Patents

Literature

35results about How to "Avoid running without load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

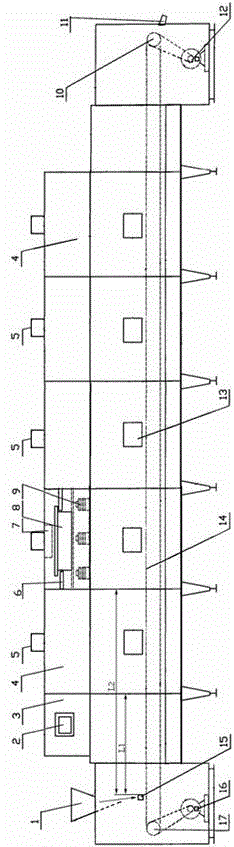

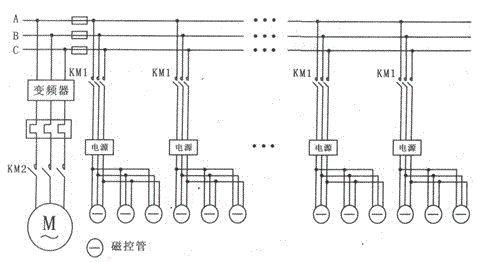

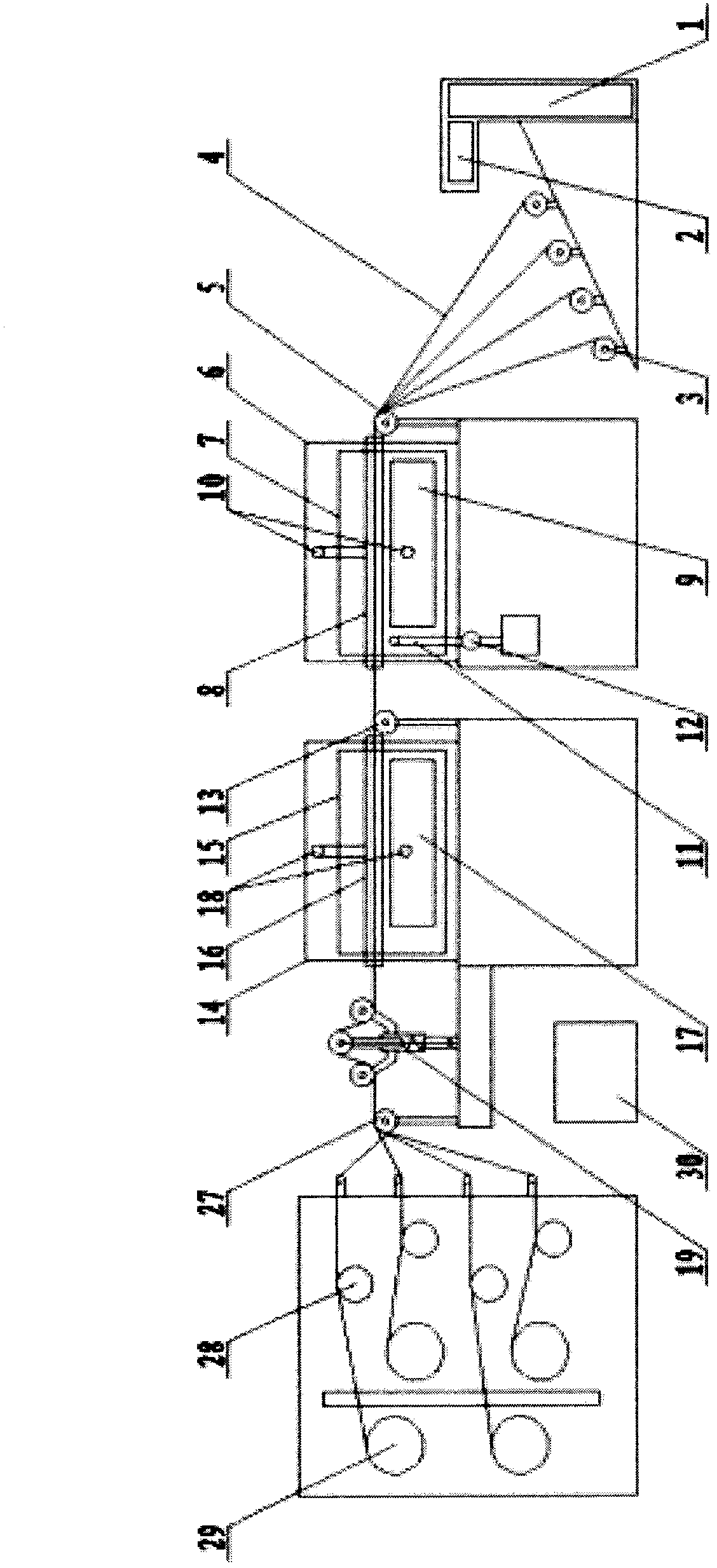

Tunnel type microwave generation magnetron automatic control drying device and method of agricultural products

InactiveCN102748928AExtended service lifeAvoid running without loadDrying solid materials with heatDrying machines with progressive movementsFrequency changerAutomatic control

The invention discloses a tunnel type microwave generation magnetron automatic control drying device and method of agricultural products. A microwave drying device comprises a feeding hopper chamber, a first connection box body, a control platform, a drying box chamber, a second connection box body, a discharge hopper chamber, a transport system, a drying and cooling system and a programmable logic controller (PLC) control system. The PLC control system comprises a PLC touch screen, a PLC control unit, a transducer for controlling transmission speed of a transmission band, a pressure sensing sensor, a revolution speed sensor and a distribution box, the PLC control system effectively calculates the transmission speed of the transmission band according to transmission ratio and effective transmission radius and calculates time transmitting to each drying box according to preset distance between a feeding hopper to each microwave drying box, and the PLC control unit controls a microwave generation magnetron corresponding to the each microwave drying box to start and stop according to calculated time. The tunnel type microwave generation magnetron automatic control drying device automatically tracks, starts and stops the microwave generation magnetron, avoids no-load running and prolongs service life of the microwave generation magnetron.

Owner:ZHEJIANG UNIV

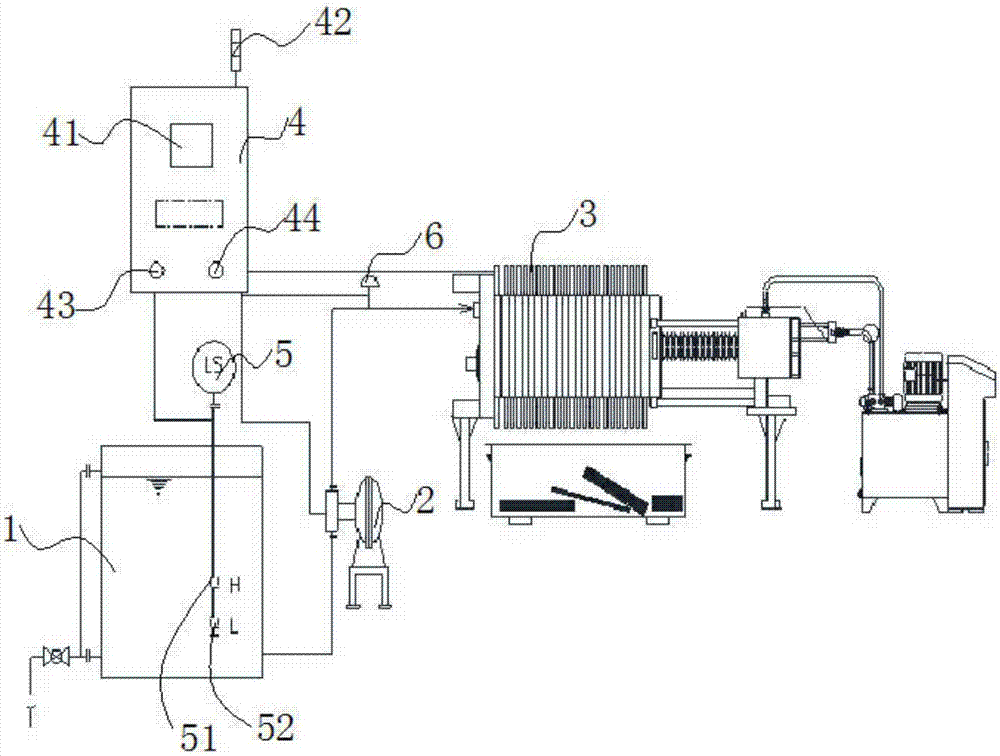

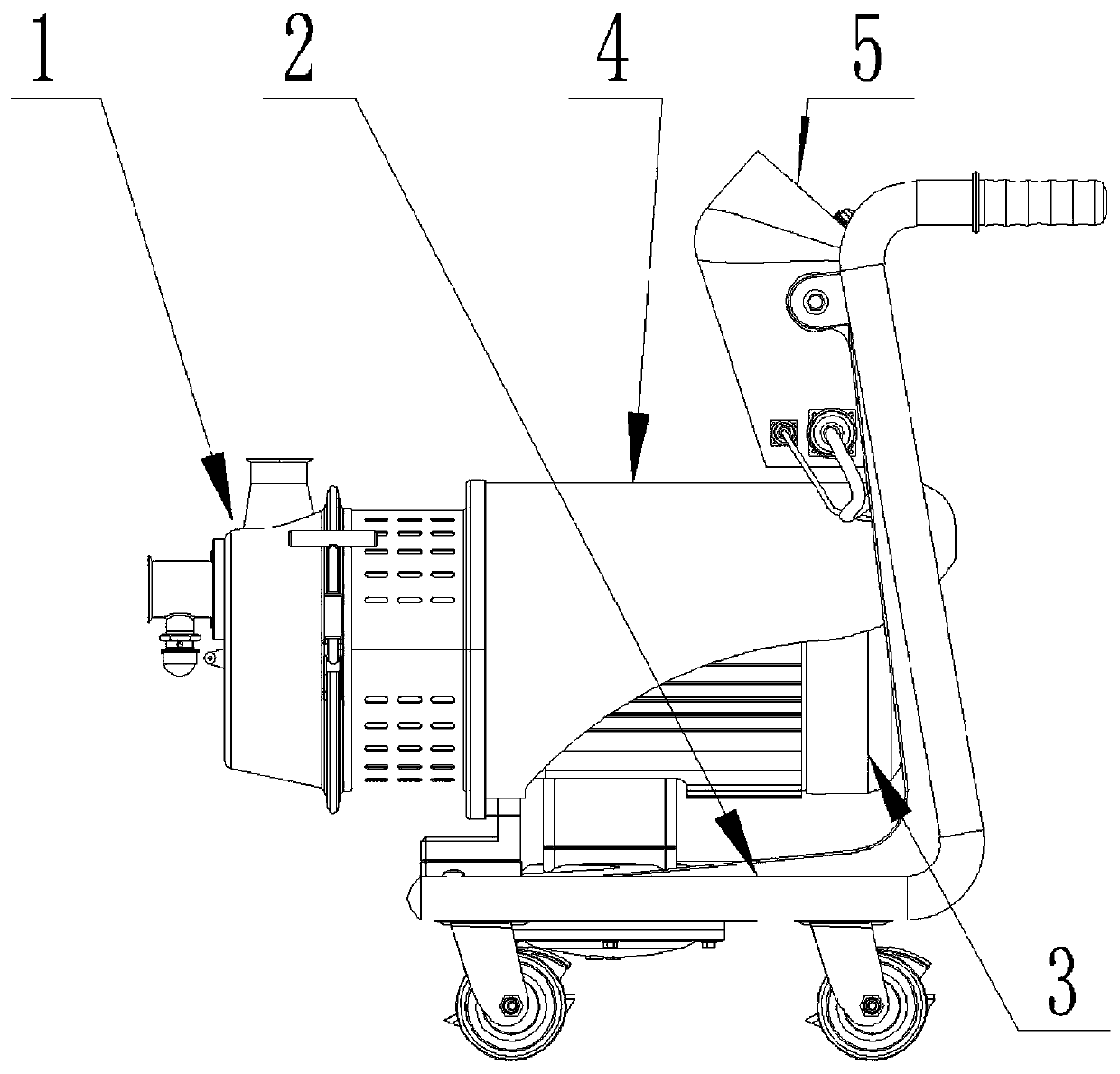

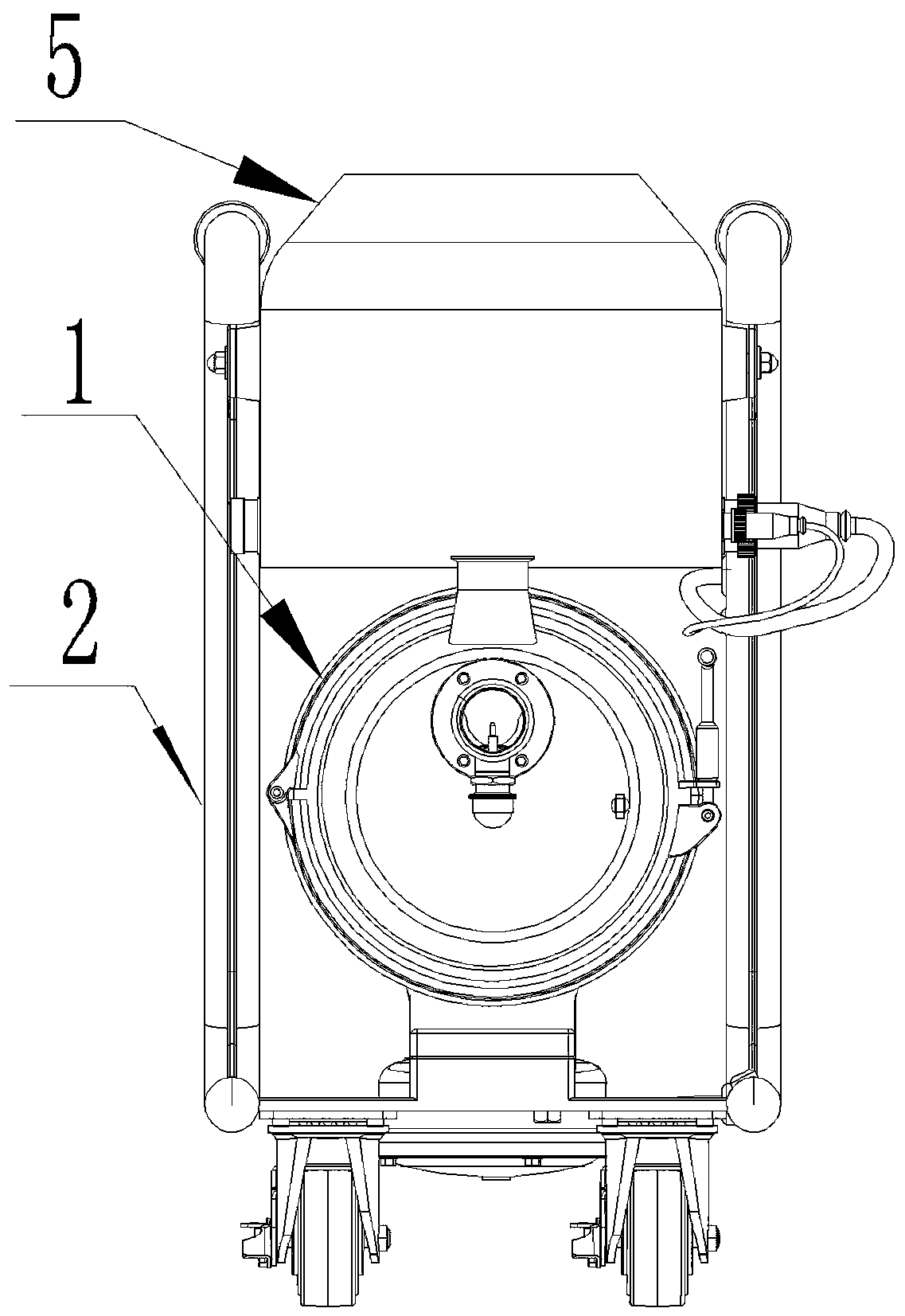

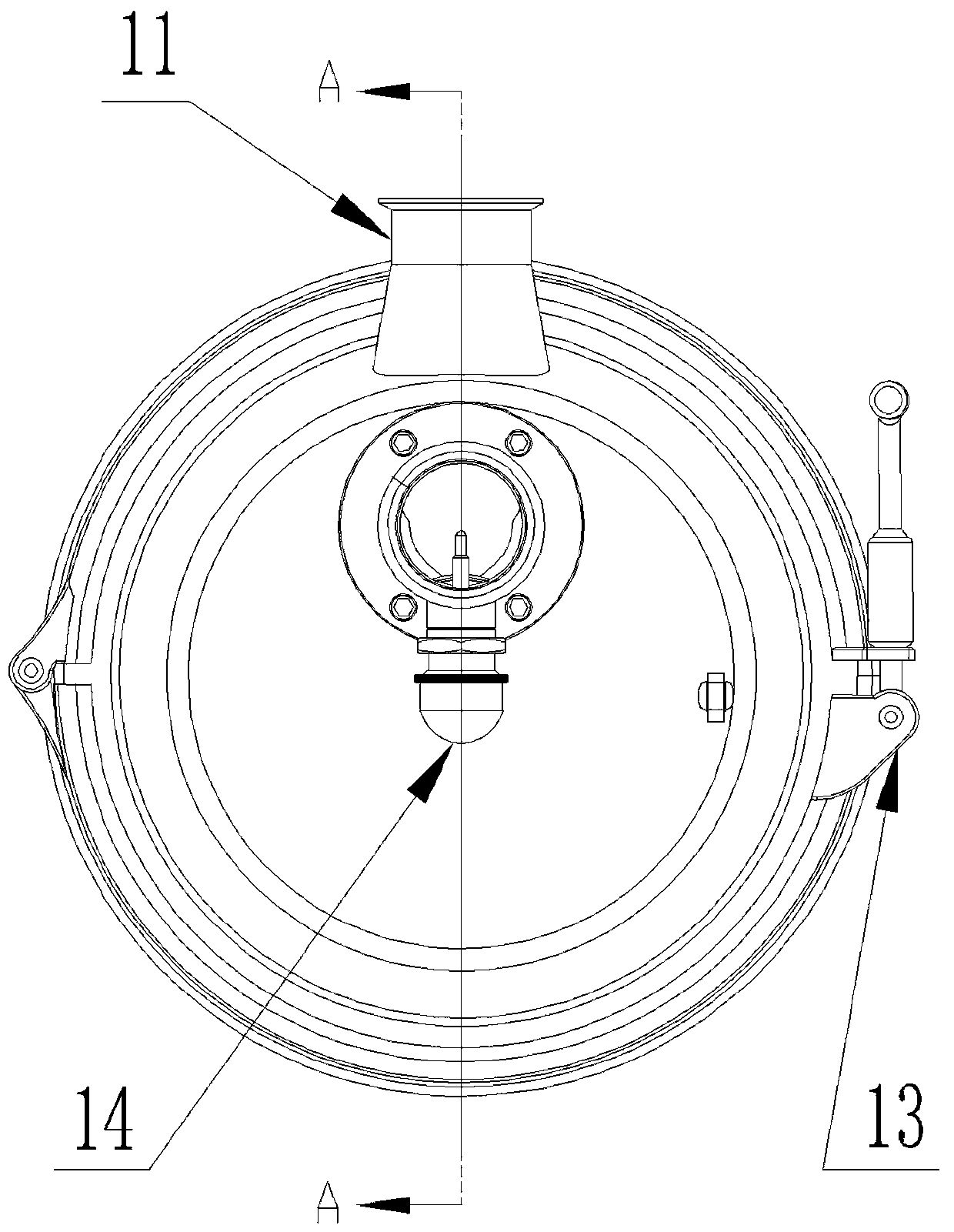

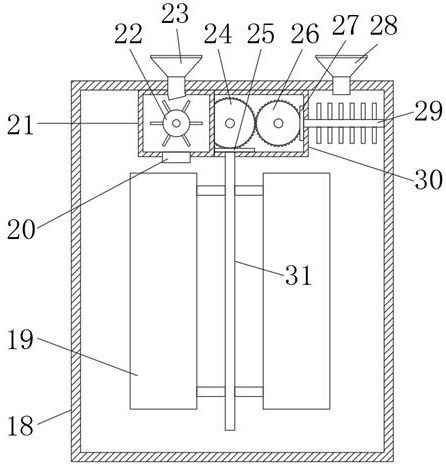

Sludge feeding system for plate-and-frame filter press

PendingCN107321019AReduce workloadAvoid running without loadWater treatment parameter controlSludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The invention discloses a sludge feeding system for a plate-and-frame filter press and belongs to the technical field of sewage disposal. The sludge feeding system for the plate-and-frame filter press comprises a sludge tank, a sludge feeding pump, a plate-and-frame filter press and a controller, wherein an input end of the sludge feeding pump is communicated with the sludge tank while an output end is communicated with the plate-and-frame filter press; the controller is connected with the sludge feeding pump and the plate-and-frame filter press; a liquid level meter is arranged in the sludge tank; the controller is used for controlling the sludge feeding pump to open or close according to the liquid level height detected by the liquid level meter; the sludge feeding pump is used for conveying a sludge water mixture in the sludge into the plate-and-frame filter press; the plate-and-frame filter press is used for performing solid-liquid separation. According to the invention, the sludge feeding system for the plate-and-frame filter press can automatically run under the action of the controller, the sludge feeding pump can be protected and prevented from idle running, the workload of the worker can be reduced and the whole service life of the system can be prolonged.

Owner:苏州依斯倍环保装备科技有限公司

An automatic medical logistics carrying system and a control method thereof

InactiveCN109685441AWill not affect normal orderImprove management levelLogisticsLogistics managementAutomatic control

The invention discloses an automatic medical logistics carrying system and a control method thereof. the system comprises a carrying robot which is used for carrying materials, and is provided with awireless communication module; The receiving and dispatching station is used for receiving and dispatching materials; The robot automatic control longitudinal conveying device is a conveying device which is arranged in a hospital building and is not loaded with non-medical staff, and is used for conveying the carrying robot to different floors; The horizontal logistics channel special for the robot is arranged in the top space of at least one floor of a hospital building; And the control center communicates with the carrying robot and is used for controlling the system. The horizontal logistics channel special for the robot is arranged in the top space of the storey of the hospital building, so that the carrying robot can walk; The medical material transportation efficiency is effectivelyimproved, time is won for medical work, the occupied space is small, the normal order of a hospital is not affected, and the management level and the modernization level of the hospital are effectively improved.

Owner:江苏振邦医用智能装备有限公司

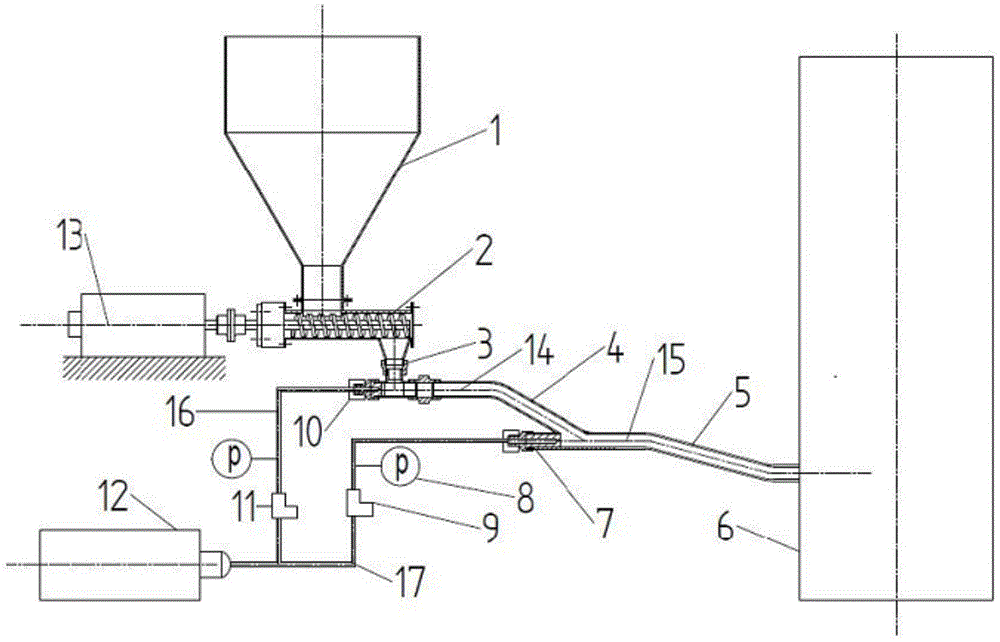

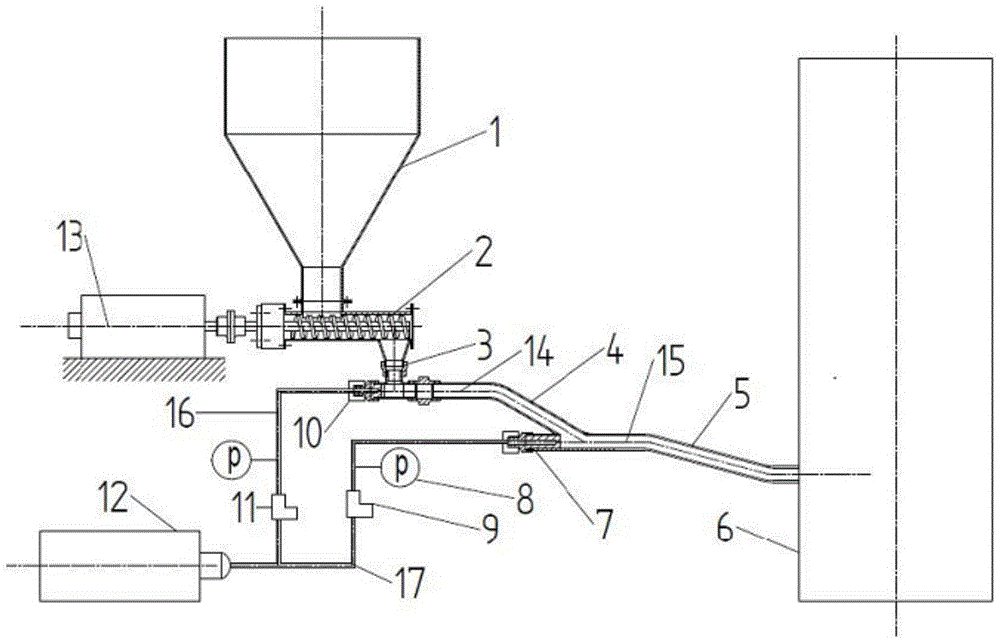

Spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis

InactiveCN104877694AAdjust feed amountPrevent blowbackBiofuelsLiquid hydrocarbon mixture productionSolenoid valveGas cylinder

The invention relates to a spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis and belongs to the technical field of biomass pyrolysis. The feeder comprises a spiral feeding device, inclined delivery pipes, solenoid valves and nozzles. The discharge port of the spiral feeding device is connected to an upper horizontal delivery pipe and the inclined delivery pipe through a transition joint and is connected to a lower horizontal delivery pipe and the inclined delivery pipe, gas of a gas bottle is sprayed through the nozzles, the nozzles are capable of adjusting the feeding amount and preventing reverse spraying, the feeding process is controllable and safe, and the reliability of the producing process is improved. The feeding port advanced charring and plugging problems can be solved, the process requirements of fast biomass pyrolysis can be met, the pyrolysis equipment producing and maintaining time can be shortened, the pyrolysis oil producing efficiency is improved, the maintaining cost is reduced effectively, and the technology guaranteeing effect can be achieved for large-scale pyrolysis production development.

