Automobile rotating shaft welding forming surface fine treatment system

A welding forming and processing system technology, applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of workers' personal safety hazards, workers' personal safety threats, and fatigue, and reduce labor. reduce the hidden danger caused by personal safety, and improve the effect of cutting and grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

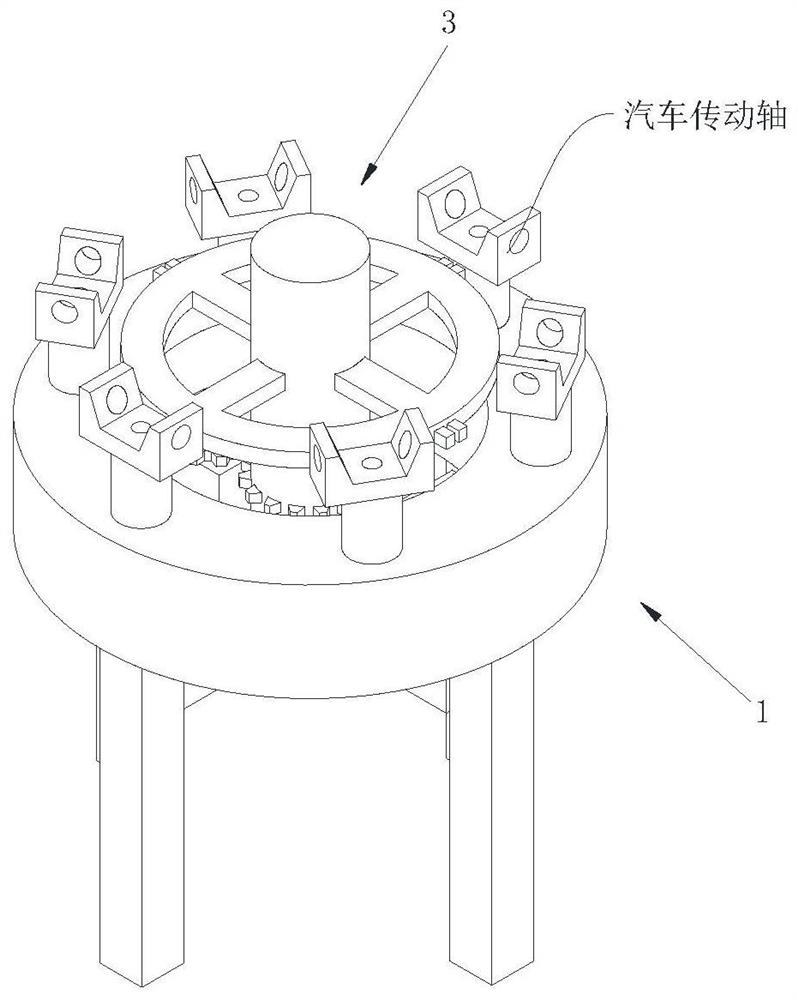

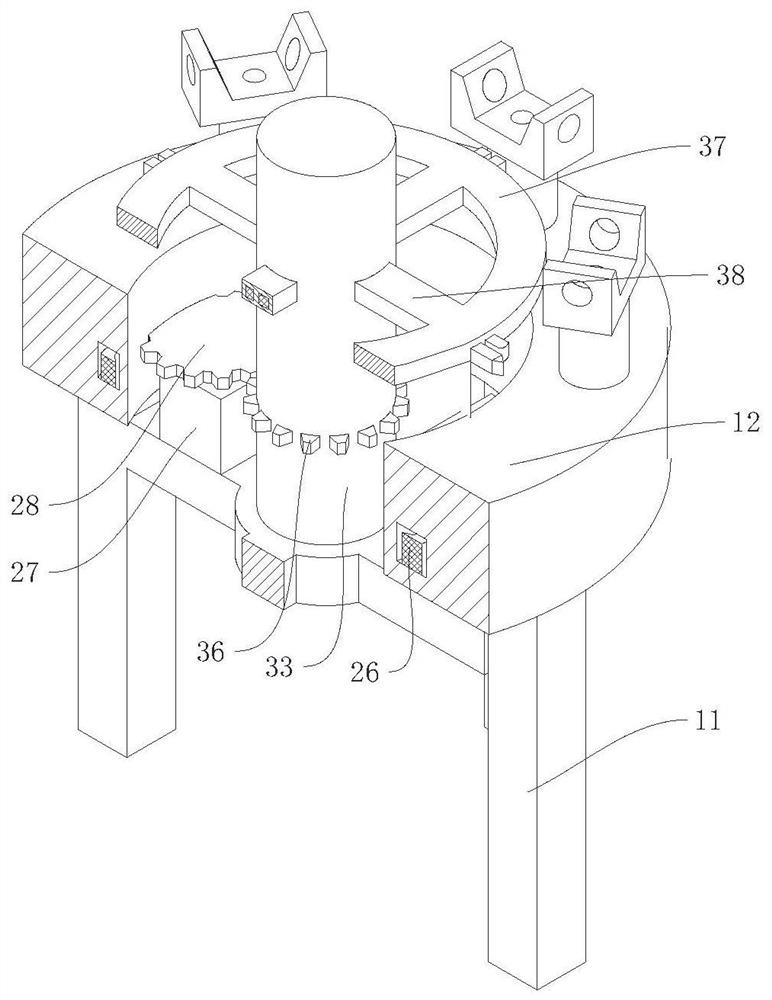

[0031] refer to figure 1 As shown, a surface refinement treatment system for automobile shaft welding and forming includes an automobile transmission shaft, a clamping device 1 for clamping the automobile transmission