Intelligent and efficient self-priming pump

A self-priming pump and high-efficiency technology, which is applied in the field of intelligent and efficient self-priming pumps, can solve the problems of difficult to completely discharge the gas, affect the pump suction range, and long water filling time, so as to avoid no-load operation, prolong the service life, and liquid speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

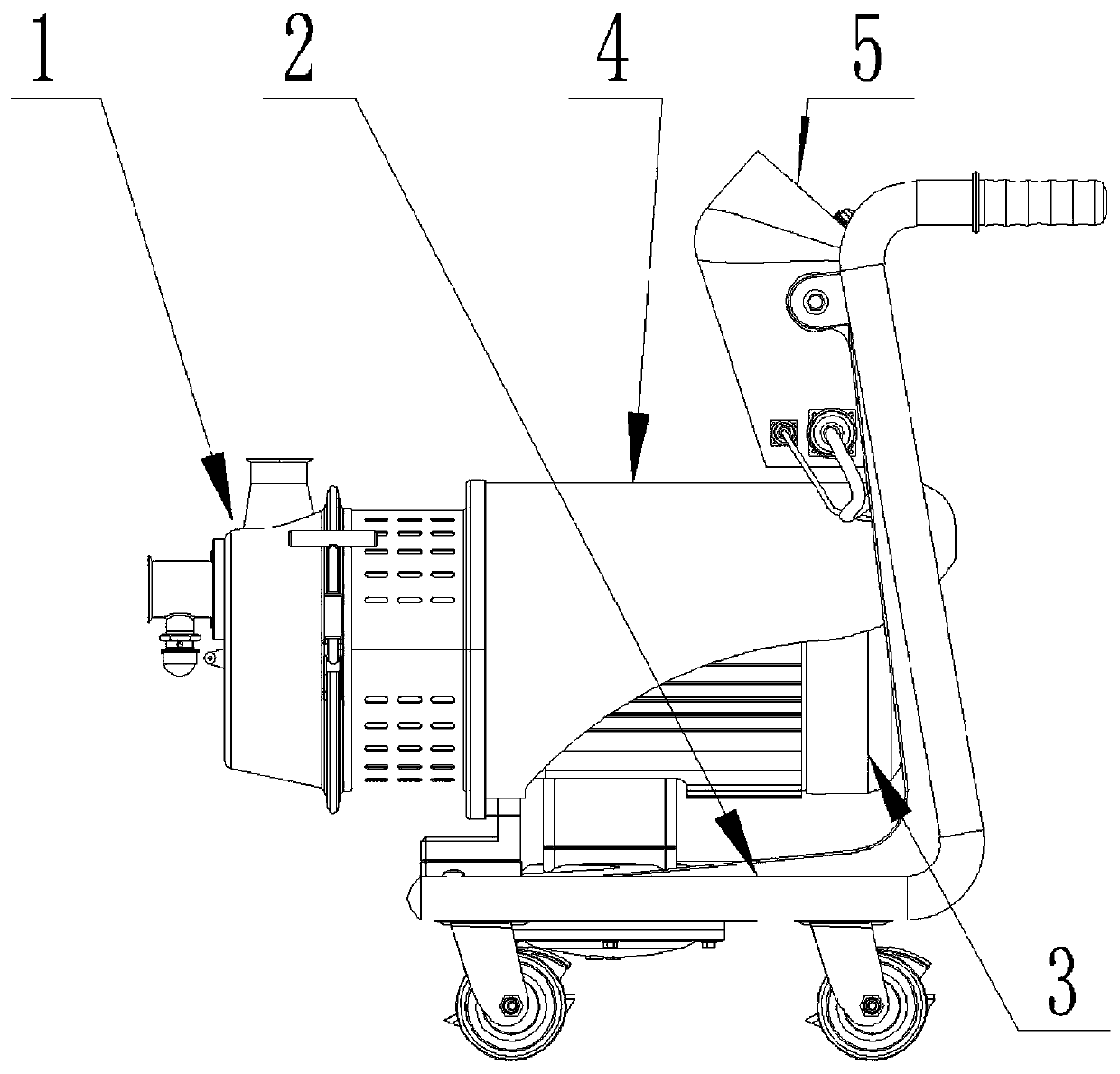

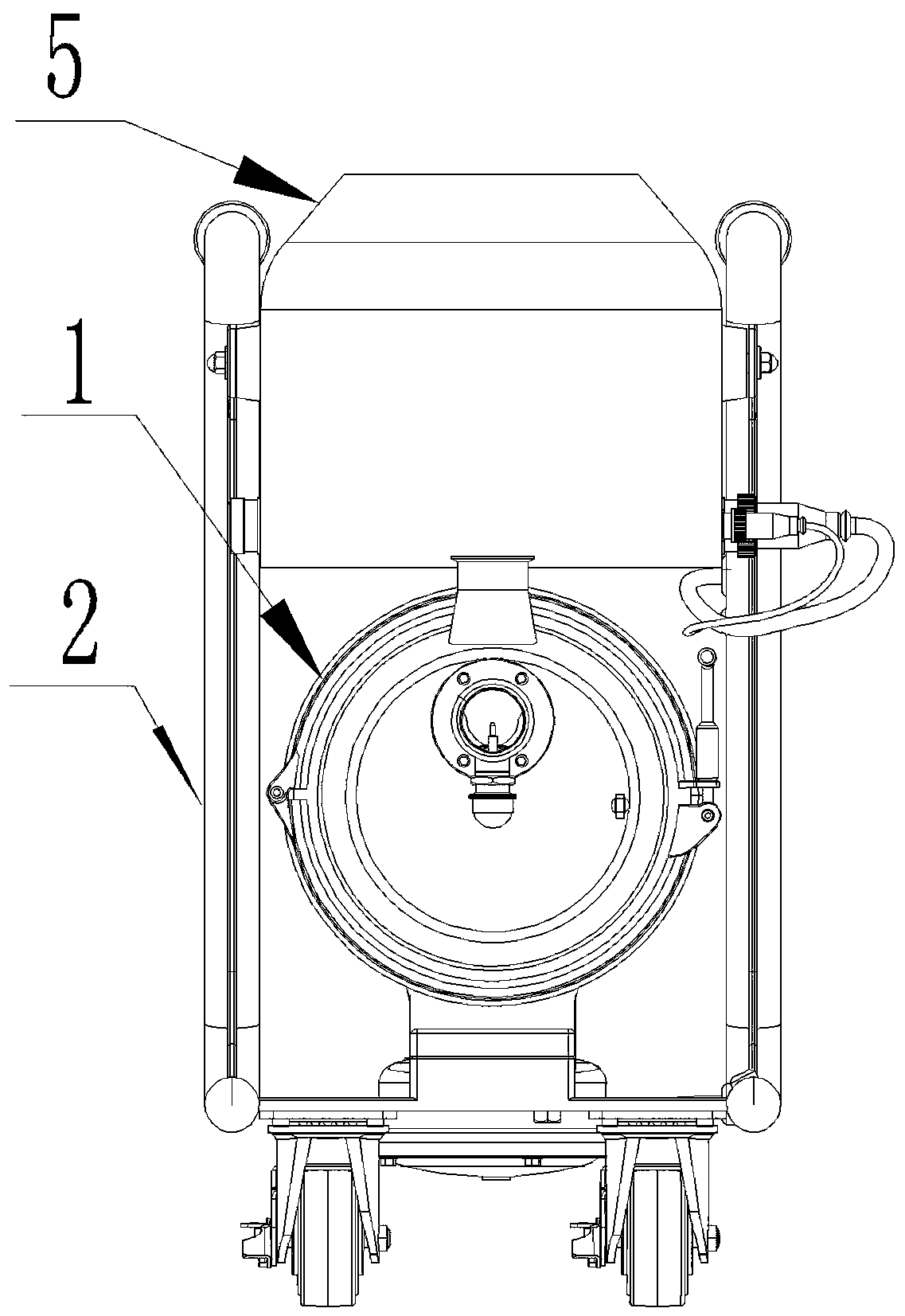

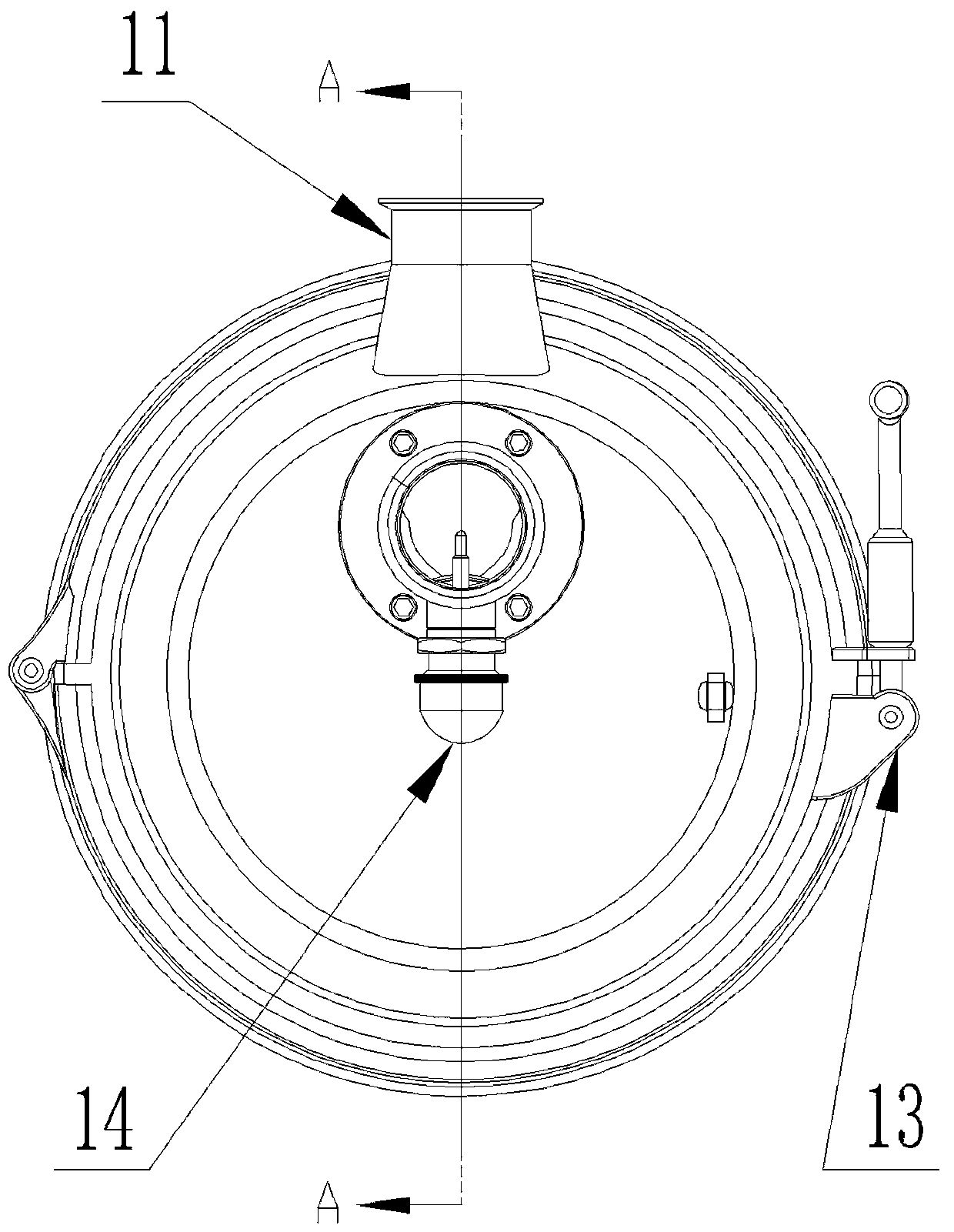

[0026] Embodiment 1, the present invention includes a pump body 1 and a motor 3 that are connected to each other. The pump body 1 includes a front pump body 11 and a rear pump body 12. A liquid sensor 14 is arranged on the liquid inlet seat 114 of the front pump body 11. The pump body 12 is provided with an isolation cavity 1251 and the throat cavity 119 in the front pump body 11 are sealed and connected with each other. The cavity 125 communicates with the throat cavity 119 , and the impeller 126 is arranged in the isolation cavity 125 , and the