Owner:BEIJING FORESTRY UNIVERSITY

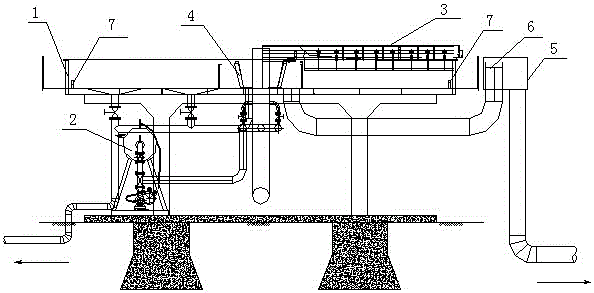

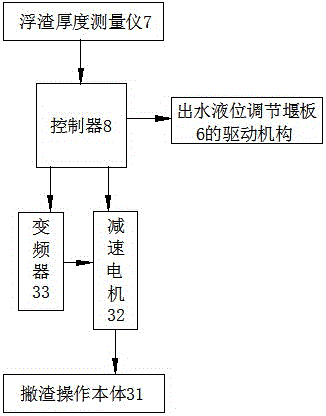

Automatic gelatin waste water drossing device applied to gas floatation clarifier

InactiveCN105905970APrevent overflowReduce cleanupWater/sewage treatment by flotationWastewaterGelatin

The invention discloses an automatic gelatin waste water drossing device applied to a gas floatation clarifier. The automatic gelatin waste water drossing device comprises the drossing device and an effluent liquid level adjusting weir plate of the gas floatation clarifier, a dross thickness measuring instrument arranged in a gas floatation pond, and an external controller. The dross thickness measuring instrument, an effluent liquid level adjusting weir plate adjusting mechanism of the gas floatation clarifier and a drossing device driving mechanism of the gas floatation clarifier are all connected with the external controller. The dross thickness measuring instrument is adopted for measuring the thickness of dross in the gas floatation clarifier, then the controller automatically adjusts the height of the effluent liquid level adjusting weir plate and the running speed, starting and stopping of a drossing machine according to thickness information, and it is avoided that the dross overflows out through the weir plate. When the thickness of the dross is reduced to a certain degree, the height of the weir plate is reduced through the controller, the running speed of the drossing device is decreased, or the drossing device is intermittently started, therefore, the dross is reasonably removed, the running efficiency of the drossing device is improved, the drossing device runs more effectively and reasonably, it is avoided that the drossing device runs in an idle mode, and the aim of energy saving and consumption reducing during daily running of a system is achieved.

Owner:ANHUI ZHONGHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

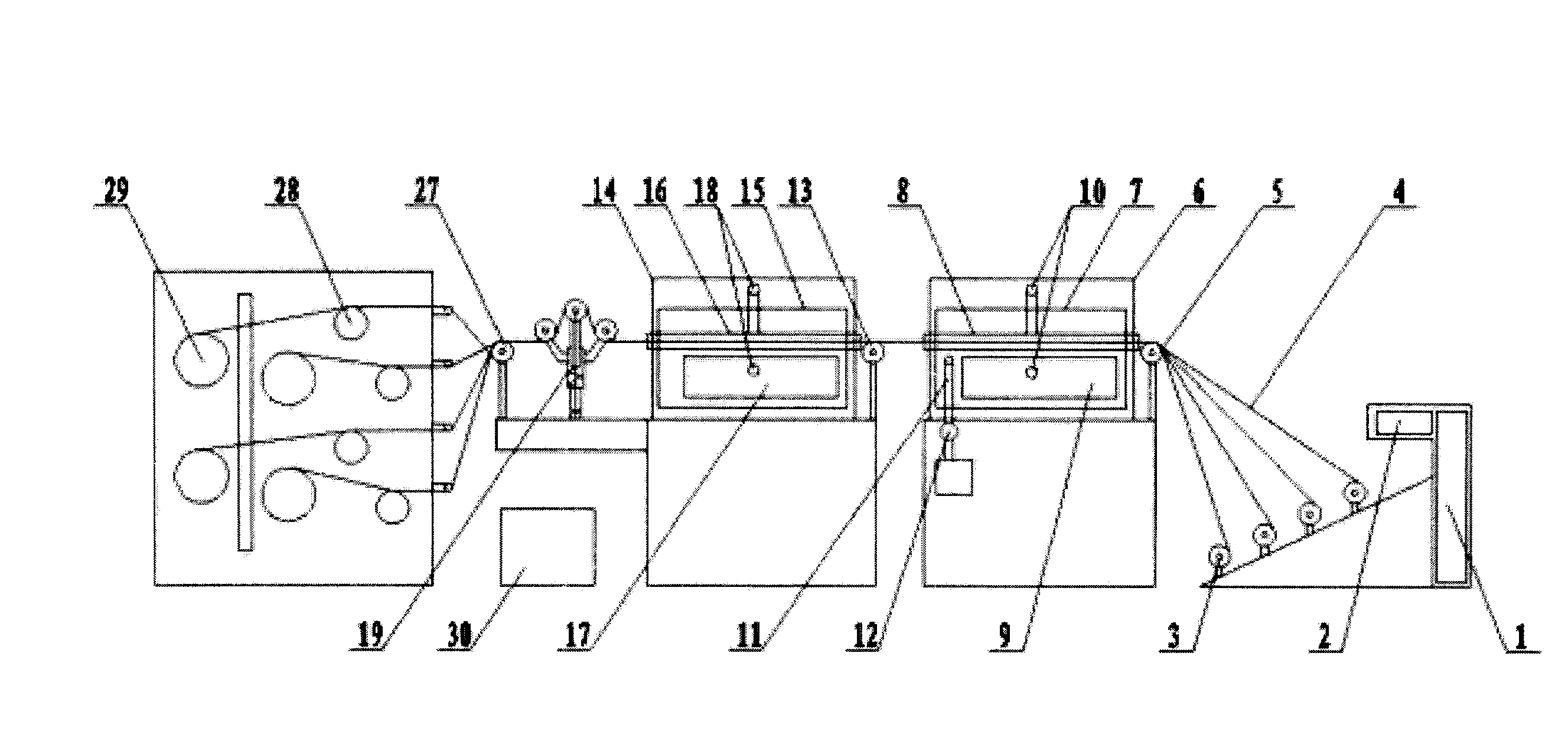

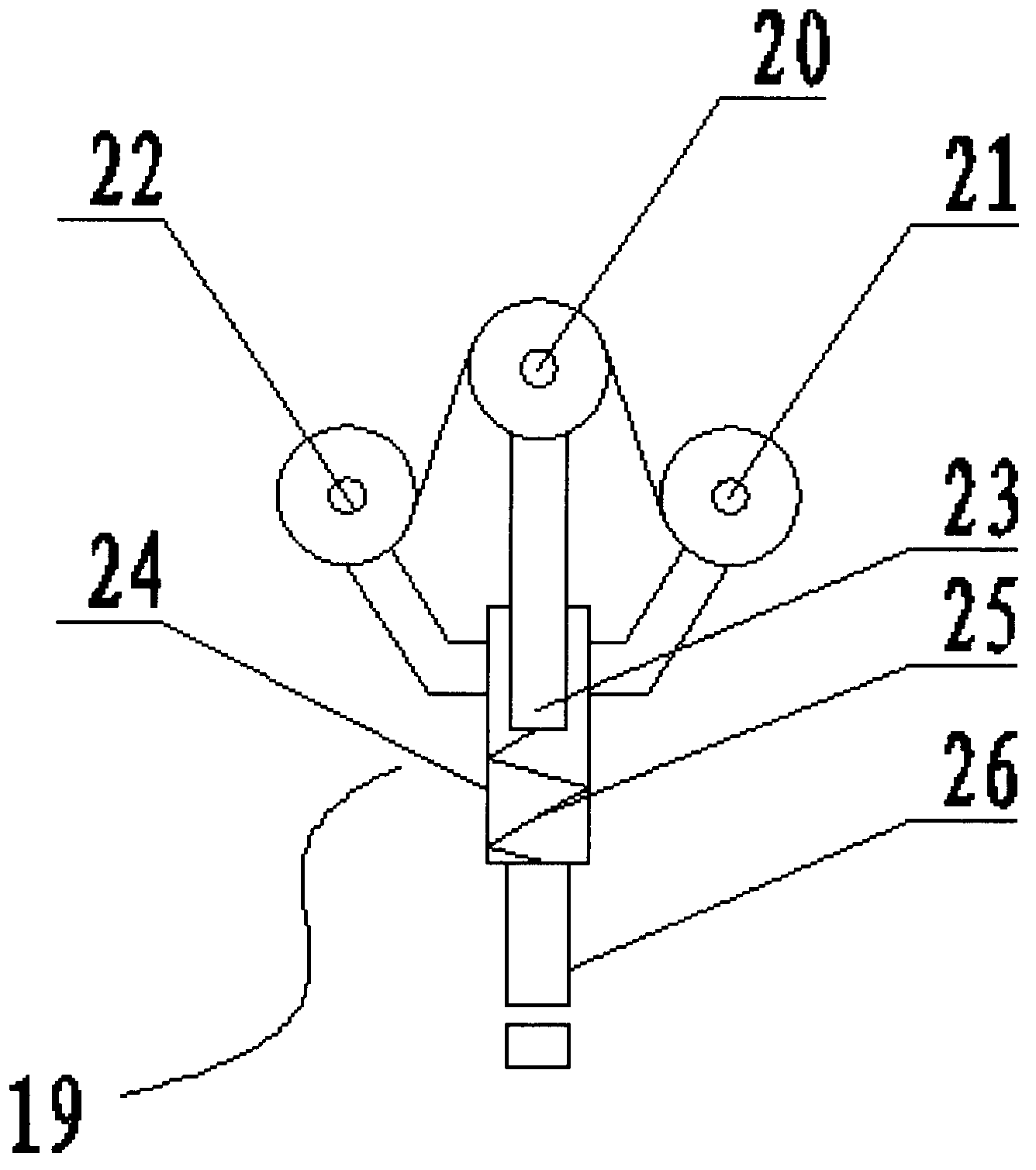

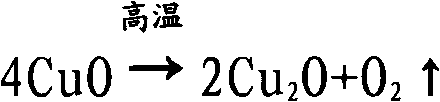

Dumet wire microwave heating production system

InactiveCN103572196APromote generationImprove inner qualitySolid state diffusion coatingMetallurgyHigh energy

The invention discloses a Dumet wire microwave heating production system which comprises a wire feeder, a microwave sintering furnace, a microwave oxidizing furnace, a wire passing device and a wire collector, wherein the wire feeder is sequentially connected with the microwave oxidizing furnace and the microwave sintering furnace in a wire feed mode; the microwave sintering furnace is connected with the wire collector in a wire collection mode; and the on-off state of microwave generators of the microwave sintering furnace and the microwave oxidizing furnace is respectively controlled by the wire passing state of the wire passing device. The wire feed speed, heating temperature and oxidizing temperature of the Dumet wire material is controlled to ensure the quick generation of CuO-free high-purity nano Cu2O; and a wire press device is matched to implement idle shutdown protection, thereby implementing digital control on the whole process. The Dumet wire microwave heating production system has the advantages of simple structure, reliable performance, high energy utilization, low use cost and the like, and is convenient to operate; and the Dumet wire material prepared by the system has no CuO generated on the outer layer, does not have color difference or bubbles in the subsequent platinum glass head seal process, and has high quality property.

Owner:樊伟

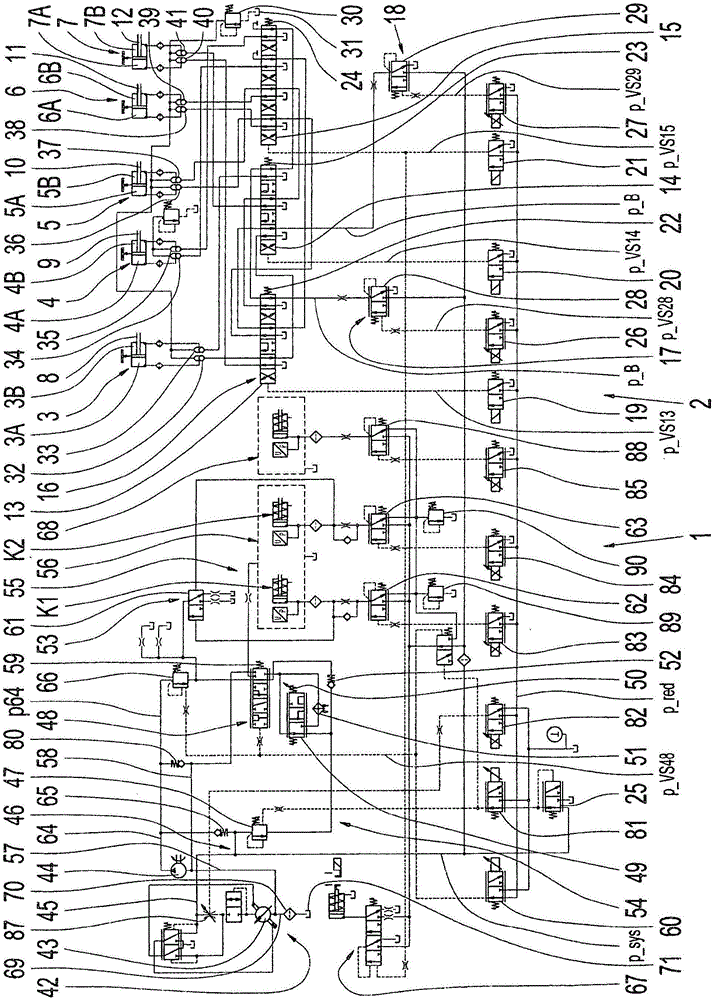

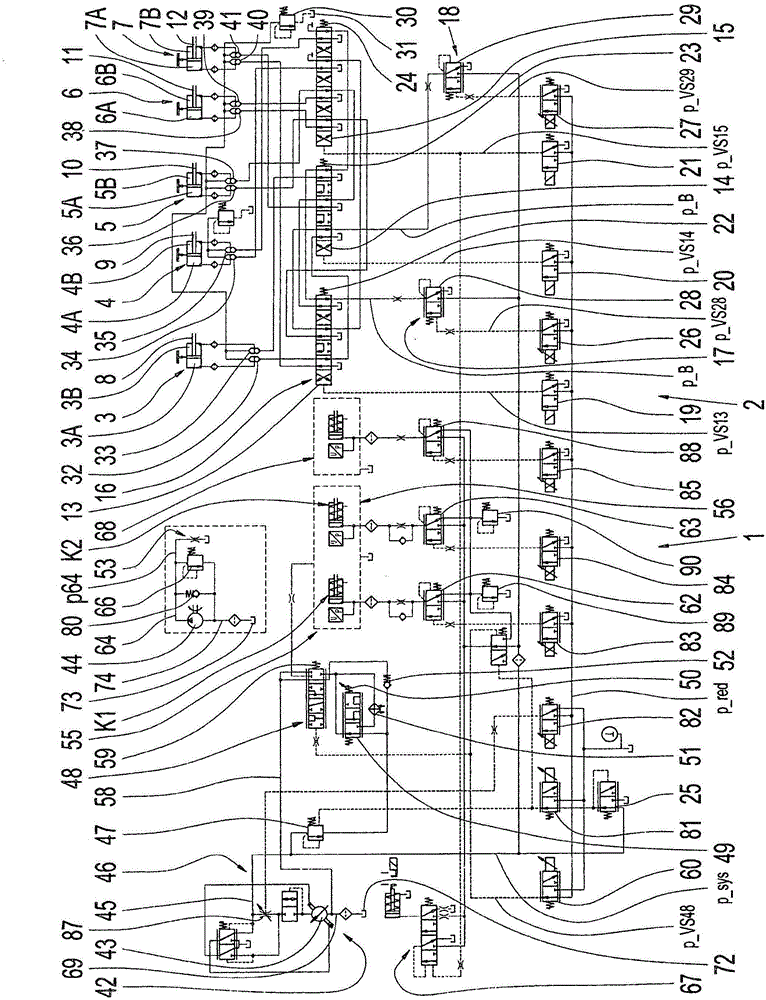

Hydraulic system of a transmission with a plurality of pressure regulating valves

ActiveCN106233042AHigh spontaneityReduced structural space requiredFluid actuated clutchesGearing controlMechanical engineeringPressure level

A hydraulic system (1) for a transmission (2) having a plurality of pressure regulating valves (62 to 29) is described, in the region of which valves, an applied pressure (p_sys) can be adjusted to a pressure level to be set downstream as a function of a total force component engaging at each valve slider depending on the operating state. The total force component appears as a function of a pilot control force component applicable on each valve slider, an actuating force component, and a regulating force component dependent on the pressure level prevailing downstream. The pilot control force component and the actuating force component can each be applied on the valve slider in an equally acting way in the direction of a first end position of the valve slider of a pressure regulating valve (62 to 29), in which position the region upstream of the pressure regulating valve (62 to 29) is connected to the region downstream of the pressure regulating valve (62 to 29) via the pressure regulating valve, whereas the pressure downstream of the pressure regulating valve (62 to 29) can be applied on the valve slider, acting counter to the pilot control force component and the actuating force component, in the direction of a second end position of the valve slider, in which position the region downstream of the pressure regulating valve (62 to 29) is connected to a low pressure region (71).

Owner:ZF FRIEDRICHSHAFEN AG

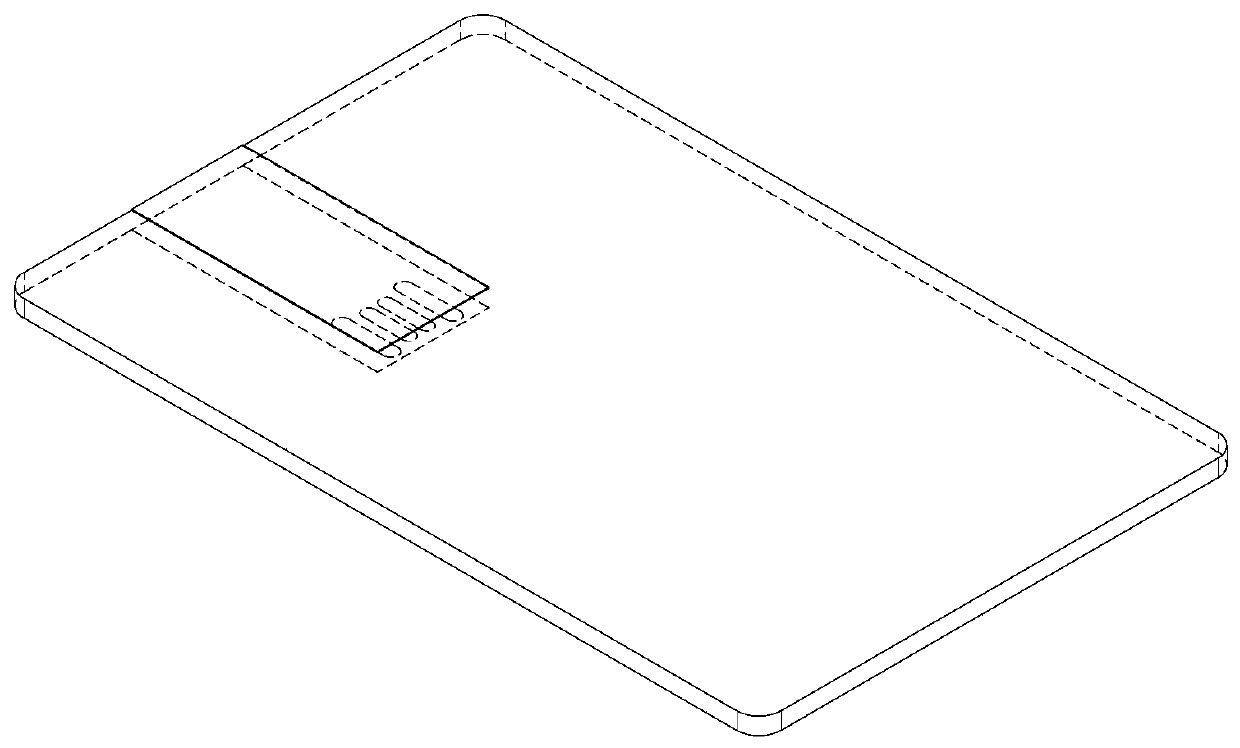

Automatic pushing device for storage cards

ActiveCN108382899AImprove cleanlinessAvoid affecting the printing effectCoupling device detailsArticle feedersComputer science

