and a locking vertical is provided on the connecting shaft. A groove, the upper surface of the groove nut 1 is provided with a number of grooves 3 along the outer edge of the threaded hole 2, one end of the groove 3 is communicated with the threaded hole 2, and a connecting threaded hole 4 is provided in the groove 3 , The groove 3 corresponding to the vertical slot on the connecting shaft is provided with a locking piece 5, and the locking piece 5 is provided with a countersunk hole 6 corresponding to the connecting threaded hole 4, and the counterbore 6, connecting A countersunk screw 7 is screwed into the threaded hole 4, and a side surface of the locking piece 5 facing the threaded hole 2 is provided with a protruding portion 8 which is c...

specific Embodiment 3

[0030] Such as Figure 1 to Figure 5 As shown,

[0031] A locking structure for a trough nut includes a trough nut 1, a threaded hole 2 penetrates through the center of the trough nut 1, a connecting shaft is screwed in the threaded hole 2, and a locking vertical is provided on the connecting shaft. A groove, the upper surface of the groove nut 1 is provided with a number of grooves 3 along the outer edge of the threaded hole 2, one end of the groove 3 is communicated with the threaded hole 2, and a connecting threaded hole 4 is provided in the groove 3 , The groove 3 corresponding to the vertical slot on the connecting shaft is provided with a locking piece 5, and the locking piece 5 is provided with a counterbore 6 corresponding to the connecting threaded hole 4, and the counterbore 6, connecting A countersunk screw 7 is screwed into the threaded hole 4, and a side surface of the locking piece 5 facing the threaded hole 2 is provided with a protruding portion 8 which is clampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com