Dumet wire microwave heating production system

A production system and microwave heating technology, applied in the field of Dumet microwave heating production system, can solve problems such as unstable performance, influence air tightness, no-load heating, etc., to improve internal quality, improve heating, and reduce heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

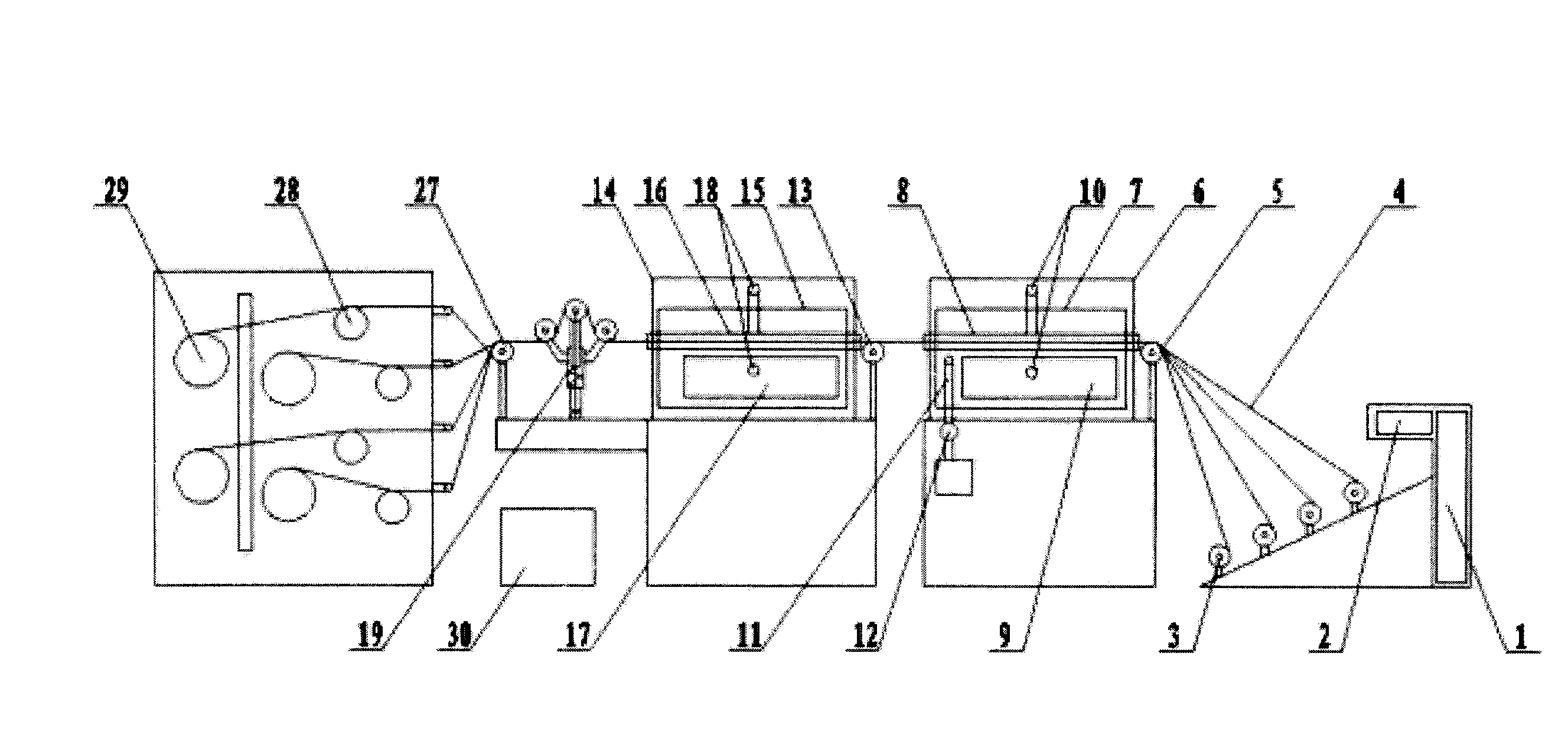

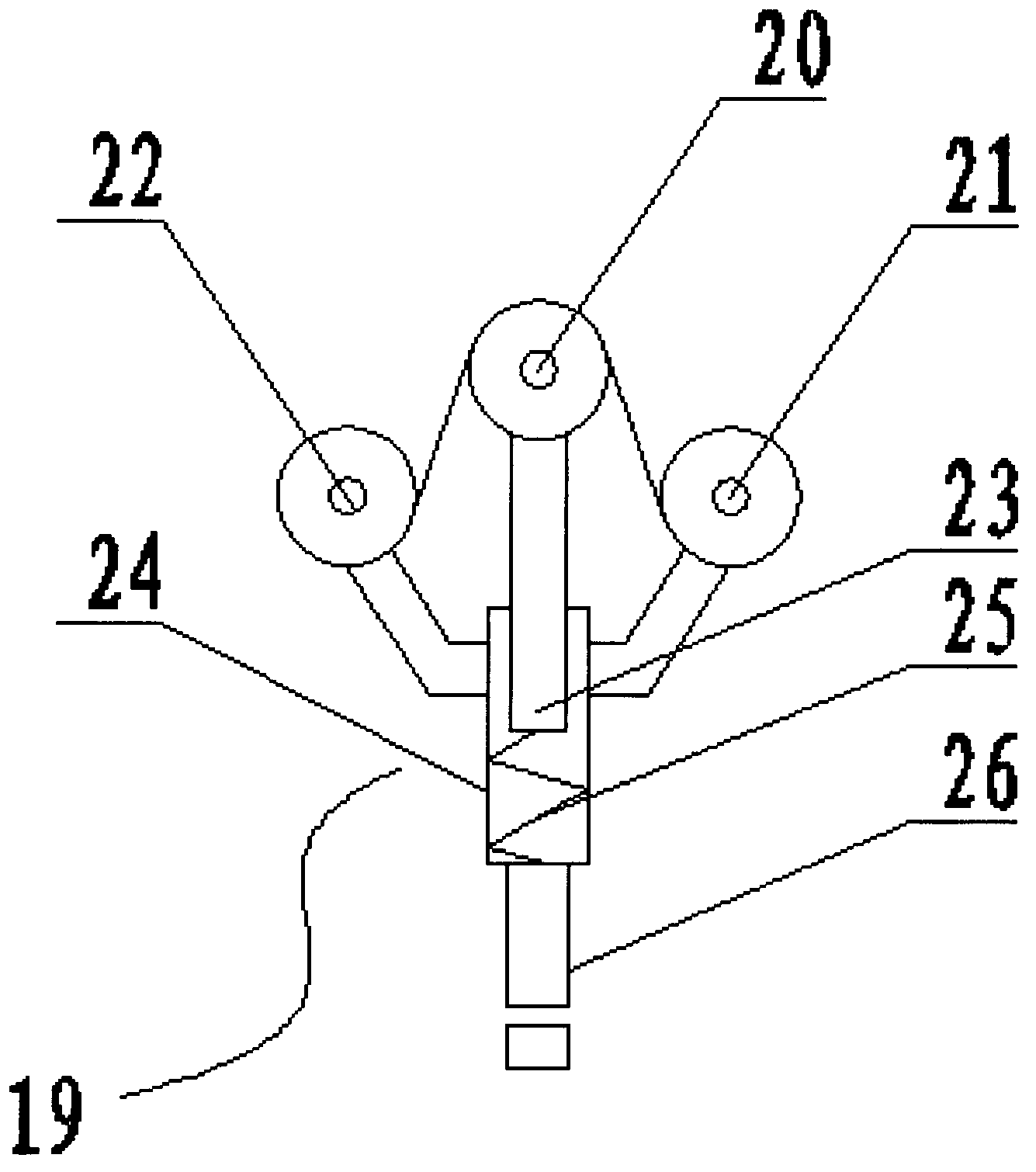

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] figure 1 , 2As shown, a Dumet wire microwave heating production system includes a wire feeding power supply 1, a wire feeding controller 2, a wire feeding disc 3, an oxidized wire wheel 5, a microwave oxidation furnace 6, a metal inner tank cavity 7 of the oxidation furnace, and an oxidized ceramic. Tube 8, oxidation microwave generator 9, oxidation infrared temperature measurement and control instrument 10, protective gas supply pipe 11, digital gas flow control valve 12, sintering wire wheel 13, microwave sintering furnace 14, sintering furnace metal liner cavity 15, sintering Ceramic tube 16, sintered microwave generator 17, sintered infrared temperature measurement and control instrument 18, wire passing device 19, wire collecting and passing wheel 27, constant speed wheel 28, wire collecting disc 29 and control system....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com