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

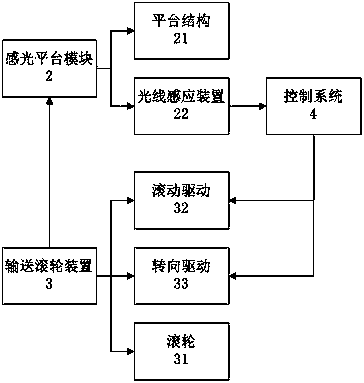

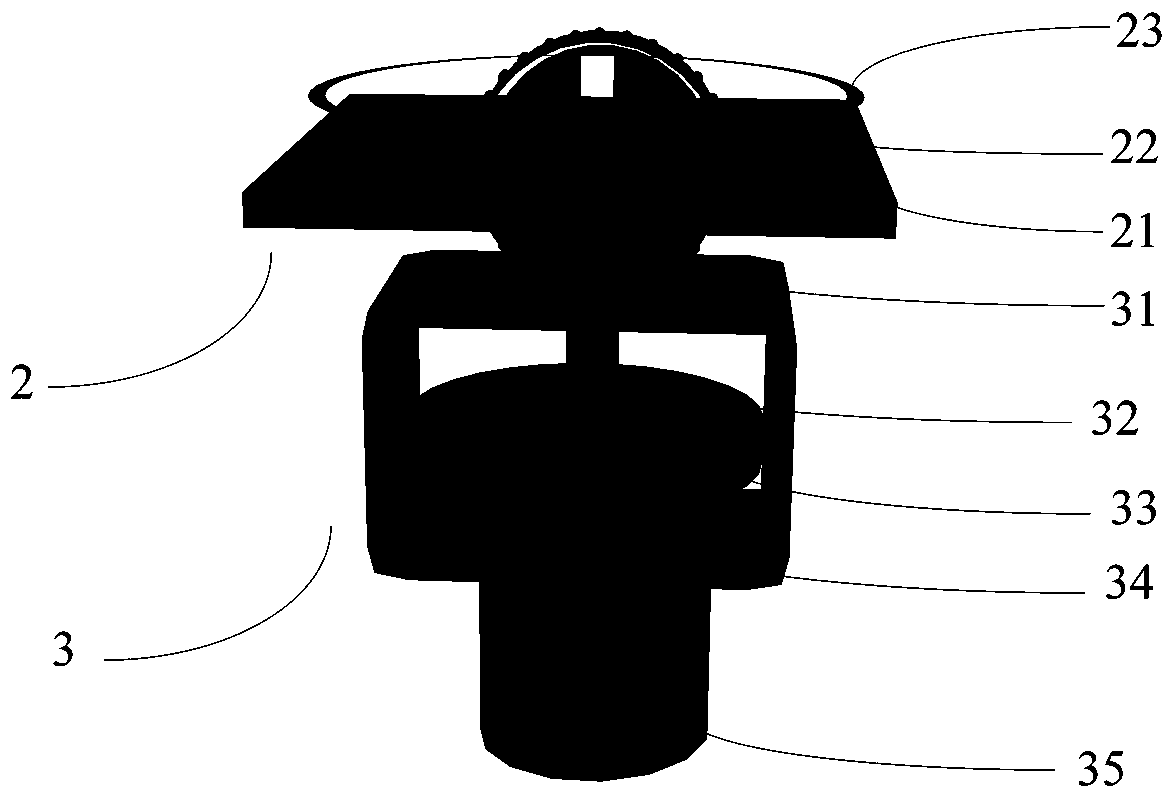

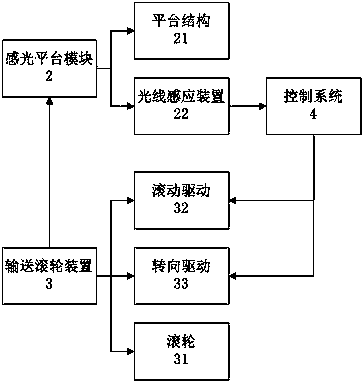

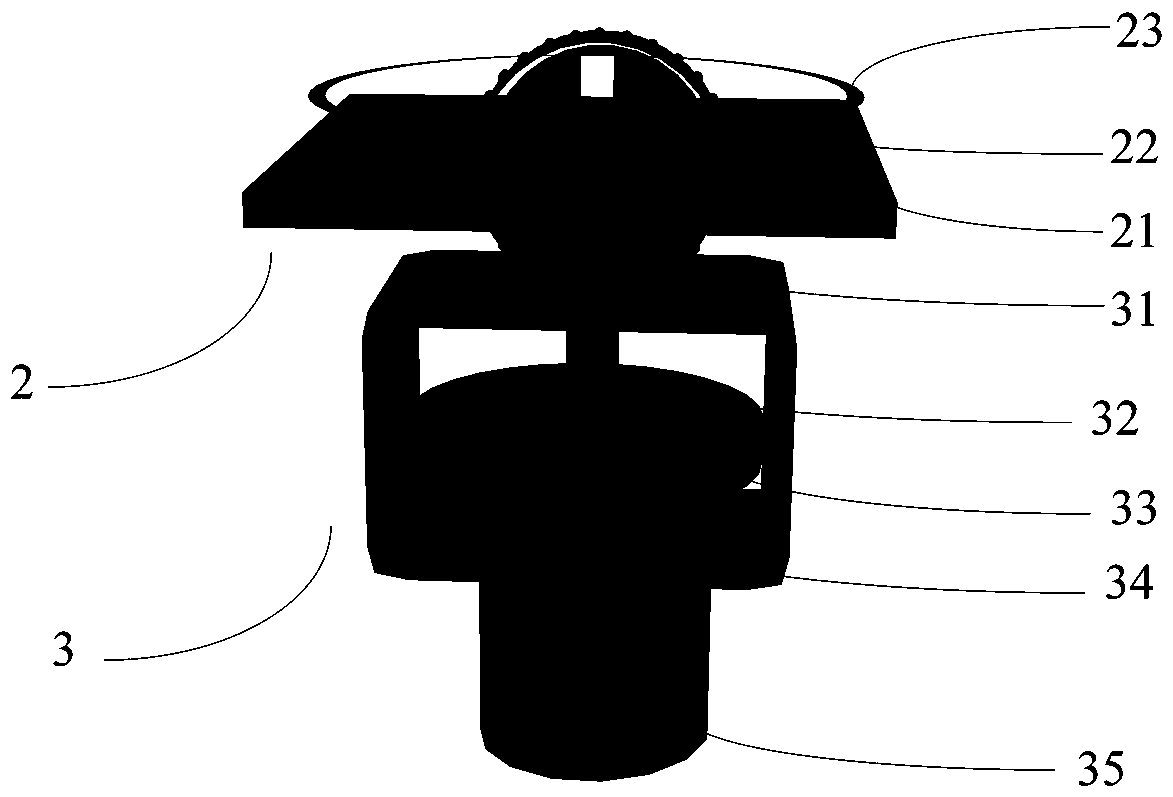

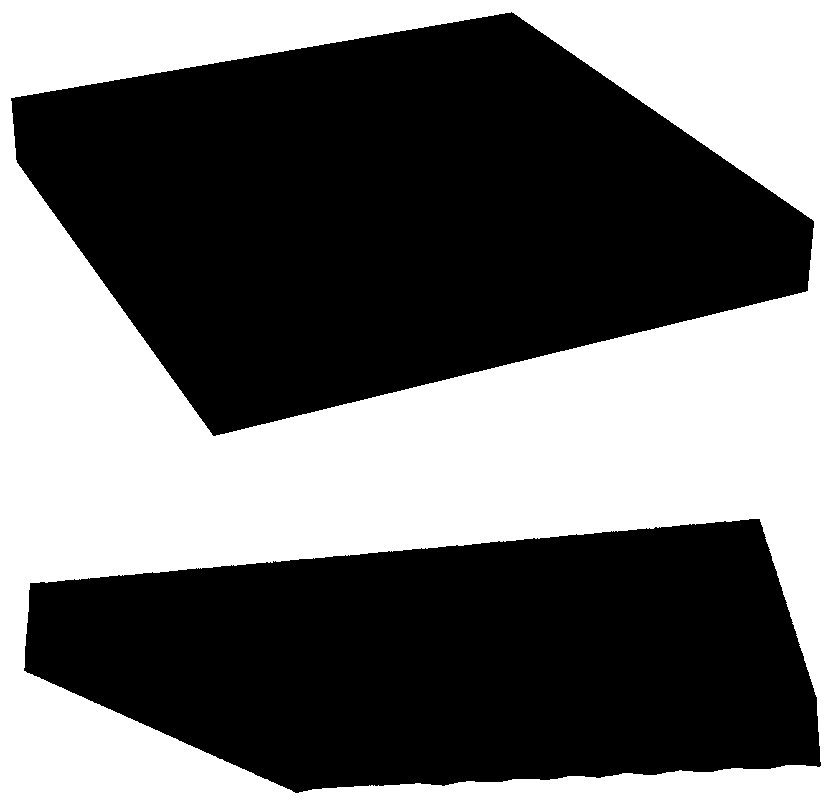

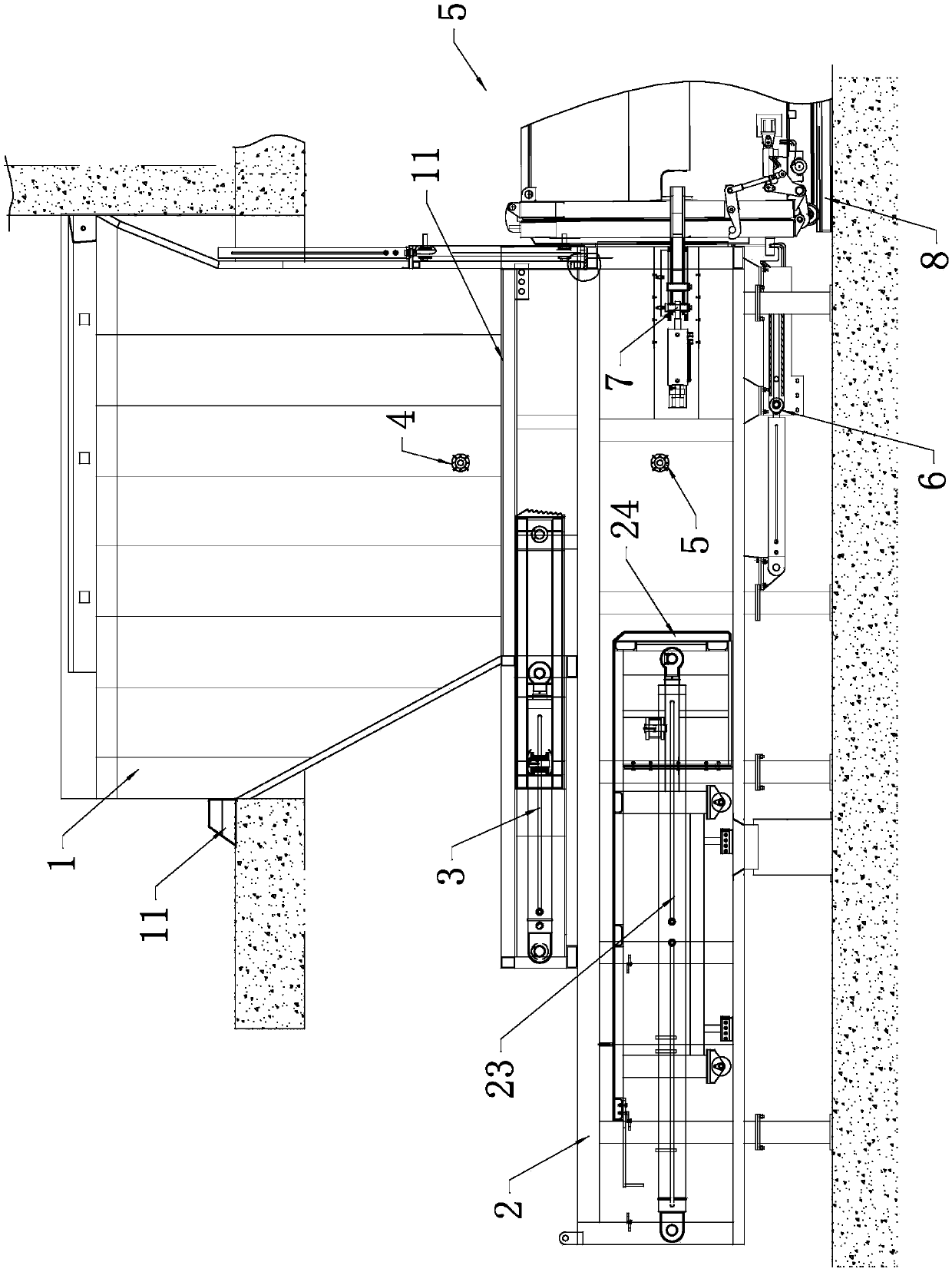

Intelligent free conveying logistics automatic system

InactiveCN109436721AAchieve positioningImprove stabilityControl devices for conveyorsMechanical conveyorsIntegrated monitoringLogistics management

The invention relates to the field of material conveying, in particular to an intelligent free conveying logistics automatic system. The intelligent free conveying logistics automatic system mainly comprises a material free conveying module platform, an open series circulation tray and a control system; the material free conveying module platform comprises a light sensing platform module, a conveying roller device and a control system; the light sensing platform module comprises a platform structure and a light sensing device, the platform structure is a unit part forming the whole conveying platform, the light sensing device is used for sensing the shading of the material open series circulation tray and transmits the sensing result to the control system; the conveying roller device is embedded in the light sensing platform module; the control system is mainly used for controlling the rolling and steering of the conveying roller; and in addition, through light sensing signals, positioning of the material open series circulation tray can be realized, and comprehensive monitoring of each platform module is realized. According to the intelligent free conveying logistics automatic system, the problem that a common conveyor belt can only perform directional conveyance can be solved, and free conveying of materials is realized.

Owner:CHANGZHOU IND TECH RES INST OF ZHEJIANG UNIV

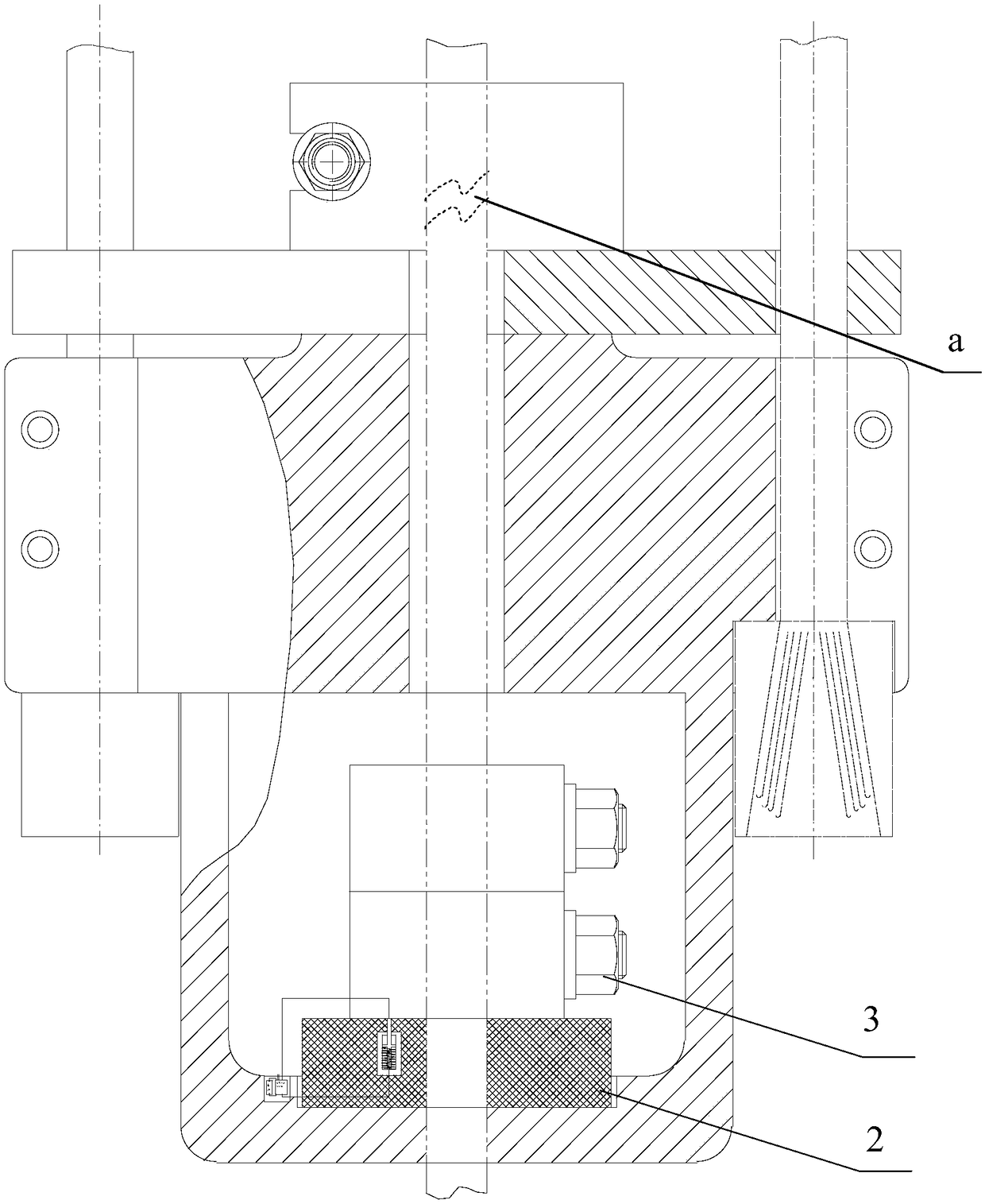

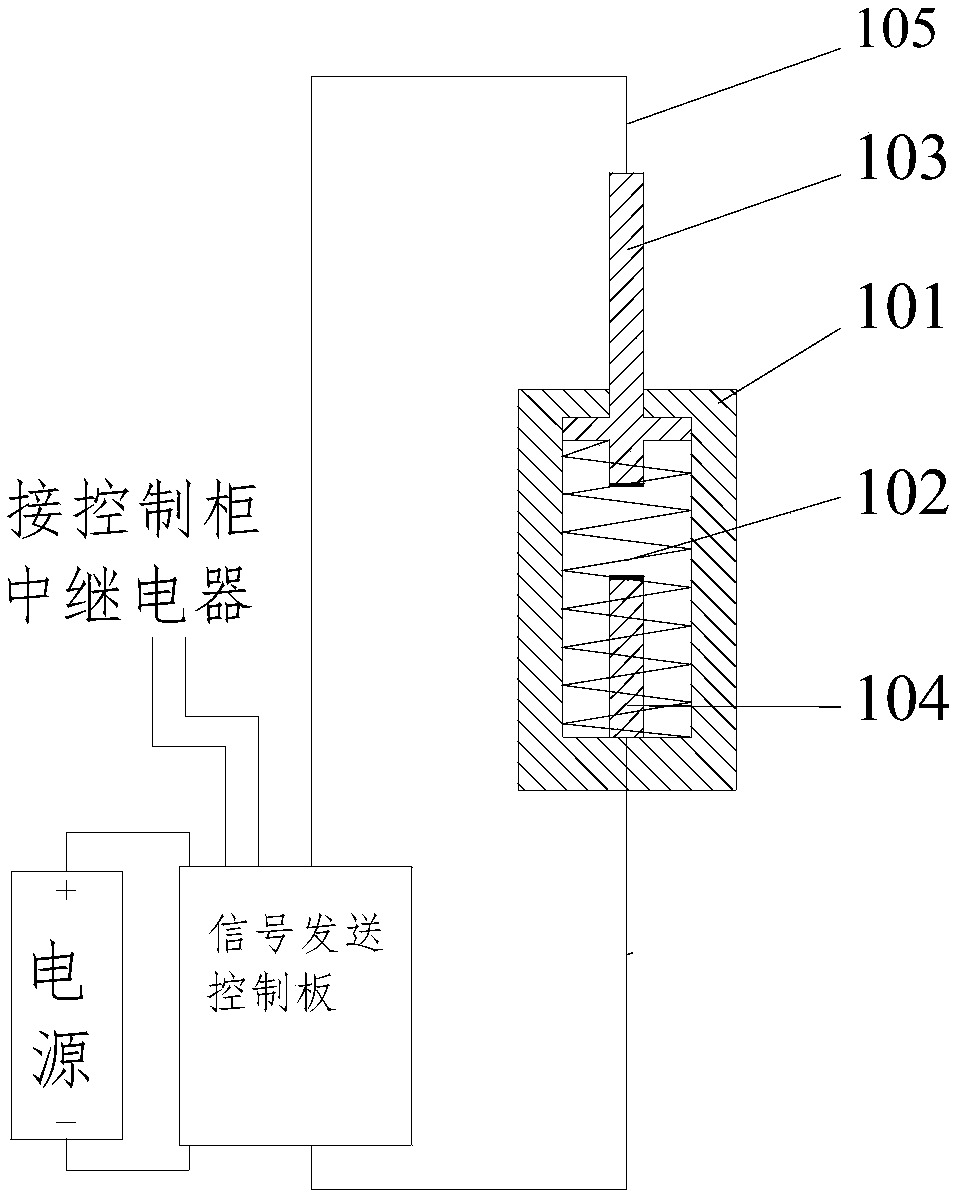

Intelligent safety rope suspension device

InactiveCN108952598AAchieve intelligenceControl momentary shutdownDrilling rodsDrilling casingsElectricityEngineering

The invention provides an intelligent safety rope suspension device. The intelligent safety rope suspension device comprises a buffering box, a rope suspension machine body, an intelligent module, oil-resistant rubber, a square clamp, a baffle, a polished rod and at least one spare clamp. A first groove is formed in the bottom end in the buffering box, the baffle is arranged on the rope suspensionmachine body, the square clamp is arranged on the baffle, and the buffering box is arranged at the bottom of the rope suspension machine body. The oil-resistant rubber is arranged in the first grooveof the buffering box, the polished rod vertically penetrates through the square clamp, the baffle, the rope suspension machine body, the buffering box, the spare clamps and the oil-resistant rubber,and the polished rod, the square clamp and the spare clamps are fixedly connected. The spare clamps are arranged in the buffering box, and the distance between the bottom faces of the spare clamps andthe oil-resistant rubber is a collision height. The intelligent module is arranged in the buffering box. The intelligent module includes a collision switch and a signal sending control board, and thecollision switch and the signal sending control board are electrically connected. When the spare clamps collide with the collision switch, the collision switch is closed, and the signal sending control board is used for sending collision signals to a control cabinet when the collision switch is closed.

