Chip cutting and cleaning equipment

A technology for cleaning equipment and chips, applied in stone processing equipment, work accessories, fine work devices, etc., can solve the problems of difficulty in cleaning debris, high purchase cost of CNC machine tools, and low cleaning efficiency of debris, etc. Low purchase cost and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

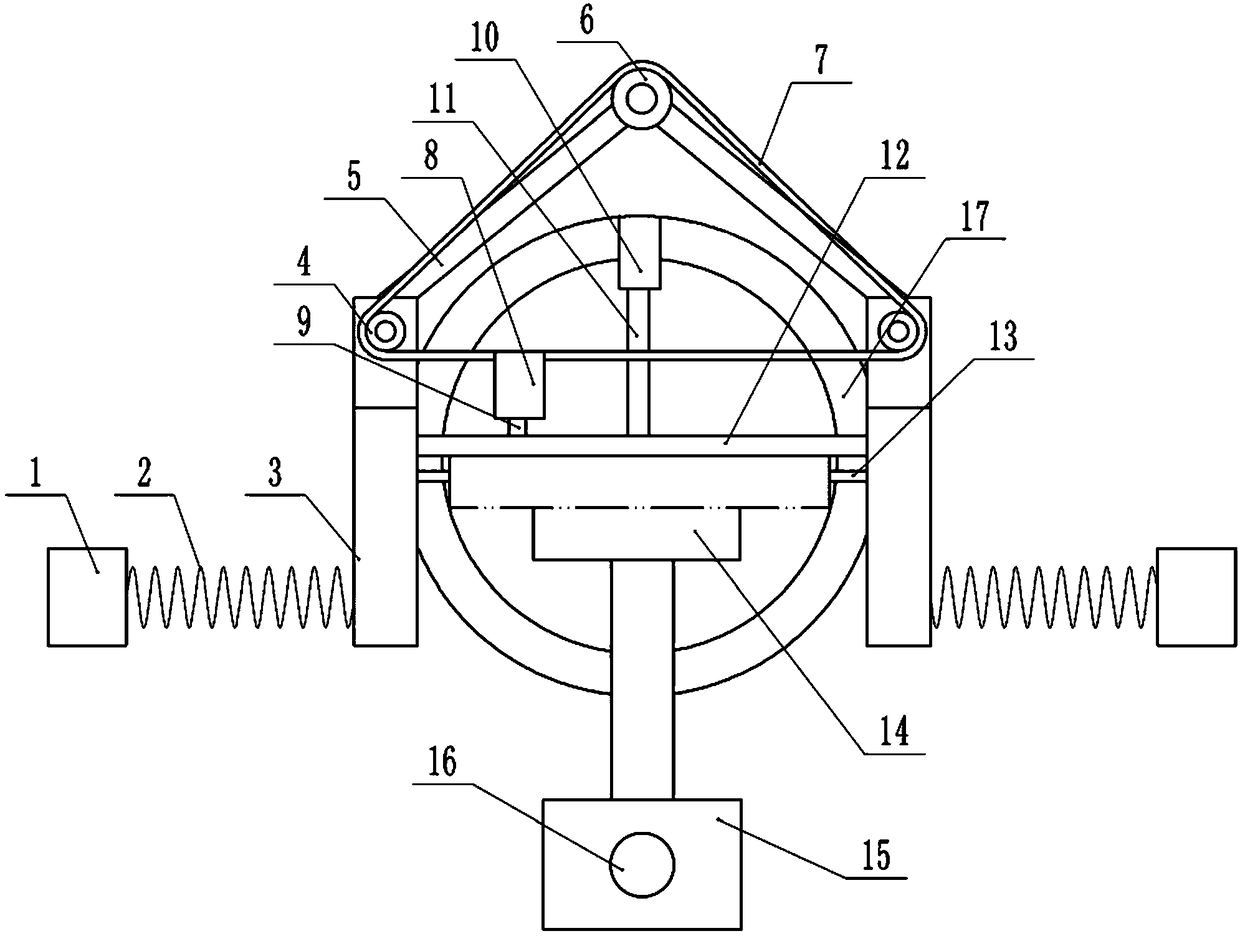

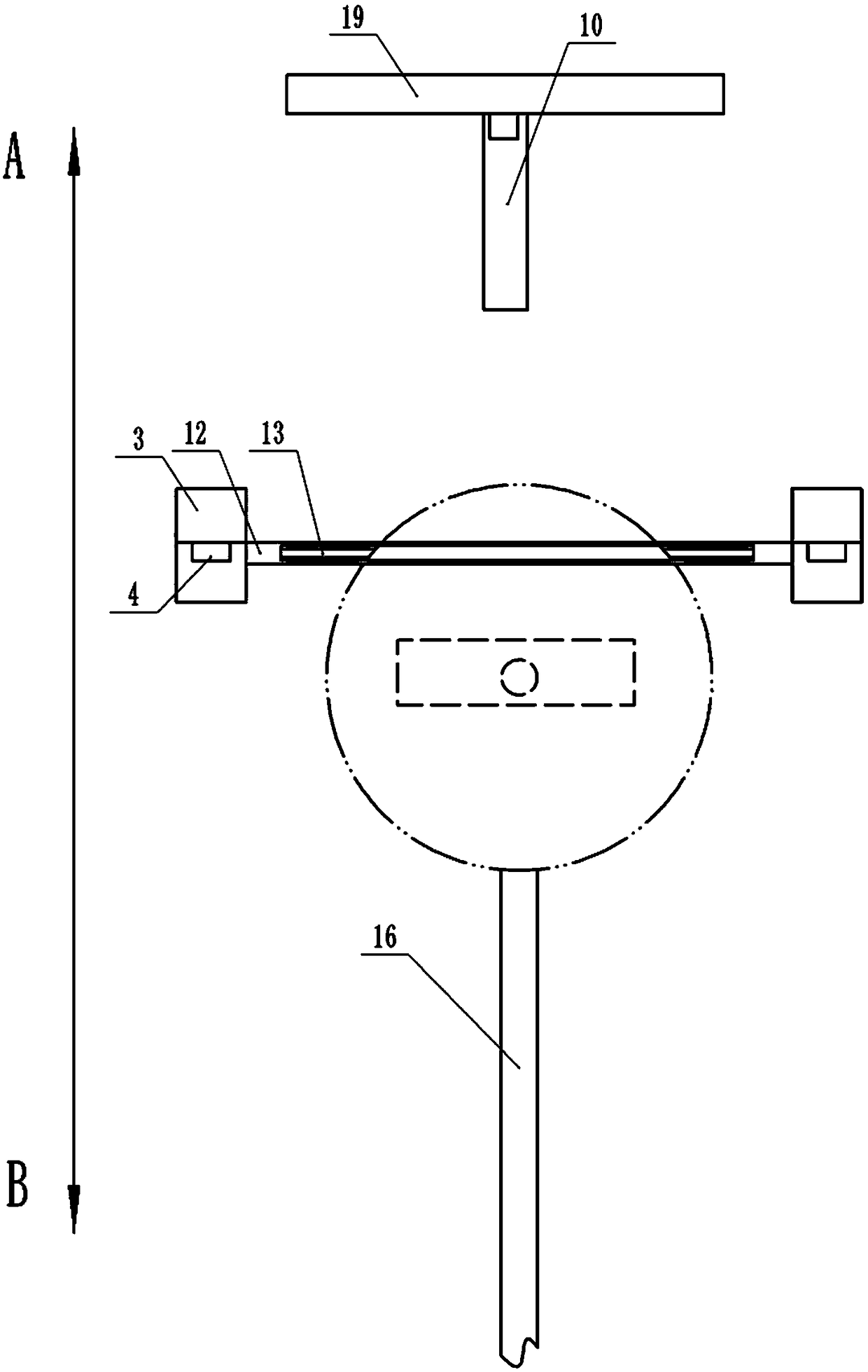

