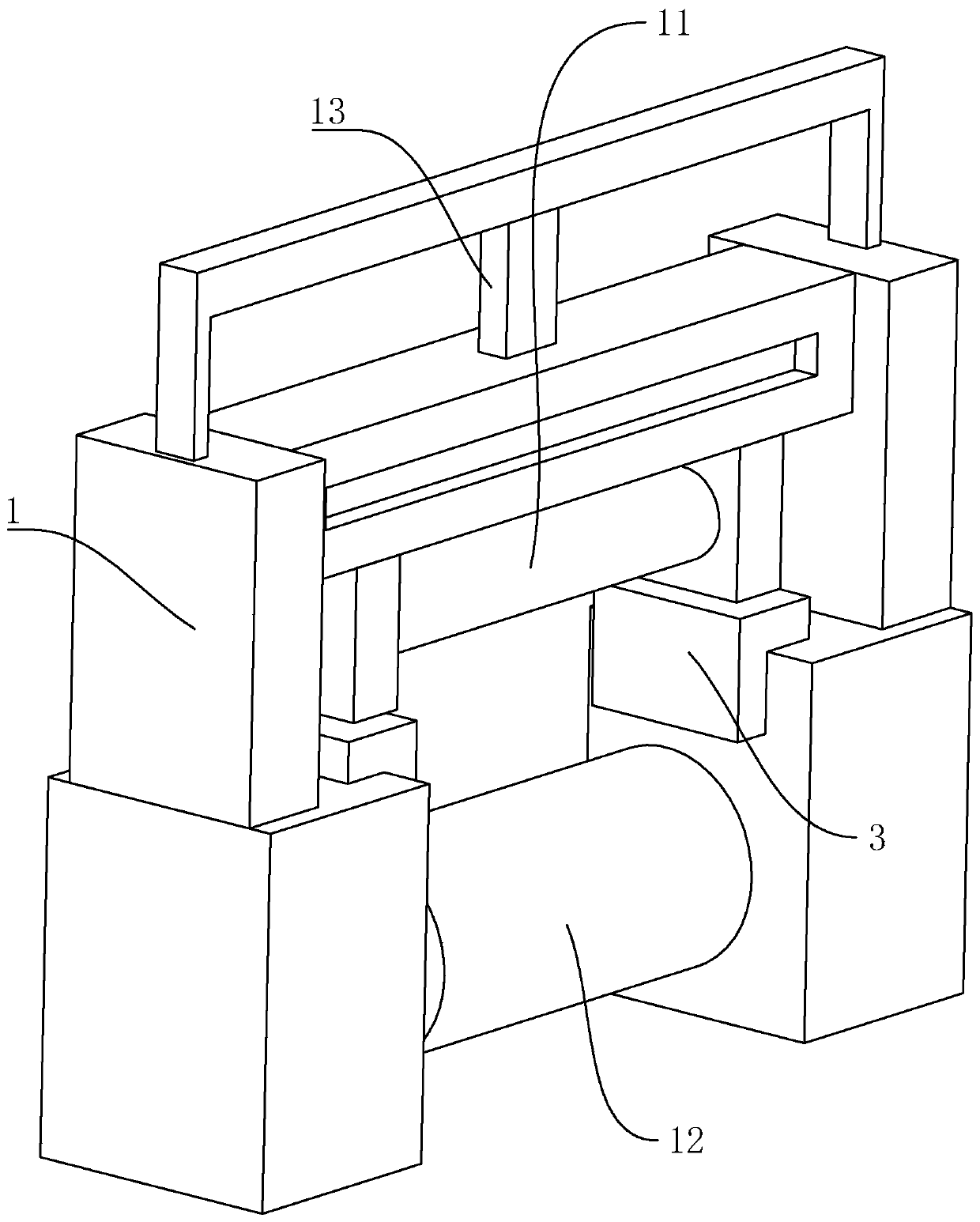

Metal plate bending machine

A bending machine and sheet metal technology, applied in the field of sheet metal bending machines, can solve problems such as the influence of bending effects, uneven surface of bending columns, and reduced work efficiency, so as to ensure firm connection, ensure surface smoothness, avoid productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