Owner:PETROCHINA CO LTD

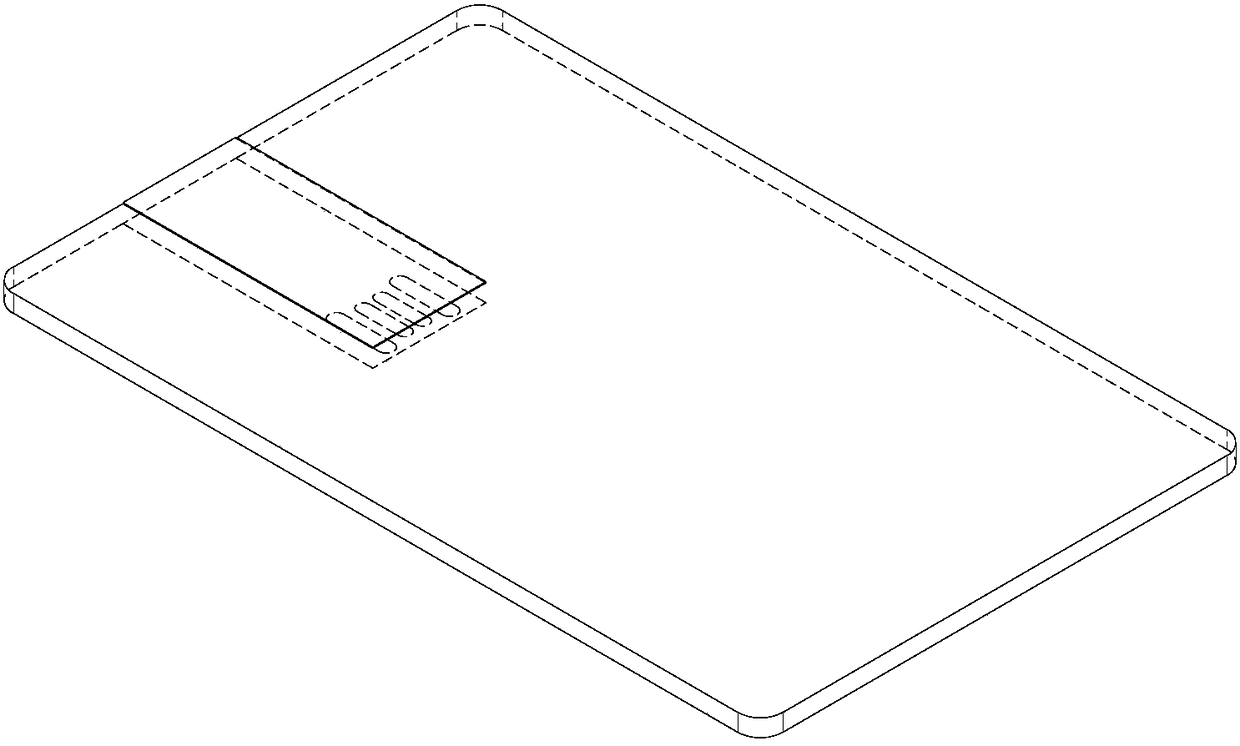

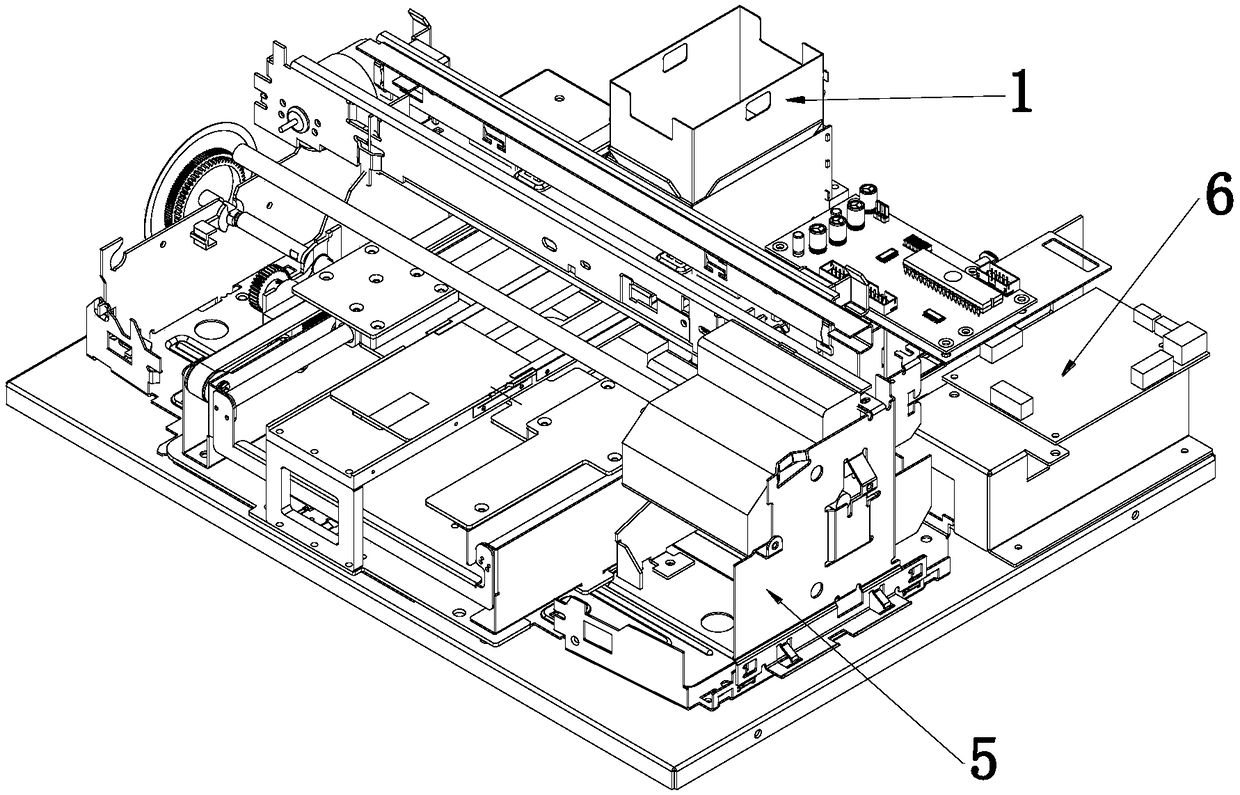

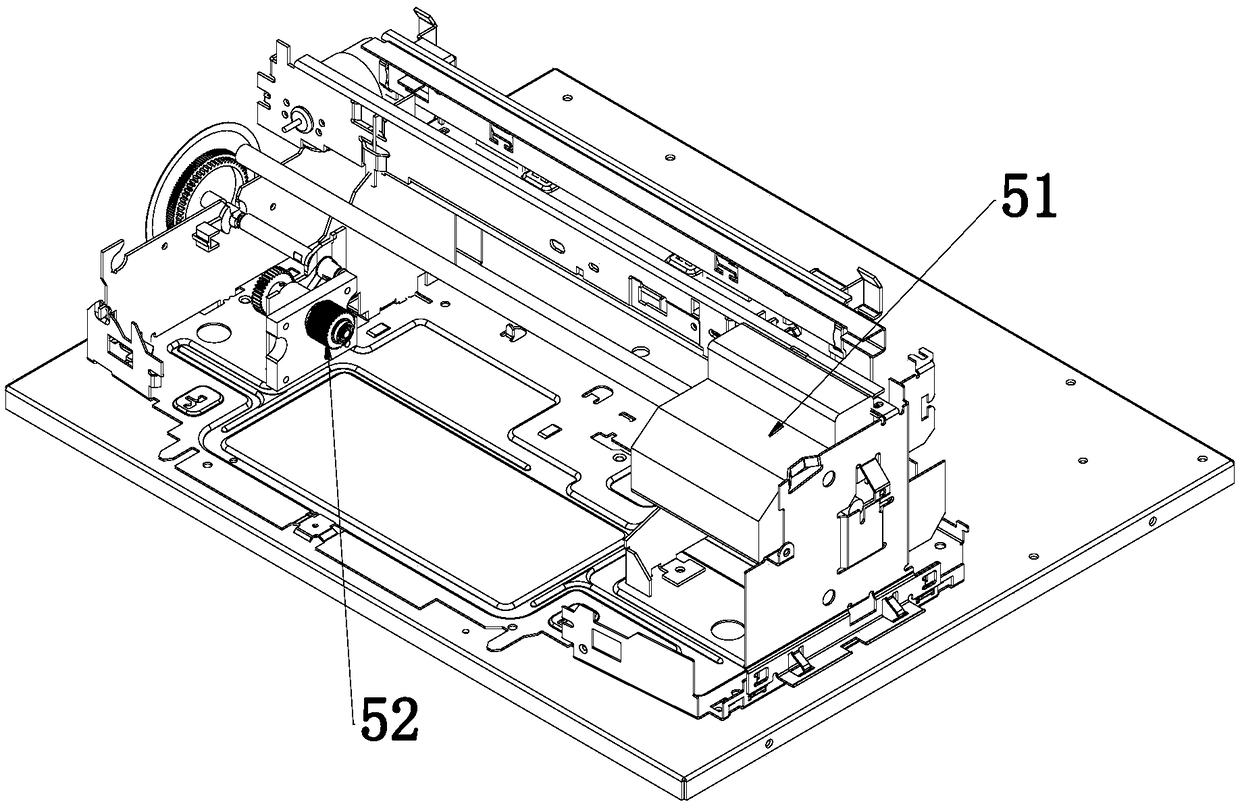

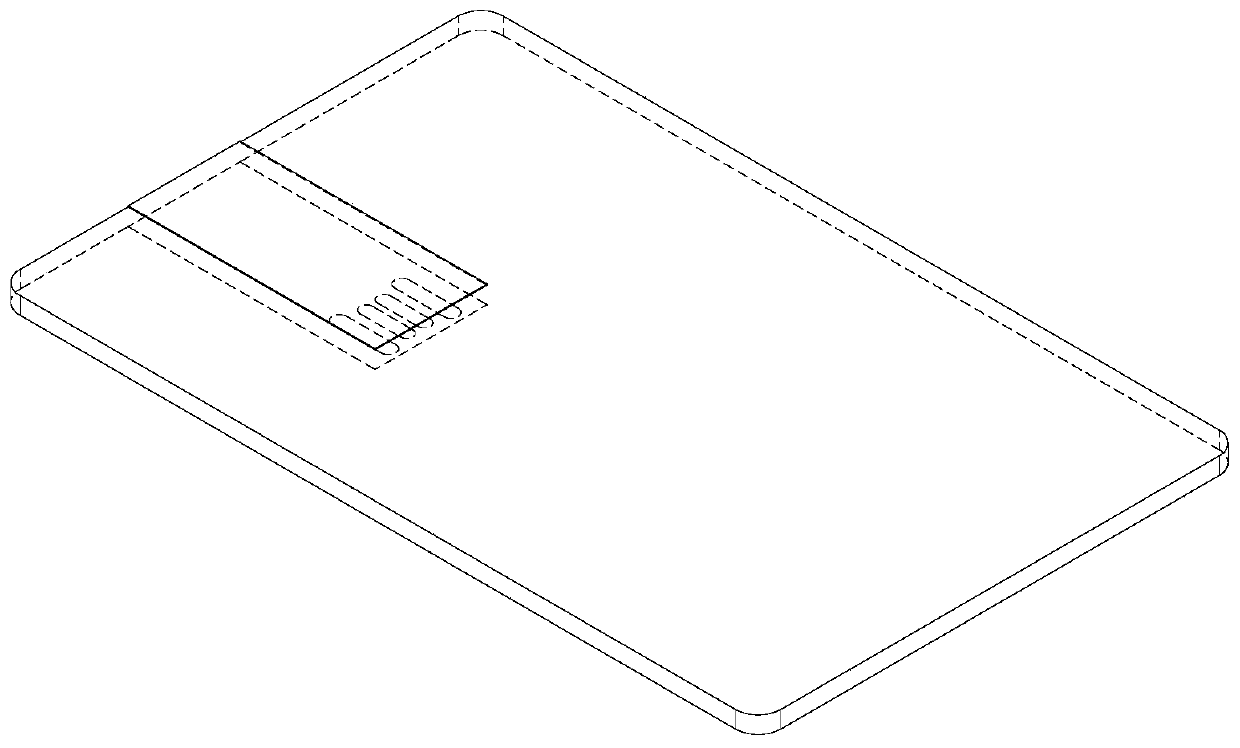

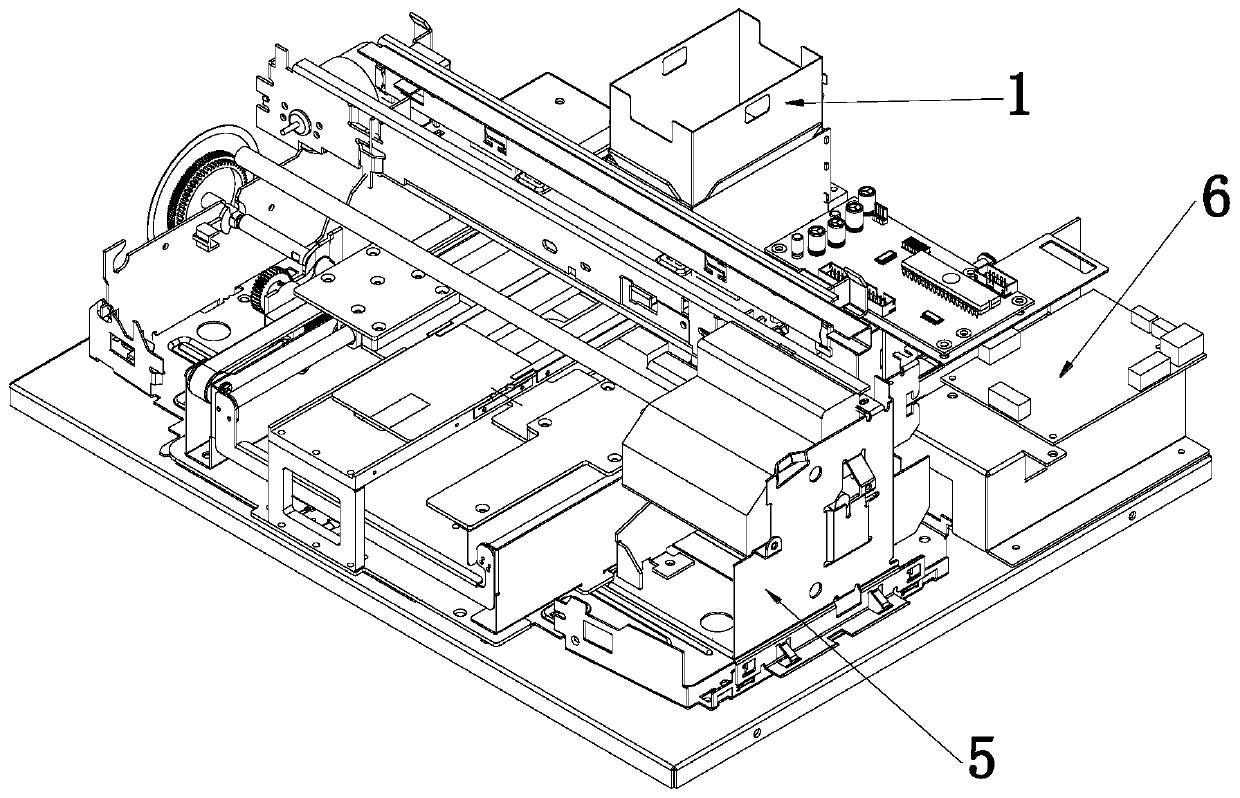

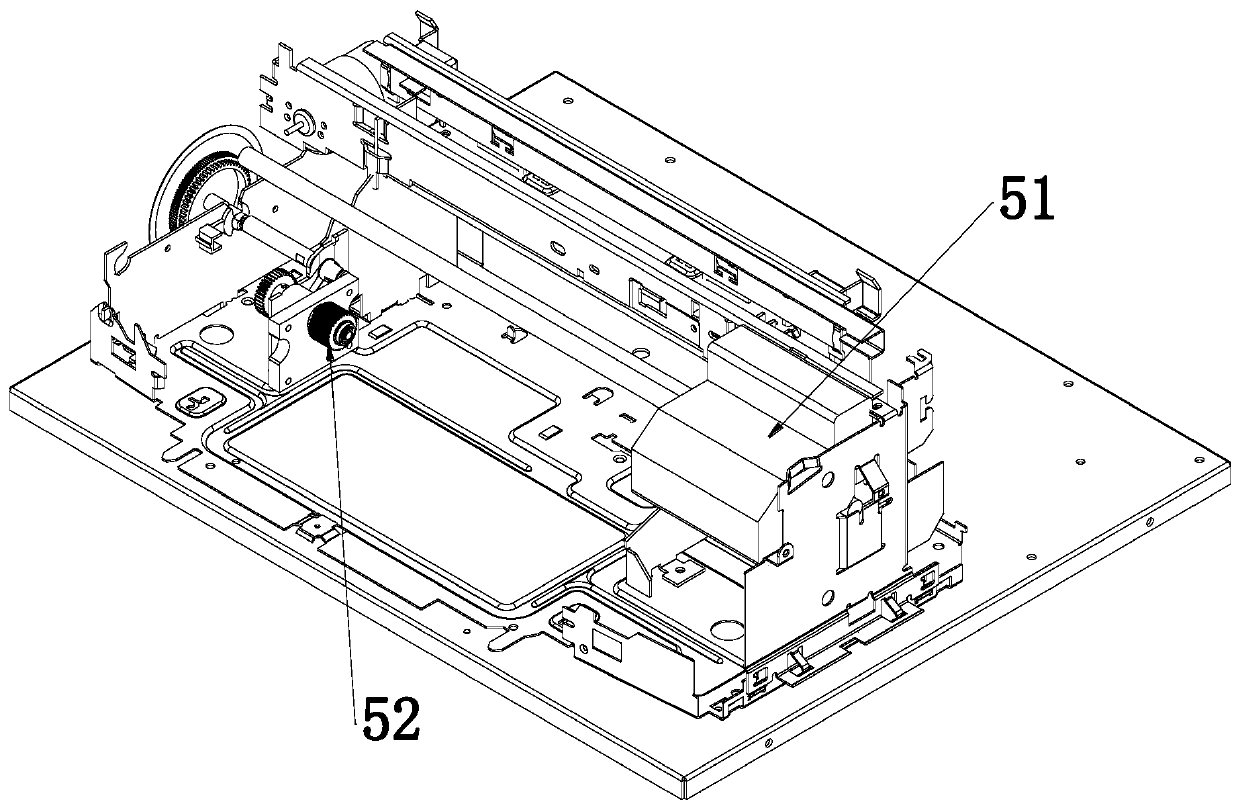

USB memory card printer

ActiveCN108437640AImprove cleanlinessAvoid affecting the printing effectTypewritersOther printing apparatusElectricityData file

The invention discloses a USB memory card printer, and the printer comprises a card box which is used for accommodating a plurality of USB memory cards; a card conveying module which is used for pulling the USB memory cards out of the card box and conveying the USB memory cards along a conveying path, wherein the conveying path is communicated with the card box; a reading-writing module which is set along the conveying path, and is used for carrying out the data reading and / or writing of the USB memory cards when the USB memory cards reaches a reading-writing region; a printing module which isdisposed above the conveying path in a crossing manner and is used for printing printed contents on the USB memory cards when the USB memory cards reaches a printing region; and a control module which is electrically connected with the card conveying module, the reading-writing module and the printing module and is used for controlling the card conveying module, the reading-writing module and theprinting module. According to the invention, the printer achieves the automatic pushing of the memory cards, can achieve the reading / writing of data files from / in the USB memory cards, also can printimages and characters on the upper surfaces of the USB memory cards, is simple in structure, and is easy to operate.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

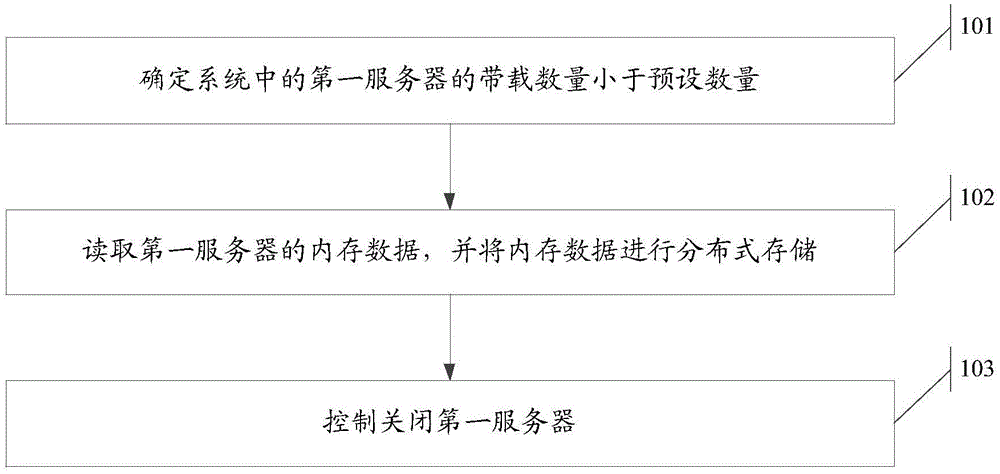

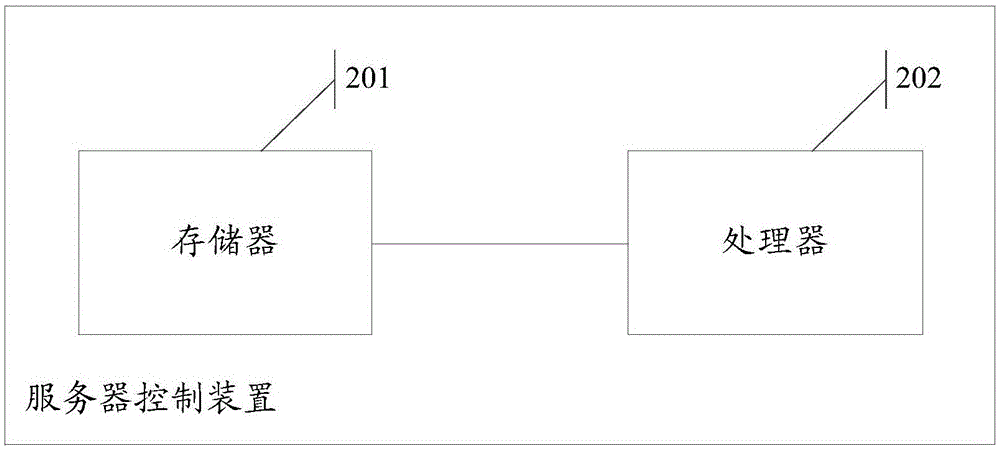

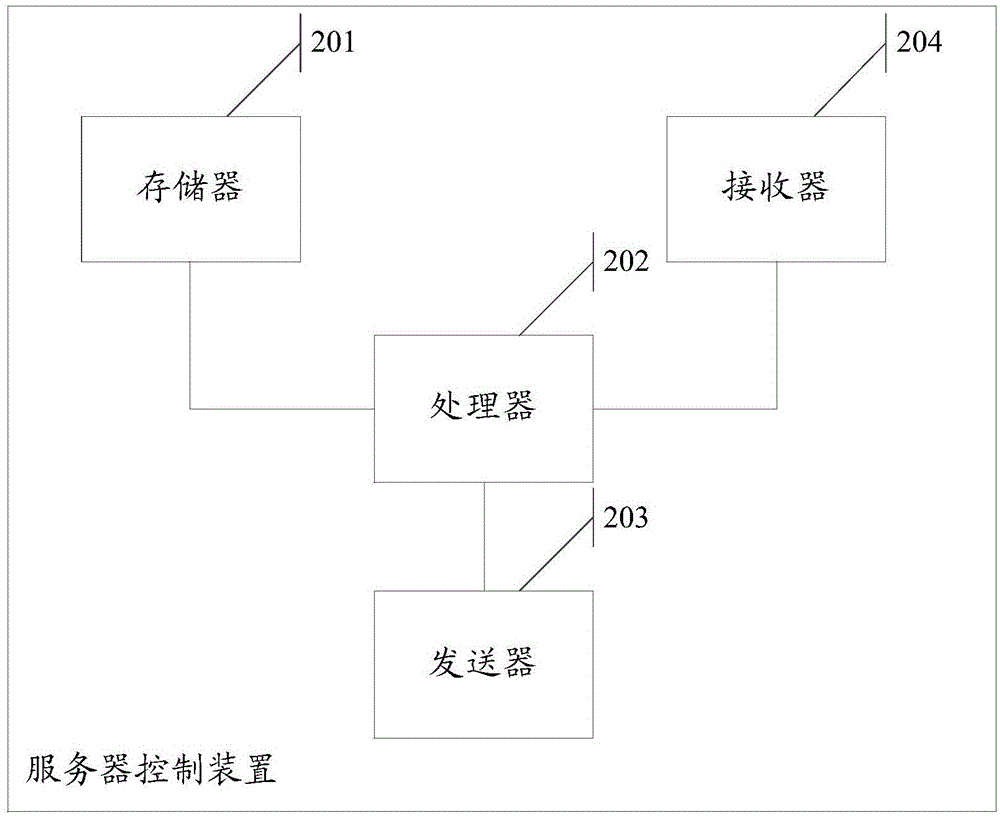

Server control method and device

ActiveCN106331036AAvoid running without loadSave power resourcesTransmissionOperating systemComputer science

The invention discloses a server control method and device and solves the technical problem of electric energy waste resulting from no load operation of a server. The method comprises the steps of determining that the load number of a first server in a system is smaller than the preset number; reading the memory data of the first server and carrying out distributed storage on the memory data; and controlling the first server to be closed.

Owner:LENOVO (BEIJING) CO LTD

Intelligent and efficient self-priming pump

PendingCN109751247ADrain fastAvoid running without loadPump componentsPriming pumpEngineeringSelf-absorbed

The invention discloses an intelligent and efficient self-priming pump, and mainly solves the technical problems of low priming stroke, long water feeding time and unstable water pressure of an existing self-absorbing pump. The intelligent and efficient self-priming pump is characterized by comprising a pump body (1) and a motor (3) mutually connected, the pump body (1) comprises a front pump body(11) and a rear pump body (12), a liquid sensor (14) is arranged on a liquid inlet seat (114) of the front pump body (11), an isolation cavity body (1251) is formed in the rear pump body (12) and isin sealed and matched connection with a laryngeal cavity (119) in the front pump body (11), the other end of the isolation cavity body (1251) is matched with a pump rear seat (121) of the rear pump body (12) in a sealed mode to form an isolation cavity (125), the isolation cavity (125) communicates with the laryngeal cavity (119), an impeller (126) is arranged in the isolation cavity (125), the impeller (126) is mounted on a pump shaft (127) in a sleeving mode, and the pump shaft (127) is connected with the motor (3).

Owner:湘潭市红高科技有限公司

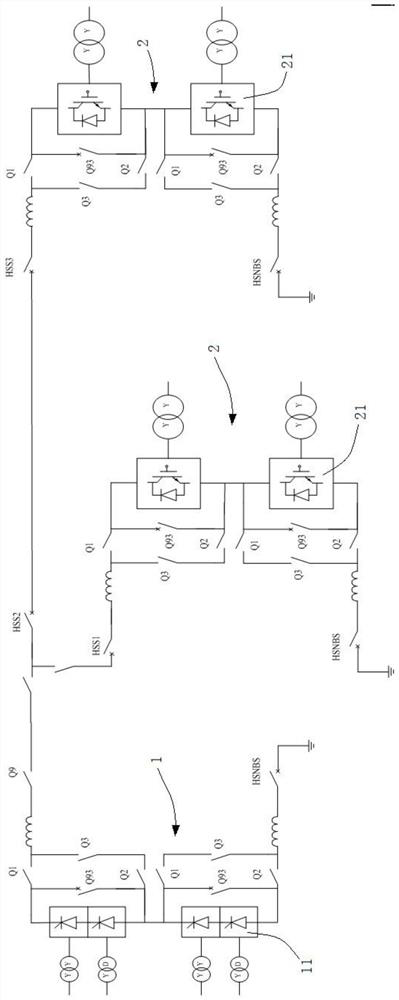

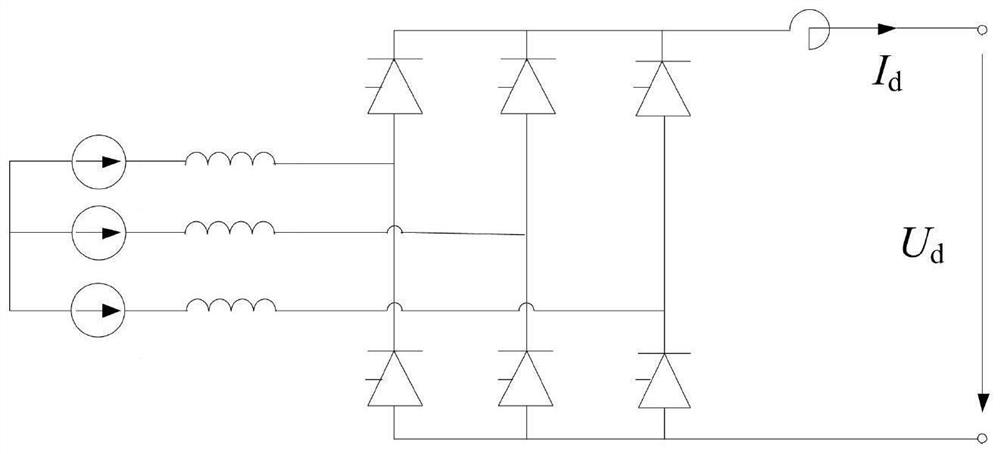

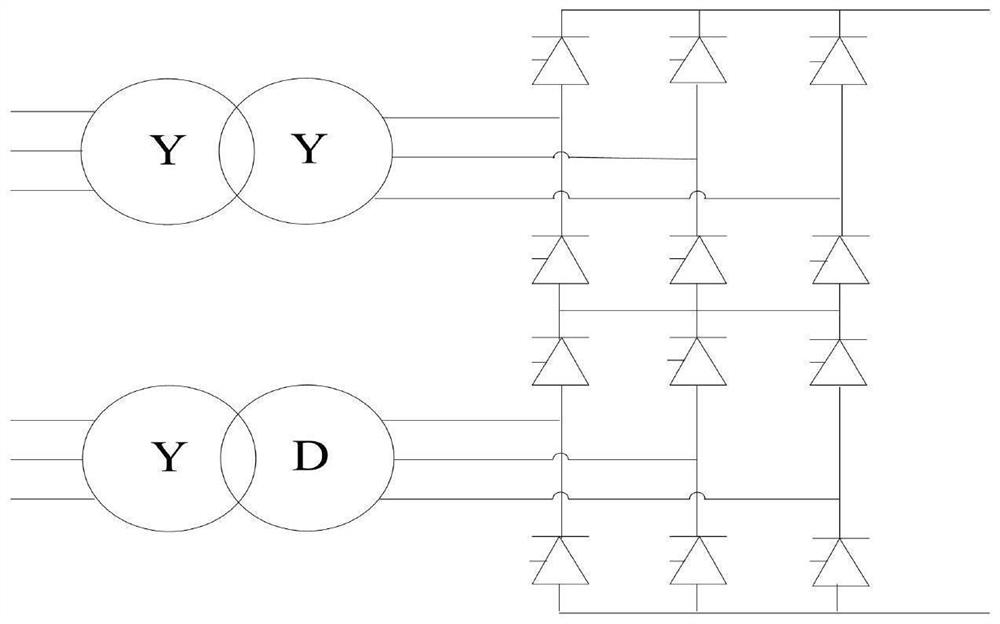

A three-terminal hybrid DC valve group failure exit method when inter-station communication failure

ActiveCN110797900BAvoid re-activation of protectionAvoid getting out of controlElectric power transfer ac networkEmergency protective circuit arrangementsOvervoltageConstant power

The present invention relates to the field of UHV multi-terminal hybrid direct current transmission fault handling, in particular, to a fault exit method for a three-terminal hybrid direct current valve group when inter-station communication fails. After a valve group of the LCC station on the rectification side fails, it should be ensured that the constant power VSC station on the inverter side is out of service first, and the constant DC voltage VSC station on the inverter side is out of service last, so as to ensure that when each station exits, the DC The voltage can be kept stable, avoiding the oscillation of the DC system and the loss of stability of the DC system. In the case of communication failure between three terminal stations, when the valve group fails to exit, the corresponding station adopts the method of extreme outage, which can effectively prevent the non-faulty valve group from being activated again due to overvoltage after the faulty valve group is blocked. If the valve group of the LCC station is faulty, after the rectifier side is out of operation, the low-current blocking method can ensure that the constant DC power VSC station on the inverter side and the constant DC voltage VSC station on the inverter side are blocked successively, effectively preventing the VSC station from being out of control.

