Dumet wire microwave-heating wire-passing device

A technology of microwave heating and wire passing, which is applied in the field of bare wire passing devices, can solve the problems of unstable performance, affecting air tightness, no-load heating, etc., and achieve the effects of reliable performance, low use cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

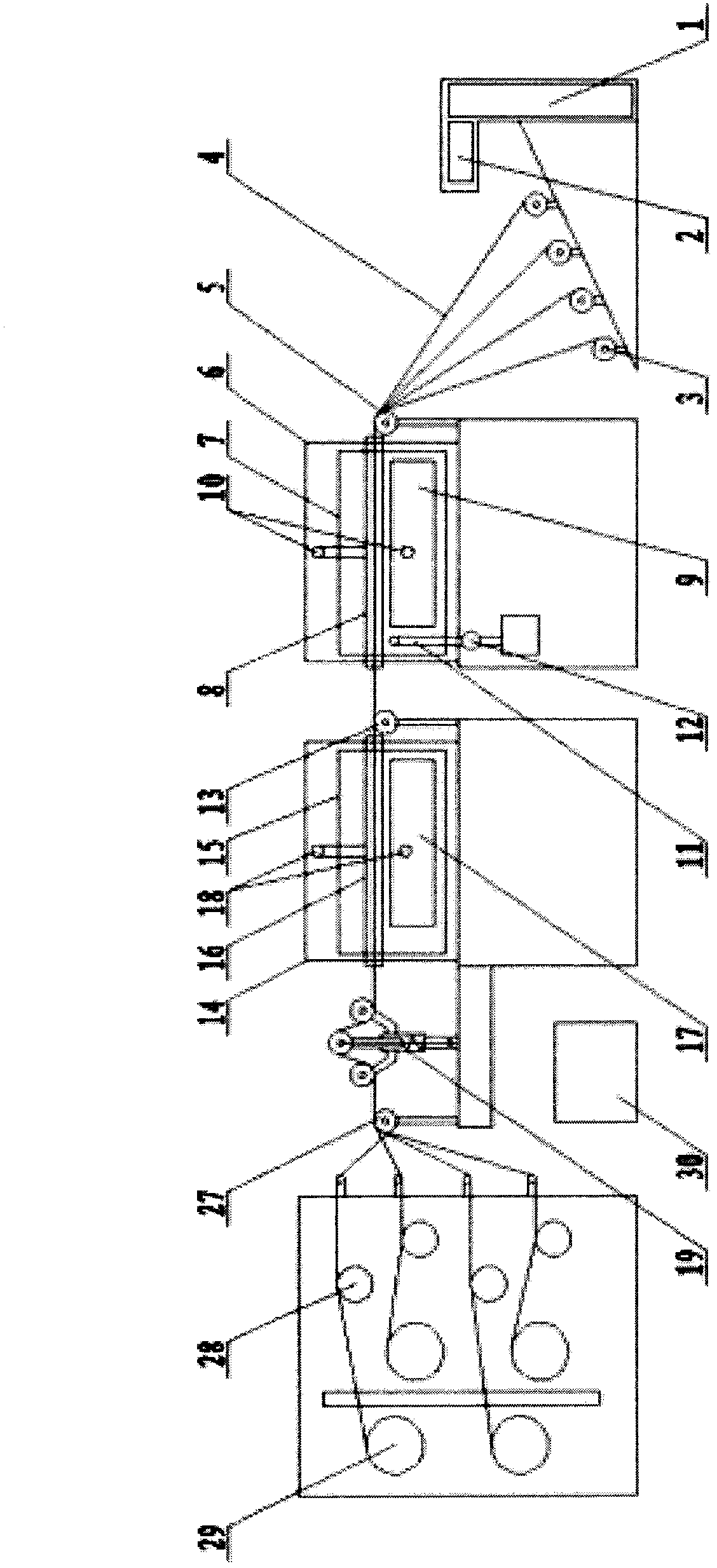

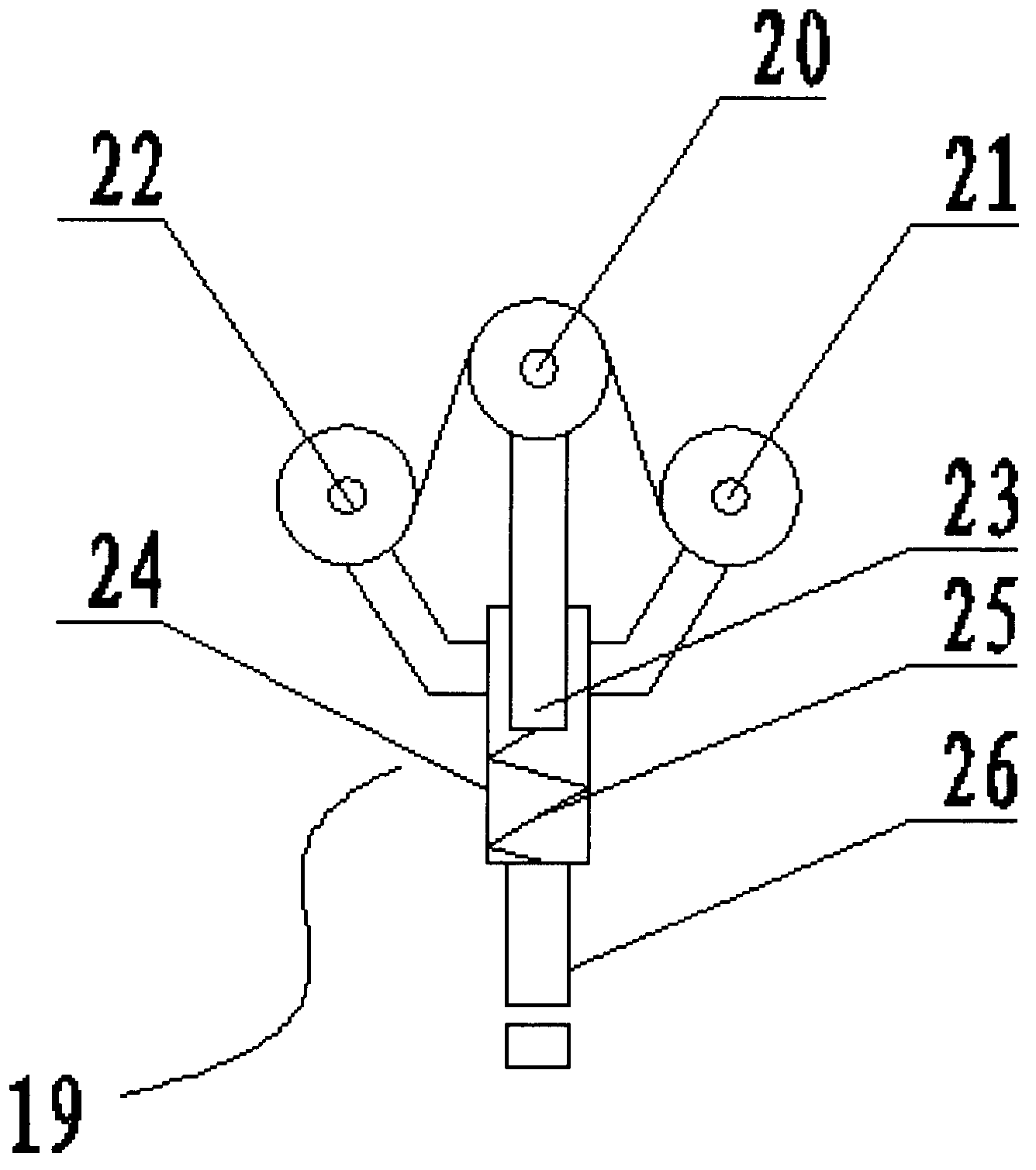

[0020] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0021] figure 1 , 2 As shown, a Dumet wire microwave heating device 19 includes a wire pressing wheel 20, guide wheels 21, 22, a piston 23, a cylinder sleeve 24, and a spring 25 close to opening and closing 26. The wire passing device is used in the production system. The wire feeding power supply 1 is controlled by the wire feeding controller 2 to connect more than one wire feeding reel 3, and more than one wire feeding reel 3 passes the bare wire 4 through the oxidation wire feeding wheel 5 Send to the microwave oxidation furnace 6, the oxidation furnace metal liner cavity 7 is set in the outer shell of the microwave oxidation furnace 6, the oxidation ceramic tube 8 penetrates into the oxidation furnace metal liner cavity 7, the oxidation microwave generator 9 corresponds to the oxidation ceramic tube 8 The bare wire 4 is connected to the microwave sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com