Assembling platform positioning mechanism of full-automatic backlight assembling machine

A positioning mechanism and assembly machine technology, applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of inability to position panels of different models, affect the efficiency and quality of backlight installation, and achieve the convenience of backlight installation, Avoid shaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

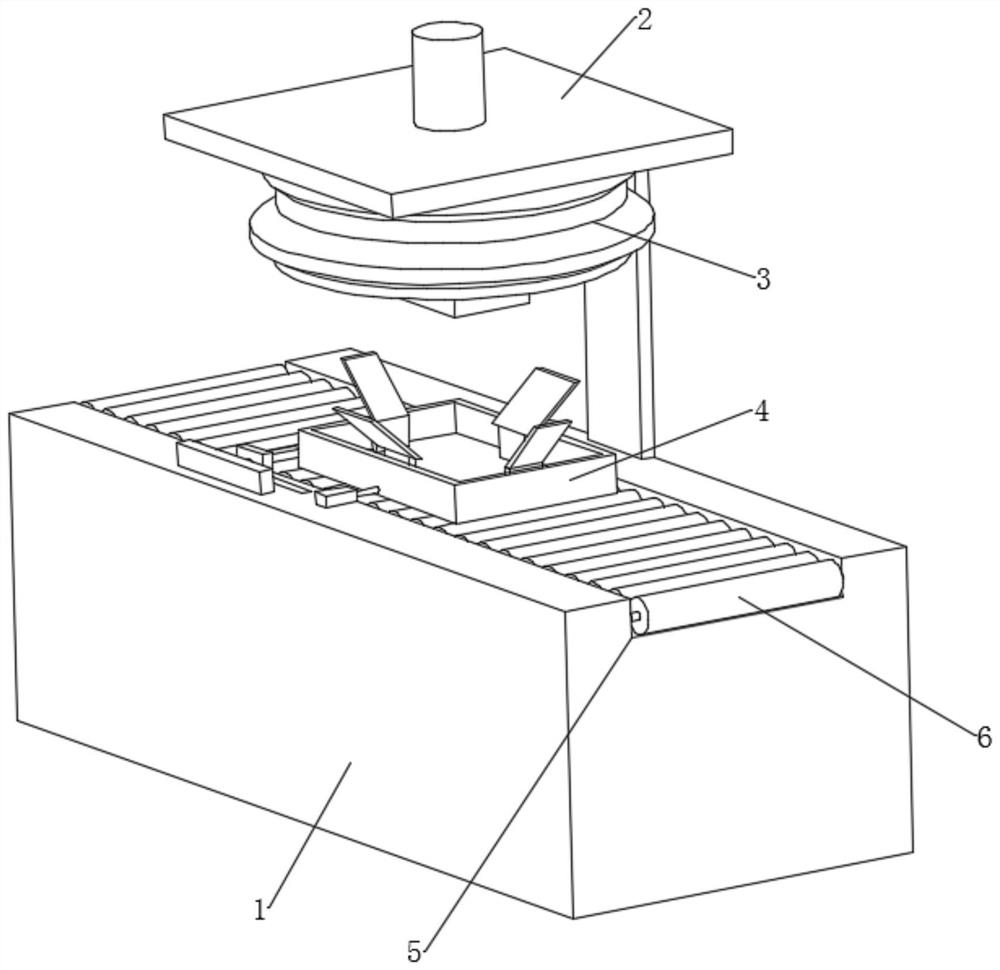

[0032] like Figure 1-4 As shown, a fully automatic backlight assembly machine assembly platform positioning mechanism electric bicycle motor detection device proposed by the present invention includes a base 1 and a backlight installation mechanism 3, the outside of the base 1 is provided with a moving groove 5, and the inside of the moving groove 5 A plurality of moving rollers 6 are rotatably connected, and the outside of the moving rollers 6 is provided with an installation platform 4, and the inside of the installation platform 4 is slidably connected with a limit unit for installing the screen. The mounting mechanism 3 is installed on the outside of the mounting plate 2, and the mounting platform 4 is slidingly connected to the outside of the moving roller 6;

[0033] The limit unit includes a plurality of positioning grooves 7 opened on the outside of the installation platform 4, the inside of the positioning grooves 7 is slidably connected with a connecting rod 8, and ...