Owner:ANNING BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION

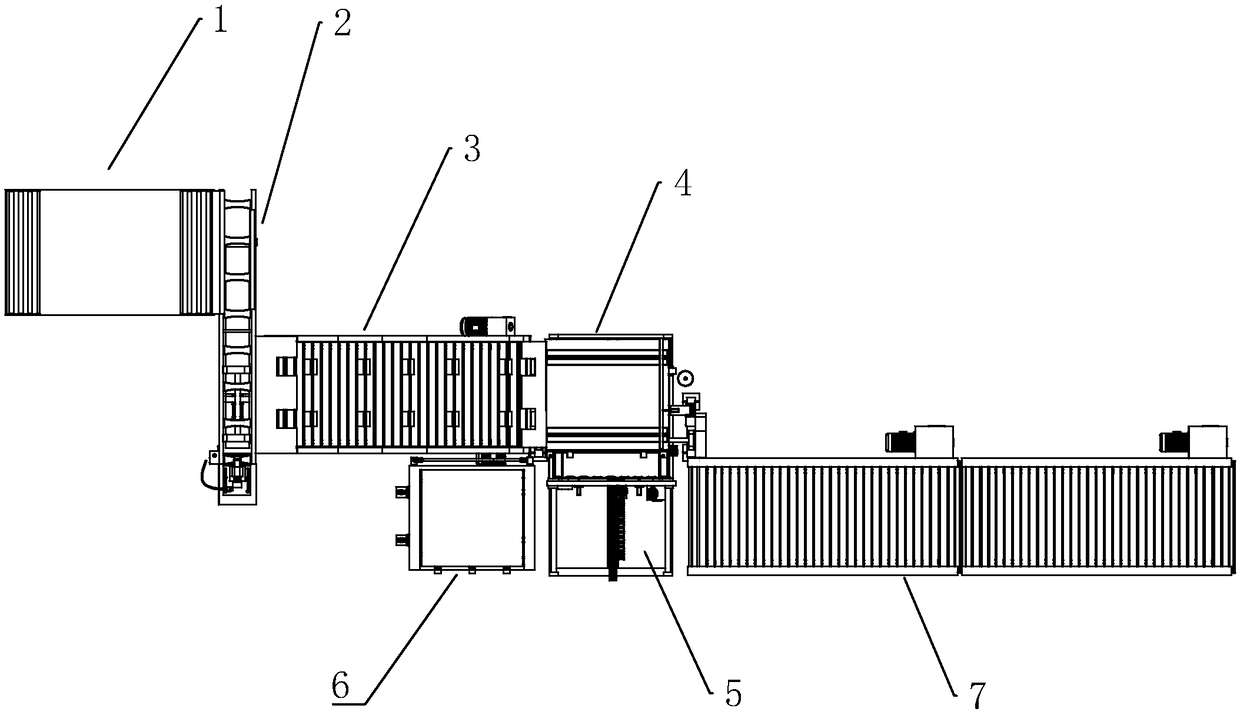

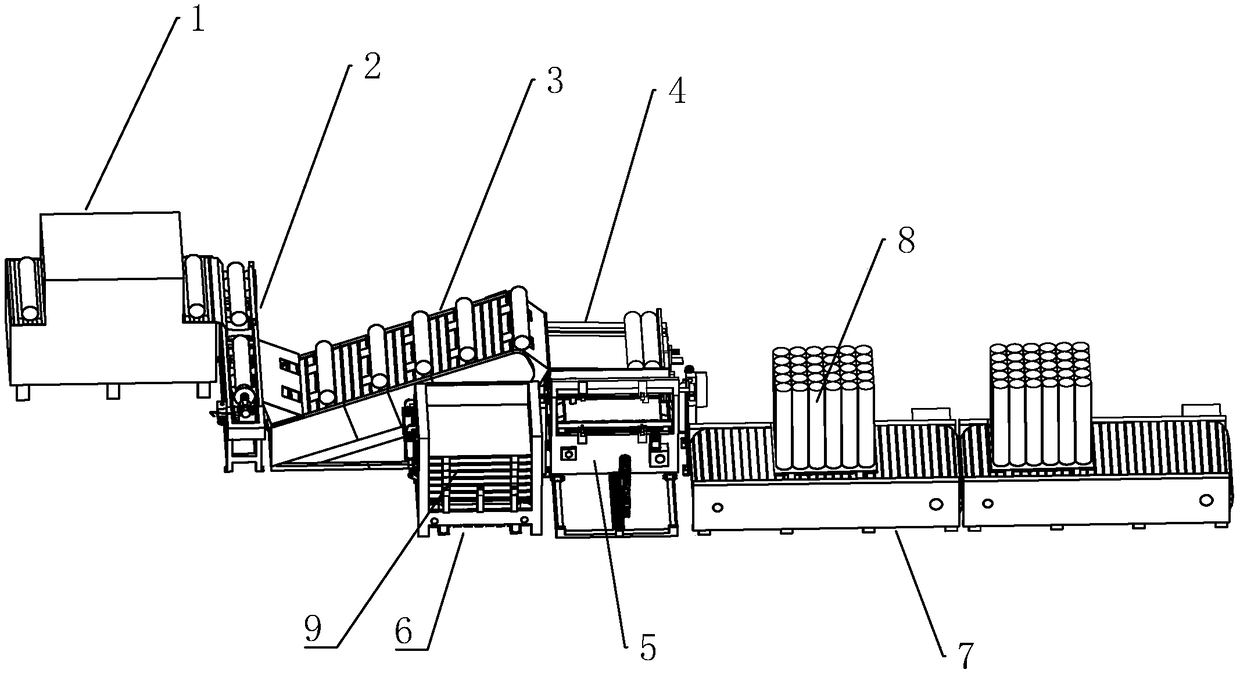

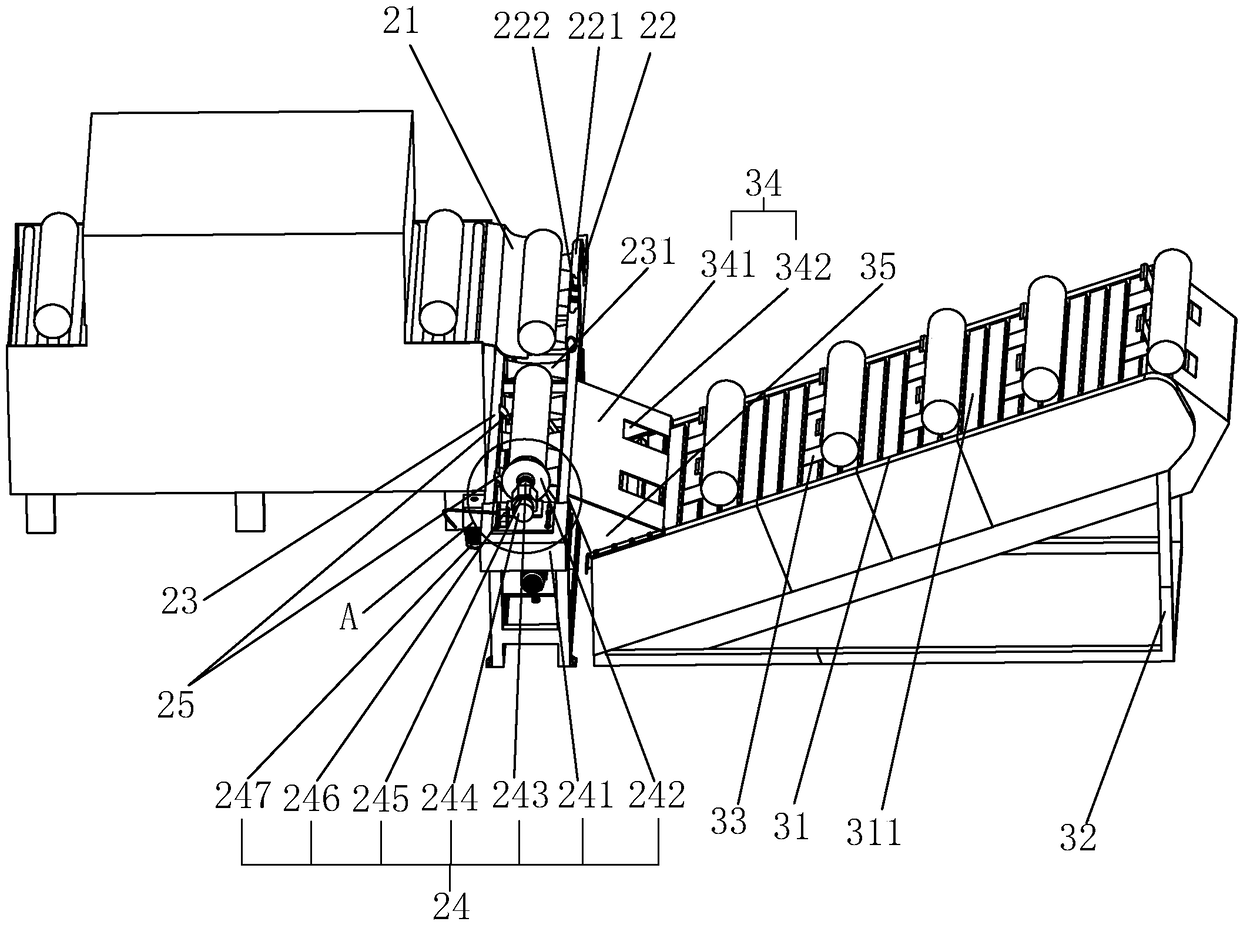

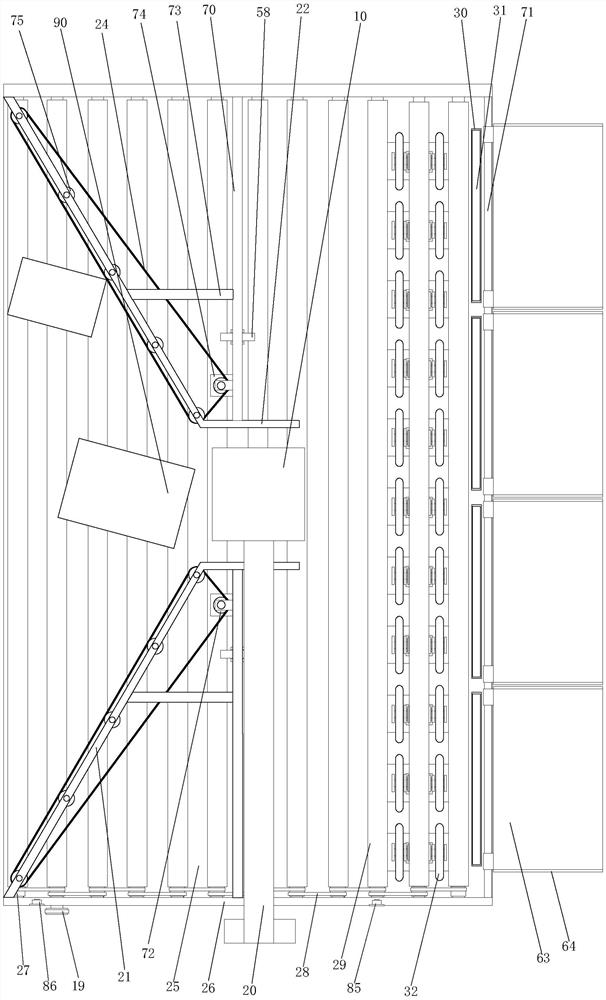

Coil palletizing line

ActiveCN106241396BStrong connectionHigh degree of automationStacking articlesConveyor partsEngineeringAssembly line

The invention discloses a coiled material stacking assembly line. The coiled material stacking assembly line comprises a film laminating mechanism which conducts film laminating outside a coiled material. The conveying tail end of the film laminating mechanism is provided with a single coiled material conveying mechanism which is perpendicular to the conveying tail end of the film laminating mechanism and used for conveying the single coiled material. The conveying tail end of the coiled material conveying mechanism is provided with a slope conveying mechanism perpendicular to the conveying tail end of the coiled material conveying mechanism. The conveying tail end of the slope conveying mechanism is provided with a turnover mechanism which receives the coiled material and vertically turns over the coiled material. A tray conveying mechanism for receiving the coiled material which is vertically turned over is arranged below the turnover mechanism. One side perpendicular to the conveying tail end of the tray conveying mechanism is provided with a tray storage mechanism for supplying trays to the tray conveying mechanism, and the other side perpendicular to the conveying tail end of the tray conveying mechanism is provided with a coiled material stacking conveying mechanism. The conveying tail end of the single coiled material conveying mechanism is provided with a switching device for controlling the subsequent processes to be continuously operated in sequence. The switching device can control starting and stopping of the follow-up series of mechanisms, real-time supervision by workers in the subsequent processes is not needed, the manpower is saved, and the efficiency is improved.

Owner:百耐尔河北建材科技有限公司

A memory card automatic pushing device

ActiveCN108382899BImprove cleanlinessAvoid affecting the printing effectCoupling device detailsArticle feedersStructural engineeringMechanical engineering

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

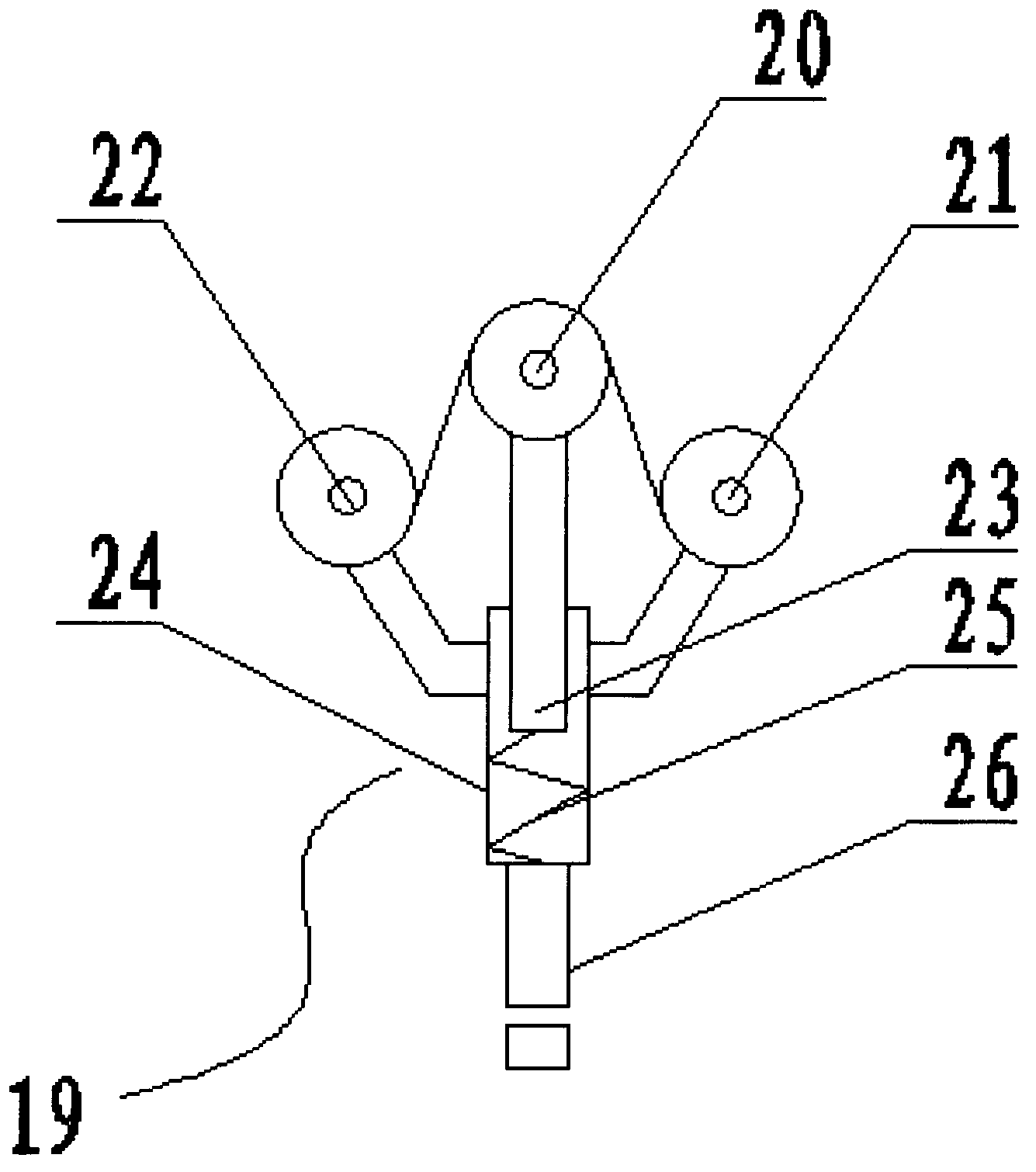

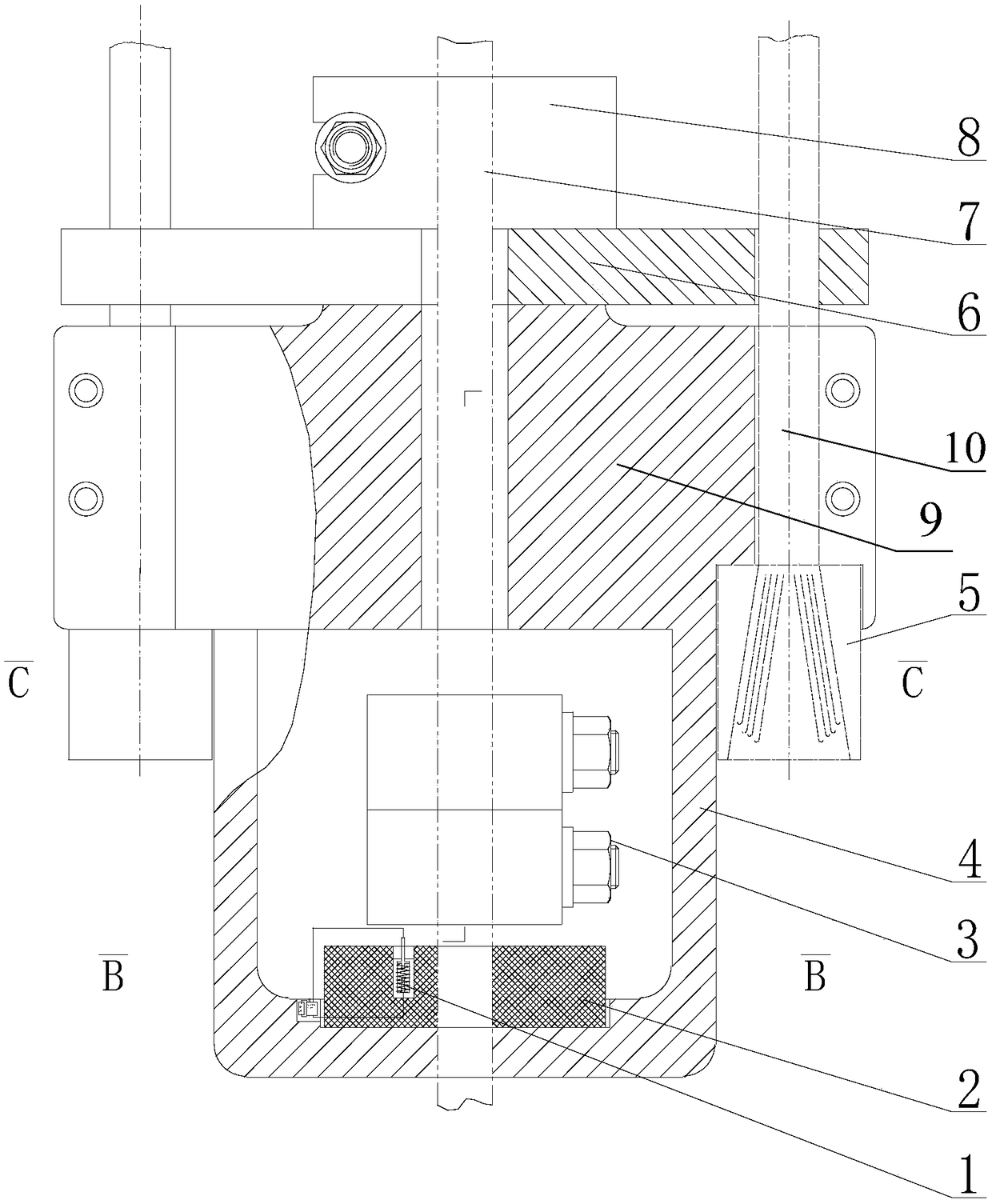

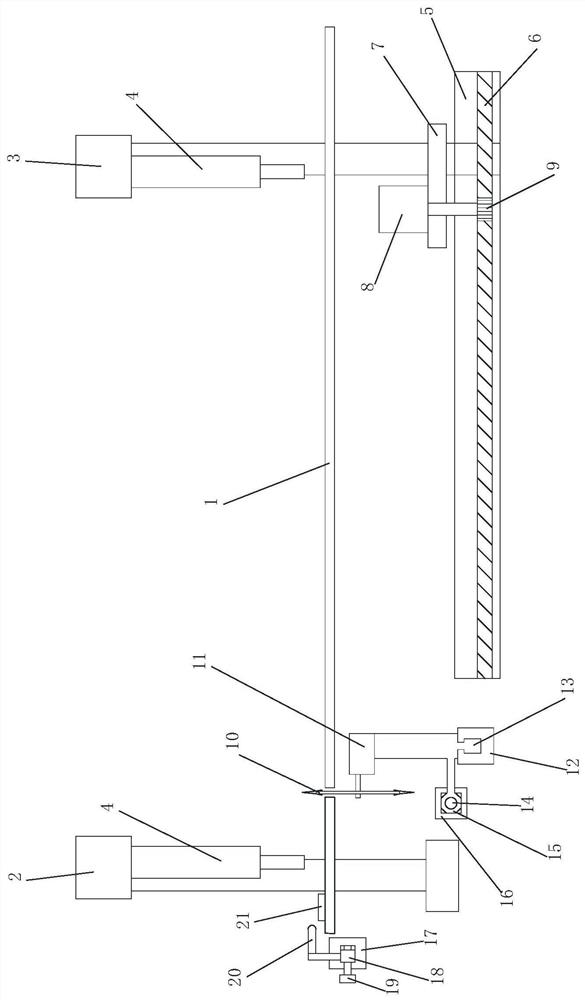

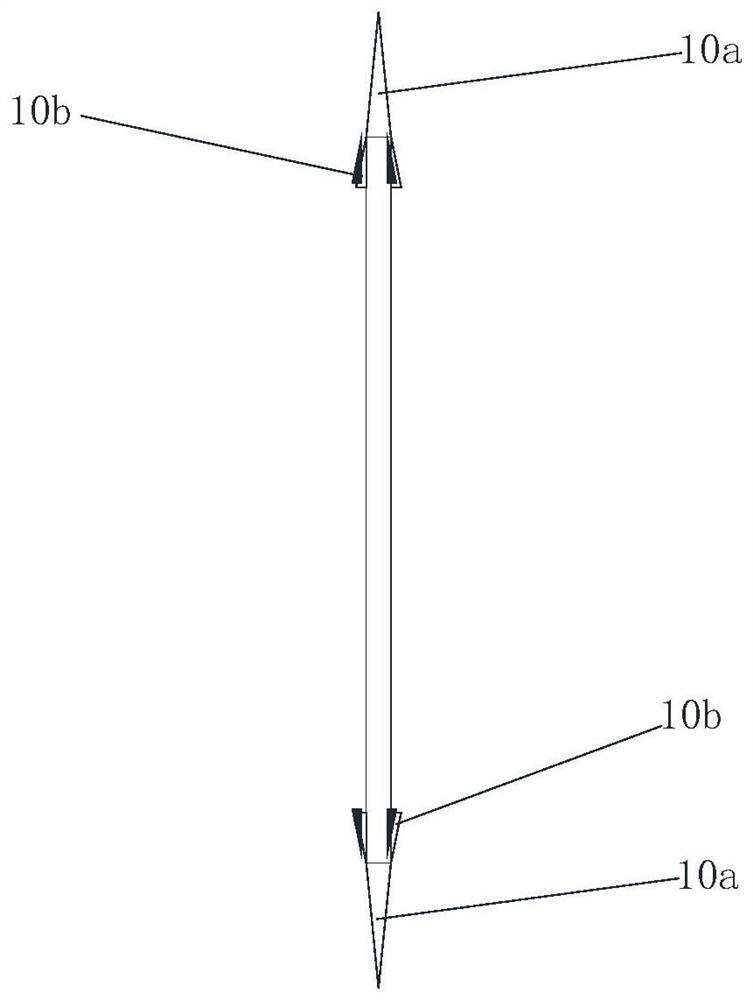

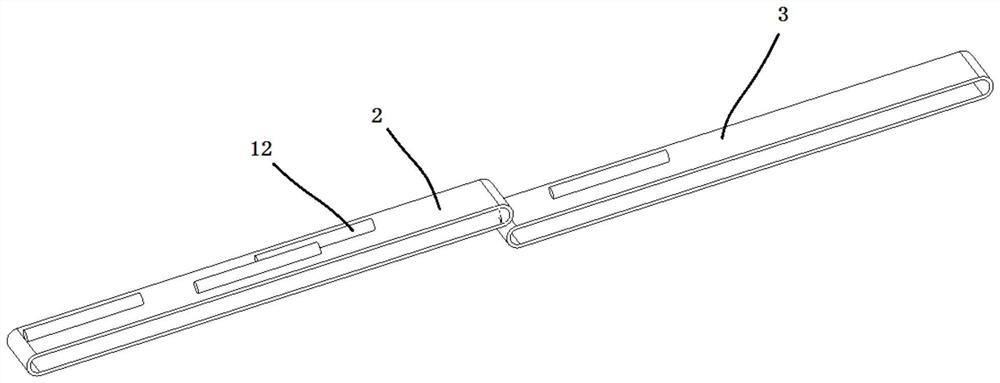

Dumet wire microwave-heating wire-passing device

InactiveCN103572197AImprove quality performanceNo color differenceSolid state diffusion coatingQuality performanceMicrowave sintering