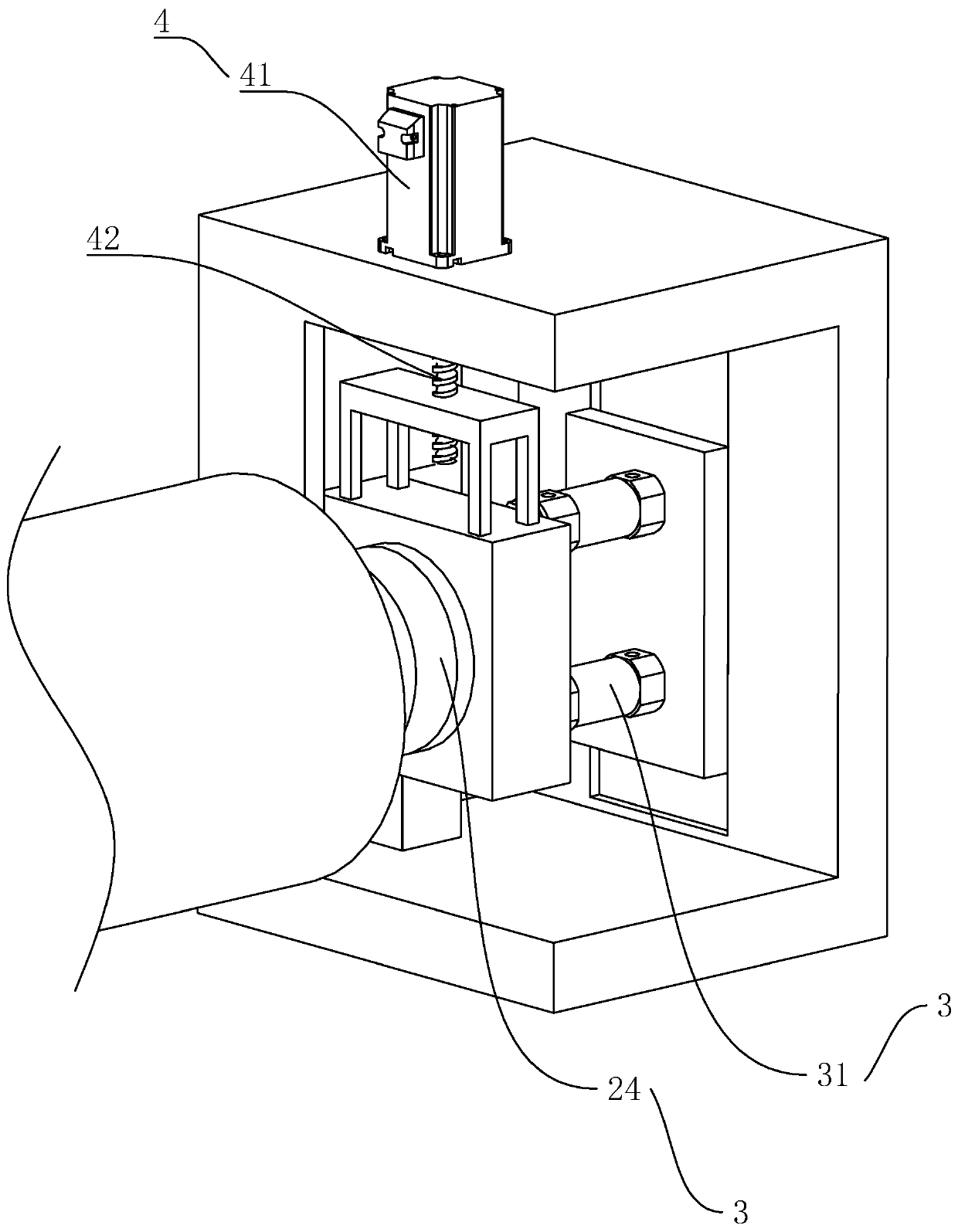

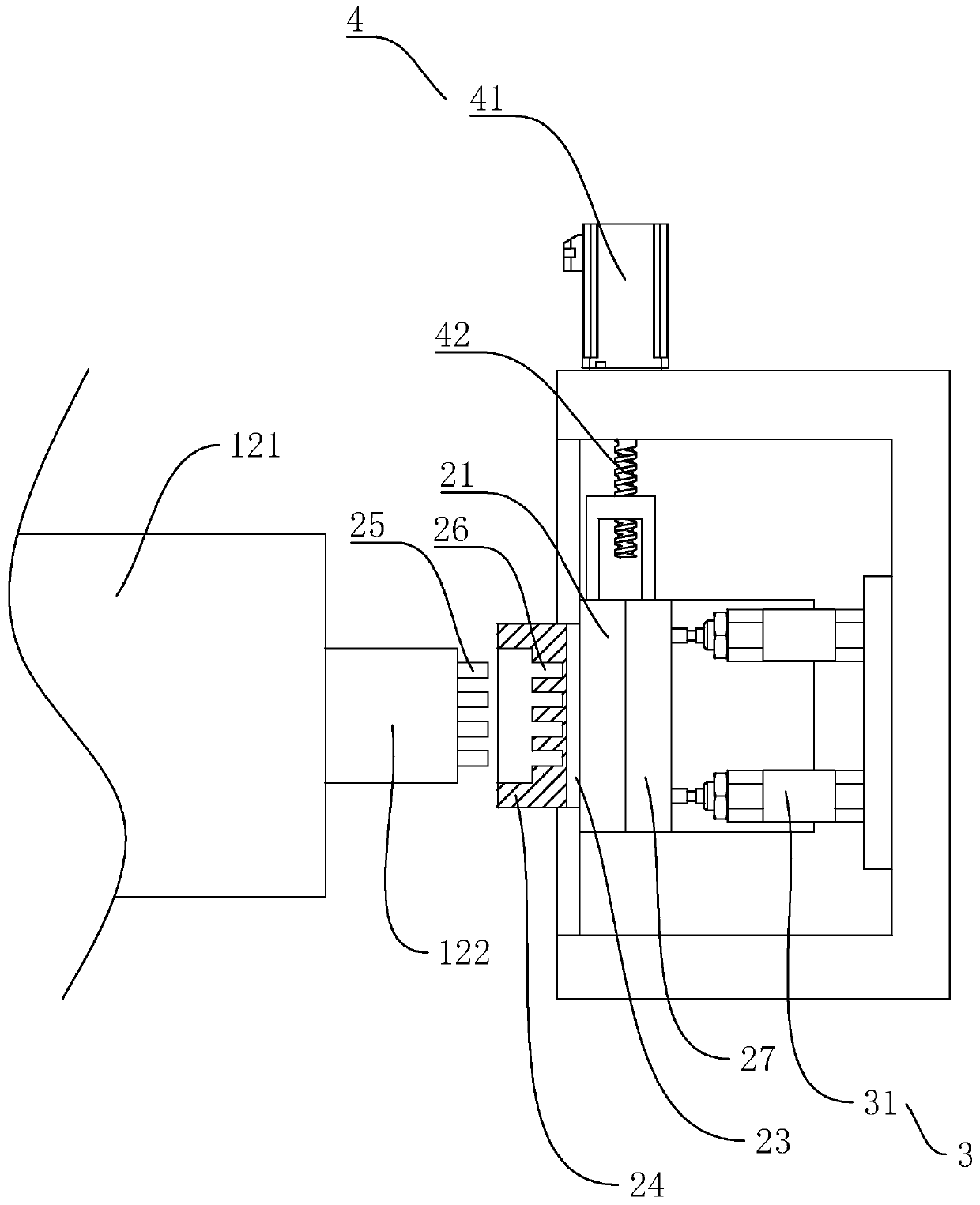

[0034] Embodiment 2: a kind of sheet metal bending machine, such as Figure 4-5As shown, the difference from Embodiment 1 is that the frame 1 is provided with a lifter 4 for pushing the slider 21 to slide in the vertical direction, and the lifter 4 includes a sliding rack 43 fixedly connected to the slider 21 , the frame 1 is rotatably connected with a rotating gear 44 through a rotating shaft, and the rotating gear 44 and the sliding rack 43 are meshed with each other. Lifting part 4 comprises the rotating worm wheel 46 that is fixed on the rotating shaft with the coaxial center, is provided with rotating worm 48 and rotating motor 47 in the frame 1, the output shaft of rotating motor 47 is integrally arranged with rotating worm 48, and rotating worm 48 and rotating worm gear 46 Mesh with each other.

[0035] The present invention can facilitate the operator to disassemble, replace and adjust the bending column 12, so that the operator can carry out surface treatment on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com