Embodiment 2

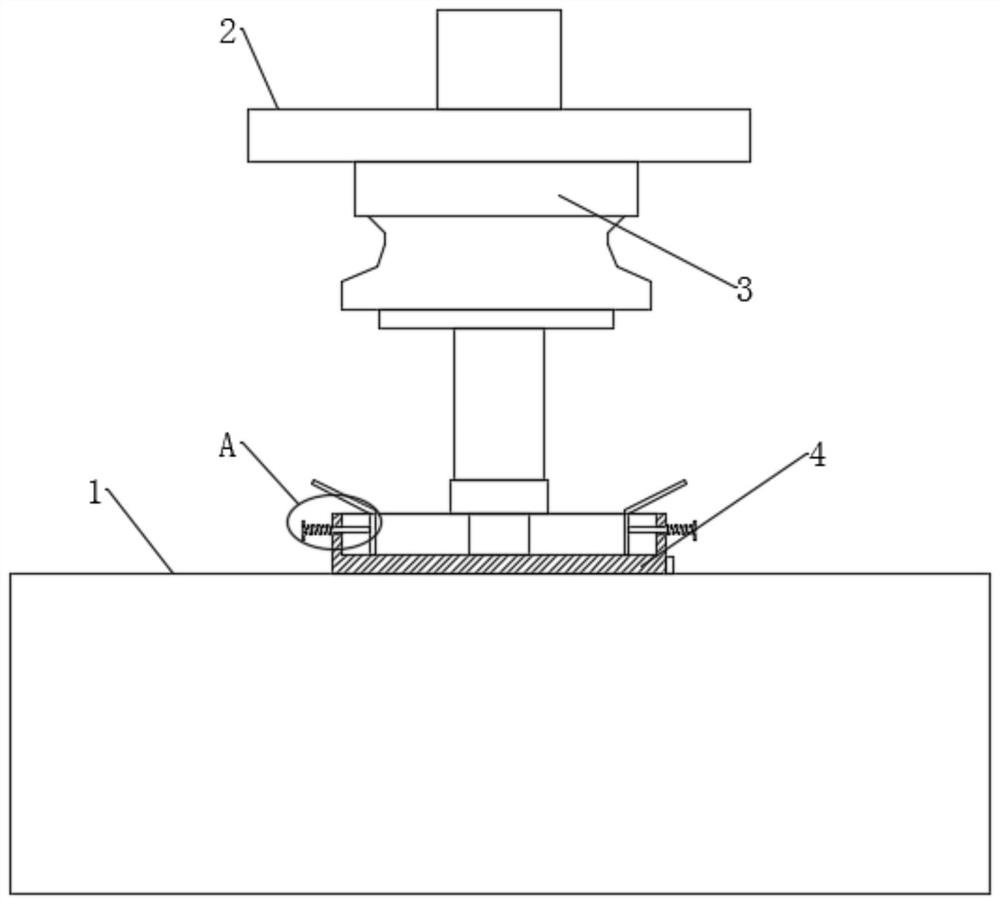

[0037] like figure 1 , figure 2 , image 3 and Figure 5As shown, based on the first embodiment, the outside of the base 1 is provided with a clamping unit for fixing the installation platform 4. The clamping unit includes two fixing blocks 12 installed on the outside of the base 1. The fixing blocks 12 There is a shrinking groove 13 inside the shrinking groove 13, and a clamping block 15 is slidably connected to the inside of the shrinking groove 13, and the two fixing blocks 12 are arranged symmetrically. The outside of the installation platform 4 is symmetrically provided with a clamping groove 16, and the clamping block 15 is far away from the shrinkage One end inside the groove 13 is pressed against the inside of the clamping groove 16, and a spring b14 is installed inside the shrinking groove 13, and the end of the spring b14 away from the shrinking groove 13 is connected to the outside of the clamping block 15, and the cross section of the clamping block 15 It is se...

Embodiment 3

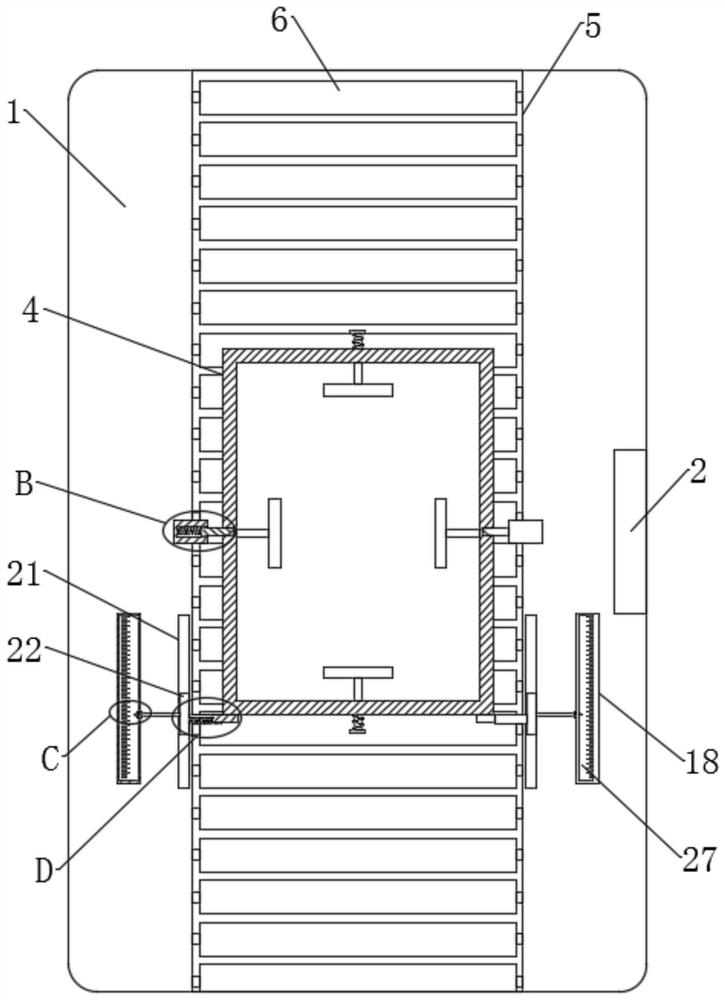

[0040] like Figure 1-7 As shown, based on the above-mentioned embodiment one or two, the outside of the base 1 is also provided with an observation unit for checking the moving distance of the installation platform 4. The observation unit includes two observation boxes 18 installed on the outside of the base 1, and the observation box The outside of 18 is provided with locking groove 17, and the exterior of base 1 is provided with chute 21 symmetrically, and the inside of chute 21 is slidably connected with sliding block 22, and the side of sliding block 22 near installation platform 4 is equipped with transmission block 23, two Two observation boxes 18 are symmetrically arranged;

[0041] The inside of the transmission block 23 is provided with a transmission groove 24, the inside of the transmission groove 24 is slidingly connected with a transmission rod 25, the inside of the transmission groove 24 is equipped with a spring c26, and the end of the spring c26 away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com