The invention discloses a Dumet wire microwave-heating wire-passing device. The wire-passing device is arranged between a wire feeding device of a Dumet wire microwave-heating production system and a microwave oxidizing furnace, or between the microwave oxidizing furnace and a microwave sintering furnace, or between the microwave sintering furnace and a wire collecting device; the wire-passing device comprises a wire pressing wheel, two guide wheels, a piston, a cylinder sleeve, a spring and a proximity switch, wherein a sintered ceramic tube is connected with the wire collecting device by passing through the guide wheel, the wire pressing wheel and the other guide wheel in sequence; the wire pressing wheel is hinged on the piston; a fed wire is pressed on the wire pressing wheel by the guide wheels at the two sides of the wire pressing wheel, so that the piston is in an up-down movement state in the cylinder sleeve through the spring; the spring moves up and down, so that the proximity switch at the bottom end of the spring is in a state of switching on or switching off microwave generators of the microwave sintering furnace and the microwave oxidizing furnace; the Dumet wire material prepared by the system has no CuO generated on the outer layer, has no chromatic aberration and no air bubbles in subsequent platinum glass fusing-sealing, and has high quality performance.

Owner:樊伟

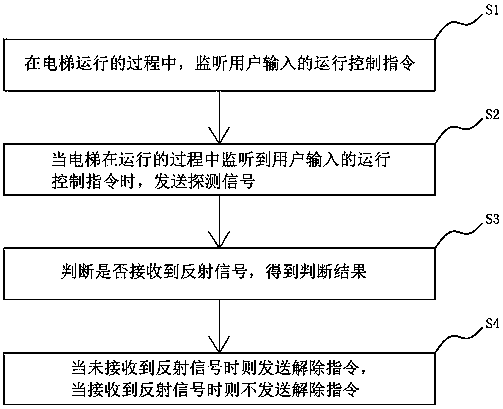

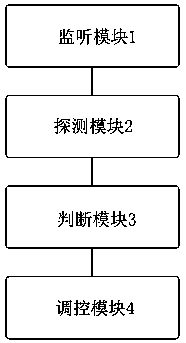

Elevator regulation and control method and system

InactiveCN109650198ALow running costImprove operational efficiencyElevatorsDirect responseEmbedded system

The invention provides an elevator regulation and control method and system. The method specifically includes the steps that in the operation process of an elevator, an operation control instruction input by a user is monitored; when the elevator monitors the operation control instruction input by the user in the operation process, a detection signal is sent; whether a reflection signal is received or not is judged, and the judgment result is obtained; when the reflection signal is not received, a relieving instruction is sent; and when the reflection signal is received, the relieving instruction is not sent, and the elevator continues to respond to the operation control instruction. When monitoring the operation control instruction in the operation process, the elevator sends the detection signal firstly instead of directly responding to the operation control instruction, and therefore whether there is the user waiting for the elevator or not can be confirmed; and when there is the user waiting for the elevator, the elevator responds to the operation control instruction, and when there is no user waiting for the elevator, the operation control instruction is relieved. By means ofthe type of technical scheme, the operation cost of the elevator can be reduced, and meanwhile the operation efficiency of the elevator can be improved.

Owner:HOMEFRIEND & FUJI ELEVATOR CO LTD

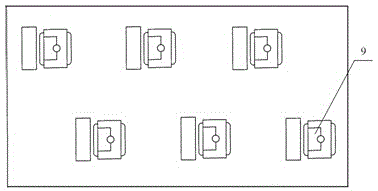

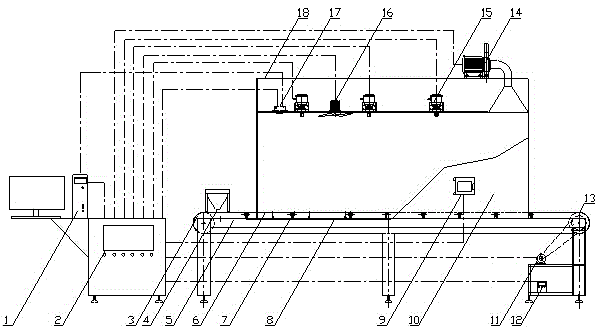

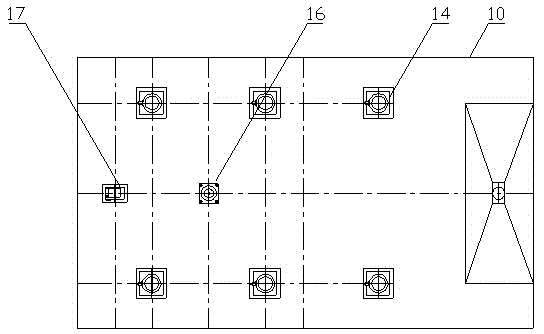

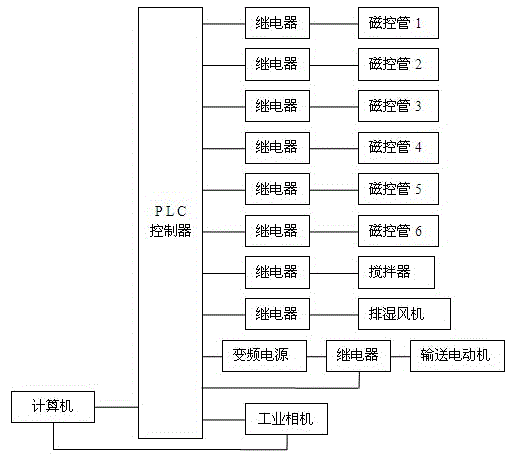

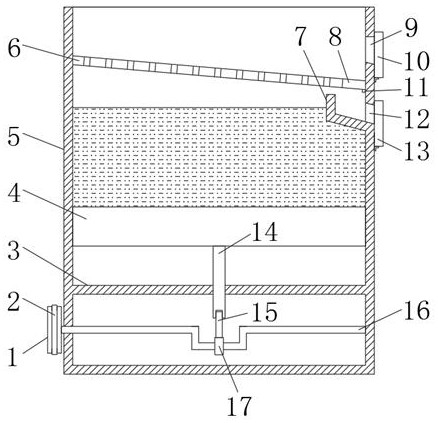

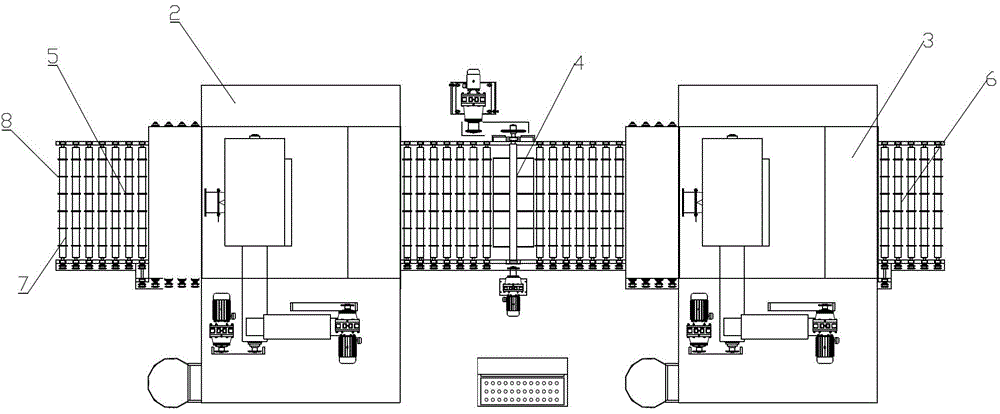

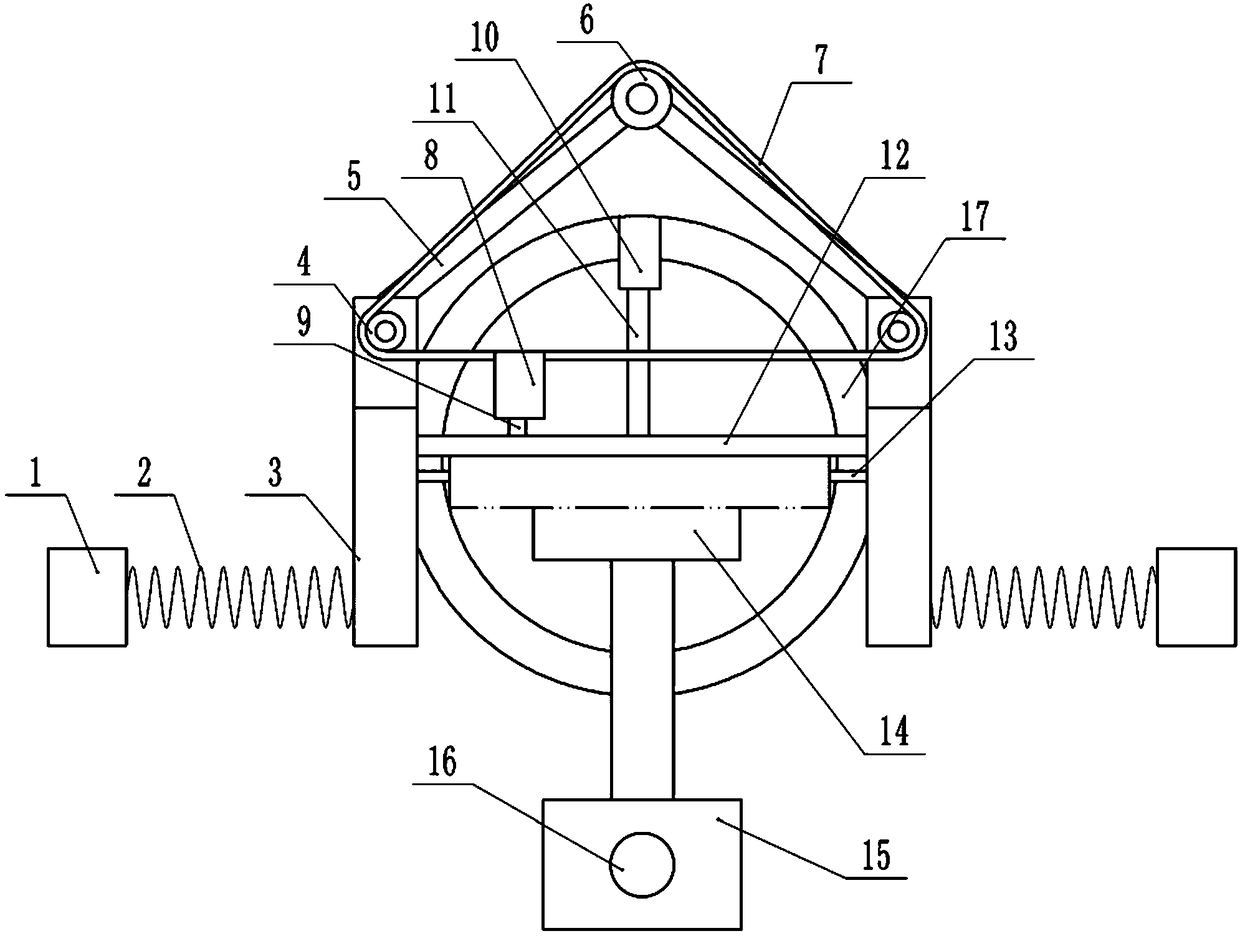

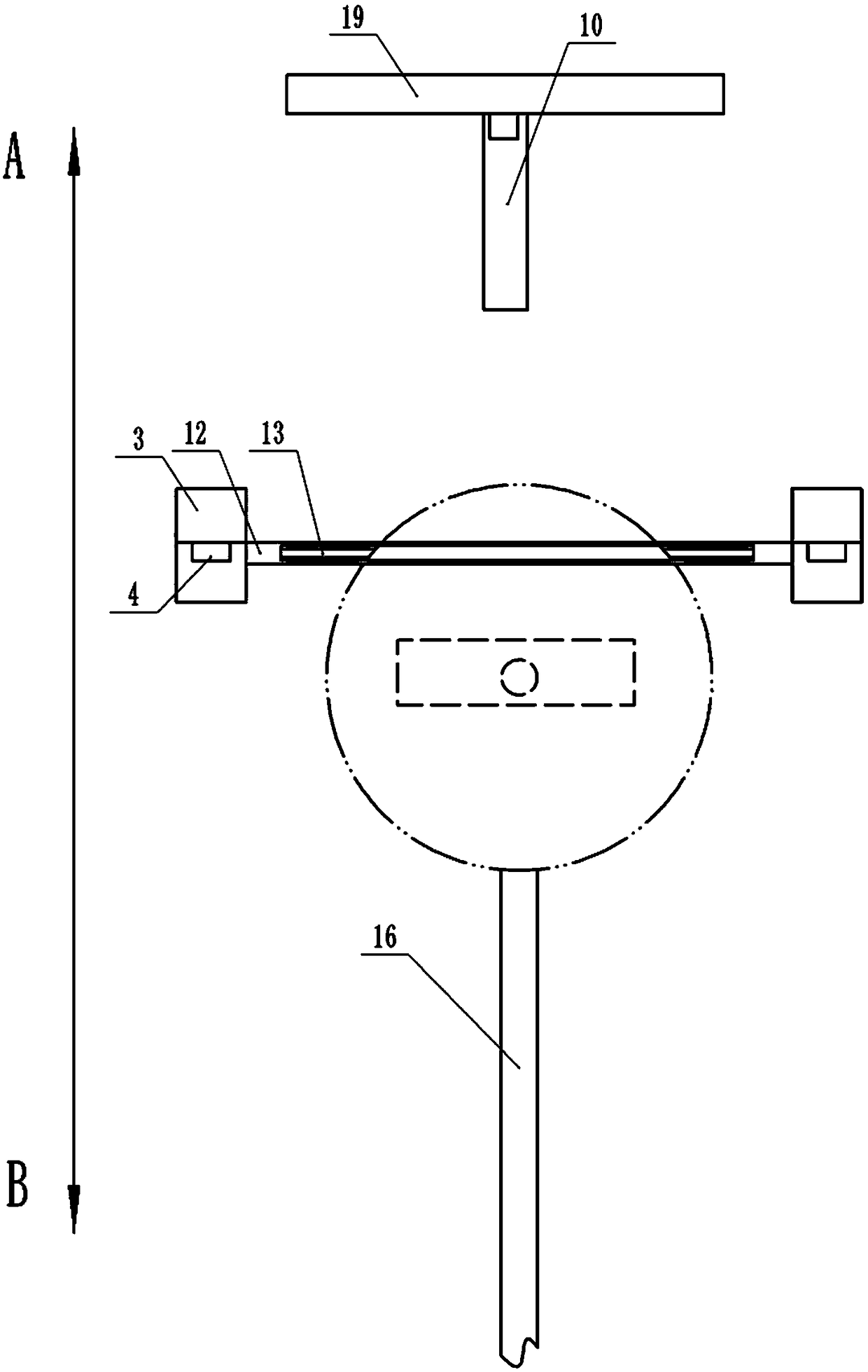

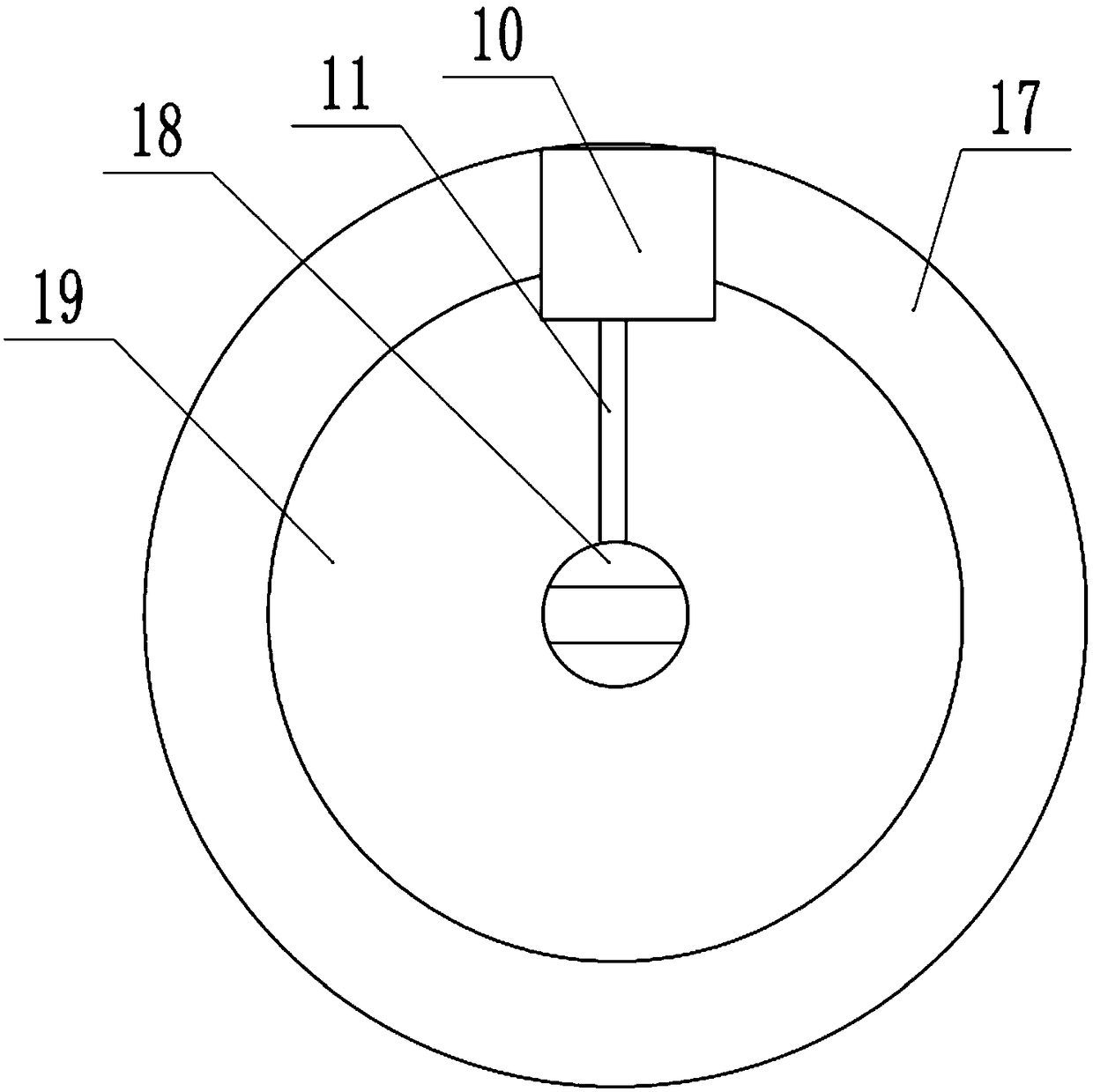

Tunnel-type vegetable microwave dryer and its automatic anti-no-load method

InactiveCN104188071BAvoid running without loadImprove uniformityDrying machines with non-progressive movementsDrying solid materialsStopped workProduction rate

The invention discloses a tunnel type vegetable microwave drying machine and an automatic no-load preventing method thereof. The tunnel type vegetable microwave drying machine comprises a conveying system, a heater and a no-load preventing system, wherein the heater is fixed on the conveying system and comprises a waveguide, a moisture exhausting fan, a magnetic control tube, a stirrer and the like. The stirrer and the magnetic control tube are fixed at the top of a box body of the waveguide, and a moisture exhausting port is formed in one end of the top of the waveguide and connected with the moisture exhausting fan. The no-load preventing system comprises a computer, a control console and an industrial camera, wherein the industrial camera is installed at the top of the other end of the waveguide and obtains RGB images on a white conveying belt at the material input end in the drying machine in real time, the computer is utilized to process the images and obtain the area of each material-free area on the white conveying belt, when the area of the single material-free area is larger than the set no-load area, the control console enables the magnetic control tube to stop working, the magnetic control tube and the conveying belt are protected, and otherwise, the magnetic control tube runs normally. The drying process of the whole drying machine is automatic, the productivity is high, and the drying and processing requirements of different agricultural products are met.

Owner:ZHEJIANG UNIV

A usb memory card printer

ActiveCN108437640BImprove cleanlinessAvoid affecting the printing effectTypewritersOther printing apparatusData fileUSB

The invention discloses a USB memory card printer, and the printer comprises a card box which is used for accommodating a plurality of USB memory cards; a card conveying module which is used for pulling the USB memory cards out of the card box and conveying the USB memory cards along a conveying path, wherein the conveying path is communicated with the card box; a reading-writing module which is set along the conveying path, and is used for carrying out the data reading and / or writing of the USB memory cards when the USB memory cards reaches a reading-writing region; a printing module which isdisposed above the conveying path in a crossing manner and is used for printing printed contents on the USB memory cards when the USB memory cards reaches a printing region; and a control module which is electrically connected with the card conveying module, the reading-writing module and the printing module and is used for controlling the card conveying module, the reading-writing module and theprinting module. According to the invention, the printer achieves the automatic pushing of the memory cards, can achieve the reading / writing of data files from / in the USB memory cards, also can printimages and characters on the upper surfaces of the USB memory cards, is simple in structure, and is easy to operate.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

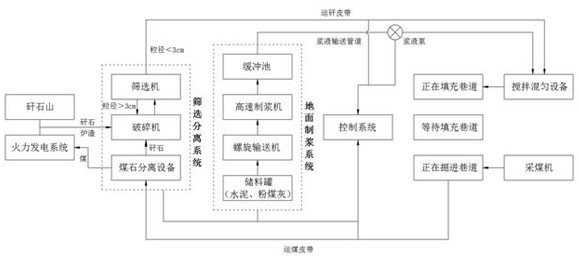

Coal mine three-under-three coal pressing filling mining system and coal mine three-under-three coal pressing filling mining method

PendingCN114151085ASituations that increase safety hazardsReduce workloadUnderground miningSurface miningPower stationSlag

The invention relates to the technical field of coal mining, and discloses a coal mine under-three coal pressing and filling mining system and method.The coal mine under-three coal pressing and filling mining system comprises a screening and separating system and a ground slurrying system.The screening and separating system comprises coal gangue separating equipment, a crusher and a screening machine; the coal gangue separation equipment is used for separating coal from coal gangue in the coal mine conveyed by the coal conveying belt; in the mined roadway, aggregate with the particle size smaller than 3 cm is formed by crushing coal gangue generated by the tunneling roadway, gangue generated by a gangue dump and slag generated by a thermal power plant, meanwhile, slurry is prepared through a high-speed slurry making machine, the aggregate and the slurry are conveyed to a filling site, the aggregate and the slurry are guided from a roadway opening of the roadway needing to be filled after being evenly mixed, and filling is completed. The roadway needing to be filled is filled by utilizing gravity and liquidity of slurry, so that the workload of post-treatment can be reduced, and the situation that potential safety hazards of a coal mining area are increased due to the existence of the roadway is greatly reduced.