shaft, an autorotation device 2 for rotating the clamping device 1, and a Cutting and grinding device for welding slag3.

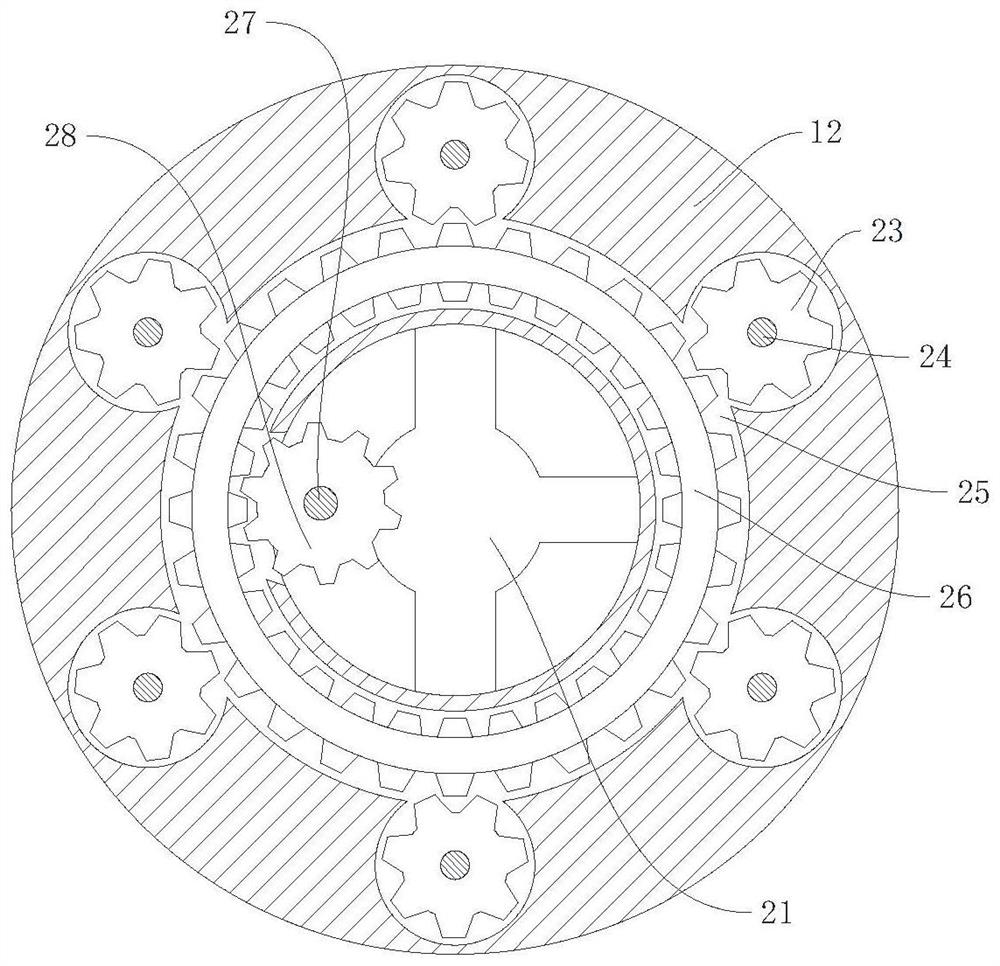

[0032] refer to figure 1 as well as Figure 4 As shown, the clamping device 1 includes a support column 11, a mounting table 12, a clamping groove 13, a clamping block 14, a placement groove 15, a clamping column 16, a clamping torsion spring 17, a clamping plate 18, and a toggle bar 19 And the inner support mechanism 4, the support column 11 is fixedly installed on the ground, the installation platform 12 is fixedly installed on the upper end surface of the support column 11, the clamping groove 13 is opened on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com