Tunnel type microwave generation magnetron automatic control drying device and method of agricultural products

A technology of microwave generation and microwave drying, which is applied in the direction of progressive dryers, drying solid materials, lighting and heating equipment, etc., can solve problems such as difficult control, and achieve the effects of prolonging service life, avoiding no-load operation, and drying evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

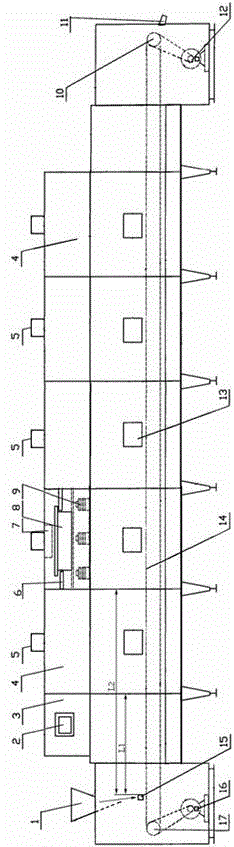

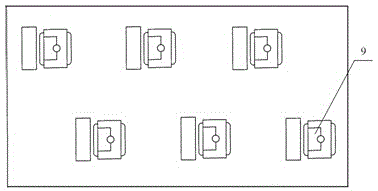

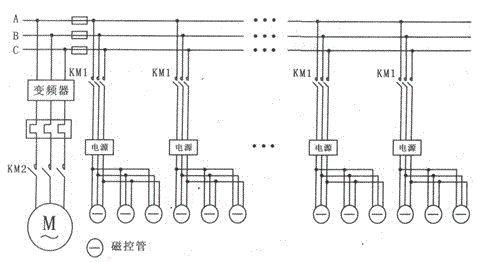

[0016] Tunnel-type microwave generator magnetron automatic control drying equipment for agricultural products includes feeding hopper room, first connection box, console, drying box room, second connection box, discharge hopper room, conveying system, drying and cooling system, PLC control System; from the side of the hopper 1 to the side of the hopper 11, there are the hopper room, the first connection box, the drying box room, the second connection box, and the hopper room; the console is set on the first connection box ; The drying box chamber includes a plurality of microwave drying boxes 4, generally 3-8, and the drying box is made of high-quality stainless steel plate and double-layer black rubber and plastic insulation board. The drying and cooling system is set on the microwave drying box 4; the top of the microwave drying box 4 is provided with a moisture discharge pipe 5, and the upper part of the microwave drying box 4 is provided with 6 microwave generating magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com