Owner:山东鲁创能源科技有限公司

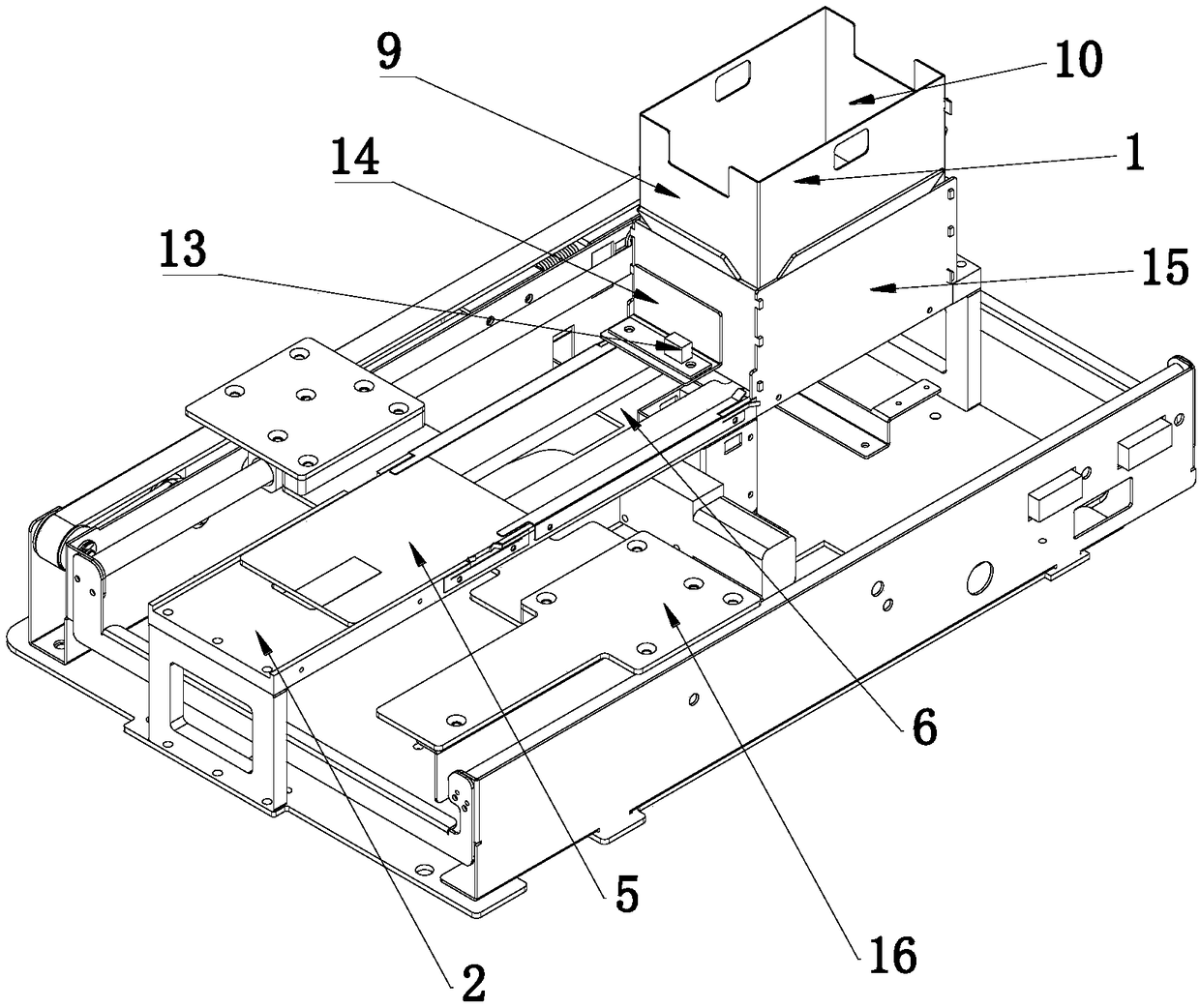

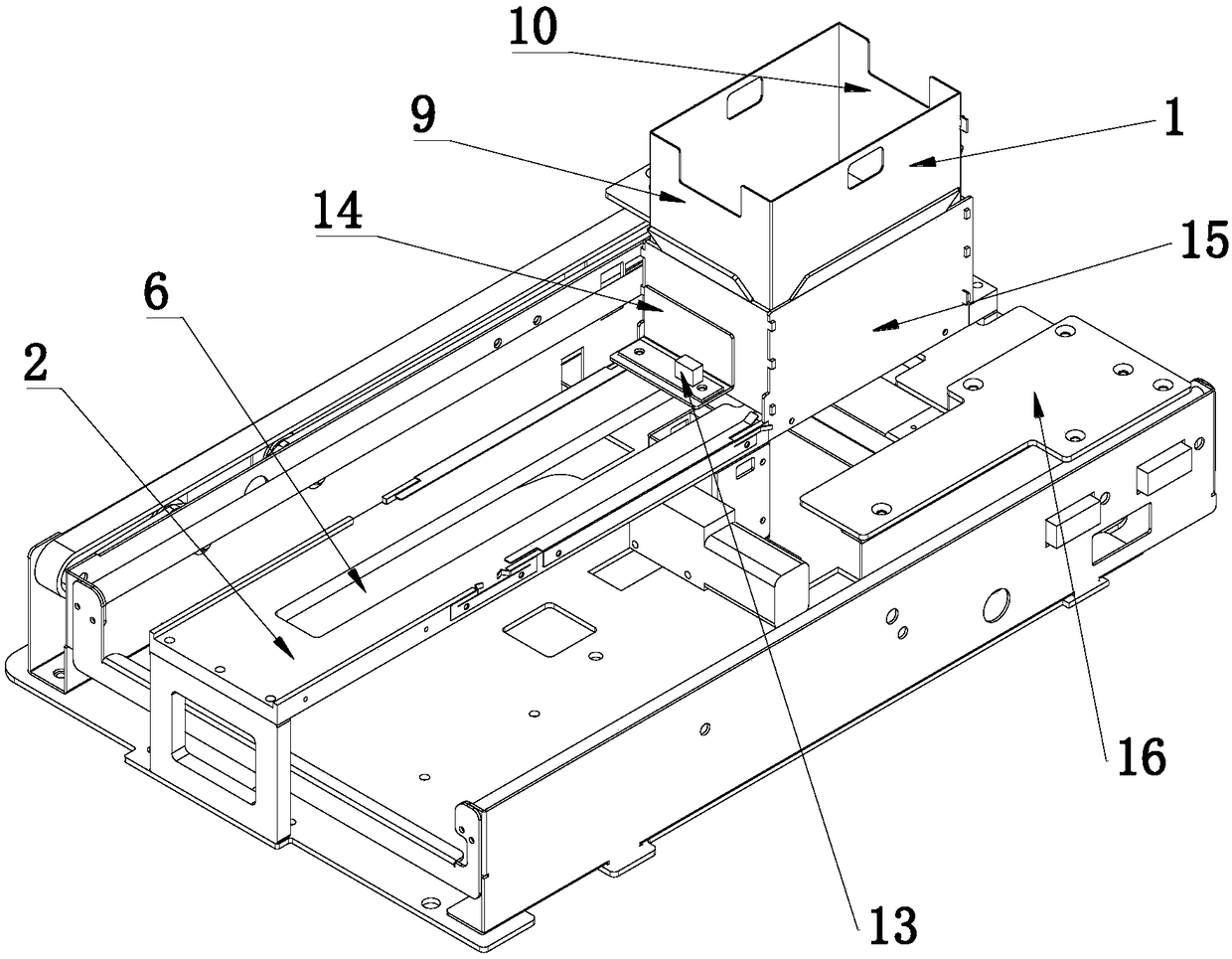

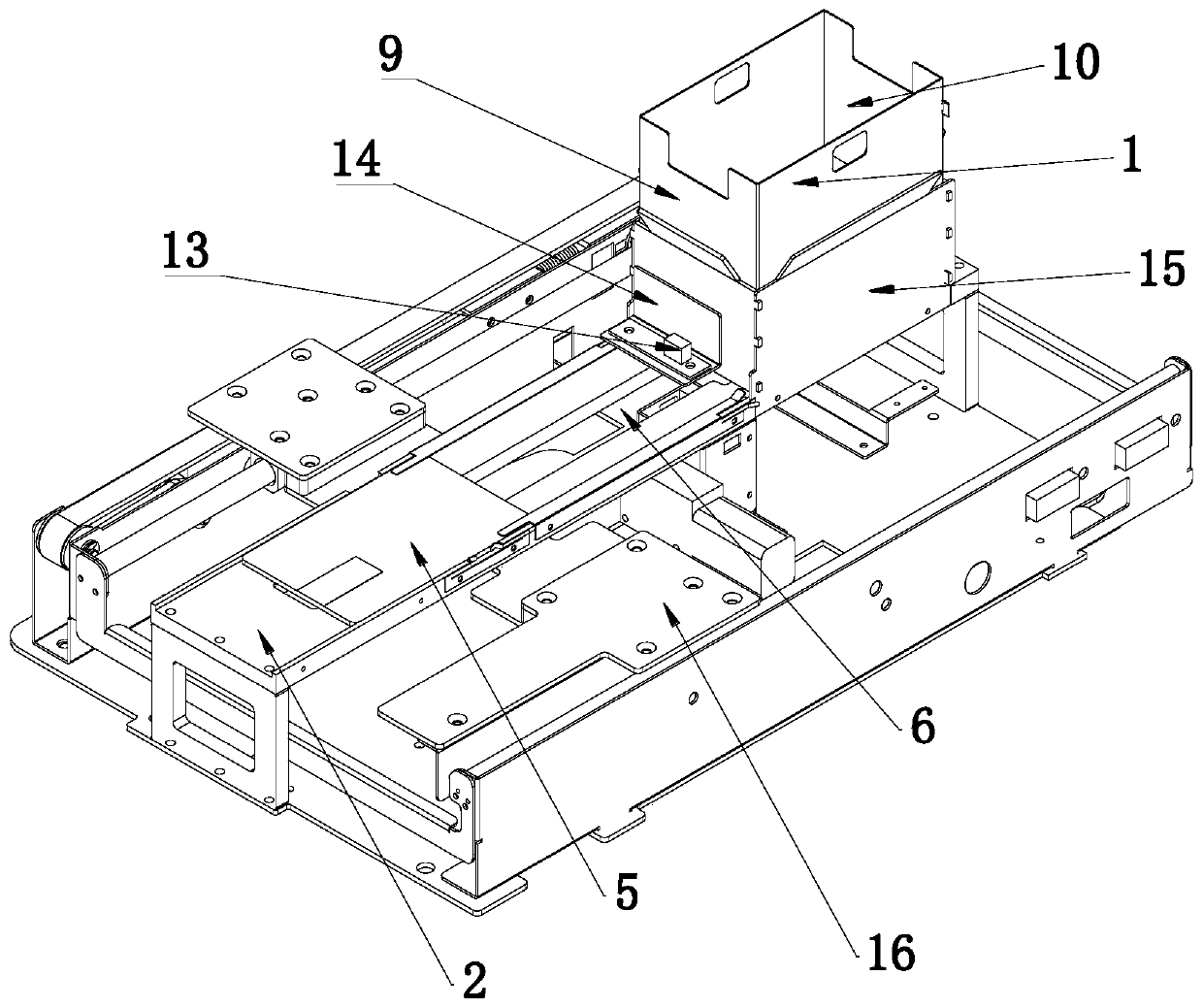

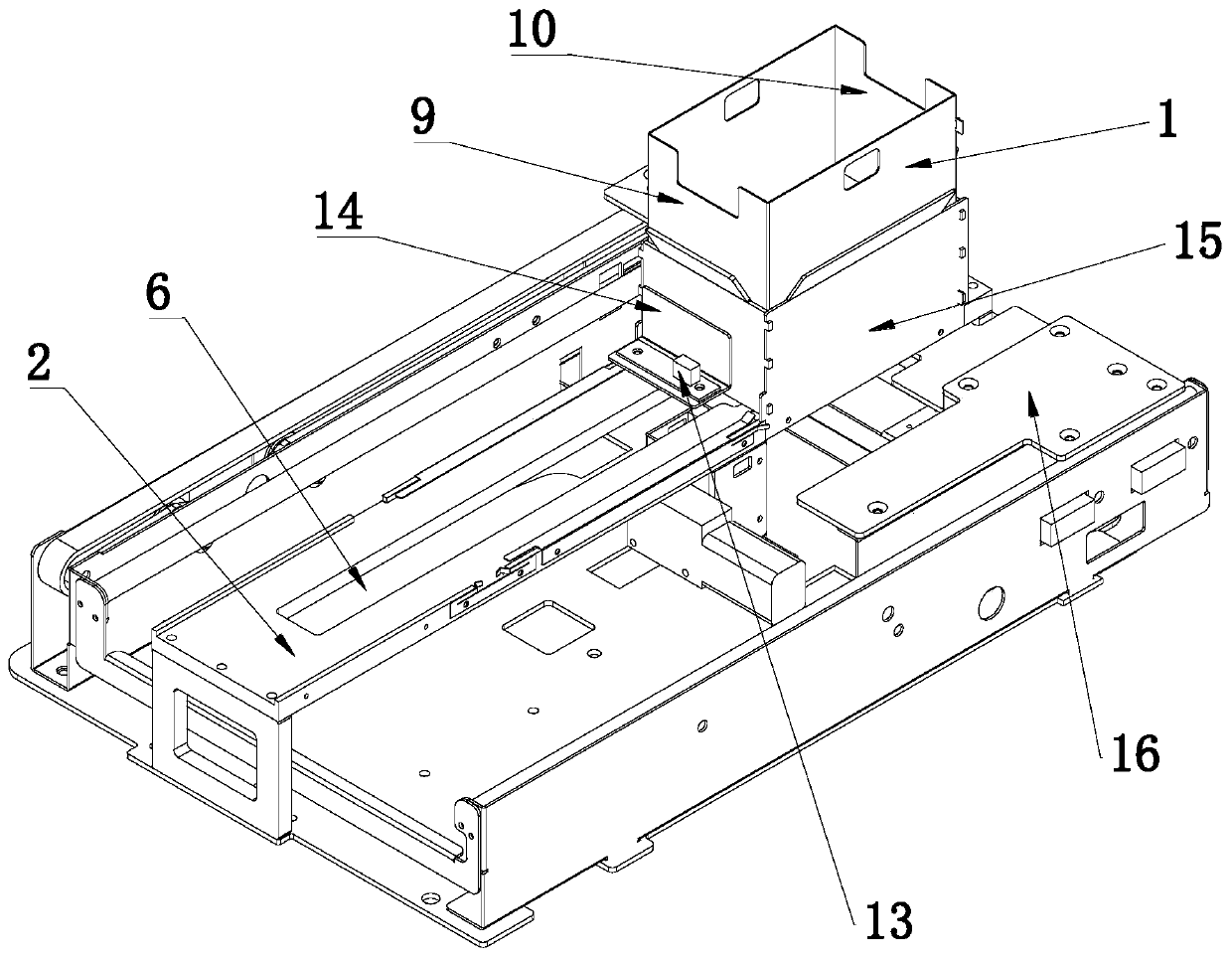

Workpiece transfer device for intelligent production line

InactiveCN112374020AAvoid running without loadImprove processing efficiencyConveyorsControl devices for conveyorsProduction lineTransfer mechanism

The invention provides a workpiece transfer device for an intelligent production line. The workpiece transfer device comprises a transfer conveying roller bed, a centering adjusting mechanism, an image recognition mechanism, a transverse moving transfer mechanism and a blocking limiting mechanism. According to the workpiece transfer device for the intelligent production line, the image recognitionmechanism is used for carrying out image recognition on workpieces conveyed on the transfer conveying roller bed, the next machining procedure needing to be carried out on each workpiece is determined, and therefore the workpieces are distributed to corresponding inclined discharging mechanisms for classified discharging through cooperation of the transverse moving transfer mechanism and the blocking limiting mechanism, the workpieces of various types can be conveniently transferred to corresponding machining equipment subsequently, and the machining efficiency of the workpieces is improved;and the centering adjusting mechanism is used for pushing the workpieces on the feeding side of the transfer conveying roller bed to the middle position, and therefore the image recognition camera cancollect the centered workpieces conveniently, and the success rate of later image recognition is ensured.

Owner:苏州南师大科技园投资管理有限公司 +1

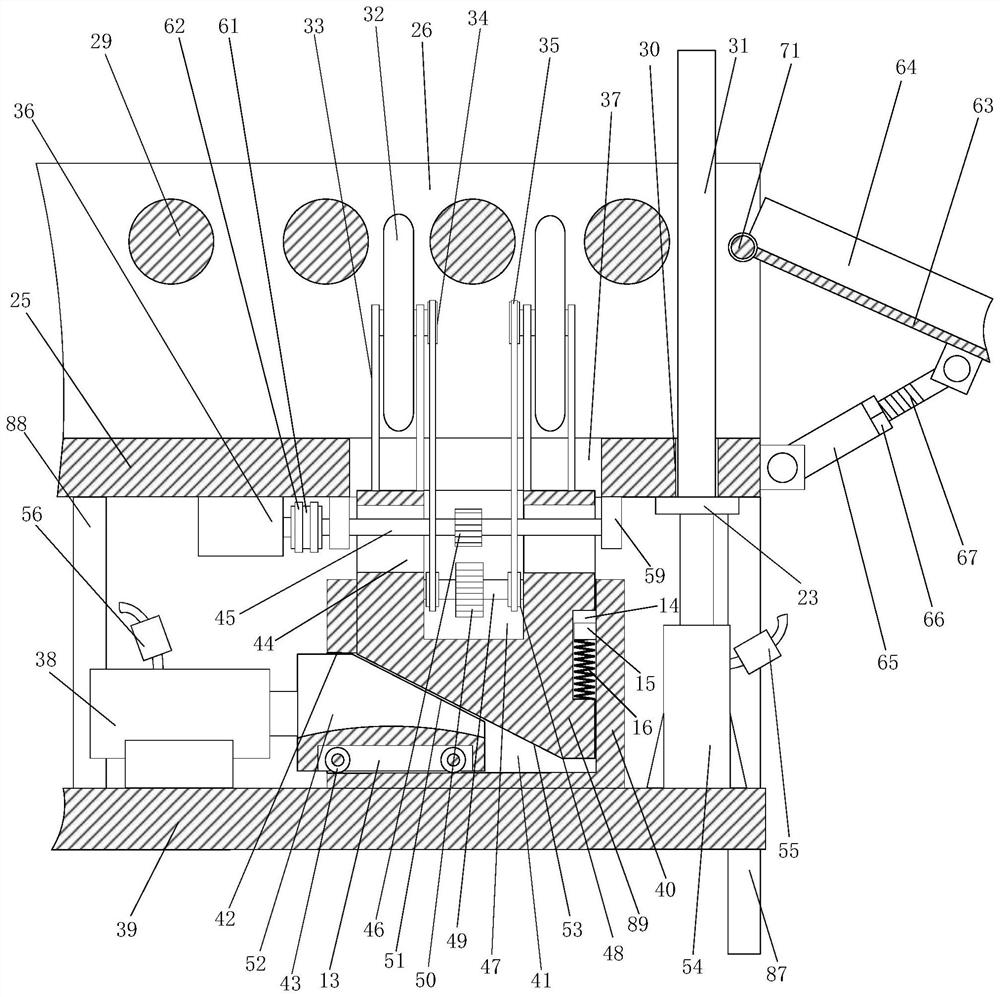

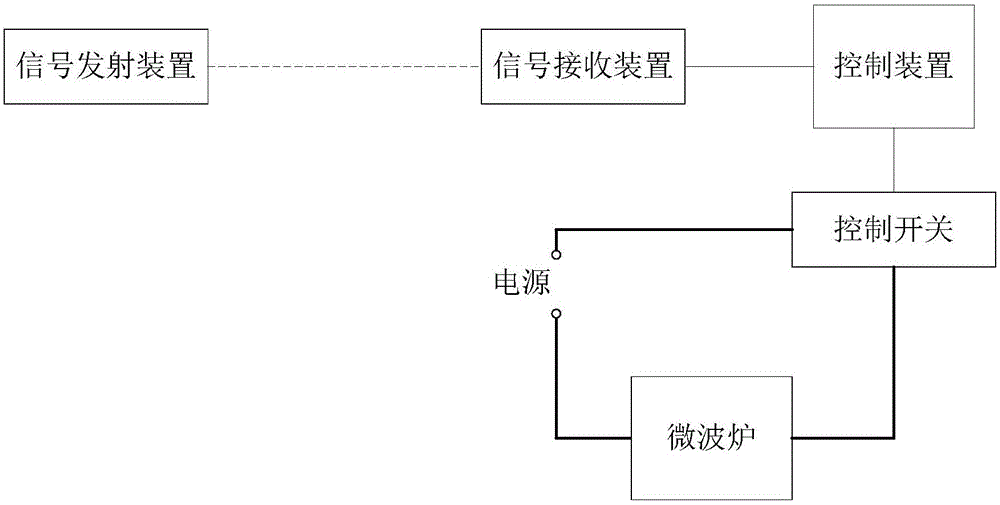

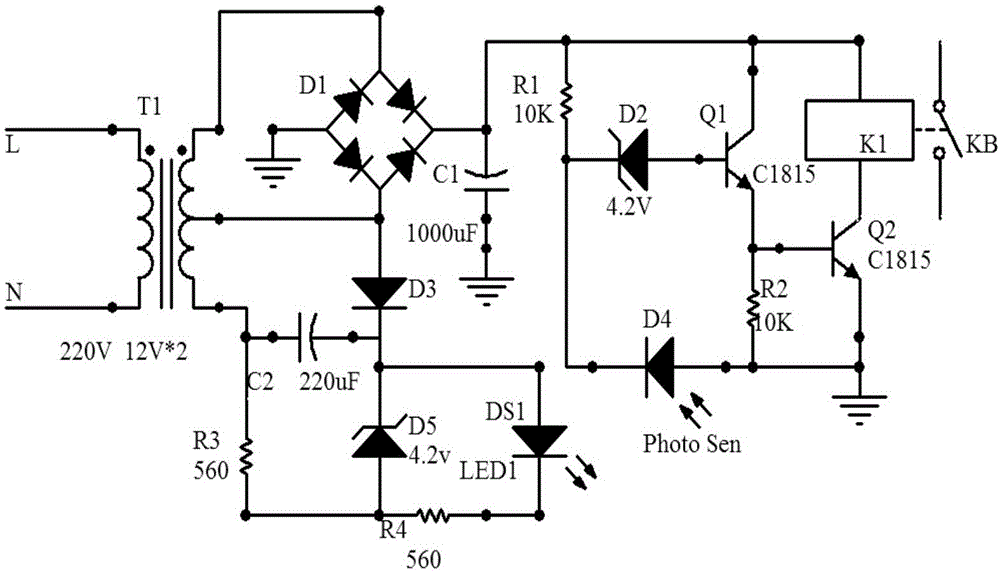

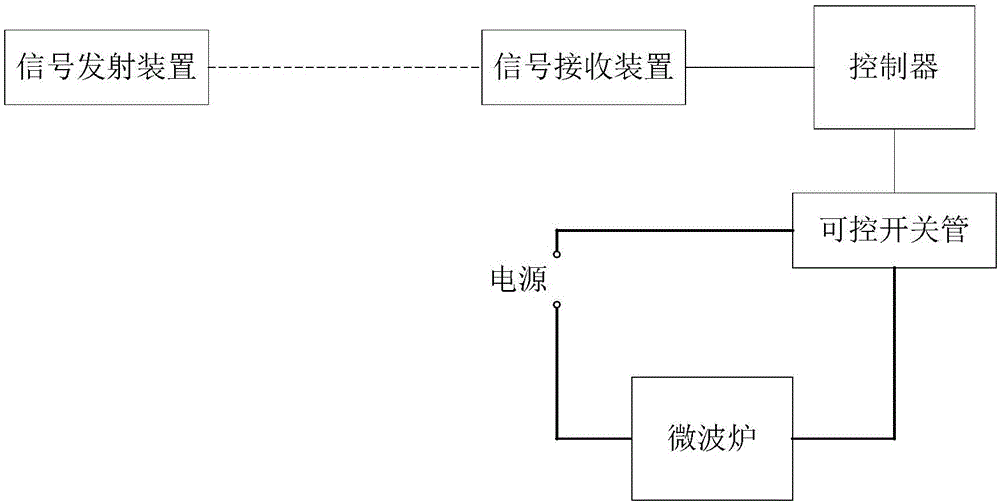

No-load automatic power off control apparatus for microwave oven, and microwave oven

PendingCN106455181ASave electricityNo noiseMicrowave heatingHome appliance efficiency improvementMicrowave ovenComputer module

The invention relates to a no-load automatic power off control apparatus for a microwave oven, and the microwave oven. The no-load automatic power off control apparatus comprises a control switch, a control apparatus, an optical signal receiving module and an optical signal transmitting module, wherein the control switch is serially arranged on a power supply loop of the microwave oven; the control apparatus is in sampling connection with the optical signal receiving module to control and connect the control switch; and the optical signal transmitting module and the optical signal receiving module are arranged in a heating cavity of the microwave oven. When there is no food in the microwave oven, the optical signal receiving module can receive a signal from the optical signal transmitting module, at the moment, the control switch in the power supply loop of the microwave oven is controlled to be switched off to realize the automatic power off of the microwave oven in a no-load state in order to enable the microwave oven not to work, so that electric energy can be reduced, and noise is not generated; and in addition, a magnetron, or a high-voltage fuse and the like of the microwave oven are not damaged, so that damage to the microwave oven is avoided.

