Fuel injection valve for injecting a gaseous and/or liquid fuel

A technology for fuel injection valves and liquid fuels, which can be used in fuel injection devices, special fuel injection devices, charging systems, etc., and can solve problems such as limited installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

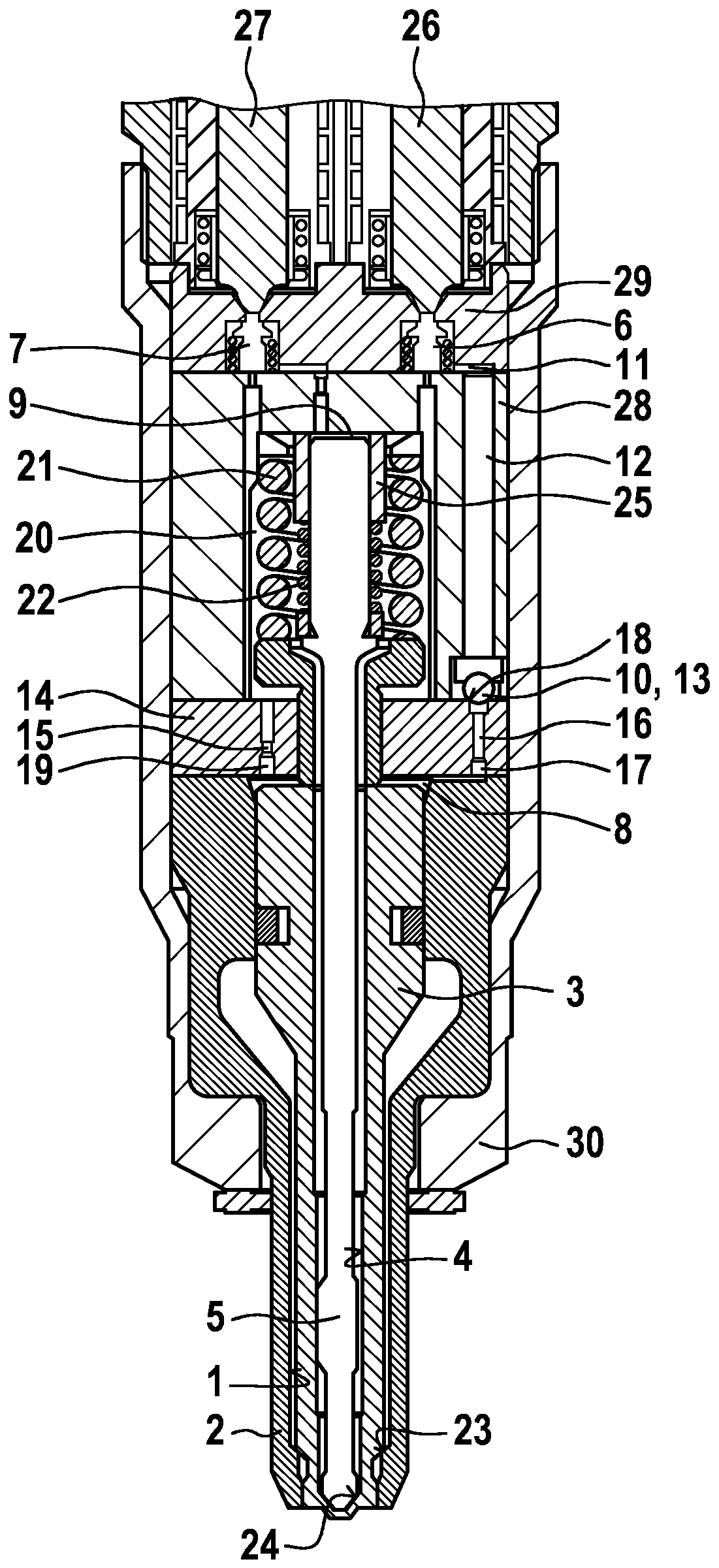

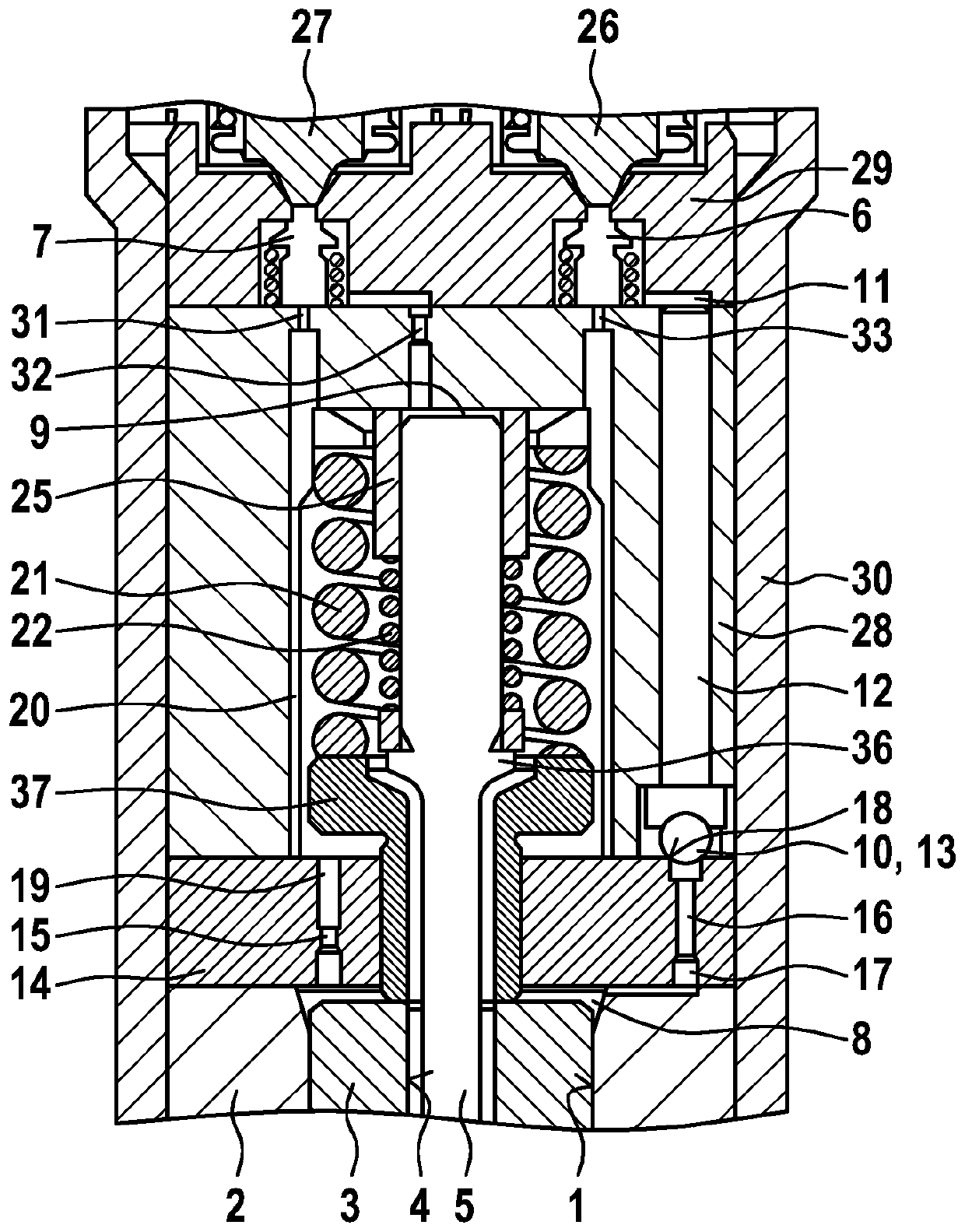

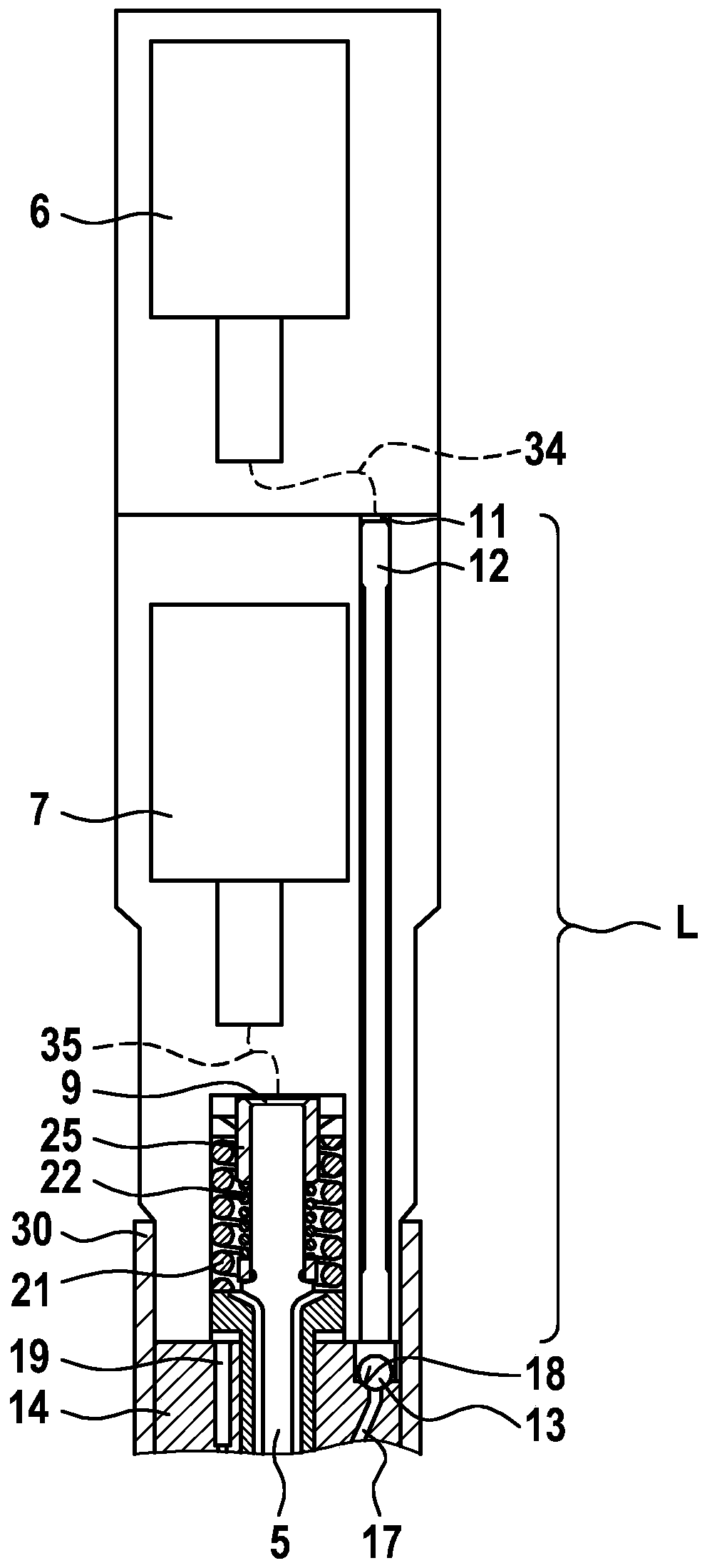

[0026] exist figure 1 A fuel injection valve for injecting gaseous fuel and / or liquid fuel into a combustion chamber of an internal combustion engine as shown in includes a nozzle body 2 having a central bore 1 in which a first valve element is reciprocally received 3. The first valve element 3 also has a central bore 4 . In this central bore the second valve element 5 is guided reciprocally. The central bore 4 of the first valve element 3 can be charged with liquid fuel, while the central bore 1 of the nozzle body 2 can be charged with gaseous fuel. Thus, gaseous fuel can be introduced into the combustion chamber by the reciprocating movement of the first valve element 3 , while the injection of liquid fuel can be achieved by the reciprocating movement of the second valve element 5 .

[0027] The first valve element 3 cooperates with a first sealing seat 23 which is formed by the nozzle body 2 . If the first valve element 3 is lifted from the sealing seat 23, it releases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com