Edge locking clamp for rolling of film rolls

A gripper and edge locking technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of film edge wrinkling, normal processing influence, and unsatisfactory film roll surface flatness, etc. Achieve the effect of avoiding running edge wrinkling and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

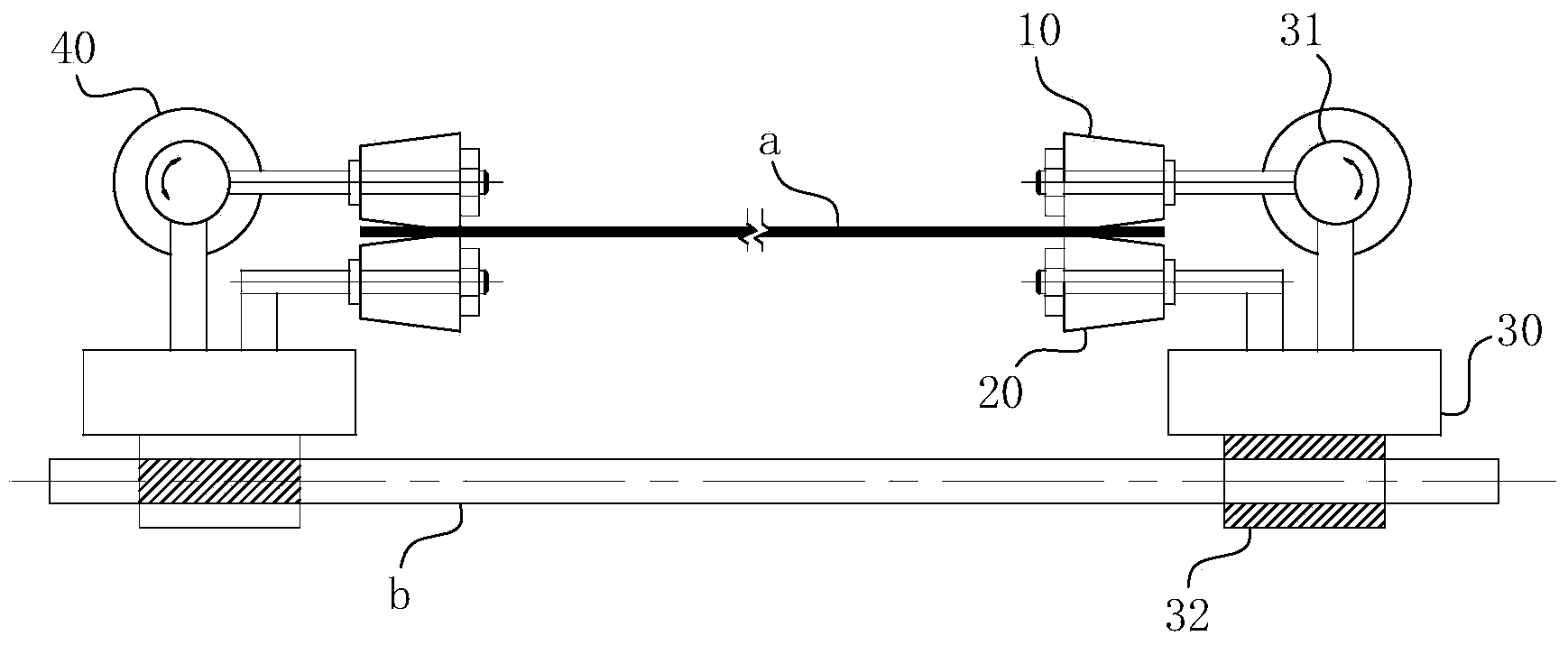

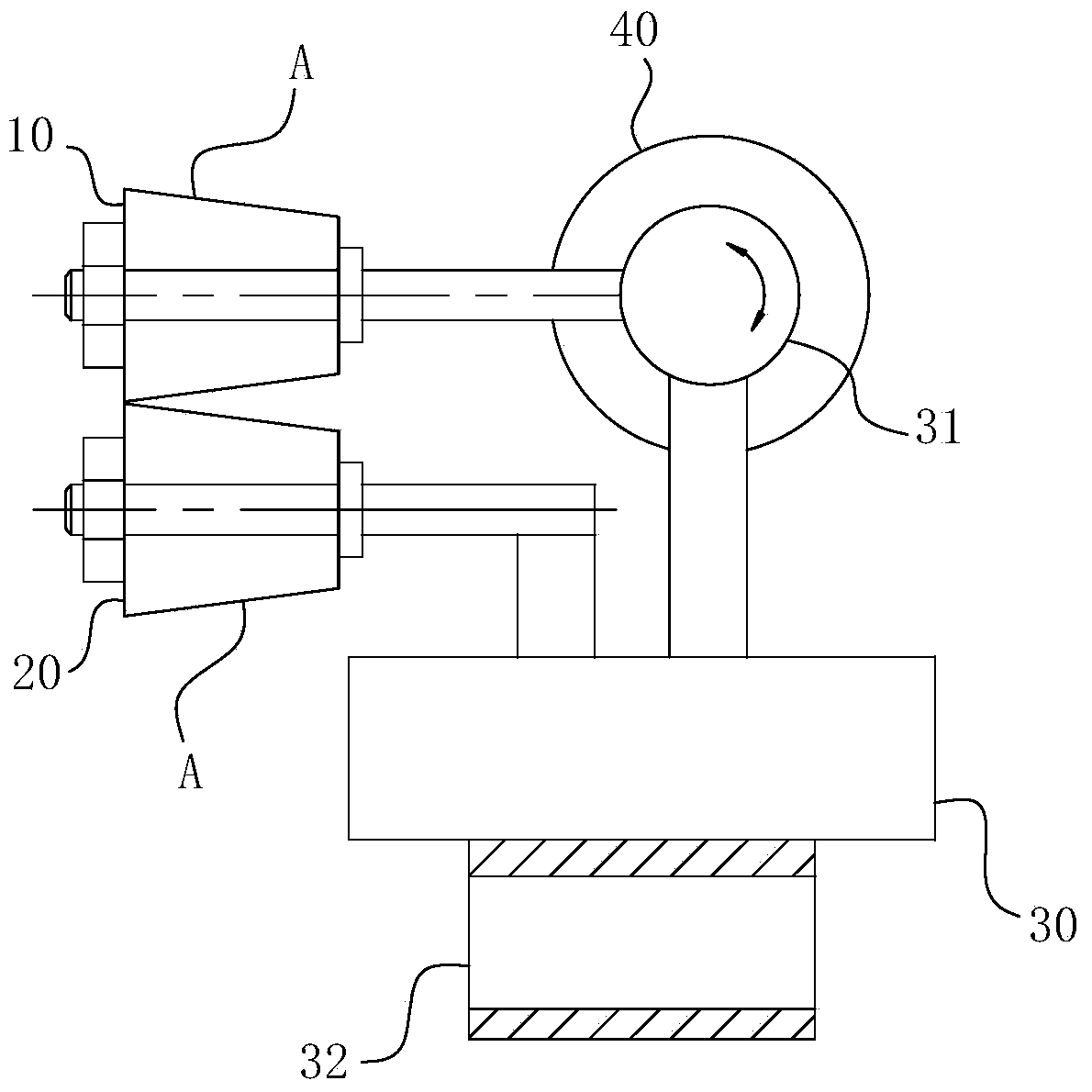

[0019] For ease of understanding, combined here Figure 1-2 Concrete structure of the present invention and working method thereof are described as follows:

[0020] Concrete structure of the present invention, as Figure 1-2 As shown, it includes pinch rollers arranged on the film travel path on the friction roller, and the pinch rollers are arranged symmetrically with the center line a of the film being pinched as the symmetry line. The clamping roller includes an upper roller 10 and a lower roller 20, and the upper roller 10 and the lower roller 20 are in the shape of a conical roller with the same shape; due to the conical structure of the rollers, the film is clamped and rotated between the two rollers. , the tapered surface A on the clamping roller will always apply to the clamped film a to clamp the side force; under the action of the clamped side force, the clamped film a is tensioned and always Traveling and conveying in a flat state, the phenomenon of wrinkling and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com