Sliding sleeve screw removing robot

A robot and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the screw thread cannot be rotated, and achieve the effect of ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

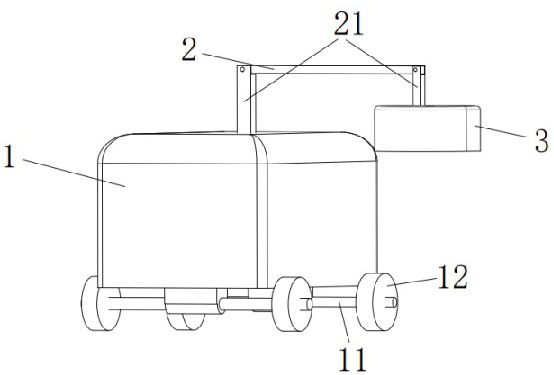

[0028] Such as Figure 1-Figure 7 As shown, a sliding sleeve screw robot is characterized in that it includes a power box 1, a positioning rod 2 and a set-releasing assembly 3, and both ends of the positioning rod 2 are provided with struts 21, and the two struts 21 are respectively Rotately connected with the power box 1 and the release assembly 3, the support rod 21 can be rotated and aligned according to the specific detailed position of the sliding sleeve screw;

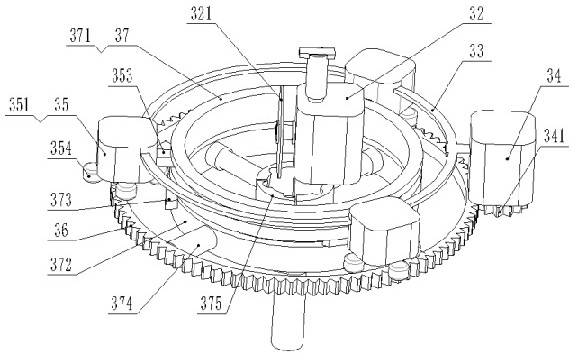

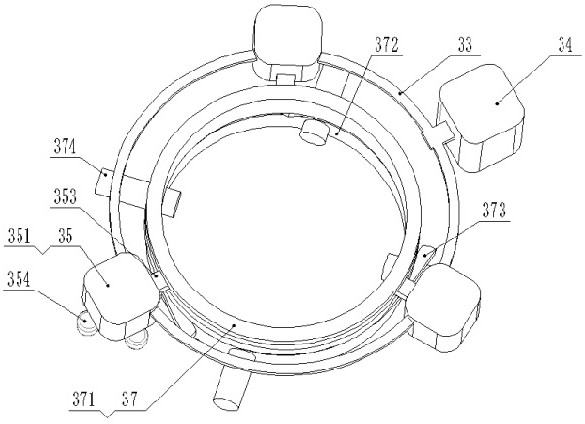

[0029] The unpacking assembly 3 includes a bottomless shell 31, a grinding motor 32, a support ring 33, a torque motor 34, an impact assembly 35, an annular guide rail 36, and a positioning ring 37; the grinding motor 32 is fixedly welded to the top in the shell 31, and the grinding motor 32 A polishing sheet 321 is installed on the top, and the polishing sheet 321 is a circular wheel shape, and the grinding direction is vertically downward with respect to the adjustment rod 2; The motor 34 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com