impeller 126 is set on the pump shaft 127 , and the pump shaft 127 is connected with the motor 3 . By setting the throat cavity and the isolation cavity, and adopting a sealed connection, the liquid inlet and the liquid outlet are isolated, and the motor starts to drive the impeller to rotate, which can quickly discharge the internal air, avoiding the internal circulation of gas and affecting the efficiency of the pump. Vacuum is form...

Embodiment 2

[0027] Embodiment 2, the upper part of the front pump casing 111 is provided with a liquid outlet 1110, the liquid inlet seat 114 is fixed on the outside of the front end of the front pump casing 111 through a screw, the liquid inlet seat gasket 115 is placed in the middle, and the throat cavity body 119 passes through the throat cavity flange 112 is sealed and fixed on the inside of the front end of the front pump casing 111, a throat cavity sealing gasket 116 is placed between the throat cavity flange 112 and the front pump casing 111, and a throat cavity sealing ring is placed between the throat cavity flange 112 and the flange bolts 117, the liquid inlet 118 communicates with the laryngeal cavity 113. refer to Figure 1 to Figure 10 , all the other are with embodiment 1.

Embodiment 3

[0028] Embodiment 3, one end of the pump seat 123 is set in the pump back seat 121, the other end is connected to the motor 3, the pump back seat 121 is set on the pump shaft 127, and the isolation chamber 1251 is fixed on the pump back seat 121 by a screw to form an isolation chamber 125, an isolation chamber sealing ring 124 is placed between the isolation chamber body 1251 and the pump back seat 121, the isolation chamber 125 is provided with an impeller 126 set on the pump shaft 127, and the end of the pump shaft 127 is provided with an impeller nut, and the impeller 126 is connected to the isolation chamber A front dynamic and static ring 15 is arranged between the chambers 1251 , a rear dynamic and static ring 128 is set between the impeller 126 and the pump back seat 121 and fitted on the pump shaft 127 , and a shield 129 is arranged outside the pump seat 123 . refer to Figure 1 to Figure 10 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com