Coil palletizing line

An assembly line and coil technology, which is used in the stacking, transportation and packaging of objects, conveyor objects, etc., to achieve the effect of strong cohesion, high degree of automation, and avoidance of no-load operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described with reference to the accompanying drawings.

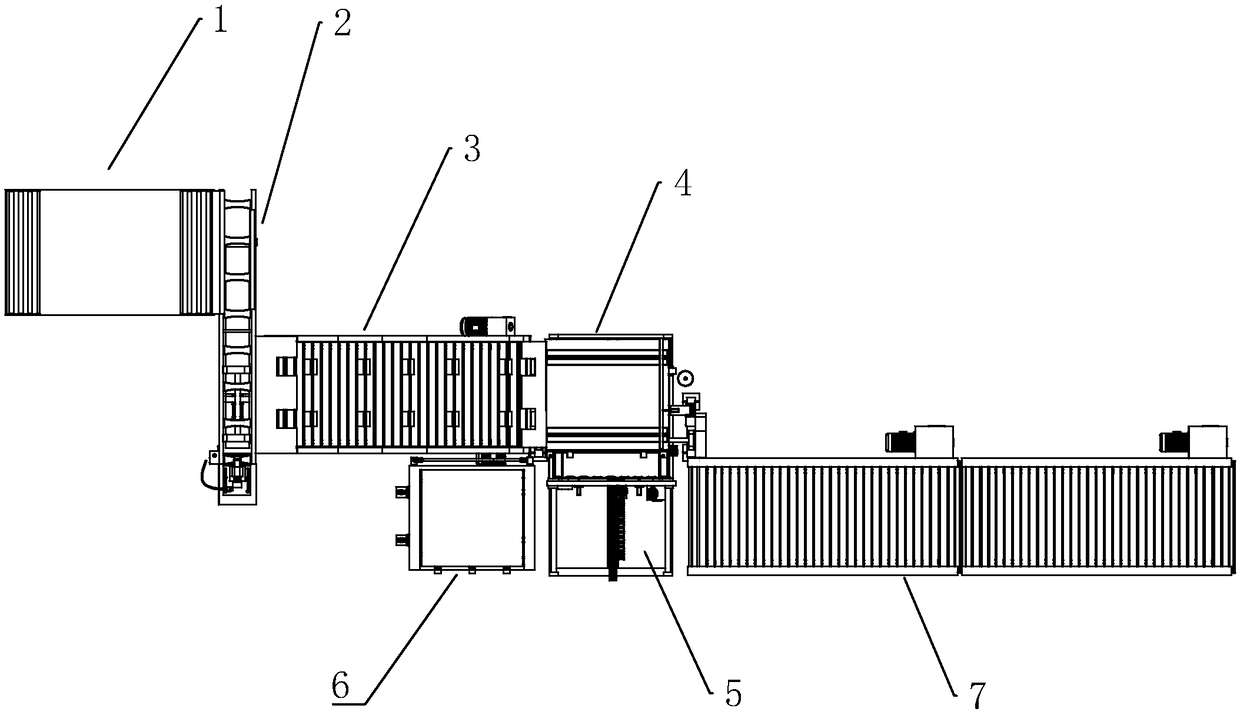

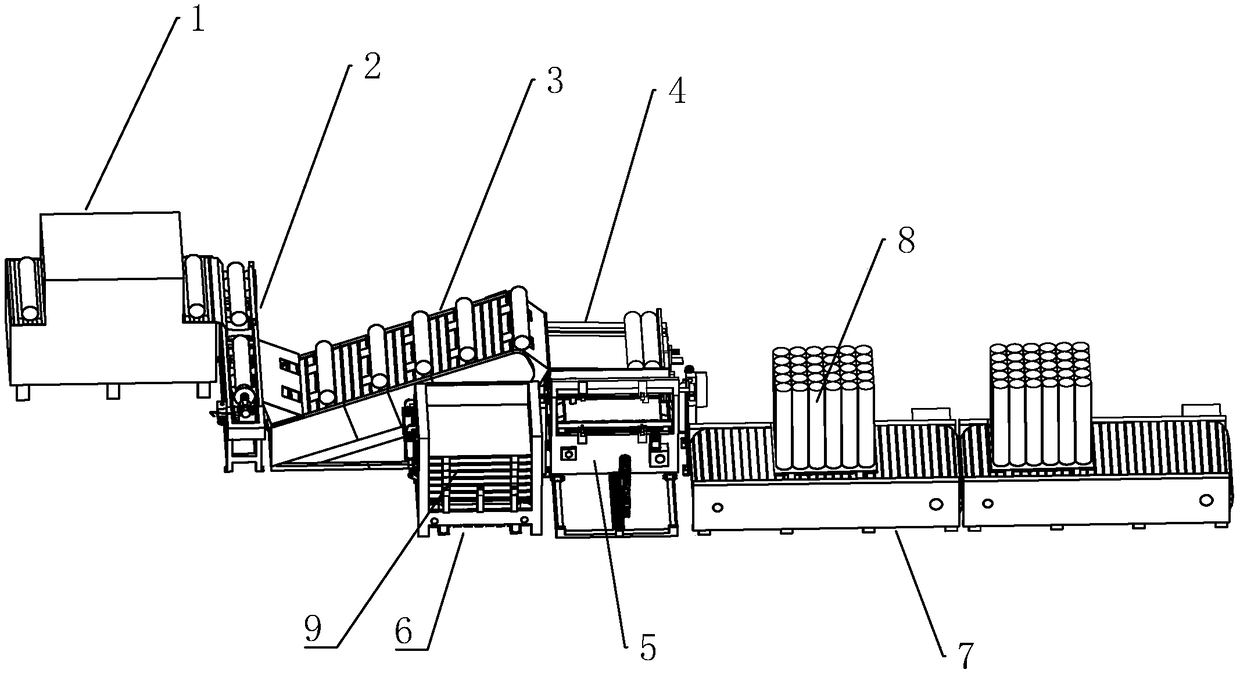

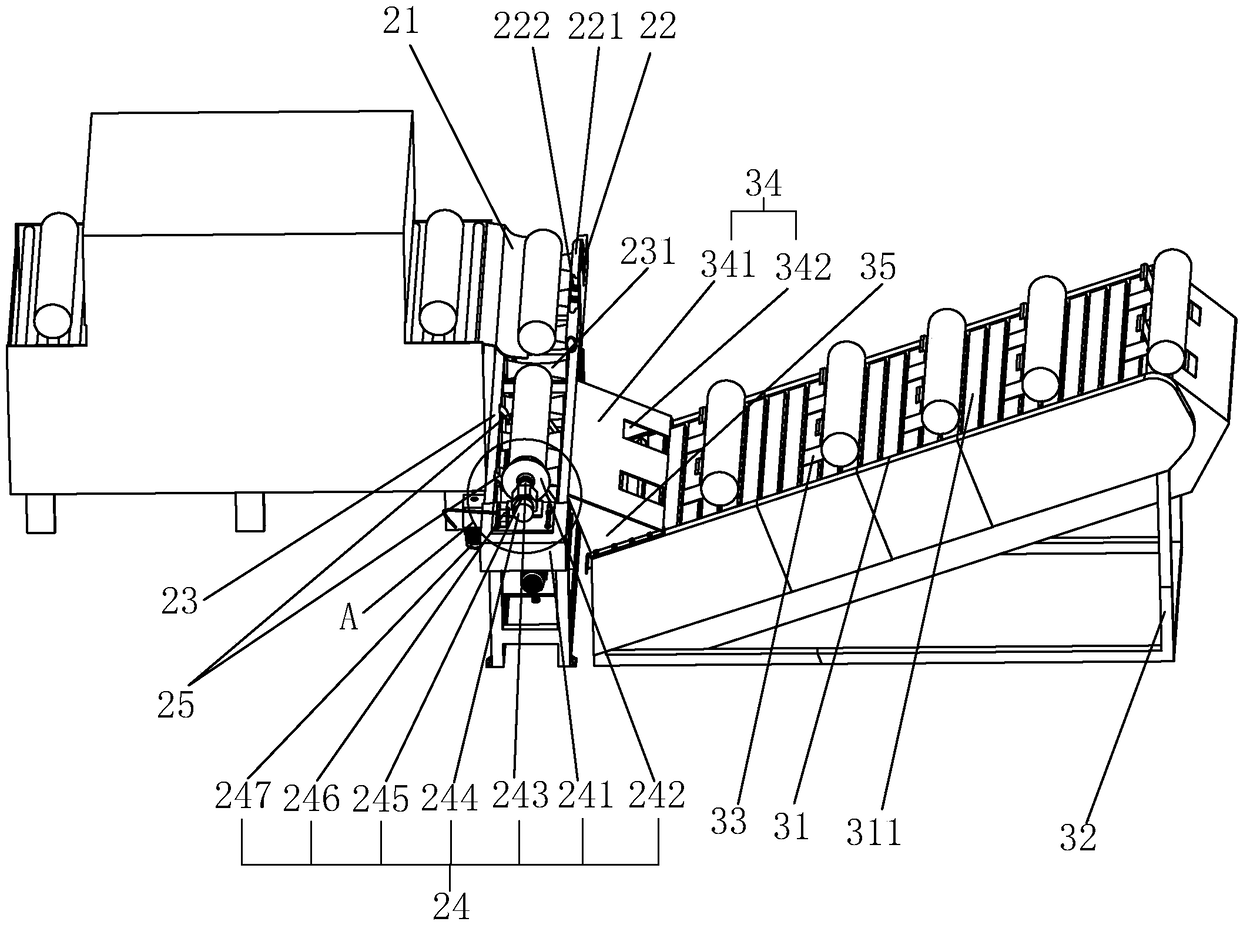

[0045] A coil palletizing line, combined with figure 1 and figure 2 , including a laminating mechanism 1, a single coil conveying mechanism 2, a slope conveying mechanism 3, an overturning mechanism 4, a tray conveying mechanism 5, a tray storing mechanism 6 and a coil stack conveying mechanism 7. The single coiled material 8 is covered with a plastic protective film on the outside of the film covering mechanism 1, and then sent to the single coiled material conveying mechanism 2. After reaching the conveying end, it is turned over to the slope conveying mechanism 3 for conveying. The single roll of coiled material 8 arrives at the end of the slope conveying mechanism 3 and falls to the turning mechanism 4 for stacking. The single roll of coiled material 8 is stacked side by side on the turning mechanism 4 for a certain number and then turned over and erected. After being e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com