Owner:郑州机电工程学校

Modular platform for free conveying of materials

InactiveCN109533844ARealization of free deliveryHigh speedControl devices for conveyorsMechanical conveyorsLight sensingIntegrated monitoring

The invention relates to the field of material conveying, in particular to a modular platform for free conveying of materials. The modular platform comprises a photosensitive platform module, a conveying wheel device and a control system, wherein the photosensitive platform module comprises a platform structure and a light sensing device; the platform structure is a unit part for composing the entire conveying platform; the light sensing device is used for sensing the material tray shading and transmitting the sensing result to the control system; the conveying wheel device is embedded in thephotosensitive platform module, and includes a wheel, a rolling driver and a steering driver; the wheel makes direct contact with a material tray; the rolling driver is controlled by the control system to make the wheel roll to achieve material conveying; and the steering driver is controlled by the control system to make the wheel change direction to achieve the control over the conveying direction. By means of the control system, the control over rolling and steering of the conveying wheel is mainly achieved; and by means of a light sensing signal, the positioning of the material tray and comprehensive monitoring of each platform module are achieved. Through the aforementioned technical scheme, the problem that an ordinary conveyor belt can only achieve oriented conveying is solved, andfree conveying of materials is achieved.

Owner:CHANGZHOU IND TECH RES INST OF ZHEJIANG UNIV

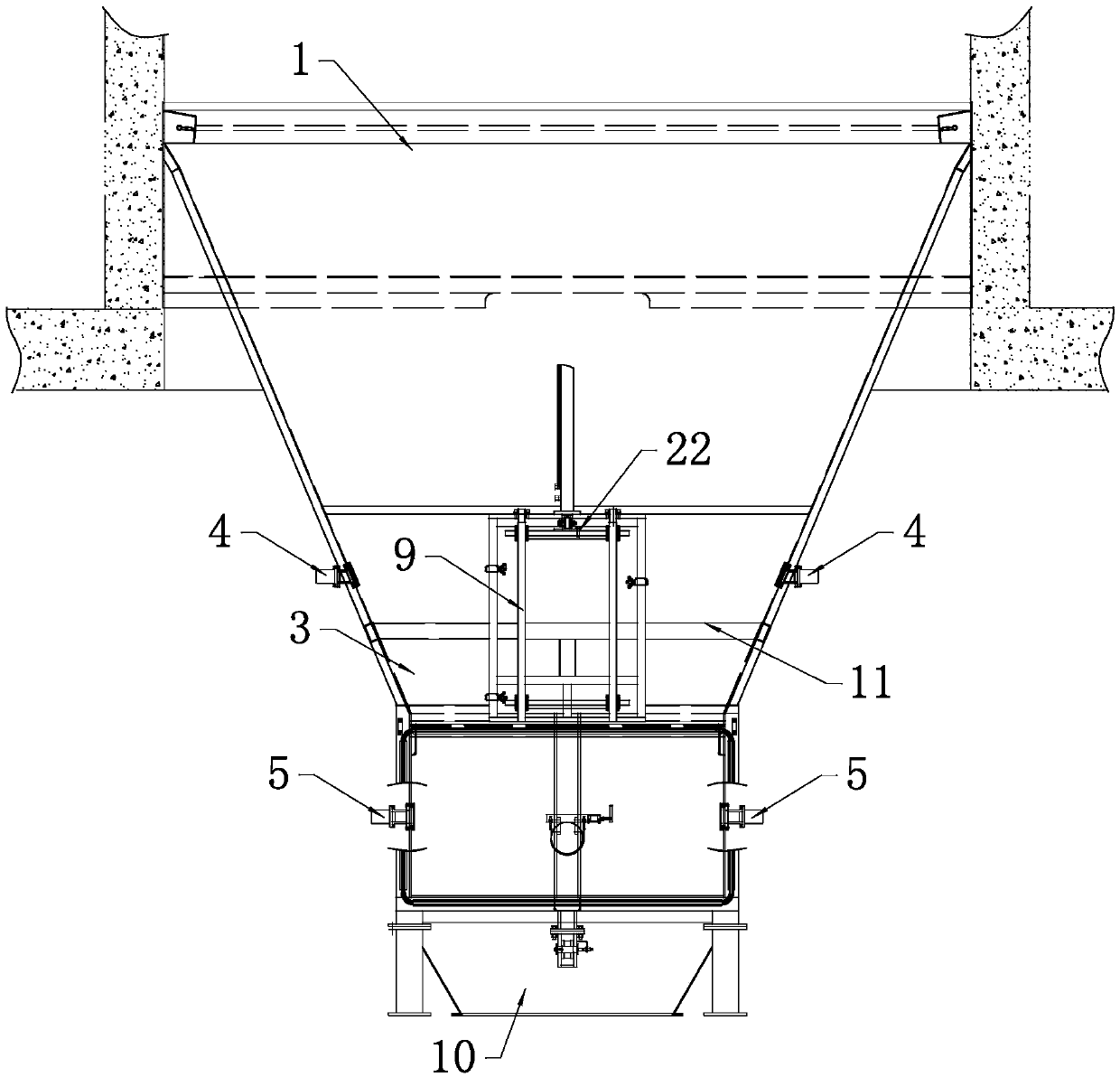

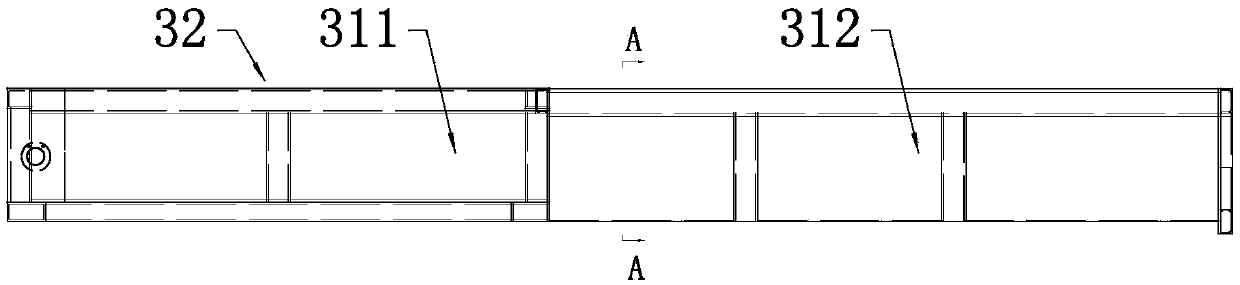

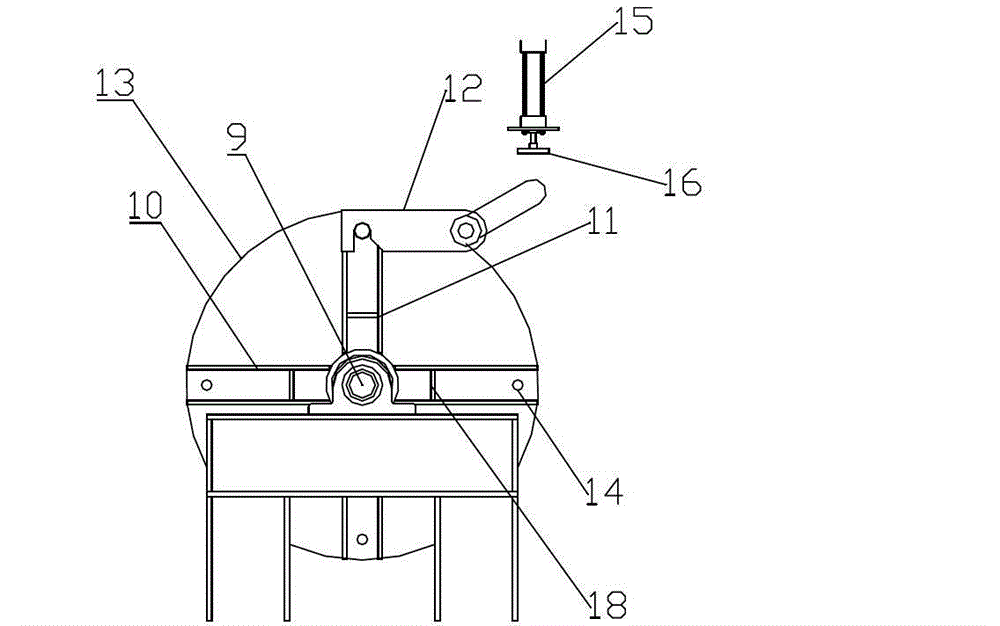

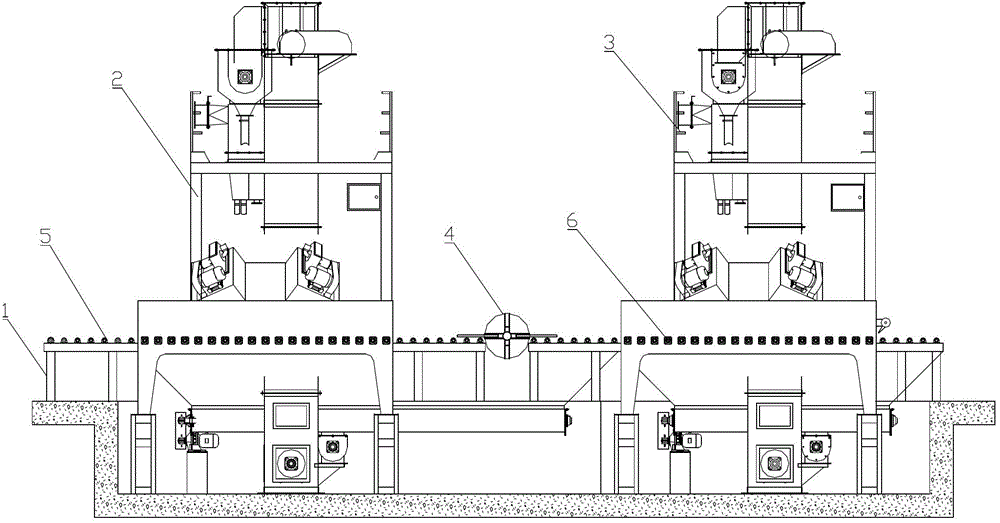

Anti-clogging device and garbage compression station with the same

InactiveCN109649870ASimple structureGood effect of breaking the cloggingLarge containersRefuse transferringMicrowaveEngineering

The invention discloses an anti-clogging device and a garbage compression station with the anti-clogging device. The anti-clogging device comprises a clogging breaking work room and a clogging breaking push head in the clogging breaking work room, wherein the clogging breaking push head comprises a body and a plurality of breaking arch blocks at the end part of the body; a plurality of teeth are arranged on each breaking arch block; the teeth are arranged at the end parts of the breaking arch blocks; slantwise side surfaces are arranged at the end parts of the breaking arch blocks; and the plurality of teeth are arranged on the slantwise side surface in sequence. The garbage compression station comprises a discharging bin, a compression cavity and the anti-clogging device, wherein a firstmicrowave material switch and a second microwave material switch are respectively arranged in the discharging bin and the compression cavity. The anti-clogging device has the advantages of simple structure, good clogging breaking effect and the like; and the garbage compression station can collect, crush and compress garbage to a garbage bin and has the advantages of smooth feeding, high loading and transporting efficiency, no secondary pollution, no non-tuilized cargo dead weight and the like, and is especially suitable for use in the environmental sanitation department

Owner:SHANDONG VICON HEAVY IND TECH

Crawler belt plate shot blasting machine

ActiveCN103508149BImprove work efficiencyGuaranteed stabilityControl devices for conveyorsRollersControl systemReducer

A crawler belt plate shot blasting machine comprises a machine frame, a control system and a shot blasting machine body which is arranged on the machine frame. The shot blasting machine body comprises a left shot blasting machine body and a right shot blasting machine body. The crawler belt plate shot blasting machine is characterized in that the machine frame is provided with a conveying device and is further provided with a turnover mechanism which is located between the left shot blasting machine body and the right shot blasting machine body, a crawler belt plate can turn over up and down through the turnover mechanism, and the conveying device is divided into a left conveying device and a right conveying device through the turnover mechanism, wherein the left conveying device and the right conveying device are composed of a plurality of conveying rollers, one end of each conveying roller is connected to a speed reducer through a transmission device, and the other end of each conveying roller is fixed to the machine frame through a shaft connection device.

Owner:QINGDAO CHANGJIA MACHINERY

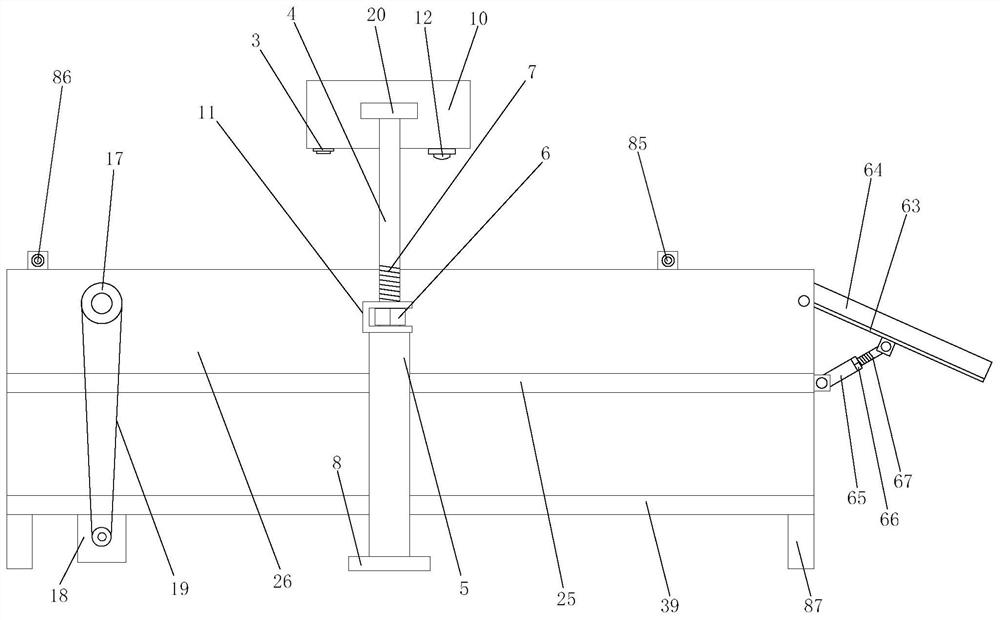

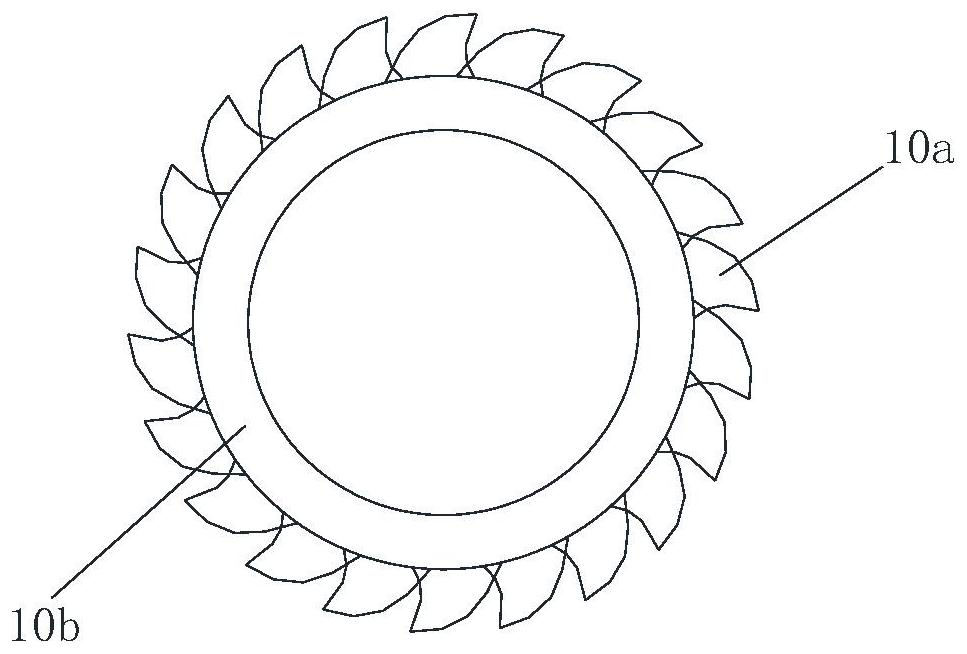

Automatic aluminum alloy cutting sawing machine and automatic cutting method

ActiveCN112139595AExpand the scope of cutting useAvoid running without loadMetal sawing devicesMetal sawing accessoriesCircular discElectric machinery

The invention provides an automatic aluminum alloy cutting sawing machine and an automatic cutting method. The automatic aluminum alloy cutting sawing machine comprises a controller and a rack, wherein a bearing platform is arranged on the rack; a positioning clamping mechanism is arranged on the edge of one side of the bearing platform; a movable clamping mechanism is arranged at the edge of theother side of the bearing platform; a clamping sliding mechanism is arranged at the bottom of the movable clamping mechanism; a cutting sliding mechanism is arranged below the bearing platform;, a rotary cutting mechanism is connected to the cutting sliding mechanism in a sliding mode; the rotary cutting mechanism comprises a cutting base; a disc cutter is hinged to the cutting base and driven bya cutting motor to be connected; a cutting seam is arranged in the bearing platform; the top of the disc cutter extends out of the cutting seam; a plurality of tooth blades are evenly arranged on theedge of the periphery of the disc cutter; an annular grinding blade is arranged on at least one side face of the disc cutter in a protruding mode and located on the inner periphery of the tooth blades; a measuring guide chute is arranged outside the edge of one side of the bearing platform; a measuring sliding block is clamped in the measuring guide chute in a sliding mode; and a photoelectric sensor is fixedly connected to the measuring sliding block.

Owner:QINGDAO HUANGHAI UNIV

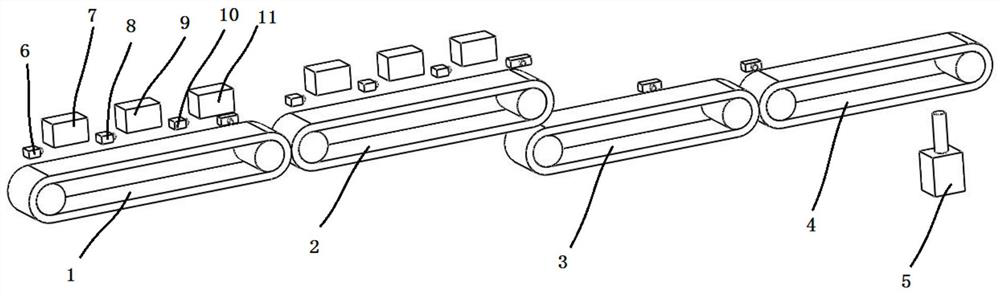

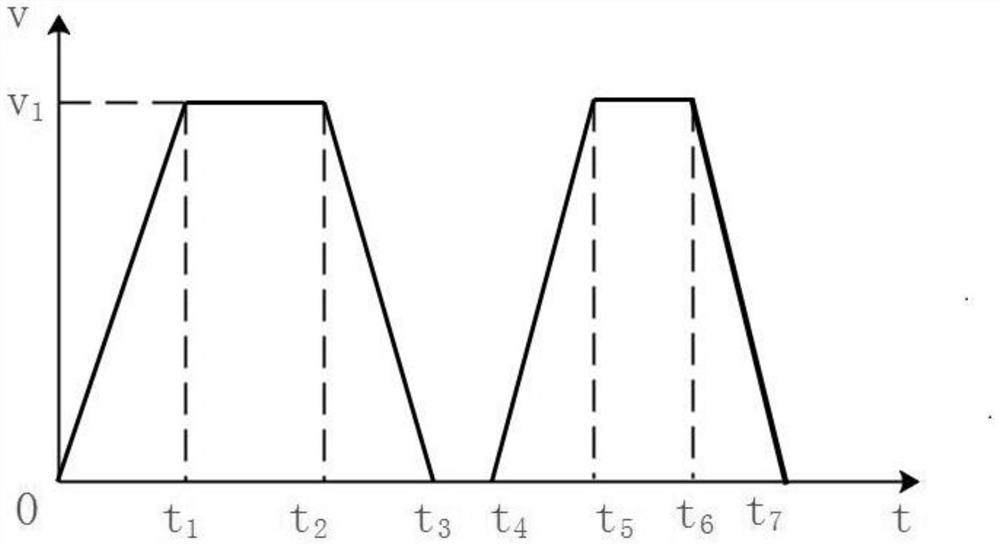

An operating method for preventing a multi-stage conveying device from running without load

ActiveCN110789959BAchieve service lifeAvoid running without loadConveyorsControl devices for conveyorsProcess engineeringMechanical engineering

The invention relates to a system and method for preventing a multi-stage conveying device from running in a no-load mode. The system comprises a conveying device and a plurality of discharging mechanisms arranged above the conveying device, wherein the conveying device comprises a plurality of stages of conveying mechanisms; the discharging mechanisms are distributed on each stage of conveying mechanism; the discharging mechanisms are sequentially marked as the first discharging mechanism, the second discharging mechanism to the M discharging mechanism in the advancing direction of the conveying device; the conveying mechanisms receive cloth bundles conveyed out by the conveying mechanism on the previous stage through the corresponding X discharging mechanism, and the value of X is 2-M. A detection mechanism is arranged at an outlet of each discharging mechanism; the detection mechanisms can detect that the cloth bundles enter the conveying mechanisms from the discharging mechanisms; the conveying detection time set after discharging of the first discharging mechanism, the second discharging mechanism to the M discharging mechanism is sequentially decreased progressively, and the conveying detection time is the time from discharging of the cloth bundles from the discharging mechanisms to conveying of the cloth bundles out of the conveying mechanisms.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Spiral-Pulse Pneumatic Mix-Feeder for Mobile Biomass Pyrolysis

InactiveCN104877694BAdjust feed amountPrevent blowbackBiofuelsLiquid hydrocarbon mixture productionSolenoid valveEngineering

The invention relates to a spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis and belongs to the technical field of biomass pyrolysis. The feeder comprises a spiral feeding device, inclined delivery pipes, solenoid valves and nozzles. The discharge port of the spiral feeding device is connected to an upper horizontal delivery pipe and the inclined delivery pipe through a transition joint and is connected to a lower horizontal delivery pipe and the inclined delivery pipe, gas of a gas bottle is sprayed through the nozzles, the nozzles are capable of adjusting the feeding amount and preventing reverse spraying, the feeding process is controllable and safe, and the reliability of the producing process is improved. The feeding port advanced charring and plugging problems can be solved, the process requirements of fast biomass pyrolysis can be met, the pyrolysis equipment producing and maintaining time can be shortened, the pyrolysis oil producing efficiency is improved, the maintaining cost is reduced effectively, and the technology guaranteeing effect can be achieved for large-scale pyrolysis production development.

Owner:BEIJING FORESTRY UNIVERSITY

Chip cutting and cleaning equipment

InactiveCN108818987AReduce adhesionEasy to cleanWorking accessoriesFine working devicesEngineeringElectrical and Electronics engineering

The invention relates to the field of chip processing, in particular to chip cutting and cleaning equipment. The chip cutting and cleaning equipment comprises a cutting mechanism and a cleaning mechanism. The cleaning mechanism comprises a vertically-arranged cleaning disc. The middle of the cleaning disc is rotationally connected with a clamp used for clamping a wafer. The cleaning disc is provided with an annular sliding groove. The clamp is located at the circle center of the sliding groove. The sliding groove is slidably connected with a spraying head. A connecting rod is connected betweenthe clamp and the spraying head. The clamp is connected with a first motor used for driving the clamp to rotate. According to the chip cutting and cleaning equipment, the cleaning efficiency of the wafer in the cutting process is improved.

Owner:重庆市嘉凌新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com