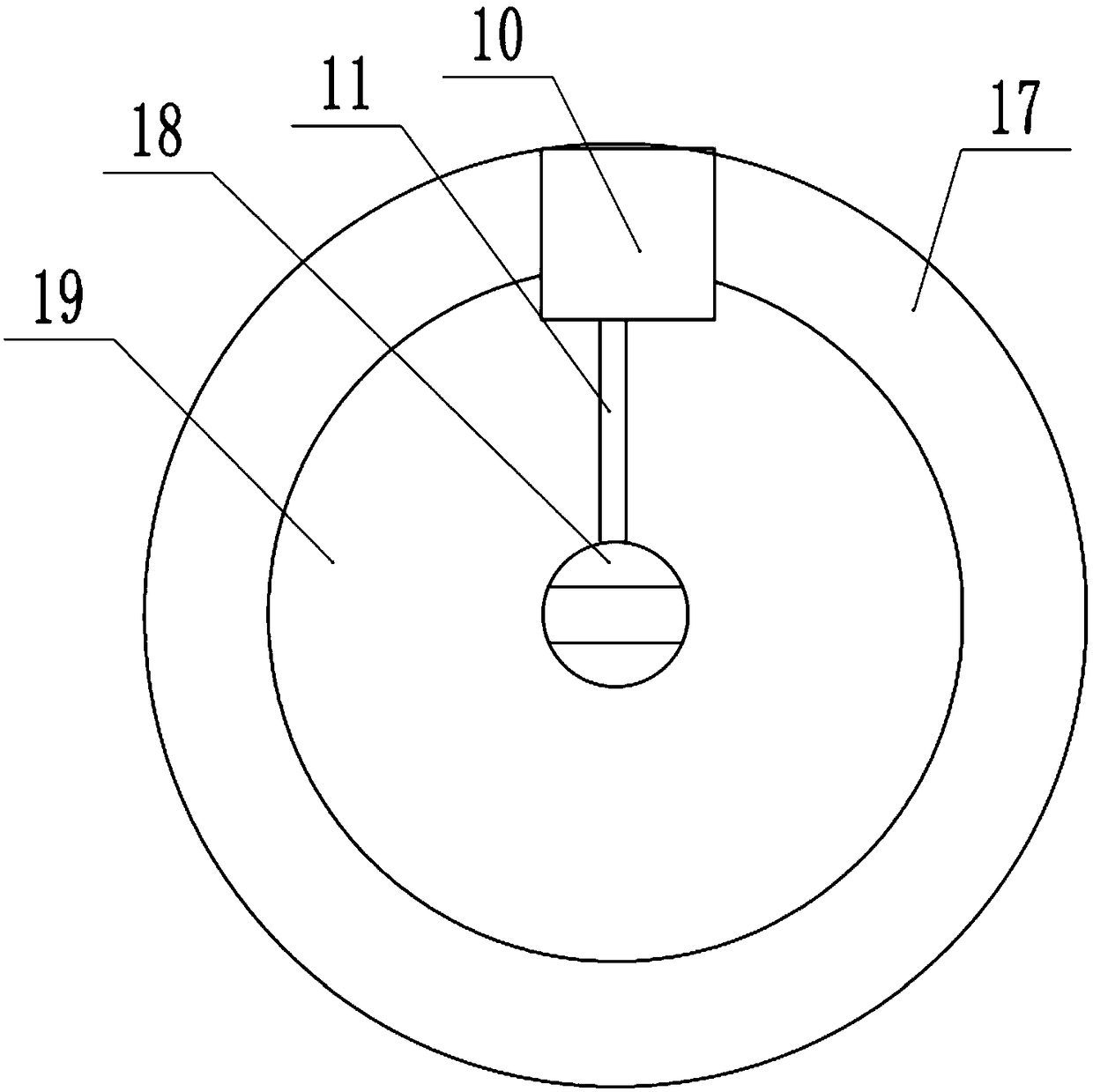

[0017] The reference signs in the drawings of the description include: pressing block 1, pressing spring 2, detection block 3, first sprocket 4, swing lever 5, second sprocket 6, chain 7, cutting machine 8, cutting knife 9, nozzle 10. Connecting rod 11, pressing plate 12, detection rod 13, suction cup 14, moving block 15, lead screw 16, chute 17, clip 18, cleaning plate 19.

[0018] The embodiment is basically as attached Figure 1-Figure 3 Shown: Chip cutting and cleaning equipment, including a frame, which is equipped with a cutting mechanism, a cleaning mechanism and a moving mechanism, combined with figure 1 and figure 2 As shown, A in this embodiment refers to the rear of the car, and B refers to the front of the car. The cleaning mechanism is located at the rear of the cutting mechanism, and the moving mechanism is located below the cutting mechanism.

[0019] combine Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com