Method for operating a fuel injector

A fuel injector and fuel technology, applied in fuel injection devices, charging systems, machines/engines, etc., can solve the problems of controlling pressure rise, hindering the opening of the outer nozzle needle, etc., and achieve the effect of full injection rate and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

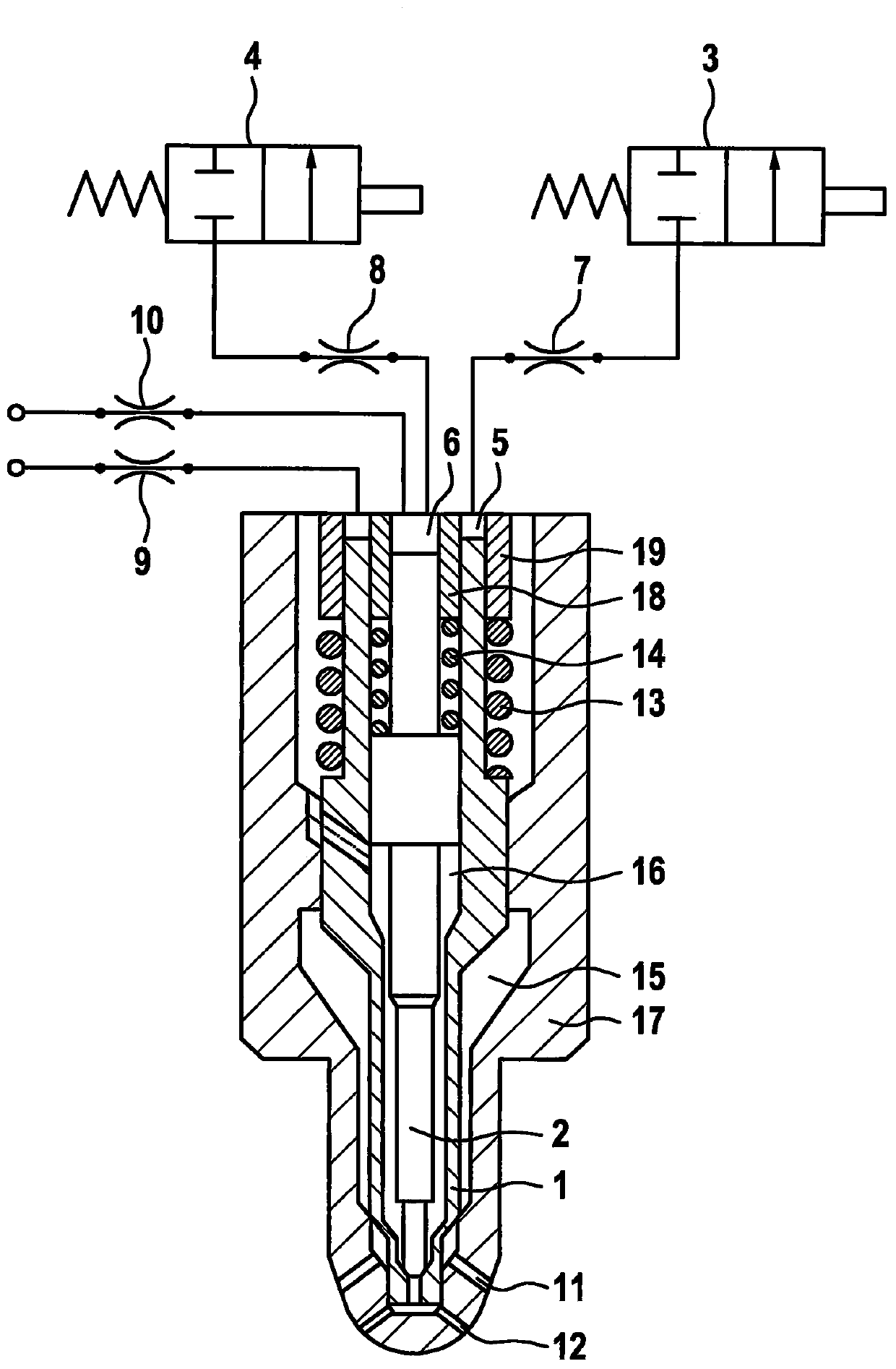

[0021] from figure 1 A fuel injector suitable for carrying out the method of the invention is known from the schematic diagram of . The fuel injector has a nozzle body 17 and two nozzle needles 1 , 2 arranged coaxially and guided one inside another. For this purpose, the outer nozzle needle 1 for releasing and closing the injection opening 11 for the gaseous fuel is embodied as a hollow needle. Injection opening 12 for injecting liquid fuel can be controlled by inner nozzle needle 2 , which is now completely accommodated in outer nozzle needle 1 , forming pressure chamber 16 . Liquid fuel is delivered to injection opening 12 via pressure chamber 16 . The gaseous fuel reaches the injection opening 11 via a pressure chamber 15 which is delimited on the one hand by the nozzle body 17 and on the other hand by the outer nozzle needle 1 . The liquid fuel may in particular be natural gas or methane, and the liquid fuel may be diesel fuel.

[0022] Since methane has such a high fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com